Technical Manual FFQN

Technical Manual FFQN

Uploaded by

khant kyaw khaingCopyright:

Available Formats

Technical Manual FFQN

Technical Manual FFQN

Uploaded by

khant kyaw khaingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Technical Manual FFQN

Technical Manual FFQN

Uploaded by

khant kyaw khaingCopyright:

Available Formats

R410A

TECHNICAL MANUAL

Split Unit Air Conditioner

Ceiling Cassette C & E Series

FCQN-E, FFQN-C, FCRN-E, FFRN-C

— Cooling only & Heatpump [50Hz] —

DAIKIN_FFRN.indb i 12/27/2012 9:28:06 AM

DAIKIN_FFRN.indb ii 12/27/2012 9:28:07 AM

Table of Contents

Table of Contents

Nomenclature......................................................................................................................1

Indoor ............................................................................................................................1

Outdoor..........................................................................................................................1

Product Line-Up.............................................................................................................2

Application Information .....................................................................................................5

Operating Range ...........................................................................................................5

Refrigerant Circuit Diagrams (C Series) ........................................................................6

Refrigerant Circuit Diagrams (E Series) ........................................................................8

Installation Guideline ................................................................................................... 11

Sound Data........................................................................................................................16

Sound Pressure Level .................................................................................................16

NC Curve .....................................................................................................................17

Engineering & Physical Data ...........................................................................................21

Performance Data .............................................................................................................26

Calculation Steps.........................................................................................................26

Performance Tables .....................................................................................................28

Outline & Dimension ........................................................................................................50

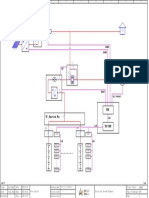

Wiring Diagram .................................................................................................................53

Service & Maintenance ....................................................................................................64

Troubleshooting ...............................................................................................................66

DAIKIN_FFRN.indb iii 12/27/2012 9:28:07 AM

Nomenclature

Nomenclature

Indoor

FFRN 25 C X V1

Power Supply

V1: 1 phase 50 Hz 220-240V

Production

X: OYLM

Product Series

C: C Series

E: E Series

Capacity

25: 2.5 kW

Model

FFRN: Ceiling Cassette 2”x2” (Cooling Only)

FCRN: Ceiling Cassette 3”x3” (Cooling Only)

FFQN: Ceiling Cassette 2”x2” (Heatpump)

FCQN: Ceiling Cassette 3”x3” (Heatpump)

Outdoor

R(Y)N 25 C X V1

Power Supply

V1: 1 phase 50 Hz 220-240V

Y1: 3 phase 50 Hz 380-415V

Production

X: OYLM

Product Series

C: C Series

D: D Series

Capacity

25: 2.5 kW

Model

RR & RN: Single Split Condensing Unit (Cooling

Only)

RYN & RQ: Single Split Condensing Unit (Heatpump)

DAIKIN_FFRN.indb 1 12/27/2012 9:28:07 AM

Nomenclature

Product Line-Up

Indoor Unit

FCQN-E, FFQN-C, FCRN-E, FFRN-C

Classification

Refrigerant Control

Panel (Handset)

PCB

Fin

Nomenclature

BYC20CXW (BRC52A61)

BYC50EXW (BRC52A61)

BC20CXW (BRC52A62)

BC50EXW (BRC52A62)

Hydrophilic (Blue)

w/o Cap Tube

L2CKE EC

L2CKE AP

L208A EC

L208A AP

Cap Tube

FFRN25CXV1 X X X X

FFRN35CXV1 X X X X

FFRN50CXV1 X X X X

COOLING

FCRN50EXV1 X X X X

FCRN60EXV1 X X X X

FCRN71EXV1 X X X X

FCRN100EXV1 X X X X

FCRN125EXV1 X X X X

FFQN25CXV1 X X X X

FFQN35CXV1 X X X X

FFQN50CXV1 X X X X

HEATPUMP

FCQN50EXV1 X X X X

FCQN60EXV1 X X X X

FCQN71EXV1 X X X X

FCQN100EXV1 X X X X

FCQN125EXV1 X X X X

DAIKIN_FFRN.indb 2 12/27/2012 9:28:07 AM

Nomenclature

Outdoor Unit

R(Y)N / RR / RQ

Classification

Refrigerant Control

Safety Devices

Compressor

Others

Fin

Nomenclature

High Pressure Switch

Low Pressure Switch

Hydrophilic (Gold)

Phase Sequencer

Hydrophilic (Blue)

Bare Aluminium

Drain Elbow

Cap Tube

Contactor

Rotary

Scroll

TXV

RN25CXV1 X X X

RN25CGXV1 X X X

RN35CXV1 X X X

RN35CGXV1 X X X

RN50CXV1 X X X

RN50CGXV1 X X X

RN60CXV1 X X X

RN60CGXV1 X X X

COOLING

RR71CXV1 X X X

RR71CGXV1 X X X

RR90DXV1 X X X X X

RR90DGXV1 X X X X X

RR100DXV1 X X X X X

RR100DGXV1 X X X X X

RR100DXY1 X X X X X X X

RR100DGXY1 X X X X X X X

RR125DXY1 X X X X X X X

RR125DGXY1 X X X X X X X

DAIKIN_FFRN.indb 3 12/27/2012 9:28:07 AM

Nomenclature

Classification

Refrigerant Control

Safety Devices

Compressor

Others

Fin

Nomenclature

High Pressure Switch

Low Pressure Switch

Hydrophilic (Gold)

Phase Sequencer

Hydrophilic (Blue)

Bare Aluminium

Drain Elbow

Cap Tube

Contactor

Rotary

Scroll

TXV

RYN25CXV1 X X X X

RYN25CGXV1 X X X X

RYN35CXV1 X X X X

RYN35CGXV1 X X X X

RYN50CXV1 X X X X

RYN50CGXV1 X X X X

RYN60CXV1 X X X X

RYN60CGXV1 X X X X

HEATPUMP

RQ71CXV1 X X X X

RQ71CGXV1 X X X X

RQ90DXV1 X X X X X X

RQ90DGXV1 X X X X X X

RQ100DXV1 X X X X X X

RQ100DGXV1 X X X X X X

RQ100DXY1 X X X X X X X X

RQ100DGXY1 X X X X X X X X

RQ125DXY1 X X X X X X X X

RQ125DGXY1 X X X X X X X X

DAIKIN_FFRN.indb 4 12/27/2012 9:28:08 AM

Application Information

Application Information

Operating Range

Ensure the operating temperature is in allowance range.

Cooling

Outdoor

DB (°C)

The use of your air conditioner

outside the range of working

temperature and humidity can

result in serious failure.

46

43

19

14 19 23 Indoor WB (°C)

Heating

Outdoor

WB (°C)

The use of your air conditioner

outside the range of working

temperature and humidity can

result in serious failure.

18

10

-9

15 20 27 Indoor DB (°C)

DAIKIN_FFRN.indb 5 12/27/2012 9:28:08 AM

Application Information

Refrigerant Circuit Diagrams (C Series)

Model: FFRN25CXV1 – RN25CXV1 / FFRN35CXV1 – RN35CXV1 / FFRN50CXV1 – RN50CXV1

Model: FFQN25CXV1 – RYN25CXV1

DAIKIN_FFRN.indb 6 12/27/2012 9:28:08 AM

Application Information

Model: FFQN35CXV1 – RYN35CXV1 / FFQN50CXV1 – RYN50CXV1

DAIKIN_FFRN.indb 7 12/27/2012 9:28:08 AM

Application Information

Refrigerant Circuit Diagrams (E Series)

Model: FCRN50EXV1 – RN50CXV1 / FCRN60EXV1 – RN60CXV1

Model: FCRN71EXV1 – RR71CXV1

DAIKIN_FFRN.indb 8 12/27/2012 9:28:08 AM

Application Information

Model: FCRN100EXV1 – RR90DXV1 / FCRN100EXV1 – RR100DXV1 / FCRN100EXV1 – RR100DXY1 /

FCRN125EXV1 – RR125DXY1

Model: FCQN50EXV1 – RYN50CXV1 / FCQN60EXV1 – RYN60CXV1

DAIKIN_FFRN.indb 9 12/27/2012 9:28:08 AM

Application Information

Model: FCQN71EXV1 – RQ71CXV1

Model: FCQN100EXV1 – RQ90DXV1 / FCQN100EXV1 – RQ100DXV1 / FCQN100EXV1 – RR100DXY1 /

FCQN125EXV1 – RR125DXY1

10

DAIKIN_FFRN.indb 10 12/27/2012 9:28:08 AM

Application Information

Installation Guideline

Safety Precautions

• Installation and maintenance should be performed Please take note of the following important points

by qualified persons who are familiar with local code when installing.

and regulation, and experienced with this type of • Do not install the unit where leakage of flammable

appliance. gas may occur.

• All field wiring must be installed in accordance with If gas leaks and accumulates around the unit, it

the national wiring regulation. may cause fire ignition.

• Ensure that the rated voltage of the unit corresponds

to that of the name plate before commencing wiring • Ensure that drainage piping is connected properly.

work according to the wiring diagram. If the drainage piping is not connected properly,

• The unit must be GROUNDED to prevent possible it may cause water leakage which will dampen

hazard due to insulation failure. the furniture.

• All electrical wiring must not touch the refrigerant

piping or any moving parts of the fan motors. • Do not overcharge the unit.

• Confirm that the unit has been switched OFF before This unit is factory pre-charged. Overcharge will

installing or servicing the unit. cause over-current or damage to the compressor.

• Disconnect from the main power supply before

• Ensure that the unit’s panel is closed after service

servicing the air conditioner unit.

or installation.

• DO NOT pull out the power cord when the power is

ON. This may cause serious electrical shocks which Unsecured panels will cause the unit to operate

may result in fire hazards. noisily.

• Keep the indoor and outdoor units, power cable and • Sharp edges and coil surfaces are potential

transmission wiring, at least 1m from TVs and radios, locations which may cause injury hazards. Avoid

to prevent distorted pictures and static. {Depending from being in contact with these places.

on the type and source of the electrical waves, static • Before turning off the power supply, set the remote

may be heard even when more than 1m away}. controller’s ON/OFF switch to the “OFF” position

to prevent the nuisance tripping of the unit. If this is

not done, the unit’s fans will start turning automatically

when power resumes, posing a hazard to service

personnel or the user.

• Do not operate any heating apparatus too close to the

air conditioner unit. This may cause the plastic panel to

melt or deform as a result of the excessive heat.

• Ensure the color of wires of the outdoor unit and

the terminal markings are same to the indoors

respectively.

• IMPORTANT : DO NOT INSTALL OR USE THE AIR

CONDITIONER UNIT IN A LAUNDRY ROOM.

• Do not use joined and twisted wires for incoming

power supply.

NOTICE

Disposal requirements

Your air conditioning product is marked with this symbol. This means that electrical and electronic products

shall not be mixed with unsorted household waste.

Do not try to dismantle the system yourself: the dismantling of the air conditioning system, treatment of the

refrigerant, of oil and of other parts must be done by a qualified installer in accordance with relevant local and

national legislation. Air conditioners must be treated at a specialized treatment facility for re-use, recycling

and recovery. By ensuring this product is disposed of correctly, you will help to prevent potential negative

consequences for the environment and human health. Please contact the installer or local authority for more

information.

Batteries must be removed from the remote controller and disposed of separately in accordance with relevant

local and national legislation.

11

DAIKIN_FFRN.indb 11 12/27/2012 9:28:08 AM

Application Information

1) Indoor Installation Clearance

Clearance must be provided for the indoor unit from wall and obstacles as shown in figure below.

Beam

Max. 0.3 m

Max. 3.0 m

Min 0.5 m Min 0.5 m Min 0.5 m

Obstacles

Floor

The installation place (handling ceiling surface) must be level and the height in the ceiling is 350mm or more.

2) Outdoor Installation Clearance

Outdoor unit must be installed such that there is no short circuit of the hot discharge air or obstruction to smooth

air flow. Select the coolest possible place where intake air should not hotter than the outside temperature

(Max. 45°C).

ALL MODELS A B C D

Minimum Distance 300 mm 1000 mm 300 mm 500 mm

If the condensing unit is operated in an atmosphere containing oils (including machine

oils), salt (coastal area), sulphide gas (near hot spring, oil refinery plant), such substances

may lead to failure the unit.

12

DAIKIN_FFRN.indb 12 12/27/2012 9:28:09 AM

Application Information

3) Cable Size

Cooling only

FFRN25/35CXV1 FFRN50CXV1 FCRN50EXV1

Model Unit

RN25/35CXV1 RN50CXV1 RN50CXV1

Power supply cable size 1.5 2.5 2.5

mm²

Number of wire 3 3 3

Interconnection cable size 1.5 2.5 2.5

mm²

Number of wire 3 3 3

Recommended fuse A 15 20 13

FCRN60EXV1 FCRN71EXV1 FCRN100EXV1

Model Unit

RN60CXV1 RR71CXV1 RR90DXV1

Power supply cable size 2.5 4.0 4.0

mm2

Number of wire 3 3 3

Interconnection cable size 2.5 2.5 2.5

mm2

Number of wire 3 3 4

Recommended fuse A 18 25 25

FCRN100EXV1 FCRN100EXV1 FCRN125EXV1

Model Unit

RR100DXV1 RR100DXY1 RR125DXY1

Power supply cable size 4.0 2.5 4.0

mm2

Number of wire 3 5 5

Interconnection cable size 2.5 1.5 1.5

mm2

Number of wire 4 4 4

Recommended fuse A 30 13 18

Heatpump

FFQN25/35CXV1 FFQN50CXV1 FCQN50EXV1

Model Unit

RYN25/35CXV1 RYN50CXV1 RYN50CXV1

Power supply cable size 1.5 2.5 2.5

mm2

Number of wire 3 3 3

Interconnection cable size 1.5 2.5 2.5

mm2

Number of wire 5 5 5

Recommended fuse A 15 20 13

FCQN60EXV1 FCQN71EXV1 FCQN100EXV1

Model Unit

RYN60CXV1 RQ71CXV1 RQ90DXV1

Power supply cable size 2.5 4.0 4.0

mm2

Number of wire 3 3 3

Interconnection cable size 2.5 2.5 2.5

mm2

Number of wire 5 5 3&4

Recommended fuse A 18 25 25

FCQN100EXV1 FCQN100EXV1 FCQN125EXV1

Model Unit

RQ100DXV1 RQ100DXY1 RQ125DXY1

Power supply cable size 4.0 2.5 2.5

mm2

Number of wire 3 5 5

Interconnection cable size 2.5 1.5 1.5

mm2

Number of wire 3&4 3&4 3&4

Recommended fuse A 30 13 18

13

DAIKIN_FFRN.indb 13 12/27/2012 9:28:09 AM

Application Information

4) Refrigerant Piping

When the pipe length becomes too long, both the capacity and reliability drop. As the number of bends increases,

system piping resistance to the refrigerant flow increases, thus lowering the cooling capacity, and as the result

the compressor may become defective. Always choose the shortest path and follow the recommendation as

tabulated below:

FFRN25CXV1 FFRN35CXV1 FFRN50CXV1

Indoor

Model FFQN25CXV1 FFQN35CXV1 FFQN50CXV1

Outdoor R(Y)N25CXV1 R(Y)N35CXV1 R(Y)N50CXV1

Max. Length, m 12 12 15

Max. Elevation, m 5 5 8

Max. No. of Bends 10 10 10

FCRN50EXV1 FCRN60EXV1 FCRN71EXV1

Indoor

FCQN50EXV1 FCQN60EXV1 FCQN71EXV1

Model

RR71CXV1

Outdoor R(Y)N50CXV1 R(Y)N60CXV1

RQ71CXV1

Max. Length, m 15 15 15

Max. Elevation, m 8 8 8

Max. No. of Bends 10 10 10

FCRN100EXV1 FCRN125EXV1

Indoor

FCQN100EXV1 FCQN125EXV1

Model

RR90/100DXV1 RR100DXY1 RR125DXY1

Outdoor

RQ90/100DXV1 RQ100DXY1 RQ125DXY1

Max. Length, m 45 45

Max. Elevation, m 25 25

Max. No. of Bends 10 10

Piping sizes (flare connection type) are as follows:

Model R(Y)N25CXV1 R(Y)N35CXV1 R(Y)N50CXV1

Liquid, mm / in 6.35 / 1/4 6.35 / 1/4 6.35 / 1/4

Suction, mm / in 9.52 / 3/8 12.70 / 1/2 12.70 / 1/2

RR71CXV1 RR90DXV1

Model R(Y)N60CXV1

RQ71CXV1 RQ90DXV1

Liquid, mm / in 6.35 / 1/4 9.52 / 3/8 9.52 / 3/8

Suction, mm / in 15.88 / 5/8 15.88 / 5/8 15.88 / 5/8

RR100DXV1 RR100DXY1 RR125DXY1

Model

RQ100DXV1 RQ100DXY1 RQ125DXY1

Liquid, mm / in 9.52 / 3/8

Suction, mm / in 15.88 / 5/8

14

DAIKIN_FFRN.indb 14 12/27/2012 9:28:09 AM

Application Information

5) Additional Charge

• The refrigerant charge has already charged into the outdoor unit. For the piping length of 7.6m, additional

refrigerant charge after vacuuming is not necessary.

• When the piping length is more than 7.6m, please use the table below (unit in gram).

Cooling Only

Indoor FFRN25CXV1 FFRN35CXV1 FFRN50CXV1

Outdoor RN25CXV1 RN35CXV1 RN50CXV1

Add. Charge, g/m 11 9 10

Indoor FCRN50EXV1 FCRN60EXV1 FCRN71EXV1

Outdoor RN50CXV1 RN60CXV1 RR71CXV1

Add. Charge, g/m 22 10 24

Indoor FCRN100EXV1 FCRN125EXV1

Outdoor RR90/100DXV1 RR100DXV1 RR100DXY1 RR125DXY1

Add. Charge, g/m 27 24 24 24

Heatpump

Indoor FFQN25CXV1 FFQN35CXV1 FFQN50CXV1

Outdoor RYN25CXV1 RYN35CXV1 RYN50CXV1

Add. Charge, g/m 15 18 12

Indoor FCQN50EXV1 FCQN60EXV1 FCQN71EXV1

Outdoor RYN50CXV1 RYN60CXV1 RQ71CXV1

Add. Charge, g/m 16 16 41

Indoor FCQN100EXV1 FCQN125EXV1

Outdoor RQ90/100DXV1 RQ100DXV1 RQ100DXY1 RQ125DXY1

Add. Charge, g/m 42 37 37 39

Example: FCRN60EXV1 & RN60CXV1 with 13m piping length, additional piping length is 5.5m. Thus,

Additional Charge = 5.5m x 10 g/m

= 55g

15

DAIKIN_FFRN.indb 15 12/27/2012 9:28:09 AM

Sound Data

Sound Data

Sound Pressure Level

1/1 Octave Sound Pressure (dB, ref 20μPa) Overall Noise

Model Speed

125Hz 250Hz 500Hz 1kHz 2kHz 4kHz 8kHz (dBA) Criteria

High 42 45 40 35 27 20 10 41 35

FF(R)(Q)N25CXV1 Med 40 42 37 32 24 15 7 38 32

Low 38 40 34 28 20 10 5 35 29

High 45 45 40 35 27 20 11 41 35

FF(R)(Q)N35CXV1 Med 41 42 37 32 23 15 9 38 32

Low 38 38 33 28 18 9 8 34 28

High 48 47 43 38 30 24 14 44 38

FF(R)(Q)N50CXV1 Med 46 45 40 35 26 19 9 41 35

Low 44 40 36 31 21 12 5 37 31

High 37 38 35 26 17 8 6 34 30

Med 35 35 34 22 12 6 6 32 29

FC(R)(Q)N50EXV1

Low 34 31 31 18 9 6 6 30 25

Quiet 32 28 29 16 7 4 5 28 23

High 39 40 37 29 22 12 6 37 32

Med 37 37 34 25 17 8 4 34 29

FC(R)(Q)N60EXV1

Low 37 37 34 23 15 7 7 33 29

Quiet 36 36 33 22 12 7 8 32 28

High 46 44 43 36 30 23 12 42 38

Med 39 40 38 30 23 15 7 38 37

FC(R)(Q)N71EXV1

Low 38 38 35 26 19 9 5 35 34

Quiet 36 36 33 24 15 6 5 33 30

High 51 48 47 41 33 31 18 47 43

Med 52 44 44 37 28 24 11 44 39

FC(R)(Q)N100EXV1

Low 50 41 40 33 23 15 8 40 35

Quiet 46 36 37 26 15 6 6 36 32

High 52 50 48 44 35 34 22 49 44

Med 53 45 44 39 29 28 14 45 39

FC(R)(Q)N125EXV1

Low 53 43 42 37 27 24 10 43 37

Quiet 51 41 39 32 23 16 6 39 34

Model Measuring Location

FF(R)(Q)N25/35/50CXV1

FC(R)(Q)N50/60/71EXV1

1.4m

Microphone

Standard : JIS C 9612

FC(R)(Q)N100EXV1

FC(R)(Q)N125EXV1 1.5m

Microphone

Standard: JIS B 8616

16

DAIKIN_FFRN.indb 16 12/27/2012 9:28:09 AM

Sound Data

NC Curve

FF(R)(Q)N25CXV1

70

60

Sound pressure level (dB, ref 20μPa)

NC-55

50 NC-50

NC-45

40 NC-40

H

M NC-35

30 L NC-30

NC-25

20 NC-20

10

0

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

FF(R)(Q)N35CXV1

70

60

Sound pressure level (dB, ref 20μPa)

NC-55

50 NC-50

NC-45

40 NC-40

H

NC-35

M

30 L NC-30

NC-25

20 NC-20

10

0

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

17

DAIKIN_FFRN.indb 17 12/27/2012 9:28:09 AM

Sound Data

FF(R)(Q)N50CXV1

70

60

Sound pressure level (dB, ref 20μPa)

NC-55

50

NC-50

NC-45

H

40

NC-40

M

L NC-35

30 NC-30

NC-25

20

NC-20

10

0

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

FC(R)(Q)N50EXV1

70

60

Sound pressure level (dB, ref 20μPa)

NC-55

50 NC-50

NC-45

40 NC-40

NC-35

30 NC-30

H

NC-25

M

20 NC-20

L

10

Q

0

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

18

DAIKIN_FFRN.indb 18 12/27/2012 9:28:09 AM

Sound Data

FC(R)(Q)N60EXV1

70

Sound pressure level (dB, ref 20μPa)

60

NC-55

50 NC-50

NC-45

40 NC-40

NC-35

H

30 NC-30

M

L NC-25

20 NC-20

Q

10

0

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

FC(R)(Q)N71EXV1

70

60

Sound pressure level (dB, ref 20μPa)

NC-55

50 NC-50

NC-45

40 NC-40

H

NC-35

M

30 NC-30

L

NC-25

20 Q NC-20

10

0

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

19

DAIKIN_FFRN.indb 19 12/27/2012 9:28:09 AM

Sound Data

FC(R)(Q)N100EXV1

70

60

Sound pressure level (dB, ref 20μPa)

NC-55

50

NC-50

NC-45

H

40

NC-40

M

NC-35

30 L

NC-30

NC-25

Q

20

NC-20

10

0

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

FC(R)(Q)N125EXV1

70

60

Sound pressure level (dB, ref 20μPa)

NC-55

50

NC-50

H NC-45

40

NC-40

M

NC-35

30 L

NC-30

Q

NC-25

20

NC-20

10

0

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

20

DAIKIN_FFRN.indb 20 12/27/2012 9:28:09 AM

Engineering & Physical Data

Engineering & Physical Data

Engineering Data - R410A model

INDOOR UNIT FFRN25CXV1 FFRN35CXV1 FFRN50CXV1

MODEL

OUTDOOR UNIT RN25CXV1 RN35CXV1 RN50CXV1

Btu/h 9500 12500 17500

NOMINAL COOLING CAPACITY

W 2780 3660 5129

NOMINAL TOTAL INPUT POWER (COOLING) W 900 1300 1690

NOMINAL RUNNING CURRENT (COOLING) A 4 5.90 7.72

EER W/W 3.09 2.82 3.03

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAPILLARY TUBE

REFRIGERANT CHARGE kg 0.73 0.83 1.38

INDOOR UNIT FFQN25CXV1 FFQN35CXV1 FFQN50CXV1

MODEL

OUTDOOR UNIT RYN25CXV1 RYN35CXV1 RYN50CXV1

Btu/h 9500 12500 17500 18000

NOMINAL COOLING CAPACITY

W 2780 3660 5129 5280

Btu/h 9500 11500 17500 18000

NOMINAL HEATING CAPACITY

W 2780 3370 5129 5420

NOMINAL TOTAL INPUT POWER (COOLING) W 900 1300 1690 1724

NOMINAL TOTAL INPUT POWER (HEATING) W 830 1020 1710 1494

NOMINAL RUNNING CURRENT (COOLING) A 4 5.9 7.72 3.3

NOMINAL RUNNING CURRENT (HEATING) A 3.7 4.60 7.75 2.80

EER W/W 3.09 2.82 3.03 3.06

COP W/W 3.35 3.30 3.00 3.63

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAPILLARY TUBE

REFRIGERANT CHARGE kg 0.73 0.83 1.38 1.38

POWER SOURCE V/Ph/Hz 220 - 240 /1/50

REFRIGERANT TYPE R410A

AIR DISCHARGE 4 WAY AUTOMATIC LOUVER (UP & DOWN)

CONTROL

OPERATION WIRELESS MICROCOMPUTER REMOTE CONTROL

HIGH l/s / CFM 194 / 410 194 / 410 212 / 450 212 / 450

AIR FLOW MEDIUM l/s / CFM 170 / 360 170 / 360 194 / 410 194 / 410

LOW l/s / CFM 156 / 330 156 / 330 160 / 340 160 / 340

SOUND PRESSURE LEVEL (H/M/L) dBA 41 / 38 / 35 41 / 38 / 34 44 / 41 / 37 44 / 41 / 37

UNIT DIMENSION [Panel] HEIGHT X WIDTH X DEPTH mm 250X 570 X 570 [295 x 640 x 640]

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 317 X 630 X 630

UNIT WEIGHT (UNIT + PANEL) kg 22 + 2 23 + 2 23 + 2 23 + 2

CONDENSATE DRAIN SIZE mm 19.05

TYPE TURBO

FAN

INDOOR UNIT

DRIVE DIRECT

TYPE INDUCTION

INDEX OF PROTECTION (IP) IP20

INSULATION GRADE CLASS B

FAN MOTOR RATED INPUT POWER W 55 65 59 59

RATED RUNNING CURRENT A 0.24 0.29 0.25 0.25

MOTOR MAX OUTPUT W 19 23 28 28

POLES 6

MATERIAL SEAMLESS INNER GROOVE COPPER

TUBE

DIAMETER mm 7

COIL MATERIAL ALUMINIUM (SLIT FIN)

FIN FACE AREA m2 0.318

ROW 1 2

TYPE WASHABLE SARANET FILTER

AIR QUALITY FILTER

QUANTITY pc 1

CASING COLOUR WITHOUT PAINT

AIR FLOW I/s / CFM 396 / 840 453 / 960 614 / 1300 614 / 1300

SOUND PRESSURE LEVEL dBA 46 49 52 52

UNIT DIMENSION HEIGHT X WIDTH X DEPTH mm 540 X 700 X 250 540 X 700 X 250 651 X 855 X 328 651 X 855 X 328

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 620 X 810 X 330 620 X 810 X 330 710 X 990 X 415 710 X 990 X 415

UNIT WEIGHT (RN / RYN) kg 28 30 47 47

TYPE FLARE VALVE

PIPE

LIQUID mm 6.35 6.35 6.35 6.35

CONNECTION SIZE

GAS mm 9.52 12.70 12.70 12.70

TYPE PROPELLER

FAN

DRIVE DIRECT

TYPE INDUCTION

INDEX OF PROTECTION (IP) IP22 IP22 IP23 IP23

INSULATION GRADE CLASS B CLASS B CLASS F CLASS F

FAN MOTOR RATED INPUT POWER W 57 70 80 80

RATED RUNNING CURRENT A 0.25 0.31 0.36 0.36

MOTOR OUTPUT W 24 35 42 42

OUTDOOR UNIT

POLES 6 6 6 6

TYPE ROTARY

OIL TYPE RB68A or FREOL ALPHA68M RB68A or FREOL ALPHA68M

OIL AMOUNT cm3 350 430 670 670

RN RATED INPUT POWER W 788 1165 1551 1693

RATED INPUT POWER

W 788 1165 1551 1693

(COOLING)

RYN

COMPRESSOR RATED INPUT POWER

W 718 881 1571 1643

(HEATING)

RATED RUNNING CURRENT A 3.51 5.3 7.11 7.49

RATED RUNNING CURRENT

A 3.51 5.3 7.11 7.49

(COOLING)

RATED RUNNING CURRENT

A 3.21 3.98 7.14 7.29

(HEATING)

LOCKED ROTOR AMP. A 19 24 26 26

MATERIAL SEAMLESS INNER GROOVE COPPER

TUBE

DIAMETER (RN/RYN) mm 7 7 / 9.52 7 7

COIL MATERIAL ALUMINIUM (RAISE LANCE)

FIN FACE AREA m2 0.36 0.51

ROW 1 1 2 2

CASING COLOUR LIGHT GREY

ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151 (NON-DUCTED UNIT) OR ISO 13253 (DUCTED UNIT).

COOLING HEATING

INDOOR: 27°C DB/ 19°C WB INDOOR: 20°C DB

OUTDOOR: 35°C DB/ 24°C WB OUTDOOR: 7°C DB/ 6°C WB

21

DAIKIN_FFRN.indb 21 12/27/2012 9:28:09 AM

Engineering & Physical Data

Engineering Data - R410A MODEL

INDOOR UNIT FCRN50EXV1 FCRN60EXV1 FCRN71EXV1 FCRN100EXV1

MODEL

OUTDOOR UNIT RN50CXV1 RN60CXV1 RR71CXV1 RR90DXV1

Btu/h 18300 22200 27000 29200

NOMINAL COOLING CAPACITY

W 5363 6506 7913 8558

NOMINAL TOTAL INPUT POWER (COOLING) W 1740 1940 2790 2820

NOMINAL RUNNING CURRENT (COOLING) A 7.72 8.67 13.10 13.70

EER W/W 3.08 3.36 2.84 3.03

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAPILLARY TUBE

REFRIGERANT CHARGE kg 1.38 1.54 2.03 2.60

INDOOR UNIT FCQN50EXV1 FCQN60EXV1 FCQN71EXV1 FCQN100EXV1

MODEL

OUTDOOR UNIT RYN50CXV1 RYN60CXV1 RQ71CXV1 RQ90DXV1

Btu/h 18300 22200 27000 29200

NOMINAL COOLING CAPACITY

W 5363 6506 7913 8558

Btu/h 17700 20500 28000 31800

NOMINAL HEATING CAPACITY

W 5188 6008 8206 9320

NOMINAL TOTAL INPUT POWER (COOLING) W 1740 1940 2790 2820

NOMINAL TOTAL INPUT POWER (HEATING) W 1490 1760 2325 2545

NOMINAL RUNNING CURRENT (COOLING) A 7.72 8.67 13.08 13.7

NOMINAL RUNNING CURRENT (HEATING) A 6.61 7.86 11.20 12.80

EER W/W 3.08 3.36 2.84 3.03

COP W/W 3.48 3.41 3.53 3.66

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAPILLARY TUBE

REFRIGERANT CHARGE kg 1.38 1.54 2.03 2.60

POWER SOURCE V/Ph/Hz 220 - 240 /1/50

REFRIGERANT TYPE R410A

AIR DISCHARGE 4 WAY AUTOMATIC LOUVER (UP & DOWN)

CONTROL

OPERATION WIRELESS MICROCOMPUTER REMOTE CONTROL

HIGH l/s / CFM 280 / 600 320 / 680 410 / 860 490 / 1030

MEDIUM l/s / CFM 250 / 530 280 / 600 340 / 725 410 / 860

AIR FLOW

LOW l/s / CFM 200 / 430 250 / 530 290 / 620 350 / 740

SUPER LOW l/s / CFM 190 / 400 200 / 430 250 / 530 295 / 620

SOUND PRESSURE LEVEL (H/M/L/SL) dBA 34 / 32 / 30 / 28 37 / 34 / 33 / 32 42 / 38 / 35 / 33 47 / 44 / 40 / 36

300 X 820 X 820

UNIT DIMENSION [Panel] HEIGHT X WIDTH X DEPTH mm 265 X 820 X 820 [340 X 990 X 990]

[375 X 990 X 990]

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 300 X 916 X 916 335 X 916 X 916

UNIT WEIGHT (UNIT + PANEL) kg 29 + 6 42 + 6

CONDENSATE DRAIN SIZE mm 19.05

INDOOR UNIT

TYPE BLOWER WHEEL

FAN

DRIVE DIRECT

TYPE INDUCTION

INDEX OF PROTECTION (IP) IP20

INSULATION GRADE CLASS B

FAN MOTOR RATED INPUT POWER W 88 101 145 176

RATED RUNNING CURRENT A 0.39 0.44 0.64 0.79

MOTOR MAX OUTPUT W 20 30 50 60

POLES 6

MATERIAL SEAMLESS INNER GROOVE COPPER

TUBE

DIAMETER mm 7

COIL MATERIAL ALUMINIUM (SLIT FIN)

FIN FACE AREA m2 0.386 0.372 0.461

ROW 2 3

TYPE WASHABLE SARANET FILTER

AIR QUALITY FILTER

QUANTITY pc 1

CASING COLOUR WITHOUT PAINT

AIR FLOW I/s / CFM 614 / 1300 689 / 1460 684 / 1450 1605 / 3400

SOUND PRESSURE LEVEL dBA 52 52 58 58

UNIT DIMENSION HEIGHT X WIDTH X DEPTH mm 651 X 855 X 328 753 X 855 X 328 852 X 1030 X 400

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 710 X 990 X 415 810 X 990 X 415 1010 X 1180 X 514

UNIT WEIGHT (RN / RYN) kg 47 50 57 86

TYPE FLARE VALVE

PIPE

LIQUID mm 6.35 9.52

CONNECTION SIZE

GAS mm 12.70 15.88 15.88 15.88

TYPE PROPELLER

FAN

DRIVE DIRECT

TYPE INDUCTION

INDEX OF PROTECTION (IP) IP23 IP23 N/A

INSULATION GRADE CLASS F CLASS F CLASS F CLASS B

FAN MOTOR RATED INPUT POWER W 80 97 124 257

RATED RUNNING CURRENT A 0.36 0.43 0.54 1.10

MOTOR OUTPUT W 42 64 75 145

POLES 6 8

OUTDOOR UNIT

TYPE ROTARY ROTARY SCROLL

RB68A or Freol MOBIL EAL ARCTIC

OIL TYPE RB68A or Freol Alpha68M

Alpha68M 22C

OIL AMOUNT cm3 670 1130 1242

RN RATED INPUT POWER W 1572 1742 2521 2387

RATED INPUT POWER

W 1572 1742 2521 2387

(COOLING)

COMPRESS RYN

OR RATED INPUT POWER

W 1322 1562 2056 2112

(HEATING)

RATED RUNNING CURRENT A 6.97 7.8 11.9 11.8

RATED RUNNING CURRENT

A 6.97 7.8 11.9 11.8

(COOLING)

RATED RUNNING CURRENT

A 5.86 6.99 10.00 10.90

(HEATING)

LOCKED ROTOR AMP. A 26 63 65 97

MATERIAL SEAMLESS INNER GROOVE COPPER

TUBE

DIAMETER (RN/RYN) mm 7

COIL MATERIAL ALUMINIUM(RAISE LANCE) ALUMINIUM (CORR. FIN)

FIN FACE AREA m2 0.51 0.62 0.62 0.87

ROW 2

CASING COLOUR LIGHT GREY

ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151 (NON-DUCTED UNIT) OR ISO 13253 (DUCTED UNIT).

COOLING HEATING

INDOOR: 27°C DB/ 19°C WB INDOOR: 20°C DB

OUTDOOR: 35°C DB/ 24°C WB OUTDOOR: 7°C DB/ 6°C WB

22

DAIKIN_FFRN.indb 22 12/27/2012 9:28:10 AM

Engineering & Physical Data

Engineering Data - R410A MODEL

INDOOR UNIT FCRN100EXV1 FCRN125EXV1

MODEL

OUTDOOR UNIT RR90DXY1 RR100DXV1 RR125DXY1

Btu/h 31000 39000 45000

NOMINAL COOLING CAPACITY

W 9086 11430 13190

NOMINAL TOTAL INPUT POWER (COOLING) W 2770 3920 4390

NOMINAL RUNNING CURRENT (COOLING) A 5.20 17.90 7.80

EER W/W 3.28 2.92 2.87

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAPILLARY TUBE

REFRIGERANT CHARGE kg 2.60 2.10 2.25

INDOOR UNIT FCQN100EXV1 FCQN125EXV1

MODEL

OUTDOOR UNIT RQ90DXY1 RQ100DXV1 RQ125DXY1

Btu/h 31000 39000 45000

NOMINAL COOLING CAPACITY

W 9086 11430 13190

Btu/h 33400 39000 48000

NOMINAL HEATING CAPACITY

W 9789 11430 14070

NOMINAL TOTAL INPUT POWER (COOLING) W 2770 3920 4390

NOMINAL TOTAL INPUT POWER (HEATING) W 2550 3740 4010

NOMINAL RUNNING CURRENT (COOLING) A 5.2 17.9 7.8

NOMINAL RUNNING CURRENT (HEATING) A 5.00 17.30 7.30

EER W/W 3.28 2.92 2.87

COP W/W 3.84 3.06 3.46

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAPILLARY TUBE

REFRIGERANT CHARGE kg 2.60 2.10 2.25

POWER SOURCE V/Ph/Hz 220 - 240 /1/50 220 - 240 /1/50 380 - 415 / 3 / 50

REFRIGERANT TYPE R410A

AIR DISCHARGE 4 WAY AUTOMATIC LOUVER (UP & DOWN)

CONTROL

OPERATION WIRELESS MICROCOMPUTER REMOTE CONTROL

HIGH l/s / CFM 490 / 1030 570 / 1200

MEDIUM l/s / CFM 410 / 860 490 / 1030

AIR FLOW

LOW l/s / CFM 350 / 740 440 / 930

SUPER LOW l/s / CFM 295 / 620 370 / 780

SOUND PRESSURE LEVEL (H/M/L/SL) dBA 47 / 44 / 40 / 36 49 / 45 / 43 / 39

UNIT DIMENSION [Panel] HEIGHT X WIDTH X DEPTH mm 300 X 820 X 820 [375 X 990 X 990]

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 335 X 916 X 916

UNIT WEIGHT (UNIT + PANEL) kg 42 + 6

CONDENSATE DRAIN SIZE mm 19.05

TYPE BLOWER WHEEL

INDOOR UNIT

FAN

DRIVE DIRECT

TYPE INDUCTION

INDEX OF PROTECTION (IP) IP20

INSULATION GRADE CLASS B

FAN MOTOR RATED INPUT POWER W 176 176 221

RATED RUNNING CURRENT A 0.79 0.79 0.97

MOTOR MAX OUTPUT W 60 100

POLES 6

MATERIAL SEAMLESS INNER GROOVE COPPER

TUBE

DIAMETER mm 7

COIL MATERIAL ALUMINIUM (SLIT FIN)

FIN FACE AREA m2 0.461 0.464

ROW 3

TYPE WASHABLE SARANET FILTER

AIR QUALITY FILTER

QUANTITY pc 1

CASING COLOUR WITHOUT PAINT

AIR FLOW I/s / CFM 1605 / 3400 2171 / 4600

SOUND PRESSURE LEVEL dBA 58 60

UNIT DIMENSION HEIGHT X WIDTH X DEPTH mm 852 X 1030 X 400

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 1010 x 1180 x 514

UNIT WEIGHT (RN / RYN) kg 86 95 98

TYPE FLARE VALVE

PIPE

LIQUID mm 9.52

CONNECTION SIZE

GAS mm 15.88

TYPE PROPELLER

FAN

DRIVE DIRECT

TYPE INDUCTION

INDEX OF PROTECTION (IP) N/A N/A IP20

INSULATION GRADE CLASS B CLASS B CLASS F

FAN MOTOR RATED INPUT POWER W 257 257 276

RATED RUNNING CURRENT A 1.1 1.1 1.34

MOTOR OUTPUT W 145

OUTDOOR UNIT

POLES 8

TYPE SCROLL

OIL TYPE MOBIL EAL ARCTIC 22C

OIL AMOUNT cm3 1242 1951 1656

RN RATED INPUT POWER W 2337 3487 3893

RATED INPUT POWER

W 2337 3487 3893

(COOLING)

RYN

COMPRESSOR RATED INPUT POWER

W 2117 3307 3513

(HEATING)

RATED RUNNING CURRENT A 4.57 16 7.03

RATED RUNNING CURRENT

A 4.57 16 7.03

(COOLING)

RATED RUNNING CURRENT

A 4.37 15.40 6.53

(HEATING)

LOCKED ROTOR AMP. A 48 136 74

MATERIAL SEAMLESS INNER GROOVE COPPER

TUBE

DIAMETER (RN/RYN) mm 7 7 7

COIL MATERIAL ALUMINIUM (CORR.FIN)

FIN FACE AREA m 2

0.87

ROW 2

CASING COLOUR LIGHT GREY

ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151 (NON-DUCTED UNIT) OR ISO 13253 (DUCTED UNIT).

COOLING HEATING

INDOOR: 27°C DB/ 19°C WB INDOOR: 20°C DB

OUTDOOR: 35°C DB/ 24°C WB OUTDOOR: 7°C DB/ 6°C WB

23

DAIKIN_FFRN.indb 23 12/27/2012 9:28:10 AM

Engineering & Physical Data

Safety Device

FFRN25/35CXV1 FFRN50CXV1

INDOOR

MODEL FFQN25/35CXV1 FFQN50CXV1

OUTDOOR R(Y)N25CXV1 R(Y)N50CXV1

TYPE N/A

HIGH PRESSURE

OPEN kPa / psi N/A

SWITCH

CLOSE kPa / psi N/A

SAFETY TYPE N/A

DEVICE LOW PRESSURE

OPEN kPa / psi N/A

SWITCH

CLOSE kPa / psi N/A

PHASE SEQUENCER N/A

DISC. THERMOSTAT SETTING °C / F N/A

FCRN50/60/71EXV1

INDOOR

FCQN50/60/71EXV1

MODEL

R(Y)N50/60CXV1

OUTDOOR

R(R )(Q)71CXV1

TYPE N/A

HIGH PRESSURE

OPEN kPa / psi N/A

SWITCH

CLOSE kPa / psi N/A

SAFETY TYPE N/A

DEVICE LOW PRESSURE

OPEN kPa / psi N/A

SWITCH

CLOSE kPa / psi N/A

PHASE SEQUENCER N/A

DISC. THERMOSTAT SETTING °C / F N/A

INDOOR FCRN100EXV1

MODEL

OUTDOOR RR90DXV1 RR100DXV1 RR100DXY1

TYPE NC

HIGH PRESSURE

OPEN kPa / psi 4140 / 600.46

SWITCH

CLOSE kPa / psi 3310 / 480.07

SAFETY TYPE NC

DEVICE LOW PRESSURE

OPEN kPa / psi 48 / 6.96

SWITCH

CLOSE kPa / psi 152 / 22.05

PHASE SEQUENCER N/A YES

DISC. THERMOSTAT SETTING °C / F N/A 130 / 266

INDOOR FCRN125EXV1

MODEL

OUTDOOR RR125DXY1

TYPE NC

HIGH PRESSURE

OPEN kPa / psi 4140 / 600.46

SWITCH

CLOSE kPa / psi 3310 / 480.07

SAFETY TYPE NC

DEVICE LOW PRESSURE

OPEN kPa / psi 48 / 6.96

SWITCH

CLOSE kPa / psi 152 / 22.05

PHASE SEQUENCER YES

DISC. THERMOSTAT SETTING °C / F 130 / 266

ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

24

DAIKIN_FFRN.indb 24 12/27/2012 9:28:10 AM

Engineering & Physical Data

INDOOR FCQN100EXV1

MODEL

OUTDOOR RQ90DXV1 RQ100DXV1 RQ100DXY1

TYPE NC

HIGH PRESSURE

OPEN kPa / psi 4140 / 600.46

SWITCH

CLOSE kPa / psi 3310 / 480.07

SAFETY TYPE NC

DEVICE LOW PRESSURE

OPEN kPa / psi 48 / 6.96

SWITCH

CLOSE kPa / psi 152 / 22.05

PHASE SEQUENCER N/A YES

DISC. THERMOSTAT SETTING °C / F N/A 130 / 266

INDOOR FCQN125EXV1

MODEL

OUTDOOR RQ125DXY1

TYPE NC

HIGH PRESSURE

OPEN kPa / psi 4140 / 600.46

SWITCH

CLOSE kPa / psi 3310 / 480.07

SAFETY TYPE NC

DEVICE LOW PRESSURE

OPEN kPa / psi 48 / 6.96

SWITCH

CLOSE kPa / psi 152 / 22.05

PHASE SEQUENCER YES

DISC. THERMOSTAT SETTING °C / F 130 / 266

ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

25

DAIKIN_FFRN.indb 25 12/27/2012 9:28:10 AM

Performance Data

Performance Data

Calculation Steps

Interpolation method can be used to get the total Solution:

cooling capacity, TC and sensible cooling capacity, Based on the Performance Table,

SC and power input, PI at those temperatures which

1. Refer to the Indoor DB column,

are not stated out in the table. Extrapolation method

- 25°C is located between 24°C & 27°C

is not allowed to be used.

for 16°C WB.

Example: - 25°C is located between 24°C & 27°C

for 19°C WB.

Model: FFRN25CXV1 - RN25CXV1 - Thus, Interpolation needs to be applied.

Indoor Condition: 25°C DB, 17°C WB

Outdoor Condition: 37°C DB 2. Refer to the Indoor WB column,

Fan Speed: High - 17°C is located between 16°C & 19°C

for 25°C DB.

- Thus, Interpolation needs to be applied.

3. Refer to the Outdoor DB column,

- 37°C is located between 35°C & 40°C.

- Thus, Interpolation needs to be applied.

1st Step 2nd Step 3rd Step

Interpolation of Indoor WB Interpolation of Indoor DB Interpolation of Outdoor DB

Find TC, SC & PI Find TC, SC & PI Find TC, SC & PI

(a) Indoor: 25°C DB, 16°C WB (a) Indoor: 25°C DB, 17°C WB (a) Indoor: 25°C DB, 17°C WB

Outdoor: 35°C DB Outdoor: 35°C DB Outdoor: 37°C DB

(b) Indoor: 25°C DB, 19°C WB (b) Indoor: 25°C DB, 17°C WB

Outdoor: 35°C DB Outdoor: 40°C DB

(c) Indoor: 25°C DB, 16°C WB

Outdoor: 40°C DB

(d) Indoor: 25°C DB, 19°C WB

Outdoor: 40°C DB

Details of Calculation:

1st Step: By Interpolation Method

To obtain the TC, SC & PI for 25°C – 24°C x1 – 3.20kW

⇒ =

27°C – 24°C 3.30kW – 3.20kW

(a) Indoor Condition: 25°C DB, 16°C WB

Outdoor Condition: 35°C DB ⇒ x1 = 3.23kW

Outdoor temperature Similarly,

EWB EDB 35°C

y1 = 3.23kW

TC SC PI

z1 = 1.27kW

24 3.20 3.20 1.27

16 25 x1 y1 z1

27 3.30 3.30 1.27

26

DAIKIN_FFRN.indb 26 12/27/2012 9:28:10 AM

Performance Data

(b) Indoor Condition: 25°C DB, 16°C WB By Interpolation Method

Outdoor Condition: 35°C DB 25°C – 24°C x2 – 3.51kW

⇒ =

Outdoor temperature 27°C – 24°C 3.52kW – 3.51kW

EWB EDB 35°C ⇒ x2 = 3.51kW

TC SC PI

Similarly,

y2 = 2.71kW

24 3.51 2.57 1.29

19 25 x2 y2 z2 z2 = 1.29kW

27 3.52 2.99 1.29

Repeat the same process for (c) & (d) in 1st Step

(c) x3 = 2.98 kW; y3 = 2.98 kW; z3 = 1.38 kW (d) x4 = 3.22 W; y4 = 2.53 kW; z4 = 1.40 kW

2nd Step: By Interpolation Method

To obtain the TC, SC & PI for 17°C – 16°C x5 – 3.23kW

⇒ =

(a) Indoor Condition: 25°C DB, 17°C WB 19°C – 16°C 3.51kW – 3.23kW

Outdoor Condition: 35°C DB ⇒ x5 = 3.32kW

Outdoor temperature Similarly,

EWB EDB 35°C

y5 = 3.06kW

TC SC PI

z5 = 1.28kW

16 3.23 3.23 1.27

17 25 x5 y5 z5

19 3.51 2.71 1.29

Repeat the same process for (b) in 2nd Step

(c) x6 = 3.06 kW; y6 = 2.83 kW; z6 = 1.39 kW

3rd Step:

To obtain the TC, SC & PI for

(a) Indoor Condition: 25°C DB, 17°C WB

Outdoor Condition: 37°C DB

Outdoor temperature

EWB EDB 35°C 37°C 40°C

TC SC PI TC SC PI TC SC PI

25 17 3.32 3.06 1.28 x y z 3.06 2.83 1.39

By Interpolation Method Similarly,

37°C – 35°C x – 3.32kW y = 2.97kW

⇒ =

40°C – 35°C 3.06kW – 3.32kW z = 1.35kW

⇒ x = 3.22kW

27

DAIKIN_FFRN.indb 27 12/27/2012 9:28:10 AM

Performance Data

Performance Tables

R410A Cooling Only

Model: FFRN25CXV1 - RN25CXV1

Cooling Mode

Outdoor temperature

AFR

EWB EDB 19°C 25°C 30°C 35°C 40°C 46°C

(CFM)

TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI

21°C 2.62 2.08 0.68 2.53 2.03 0.74 2.43 1.97 0.80 2.34 1.92 0.87 2.15 1.78 0.94 1.98 1.68 1.04

24°C 2.63 2.49 0.68 2.53 2.44 0.74 2.44 2.38 0.80 2.34 2.32 0.87 2.15 2.15 0.94 1.99 1.99 1.04

16°C

27°C 2.65 2.65 0.69 2.56 2.56 0.74 2.47 2.47 0.80 2.37 2.37 0.87 2.19 2.19 0.95 2.04 2.04 1.04

30°C 2.73 2.73 0.69 2.65 2.65 0.75 2.57 2.57 0.81 2.49 2.49 0.88 2.30 2.30 0.95 2.16 2.16 1.05

24°C 2.89 1.94 0.69 2.79 1.89 0.75 2.69 1.84 0.81 2.58 1.79 0.88 2.37 1.67 0.96 2.19 1.57 1.06

27°C 2.89 2.22 0.69 2.79 2.17 0.75 2.69 2.12 0.81 2.58 2.07 0.88 2.37 1.94 0.96 2.20 1.84 1.06

330 19°C

30°C 2.90 2.74 0.69 2.80 2.69 0.75 2.70 2.63 0.82 2.60 2.56 0.88 2.39 2.39 0.96 2.22 2.22 1.06

33°C 2.93 2.93 0.70 2.84 2.84 0.75 2.75 2.75 0.82 2.65 2.65 0.89 2.45 2.45 0.96 2.29 2.29 1.07

27°C 3.18 1.90 0.71 3.07 1.86 0.77 2.96 1.81 0.83 2.84 1.76 0.90 2.61 1.64 0.98 2.42 1.55 1.08

30°C 3.18 2.32 0.71 3.07 2.27 0.77 2.96 2.22 0.83 2.84 2.16 0.90 2.62 2.03 0.98 2.42 1.92 1.08

22°C

33°C 3.18 2.71 0.71 3.07 2.66 0.77 2.96 2.60 0.83 2.85 2.55 0.90 2.62 2.39 0.98 2.43 2.27 1.08

36°C 3.19 3.07 0.71 3.09 3.01 0.77 2.98 2.95 0.83 2.87 2.87 0.90 2.65 2.65 0.98 2.46 2.46 1.08

21°C 2.73 2.17 0.69 2.63 2.11 0.75 2.53 2.06 0.81 2.43 2.00 0.88 2.23 1.86 0.95 2.05 1.75 1.05

24°C 2.74 2.63 0.69 2.64 2.57 0.75 2.54 2.51 0.81 2.44 2.44 0.88 2.24 2.24 0.95 2.07 2.07 1.05

16°C

27°C 2.77 2.77 0.69 2.68 2.68 0.75 2.58 2.58 0.81 2.49 2.49 0.88 2.30 2.30 0.96 2.14 2.14 1.05

30°C 2.88 2.88 0.70 2.80 2.80 0.75 2.72 2.72 0.82 2.63 2.63 0.89 2.43 2.43 0.97 2.27 2.27 1.07

24°C 3.00 2.05 0.70 2.90 2.00 0.76 2.79 1.95 0.82 2.68 1.90 0.89 2.46 1.77 0.97 2.27 1.67 1.07

27°C 3.01 2.37 0.70 2.90 2.31 0.76 2.79 2.26 0.82 2.68 2.21 0.89 2.46 2.06 0.97 2.28 1.95 1.07

360 19°C

30°C 3.02 2.92 0.70 2.92 2.85 0.76 2.81 2.79 0.82 2.71 2.71 0.89 2.49 2.49 0.97 2.31 2.31 1.07

33°C 3.07 3.07 0.70 2.98 2.98 0.76 2.89 2.89 0.83 2.79 2.79 0.90 2.58 2.58 0.98 2.42 2.42 1.08

27°C 3.30 2.01 0.71 3.19 1.96 0.77 3.07 1.91 0.84 2.94 1.86 0.91 2.71 1.74 0.99 2.50 1.64 1.09

30°C 3.31 2.47 0.71 3.19 2.42 0.77 3.07 2.36 0.84 2.95 2.31 0.91 2.71 2.16 0.99 2.51 2.05 1.09

22°C

33°C 3.31 2.89 0.71 3.20 2.84 0.77 3.08 2.78 0.84 2.96 2.72 0.91 2.72 2.55 0.99 2.52 2.42 1.09

36°C 3.33 3.27 0.72 3.22 3.21 0.78 3.11 3.11 0.84 3.00 3.00 0.91 2.77 2.77 0.99 2.58 2.58 1.09

21°C 2.83 2.27 0.70 2.72 2.21 0.75 2.62 2.15 0.81 2.51 2.09 0.88 2.30 1.95 0.96 2.12 1.83 1.06

24°C 2.84 2.75 0.70 2.74 2.69 0.75 2.64 2.62 0.82 2.53 2.53 0.88 2.32 2.32 0.96 2.15 2.15 1.06

16°C

27°C 2.89 2.89 0.70 2.79 2.79 0.76 2.70 2.70 0.82 2.60 2.60 0.89 2.41 2.41 0.97 2.24 2.24 1.07

30°C 3.03 3.03 0.70 2.94 2.94 0.76 2.85 2.85 0.83 2.76 2.76 0.90 2.56 2.56 0.98 2.39 2.39 1.08

24°C 3.11 2.17 0.71 3.00 2.12 0.77 2.89 2.06 0.83 2.77 2.01 0.90 2.54 1.87 0.98 2.35 1.77 1.07

27°C 3.12 2.51 0.71 3.01 2.46 0.77 2.90 2.40 0.83 2.78 2.34 0.90 2.55 2.19 0.98 2.36 2.07 1.08

410 19°C

30°C 3.15 3.09 0.71 3.04 3.03 0.77 2.93 2.93 0.83 2.82 2.82 0.90 2.59 2.59 0.98 2.41 2.41 1.08

33°C 3.22 3.22 0.71 3.12 3.12 0.77 3.03 3.03 0.84 2.93 2.93 0.91 2.71 2.71 0.99 2.54 2.54 1.09

27°C 3.42 2.13 0.72 3.29 2.08 0.78 3.17 2.03 0.85 3.04 1.97 0.92 2.80 1.84 0.99 2.58 1.74 1.10

30°C 3.42 2.62 0.72 3.30 2.57 0.78 3.18 2.51 0.85 3.05 2.46 0.92 2.80 2.30 1.00 2.59 2.18 1.10

22°C

33°C 3.43 3.07 0.72 3.32 3.02 0.78 3.19 2.95 0.85 3.07 2.89 0.92 2.82 2.71 1.00 2.62 2.57 1.10

36°C 3.47 3.47 0.72 3.36 3.36 0.78 3.24 3.24 0.85 3.12 3.12 0.92 2.89 2.89 1.00 2.69 2.69 1.11

Remark:

AFR: Air flow rate (CFM)

EWB: Entering Wet Bulb Temp. (°C)

EDB: Entering Dry Bulb Temp. (°C)

TC: Total Cooling Capacity (kW)

SC: Sensible Cooling Capacity (kW)

PI: Power Input (kW)

Notes:

1. Ratings shown are net capacities.

2. shows nominal capacities.

3. Direct interpolation is permissible. Do not extrapolate.

4. Unit is able to operate at ambient from 19°C to 46°C DB without pressure trip.

28

DAIKIN_FFRN.indb 28 12/27/2012 9:28:10 AM

Performance Data

Model: FFRN35CXV1 - RN35CXV1

Cooling Mode

Outdoor temperature

AFR

EWB EDB 19°C 25°C 30°C 35°C 40°C 46°C

(CFM)

TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI

21°C 3.45 2.73 0.99 3.33 2.66 1.07 3.21 2.59 1.16 3.08 2.51 1.25 2.83 2.34 1.36 2.61 2.20 1.50

24°C 3.46 3.27 0.99 3.33 3.20 1.07 3.21 3.12 1.16 3.08 3.04 1.26 2.83 2.83 1.36 2.62 2.62 1.50

16°C

27°C 3.48 3.48 0.99 3.37 3.37 1.07 3.25 3.25 1.16 3.13 3.13 1.26 2.88 2.88 1.37 2.68 2.68 1.51

30°C 3.59 3.59 0.99 3.49 3.49 1.08 3.38 3.38 1.17 3.27 3.27 1.27 3.03 3.03 1.38 2.84 2.84 1.52

24°C 3.81 2.55 1.00 3.67 2.49 1.09 3.54 2.42 1.18 3.40 2.35 1.28 3.12 2.19 1.38 2.89 2.06 1.53

27°C 3.81 2.92 1.00 3.68 2.85 1.09 3.54 2.79 1.18 3.40 2.72 1.28 3.13 2.54 1.39 2.89 2.41 1.53

330 19°C

30°C 3.82 3.60 1.00 3.68 3.52 1.09 3.55 3.45 1.18 3.42 3.36 1.28 3.15 3.14 1.39 2.92 2.92 1.53

33°C 3.86 3.86 1.01 3.74 3.74 1.09 3.61 3.61 1.18 3.49 3.49 1.28 3.23 3.23 1.39 3.02 3.02 1.54

27°C 4.19 2.50 1.02 4.04 2.44 1.11 3.90 2.37 1.20 3.74 2.31 1.30 3.44 2.15 1.41 3.19 2.03 1.56

30°C 4.19 3.04 1.02 4.04 2.98 1.11 3.90 2.91 1.20 3.74 2.84 1.30 3.44 2.66 1.41 3.19 2.52 1.56

22°C

33°C 4.19 3.55 1.02 4.05 3.49 1.11 3.90 3.42 1.20 3.75 3.35 1.30 3.45 3.14 1.41 3.20 2.98 1.56

36°C 4.21 4.03 1.02 4.07 3.95 1.11 3.93 3.87 1.20 3.78 3.78 1.30 3.49 3.49 1.42 3.24 3.24 1.56

21°C 3.59 2.85 1.00 3.46 2.77 1.08 3.33 2.70 1.17 3.19 2.62 1.27 2.93 2.44 1.37 2.70 2.30 1.51

24°C 3.60 3.46 1.00 3.47 3.38 1.08 3.34 3.30 1.17 3.21 3.21 1.27 2.95 2.95 1.37 2.72 2.72 1.51

16°C

27°C 3.64 3.64 1.00 3.52 3.52 1.08 3.40 3.40 1.17 3.28 3.28 1.27 3.03 3.03 1.38 2.82 2.82 1.52

30°C 3.80 3.80 1.01 3.69 3.69 1.09 3.57 3.57 1.18 3.46 3.46 1.28 3.20 3.20 1.39 3.00 3.00 1.54

24°C 3.96 2.69 1.01 3.81 2.63 1.10 3.67 2.56 1.19 3.52 2.49 1.29 3.24 2.32 1.40 2.99 2.19 1.54

27°C 3.96 3.10 1.01 3.82 3.03 1.10 3.68 2.97 1.19 3.53 2.90 1.29 3.24 2.71 1.40 3.00 2.56 1.54

360 19°C

30°C 3.98 3.83 1.01 3.84 3.75 1.10 3.71 3.66 1.19 3.56 3.56 1.29 3.28 3.28 1.40 3.04 3.04 1.54

33°C 4.05 4.05 1.02 3.92 3.92 1.10 3.80 3.80 1.20 3.67 3.67 1.30 3.40 3.40 1.41 3.18 3.18 1.56

27°C 4.35 2.64 1.03 4.19 2.58 1.12 4.04 2.51 1.21 3.88 2.44 1.31 3.56 2.28 1.42 3.30 2.15 1.57

30°C 4.35 3.24 1.03 4.20 3.17 1.12 4.04 3.10 1.21 3.88 3.03 1.31 3.57 2.83 1.43 3.30 2.69 1.57

22°C

33°C 4.36 3.79 1.03 4.21 3.72 1.12 4.05 3.64 1.21 3.89 3.57 1.32 3.58 3.35 1.43 3.32 3.18 1.57

36°C 4.39 4.29 1.03 4.24 4.21 1.12 4.10 4.10 1.22 3.95 3.95 1.32 3.64 3.64 1.43 3.40 3.40 1.58

21°C 3.72 2.97 1.00 3.59 2.90 1.09 3.45 2.82 1.18 3.31 2.74 1.28 3.03 2.55 1.38 2.80 2.40 1.52

24°C 3.74 3.61 1.01 3.61 3.53 1.09 3.47 3.44 1.18 3.33 3.33 1.28 3.06 3.06 1.39 2.83 2.83 1.53

16°C

27°C 3.80 3.80 1.01 3.68 3.68 1.09 3.55 3.55 1.18 3.43 3.43 1.28 3.17 3.17 1.39 2.95 2.95 1.54

30°C 3.99 3.99 1.02 3.88 3.88 1.10 3.76 3.76 1.20 3.63 3.63 1.30 3.36 3.36 1.41 3.14 3.14 1.56

24°C 4.10 2.85 1.02 3.95 2.78 1.11 3.80 2.71 1.20 3.65 2.64 1.30 3.35 2.46 1.41 3.09 2.32 1.55

27°C 4.11 3.30 1.02 3.96 3.22 1.11 3.81 3.15 1.20 3.66 3.07 1.30 3.36 2.87 1.41 3.11 2.72 1.55

410 19°C

30°C 4.14 4.06 1.02 4.00 3.97 1.11 3.85 3.85 1.20 3.71 3.71 1.30 3.41 3.41 1.41 3.17 3.17 1.56

33°C 4.23 4.23 1.03 4.11 4.11 1.12 3.98 3.98 1.21 3.85 3.85 1.31 3.57 3.57 1.43 3.34 3.34 1.58

27°C 4.50 2.79 1.04 4.34 2.73 1.13 4.17 2.66 1.22 4.01 2.59 1.32 3.68 2.42 1.44 3.40 2.28 1.58

30°C 4.51 3.44 1.04 4.35 3.37 1.13 4.18 3.30 1.22 4.01 3.22 1.33 3.69 3.02 1.44 3.41 2.86 1.58

22°C

33°C 4.52 4.03 1.04 4.37 3.96 1.13 4.21 3.88 1.22 4.04 3.79 1.33 3.72 3.55 1.44 3.44 3.37 1.59

36°C 4.56 4.55 1.04 4.42 4.42 1.13 4.27 4.27 1.23 4.11 4.11 1.33 3.80 3.80 1.45 3.55 3.55 1.60

Remark:

AFR: Air flow rate (CFM)

EWB: Entering Wet Bulb Temp. (°C)

EDB: Entering Dry Bulb Temp. (°C)

TC: Total Cooling Capacity (kW)

SC: Sensible Cooling Capacity (kW)

PI: Power Input (kW)

Notes:

1. Ratings shown are net capacities.

2. shows nominal capacities.

3. Direct interpolation is permissible. Do not extrapolate.

4. Unit is able to operate at ambient from 19°C to 46°C DB without pressure trip.

29

DAIKIN_FFRN.indb 29 12/27/2012 9:28:11 AM

Performance Data

Model: FFRN50CXV1 - RN50CXV1

Cooling Mode

Outdoor temperature

AFR

EWB EDB 19°C 25°C 30°C 35°C 40°C 46°C

(CFM)

TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI

21°C 4.84 3.33 1.28 4.67 3.24 1.39 4.49 3.15 1.50 4.31 3.06 1.63 3.96 2.85 1.77 3.66 2.68 1.95

24°C 4.84 3.98 1.28 4.67 3.89 1.39 4.50 3.80 1.50 4.32 3.71 1.63 3.97 3.46 1.77 3.67 3.27 1.95

16°C

27°C 4.88 4.52 1.29 4.72 4.41 1.39 4.55 4.31 1.51 4.38 4.20 1.64 4.04 3.91 1.77 3.76 3.67 1.96

30°C 5.03 5.03 1.29 4.89 4.89 1.40 4.74 4.74 1.52 4.59 4.59 1.65 4.25 4.25 1.79 3.98 3.98 1.98

24°C 5.34 3.11 1.30 5.15 3.03 1.41 4.96 2.95 1.53 4.76 2.86 1.66 4.38 2.67 1.80 4.05 2.51 1.98

27°C 5.34 3.55 1.30 5.15 3.47 1.41 4.96 3.39 1.53 4.77 3.31 1.66 4.38 3.10 1.80 4.05 2.93 1.98

340 19°C

30°C 5.35 4.39 1.30 5.16 4.29 1.41 4.98 4.20 1.53 4.79 4.10 1.66 4.41 3.83 1.80 4.09 3.62 1.99

33°C 5.41 5.41 1.31 5.23 5.23 1.42 5.06 5.06 1.54 4.89 4.89 1.67 4.53 4.53 1.81 4.23 4.23 2.00

27°C 5.87 3.04 1.33 5.67 2.97 1.44 5.46 2.89 1.56 5.25 2.81 1.69 4.82 2.62 1.84 4.47 2.47 2.02

30°C 5.87 3.70 1.33 5.67 3.63 1.44 5.46 3.54 1.56 5.25 3.46 1.69 4.83 3.24 1.84 4.47 3.07 2.02

22°C

33°C 5.87 4.33 1.33 5.67 4.24 1.44 5.46 4.16 1.56 5.25 4.07 1.69 4.83 3.82 1.84 4.48 3.63 2.02

36°C 5.89 4.91 1.33 5.70 4.81 1.44 5.50 4.71 1.56 5.30 4.60 1.70 4.89 4.32 1.84 4.55 4.10 2.03

21°C 5.03 3.47 1.30 4.85 3.38 1.40 4.67 3.29 1.52 4.48 3.20 1.65 4.11 2.98 1.78 3.79 2.80 1.97

24°C 5.05 4.21 1.30 4.87 4.11 1.40 4.68 4.01 1.52 4.50 3.91 1.65 4.13 3.65 1.79 3.82 3.45 1.97

16°C

27°C 5.11 4.78 1.30 4.94 4.67 1.41 4.77 4.55 1.52 4.60 4.42 1.65 4.24 4.10 1.79 3.95 3.84 1.98

30°C 5.32 5.32 1.31 5.17 5.17 1.42 5.01 5.01 1.54 4.85 4.85 1.67 4.49 4.49 1.81 4.20 4.20 2.00

24°C 5.54 3.28 1.32 5.35 3.20 1.43 5.15 3.12 1.54 4.94 3.03 1.67 4.54 2.82 1.82 4.19 2.66 2.00

27°C 5.55 3.78 1.32 5.36 3.70 1.43 5.16 3.61 1.54 4.95 3.53 1.68 4.55 3.30 1.82 4.20 3.12 2.00

410 19°C

30°C 5.58 4.66 1.32 5.39 4.56 1.43 5.19 4.46 1.55 5.00 4.35 1.68 4.60 4.07 1.82 4.27 3.84 2.01

33°C 5.67 5.67 1.32 5.50 5.50 1.43 5.33 5.33 1.56 5.15 5.15 1.69 4.77 4.77 1.83 4.46 4.46 2.03

27°C 6.09 3.21 1.34 5.88 3.14 1.45 5.66 3.06 1.57 5.43 2.98 1.71 4.99 2.78 1.85 4.62 2.62 2.04

30°C 6.10 3.94 1.34 5.88 3.86 1.45 5.67 3.78 1.58 5.44 3.69 1.71 5.00 3.45 1.85 4.63 3.28 2.04

22°C

33°C 6.11 4.62 1.34 5.90 4.53 1.45 5.68 4.44 1.58 5.46 4.35 1.71 5.02 4.08 1.85 4.65 3.87 2.04

36°C 6.15 5.22 1.34 5.95 5.13 1.46 5.74 5.02 1.58 5.53 4.90 1.71 5.11 4.59 1.86 4.76 4.33 2.05

21°C 5.22 3.62 1.31 5.03 3.53 1.41 4.83 3.44 1.53 4.63 3.34 1.66 4.25 3.11 1.80 3.92 2.93 1.98

24°C 5.25 4.40 1.31 5.06 4.29 1.41 4.87 4.19 1.53 4.67 4.08 1.66 4.29 3.81 1.80 3.96 3.59 1.99

16°C

27°C 5.33 5.04 1.31 5.16 4.91 1.42 4.98 4.77 1.54 4.80 4.63 1.67 4.44 4.29 1.81 4.14 4.00 2.00

30°C 5.60 5.60 1.32 5.43 5.43 1.43 5.27 5.27 1.55 5.09 5.09 1.69 4.72 4.72 1.83 4.40 4.40 2.02

24°C 5.74 3.47 1.33 5.54 3.39 1.44 5.33 3.30 1.56 5.11 3.21 1.69 4.69 2.99 1.83 4.33 2.82 2.02

27°C 5.76 4.02 1.33 5.55 3.93 1.44 5.35 3.83 1.56 5.13 3.74 1.69 4.71 3.50 1.83 4.35 3.31 2.02

450 19°C

30°C 5.81 4.94 1.33 5.60 4.84 1.44 5.40 4.73 1.56 5.20 4.61 1.69 4.78 4.30 1.84 4.44 4.06 2.03

33°C 5.93 5.93 1.34 5.76 5.76 1.45 5.58 5.58 1.57 5.40 5.40 1.71 5.00 5.00 1.86 4.68 4.68 2.05

27°C 6.30 3.40 1.35 6.08 3.32 1.47 5.85 3.24 1.59 5.62 3.15 1.72 5.16 2.94 1.87 4.77 2.78 2.06

30°C 6.32 4.19 1.35 6.09 4.11 1.47 5.86 4.02 1.59 5.63 3.93 1.72 5.17 3.68 1.87 4.78 3.49 2.06

22°C

33°C 6.34 4.91 1.35 6.12 4.82 1.47 5.89 4.72 1.59 5.66 4.62 1.73 5.21 4.33 1.87 4.83 4.11 2.06

36°C 6.39 5.54 1.36 6.19 5.44 1.47 5.98 5.32 1.60 5.77 5.19 1.73 5.33 4.84 1.88 4.97 4.56 2.08

Remark:

AFR: Air flow rate (CFM)

EWB: Entering Wet Bulb Temp. (°C)

EDB: Entering Dry Bulb Temp. (°C)

TC: Total Cooling Capacity (kW)

SC: Sensible Cooling Capacity (kW)

PI: Power Input (kW)

Notes:

1. Ratings shown are net capacities.

2. shows nominal capacities.

3. Direct interpolation is permissible. Do not extrapolate.

4. Unit is able to operate at ambient from 19°C to 46°C DB without pressure trip.

30

DAIKIN_FFRN.indb 30 12/27/2012 9:28:11 AM

Performance Data

Model: FFRN50CXV1 - RN50CXV1

Cooling Mode

Outdoor temperature

AFR

EWB EDB 19°C 25°C 30°C 35°C 40°C 46°C

(CFM)

TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI

21°C 4.98 3.42 1.31 4.80 3.34 1.42 4.62 3.25 1.53 4.44 3.15 1.66 4.08 2.93 1.80 3.76 2.76 1.99

24°C 4.99 4.10 1.31 4.81 4.01 1.42 4.63 3.91 1.53 4.44 3.82 1.66 4.08 3.56 1.81 3.78 3.36 1.99

16°C

27°C 5.02 4.65 1.31 4.86 4.54 1.42 4.69 4.44 1.54 4.51 4.32 1.67 4.16 4.02 1.81 3.87 3.78 2.00

30°C 5.18 5.18 1.32 5.03 5.03 1.43 4.88 4.88 1.55 4.72 4.72 1.68 4.38 4.38 1.83 4.09 4.09 2.02

24°C 5.49 3.20 1.33 5.30 3.12 1.44 5.10 3.03 1.56 4.90 2.95 1.69 4.51 2.75 1.84 4.16 2.59 2.02

27°C 5.49 3.66 1.33 5.30 3.58 1.44 5.11 3.49 1.56 4.91 3.41 1.69 4.51 3.19 1.84 4.17 3.02 2.02

340 19°C

30°C 5.50 4.51 1.33 5.31 4.42 1.44 5.13 4.32 1.56 4.93 4.22 1.69 4.54 3.94 1.84 4.21 3.73 2.03

33°C 5.57 5.57 1.33 5.39 5.39 1.45 5.21 5.21 1.57 5.03 5.03 1.70 4.66 4.66 1.85 4.36 4.36 2.04

27°C 6.04 3.13 1.35 5.83 3.05 1.47 5.62 2.98 1.59 5.40 2.90 1.73 4.97 2.70 1.87 4.60 2.54 2.06

30°C 6.04 3.81 1.35 5.83 3.73 1.47 5.62 3.65 1.59 5.40 3.56 1.73 4.97 3.33 1.87 4.60 3.16 2.06

22°C

33°C 6.05 4.45 1.35 5.84 4.37 1.47 5.62 4.28 1.59 5.41 4.19 1.73 4.97 3.94 1.87 4.61 3.74 2.06

36°C 6.07 5.05 1.36 5.87 4.95 1.47 5.66 4.85 1.59 5.46 4.74 1.73 5.03 4.44 1.88 4.68 4.22 2.07

21°C 5.18 3.57 1.32 4.99 3.48 1.43 4.80 3.39 1.55 4.61 3.29 1.68 4.23 3.07 1.82 3.90 2.88 2.01

24°C 5.20 4.34 1.32 5.01 4.23 1.43 4.82 4.13 1.55 4.63 4.03 1.68 4.25 3.76 1.82 3.93 3.55 2.01

16°C

27°C 5.26 4.92 1.33 5.08 4.81 1.43 4.91 4.69 1.55 4.73 4.55 1.69 4.37 4.22 1.83 4.07 3.95 2.02

30°C 5.48 5.48 1.33 5.32 5.32 1.45 5.16 5.16 1.57 4.99 4.99 1.70 4.62 4.62 1.85 4.32 4.32 2.04

24°C 5.71 3.38 1.34 5.50 3.29 1.45 5.30 3.21 1.58 5.08 3.12 1.71 4.67 2.91 1.85 4.31 2.74 2.04

27°C 5.72 3.89 1.34 5.51 3.81 1.45 5.31 3.72 1.58 5.09 3.63 1.71 4.68 3.40 1.85 4.33 3.21 2.04

410 19°C

30°C 5.74 4.80 1.35 5.54 4.70 1.46 5.35 4.59 1.58 5.14 4.48 1.71 4.73 4.19 1.86 4.39 3.96 2.05

33°C 5.84 5.84 1.35 5.66 5.66 1.46 5.48 5.48 1.59 5.30 5.30 1.72 4.91 4.91 1.87 4.59 4.59 2.07

27°C 6.27 3.31 1.37 6.05 3.23 1.48 5.82 3.15 1.61 5.59 3.06 1.74 5.14 2.86 1.89 4.75 2.70 2.08

30°C 6.28 4.06 1.37 6.06 3.98 1.48 5.83 3.89 1.61 5.60 3.80 1.74 5.15 3.56 1.89 4.76 3.37 2.08

22°C

33°C 6.29 4.76 1.37 6.07 4.67 1.48 5.85 4.57 1.61 5.62 4.47 1.74 5.17 4.20 1.89 4.79 3.98 2.08

36°C 6.33 5.38 1.37 6.12 5.28 1.49 5.91 5.17 1.61 5.70 5.05 1.75 5.25 4.72 1.90 4.90 4.45 2.09

21°C 5.37 3.73 1.33 5.17 3.63 1.44 4.98 3.54 1.56 4.77 3.44 1.69 4.37 3.20 1.83 4.03 3.01 2.02

24°C 5.40 4.53 1.33 5.20 4.42 1.44 5.01 4.31 1.56 4.81 4.20 1.69 4.41 3.92 1.84 4.08 3.70 2.03

16°C

27°C 5.49 5.19 1.34 5.31 5.06 1.45 5.13 4.91 1.57 4.94 4.76 1.70 4.57 4.41 1.85 4.26 4.12 2.04

30°C 5.76 5.76 1.35 5.59 5.59 1.46 5.42 5.42 1.59 5.24 5.24 1.72 4.85 4.85 1.87 4.53 4.53 2.06

24°C 5.91 3.57 1.35 5.70 3.49 1.47 5.48 3.40 1.59 5.26 3.30 1.72 4.83 3.08 1.87 4.46 2.91 2.06

27°C 5.93 4.14 1.36 5.72 4.04 1.47 5.50 3.95 1.59 5.28 3.85 1.72 4.85 3.60 1.87 4.48 3.41 2.06

450 19°C

30°C 5.98 5.09 1.36 5.77 4.98 1.47 5.56 4.86 1.59 5.35 4.74 1.73 4.92 4.43 1.88 4.57 4.18 2.07

33°C 6.11 6.11 1.36 5.93 5.93 1.48 5.75 5.75 1.60 5.56 5.56 1.74 5.15 5.15 1.89 4.81 4.81 2.09

27°C 6.49 3.50 1.38 6.26 3.42 1.49 6.02 3.33 1.62 5.78 3.25 1.76 5.31 3.03 1.90 4.91 2.86 2.10

30°C 6.50 4.31 1.38 6.27 4.23 1.50 6.03 4.14 1.62 5.79 4.04 1.76 5.32 3.79 1.91 4.92 3.59 2.10

22°C

33°C 6.52 5.05 1.38 6.30 4.96 1.50 6.07 4.86 1.62 5.83 4.75 1.76 5.36 4.45 1.91 4.97 4.23 2.10

36°C 6.58 5.70 1.39 6.38 5.60 1.50 6.16 5.48 1.63 5.93 5.34 1.77 5.48 4.98 1.92 5.11 4.69 2.12

Remark:

AFR: Air flow rate (CFM)

EWB: Entering Wet Bulb Temp. (°C)

EDB: Entering Dry Bulb Temp. (°C)

TC: Total Cooling Capacity (kW)

SC: Sensible Cooling Capacity (kW)

PI: Power Input (kW)

Notes:

1. Ratings shown are net capacities.

2. shows nominal capacities.

3. Direct interpolation is permissible. Do not extrapolate.

4. Unit is able to operate at ambient from 19°C to 46°C DB without pressure trip.

31

DAIKIN_FFRN.indb 31 12/27/2012 9:28:11 AM

Performance Data

Model: FCRN50EXV1 - RN50CXV1

Cooling Mode

Outdoor temperature

AFR

EWB EDB 19°C 25°C 30°C 35°C 40°C 46°C

(CFM)

TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI

21°C 5.05 3.81 1.32 4.87 3.71 1.43 4.69 3.61 1.55 4.50 3.51 1.68 4.14 3.27 1.82 3.82 3.07 2.01

24°C 5.06 4.57 1.32 4.88 4.46 1.43 4.70 4.36 1.55 4.51 4.25 1.68 4.14 3.97 1.82 3.83 3.74 2.01

16°C

27°C 5.10 5.10 1.32 4.93 4.93 1.43 4.76 4.76 1.55 4.58 4.58 1.68 4.22 4.22 1.83 3.93 3.93 2.02

30°C 5.26 5.26 1.33 5.11 5.11 1.44 4.95 4.95 1.56 4.79 4.79 1.70 4.44 4.44 1.84 4.16 4.16 2.04

24°C 5.57 3.56 1.34 5.38 3.47 1.45 5.18 3.38 1.58 4.98 3.28 1.71 4.57 3.06 1.85 4.23 2.88 2.04

27°C 5.58 4.07 1.34 5.38 3.98 1.45 5.18 3.89 1.58 4.98 3.80 1.71 4.58 3.55 1.85 4.23 3.36 2.04

430 19°C

30°C 5.59 5.03 1.34 5.39 4.92 1.45 5.20 4.81 1.58 5.01 4.69 1.71 4.61 4.39 1.86 4.28 4.15 2.05

33°C 5.65 5.65 1.35 5.47 5.47 1.46 5.29 5.29 1.58 5.11 5.11 1.72 4.73 4.73 1.86 4.42 4.42 2.06

27°C 6.13 3.48 1.37 5.92 3.40 1.48 5.70 3.32 1.61 5.48 3.22 1.74 5.04 3.00 1.89 4.67 2.83 2.08

30°C 6.13 4.25 1.37 5.92 4.16 1.48 5.70 4.06 1.61 5.48 3.97 1.74 5.04 3.71 1.89 4.67 3.52 2.08

22°C

33°C 6.14 4.96 1.37 5.92 4.87 1.48 5.71 4.77 1.61 5.49 4.67 1.74 5.05 4.38 1.89 4.68 4.16 2.08

36°C 6.16 5.62 1.37 5.95 5.51 1.48 5.75 5.40 1.61 5.54 5.28 1.75 5.11 4.95 1.89 4.75 4.69 2.09

21°C 5.26 3.98 1.33 5.07 3.88 1.44 4.88 3.77 1.56 4.68 3.67 1.69 4.29 3.41 1.84 3.96 3.21 2.03

24°C 5.27 4.83 1.33 5.08 4.72 1.44 4.89 4.60 1.56 4.70 4.49 1.70 4.31 4.19 1.84 3.99 3.95 2.03

16°C

27°C 5.34 5.34 1.34 5.16 5.16 1.45 4.98 4.98 1.57 4.80 4.80 1.70 4.43 4.43 1.85 4.13 4.13 2.04

30°C 5.56 5.56 1.35 5.40 5.40 1.46 5.23 5.23 1.58 5.06 5.06 1.72 4.69 4.69 1.87 4.39 4.39 2.06

24°C 5.79 3.76 1.36 5.59 3.67 1.47 5.38 3.57 1.59 5.16 3.47 1.72 4.74 3.24 1.87 4.38 3.05 2.06

27°C 5.80 4.33 1.36 5.60 4.24 1.47 5.39 4.14 1.59 5.17 4.04 1.72 4.75 3.78 1.87 4.39 3.58 2.06

530 19°C

30°C 5.83 5.35 1.36 5.63 5.23 1.47 5.43 5.11 1.59 5.22 4.99 1.73 4.81 4.67 1.87 4.46 4.41 2.07

33°C 5.93 5.93 1.36 5.75 5.75 1.48 5.56 5.56 1.60 5.38 5.38 1.74 4.98 4.98 1.89 4.66 4.66 2.09

27°C 6.37 3.68 1.38 6.14 3.60 1.50 5.91 3.51 1.62 5.68 3.41 1.76 5.22 3.18 1.91 4.83 3.00 2.10

30°C 6.37 4.52 1.38 6.15 4.43 1.50 5.92 4.33 1.62 5.68 4.23 1.76 5.22 3.96 1.91 4.83 3.76 2.10

22°C

33°C 6.38 5.30 1.38 6.16 5.20 1.50 5.94 5.09 1.62 5.70 4.98 1.76 5.25 4.67 1.91 4.86 4.44 2.10

36°C 6.42 5.99 1.38 6.22 5.88 1.50 6.00 5.75 1.63 5.78 5.62 1.77 5.33 5.26 1.92 4.97 4.96 2.11

21°C 5.45 4.15 1.34 5.25 4.05 1.45 5.05 3.94 1.57 4.84 3.83 1.71 4.44 3.57 1.85 4.09 3.36 2.04

24°C 5.48 5.04 1.35 5.28 4.92 1.46 5.08 4.80 1.58 4.88 4.68 1.71 4.48 4.36 1.85 4.14 4.12 2.04

16°C

27°C 5.57 5.57 1.35 5.39 5.39 1.46 5.21 5.21 1.58 5.02 5.02 1.72 4.64 4.64 1.87 4.32 4.32 2.06

30°C 5.85 5.85 1.36 5.68 5.68 1.48 5.50 5.50 1.60 5.32 5.32 1.74 4.93 4.93 1.89 4.60 4.60 2.08

24°C 6.00 3.98 1.37 5.78 3.88 1.48 5.57 3.78 1.60 5.34 3.68 1.74 4.90 3.43 1.89 4.52 3.24 2.08

27°C 6.02 4.61 1.37 5.80 4.50 1.48 5.59 4.40 1.60 5.36 4.29 1.74 4.92 4.01 1.89 4.55 3.79 2.08

600 19°C

30°C 6.07 5.67 1.37 5.85 5.55 1.48 5.64 5.42 1.61 5.43 5.28 1.74 5.00 4.93 1.89 4.64 4.64 2.09

33°C 6.20 6.20 1.38 6.02 6.02 1.49 5.83 5.83 1.62 5.64 5.64 1.76 5.23 5.23 1.91 4.89 4.89 2.11

27°C 6.59 3.89 1.39 6.35 3.81 1.51 6.11 3.71 1.64 5.87 3.62 1.77 5.39 3.37 1.92 4.98 3.19 2.12

30°C 6.60 4.80 1.39 6.36 4.71 1.51 6.13 4.61 1.64 5.88 4.50 1.77 5.40 4.22 1.92 5.00 4.00 2.12

22°C

33°C 6.62 5.63 1.39 6.39 5.53 1.51 6.16 5.41 1.64 5.92 5.29 1.78 5.44 4.96 1.93 5.04 4.71 2.12

36°C 6.68 6.35 1.40 6.47 6.24 1.52 6.25 6.10 1.64 6.02 5.95 1.78 5.57 5.55 1.94 5.19 5.19 2.14

Remark:

AFR: Air flow rate (CFM)

EWB: Entering Wet Bulb Temp. (°C)

EDB: Entering Dry Bulb Temp. (°C)

TC: Total Cooling Capacity (kW)

SC: Sensible Cooling Capacity (kW)

PI: Power Input (kW)

Notes:

1. Ratings shown are net capacities.

2. shows nominal capacities.

3. Direct interpolation is permissible. Do not extrapolate.

4. Unit is able to operate at ambient from 19°C to 46°C DB without pressure trip.

32

DAIKIN_FFRN.indb 32 12/27/2012 9:28:11 AM

Performance Data

Model: FCRN60EXV1 - RN60CXV1

Cooling Mode

Outdoor temperature

AFR

EWB EDB 19°C 25°C 30°C 35°C 40°C 46°C

(CFM)

TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI

21°C 6.14 4.34 1.47 5.92 4.23 1.59 5.70 4.11 1.73 5.47 4.00 1.87 5.03 3.72 2.03 4.64 3.50 2.24

24°C 6.15 5.20 1.47 5.93 5.08 1.59 5.71 4.96 1.73 5.48 4.84 1.87 5.04 4.52 2.03 4.66 4.26 2.24

16°C

27°C 6.20 5.89 1.48 5.99 5.76 1.60 5.78 5.62 1.73 5.56 5.48 1.88 5.13 5.10 2.04 4.77 4.77 2.25

30°C 6.39 6.39 1.48 6.20 6.20 1.61 6.01 6.01 1.74 5.82 5.82 1.89 5.40 5.40 2.06 5.05 5.05 2.27

24°C 6.77 4.05 1.50 6.53 3.95 1.62 6.29 3.85 1.76 6.04 3.74 1.90 5.56 3.48 2.07 5.14 3.28 2.28

27°C 6.78 4.64 1.50 6.54 4.53 1.62 6.30 4.43 1.76 6.05 4.32 1.91 5.56 4.04 2.07 5.14 3.83 2.28

530 19°C

30°C 6.79 5.72 1.50 6.55 5.60 1.62 6.32 5.48 1.76 6.08 5.34 1.91 5.60 5.00 2.07 5.19 4.73 2.28

33°C 6.87 6.87 1.50 6.64 6.64 1.63 6.43 6.43 1.76 6.21 6.21 1.91 5.74 5.74 2.08 5.37 5.37 2.30

27°C 7.45 3.97 1.52 7.19 3.87 1.65 6.93 3.77 1.79 6.66 3.67 1.94 6.12 3.42 2.11 5.67 3.22 2.32

30°C 7.45 4.83 1.52 7.19 4.73 1.65 6.93 4.62 1.79 6.66 4.51 1.94 6.12 4.23 2.11 5.67 4.01 2.32

22°C

33°C 7.46 5.65 1.52 7.20 5.54 1.65 6.94 5.43 1.79 6.66 5.32 1.94 6.13 4.99 2.11 5.68 4.74 2.32

36°C 7.48 6.40 1.53 7.23 6.27 1.65 6.98 6.14 1.79 6.73 6.01 1.95 6.20 5.63 2.11 5.77 5.34 2.33

21°C 6.39 4.53 1.49 6.16 4.41 1.61 5.92 4.29 1.74 5.68 4.17 1.89 5.21 3.88 2.05 4.81 3.66 2.26

24°C 6.41 5.50 1.49 6.18 5.37 1.61 5.94 5.24 1.74 5.70 5.11 1.89 5.24 4.76 2.05 4.84 4.50 2.26

16°C

27°C 6.48 6.24 1.49 6.27 6.10 1.61 6.05 5.94 1.75 5.83 5.76 1.90 5.38 5.35 2.06 5.02 5.01 2.27

30°C 6.75 6.75 1.50 6.56 6.56 1.63 6.36 6.36 1.76 6.15 6.15 1.92 5.70 5.70 2.08 5.33 5.33 2.30

24°C 7.04 4.28 1.51 6.79 4.18 1.64 6.53 4.07 1.77 6.27 3.95 1.92 5.76 3.69 2.08 5.32 3.47 2.30

27°C 7.05 4.93 1.51 6.80 4.82 1.64 6.54 4.71 1.77 6.28 4.60 1.92 5.77 4.30 2.09 5.33 4.07 2.30

600 19°C

30°C 7.08 6.09 1.51 6.84 5.95 1.64 6.59 5.82 1.78 6.34 5.68 1.93 5.84 5.31 2.09 5.41 5.02 2.30

33°C 7.20 7.20 1.52 6.98 6.98 1.65 6.76 6.76 1.79 6.53 6.53 1.94 6.05 6.05 2.11 5.66 5.66 2.32

27°C 7.73 4.19 1.54 7.46 4.09 1.67 7.18 3.99 1.81 6.90 3.88 1.96 6.34 3.62 2.13 5.86 3.42 2.34

30°C 7.74 5.15 1.54 7.47 5.04 1.67 7.19 4.93 1.81 6.90 4.81 1.96 6.35 4.51 2.13 5.87 4.28 2.34

22°C

33°C 7.75 6.03 1.54 7.48 5.91 1.67 7.21 5.79 1.81 6.93 5.67 1.96 6.37 5.32 2.13 5.91 5.05 2.35

36°C 7.80 6.82 1.54 7.55 6.69 1.67 7.29 6.55 1.81 7.02 6.40 1.97 6.48 5.98 2.14 6.04 5.65 2.36

21°C 6.62 4.72 1.50 6.38 4.60 1.62 6.14 4.48 1.76 5.88 4.36 1.90 5.39 4.06 2.06 4.97 3.82 2.28

24°C 6.66 5.74 1.50 6.42 5.60 1.62 6.17 5.47 1.76 5.92 5.32 1.91 5.44 4.97 2.07 5.03 4.68 2.28

16°C

27°C 6.76 6.58 1.51 6.54 6.41 1.63 6.32 6.23 1.77 6.10 6.04 1.92 5.63 5.59 2.08 5.25 5.22 2.30

30°C 7.10 7.10 1.52 6.90 6.90 1.65 6.68 6.68 1.78 6.46 6.46 1.94 5.98 5.98 2.10 5.59 5.59 2.32

24°C 7.29 4.53 1.52 7.03 4.42 1.65 6.76 4.31 1.79 6.48 4.19 1.94 5.95 3.91 2.10 5.49 3.68 2.32

27°C 7.31 5.24 1.53 7.05 5.12 1.65 6.78 5.00 1.79 6.51 4.88 1.94 5.98 4.56 2.10 5.52 4.32 2.32

680 19°C

30°C 7.37 6.45 1.53 7.11 6.31 1.65 6.86 6.17 1.79 6.59 6.01 1.94 6.07 5.61 2.11 5.64 5.29 2.33

33°C 7.53 7.53 1.54 7.31 7.31 1.66 7.09 7.09 1.81 6.85 6.85 1.96 6.35 6.35 2.13 5.94 5.94 2.35

27°C 8.00 4.43 1.55 7.71 4.34 1.68 7.42 4.23 1.82 7.13 4.12 1.98 6.55 3.84 2.14 6.05 3.63 2.36

30°C 8.02 5.46 1.55 7.73 5.36 1.68 7.44 5.24 1.82 7.14 5.12 1.98 6.56 4.80 2.15 6.07 4.55 2.36

22°C

33°C 8.04 6.40 1.56 7.77 6.29 1.69 7.48 6.16 1.83 7.19 6.02 1.98 6.61 5.65 2.15 6.12 5.36 2.37

36°C 8.11 7.23 1.56 7.86 7.10 1.69 7.59 6.94 1.83 7.32 6.77 1.99 6.76 6.32 2.16 6.31 5.95 2.38

Remark:

AFR: Air flow rate (CFM)

EWB: Entering Wet Bulb Temp. (°C)

EDB: Entering Dry Bulb Temp. (°C)

TC: Total Cooling Capacity (kW)

SC: Sensible Cooling Capacity (kW)

PI: Power Input (kW)

Notes:

1. Ratings shown are net capacities.

2. shows nominal capacities.

3. Direct interpolation is permissible. Do not extrapolate.

4. Unit is able to operate at ambient from 19°C to 46°C DB without pressure trip.

33

DAIKIN_FFRN.indb 33 12/27/2012 9:28:11 AM

Performance Data

Model: FCRN71EXV1 - RR71CXV1

Cooling Mode

Outdoor temperature

AFR

EWB EDB 19°C 25°C 30°C 35°C 40°C 46°C

(CFM)

TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI

21°C 7.46 5.49 2.12 7.19 5.34 2.29 6.93 5.20 2.48 6.65 5.05 2.69 6.10 4.70 2.92 5.64 4.42 3.22

24°C 7.47 6.57 2.12 7.20 6.42 2.29 6.94 6.27 2.48 6.66 6.11 2.69 6.12 5.71 2.92 5.66 5.39 3.22

16°C

27°C 7.53 7.45 2.12 7.28 7.28 2.30 7.02 7.02 2.49 6.76 6.76 2.70 6.23 6.23 2.93 5.80 5.80 3.23

30°C 7.76 7.76 2.13 7.54 7.54 2.31 7.31 7.31 2.51 7.07 7.07 2.72 6.55 6.55 2.96 6.13 6.13 3.26

24°C 8.23 5.12 2.15 7.94 4.99 2.33 7.65 4.86 2.53 7.34 4.72 2.74 6.75 4.40 2.97 6.24 4.14 3.28

27°C 8.23 5.86 2.15 7.94 5.73 2.33 7.65 5.60 2.53 7.35 5.46 2.74 6.76 5.11 2.97 6.25 4.84 3.28

620 19°C

30°C 8.24 7.23 2.15 7.96 7.08 2.33 7.68 6.92 2.53 7.39 6.76 2.74 6.80 6.32 2.98 6.31 5.98 3.28

33°C 8.34 8.34 2.16 8.07 8.07 2.34 7.81 7.81 2.54 7.54 7.54 2.75 6.98 6.98 2.99 6.52 6.52 3.30

27°C 9.05 5.01 2.19 8.74 4.89 2.38 8.42 4.77 2.57 8.09 4.64 2.79 7.44 4.32 3.03 6.89 4.08 3.34

30°C 9.05 6.11 2.19 8.74 5.98 2.38 8.42 5.84 2.58 8.09 5.71 2.79 7.44 5.34 3.03 6.89 5.06 3.34

22°C

33°C 9.06 7.14 2.19 8.74 7.00 2.38 8.43 6.86 2.58 8.10 6.72 2.79 7.45 6.31 3.03 6.91 5.99 3.34

36°C 9.09 8.09 2.19 8.79 7.93 2.38 8.48 7.77 2.58 8.17 7.59 2.80 7.54 7.12 3.04 7.01 6.75 3.35

21°C 7.76 5.72 2.14 7.48 5.58 2.31 7.20 5.43 2.51 6.90 5.27 2.72 6.33 4.91 2.95 5.84 4.62 3.25

24°C 7.78 6.95 2.14 7.50 6.78 2.31 7.22 6.62 2.51 6.93 6.46 2.72 6.37 6.02 2.95 5.89 5.68 3.25

16°C

27°C 7.88 7.88 2.15 7.61 7.61 2.32 7.35 7.35 2.51 7.09 7.09 2.73 6.54 6.54 2.96 6.09 6.09 3.27

30°C 8.21 8.21 2.16 7.97 7.97 2.34 7.72 7.72 2.54 7.47 7.47 2.75 6.92 6.92 2.99 6.47 6.47 3.30

24°C 8.55 5.41 2.17 8.24 5.28 2.35 7.93 5.14 2.55 7.62 5.00 2.76 6.99 4.66 3.00 6.46 4.39 3.30

27°C 8.56 6.24 2.17 8.26 6.10 2.35 7.95 5.96 2.55 7.63 5.82 2.77 7.01 5.44 3.00 6.48 5.15 3.31

725 19°C

30°C 8.60 7.69 2.18 8.31 7.53 2.36 8.01 7.36 2.55 7.70 7.18 2.77 7.09 6.71 3.01 6.58 6.34 3.31

33°C 8.75 8.75 2.18 8.48 8.48 2.37 8.21 8.21 2.57 7.94 7.94 2.79 7.35 7.35 3.03 6.87 6.87 3.34

27°C 9.39 5.30 2.21 9.06 5.18 2.40 8.73 5.05 2.60 8.38 4.91 2.82 7.70 4.58 3.06 7.12 4.32 3.37

30°C 9.40 6.50 2.21 9.07 6.37 2.40 8.73 6.23 2.60 8.39 6.08 2.82 7.71 5.70 3.06 7.13 5.41 3.37

22°C

33°C 9.42 7.62 2.22 9.09 7.48 2.40 8.76 7.32 2.60 8.42 7.17 2.82 7.74 6.72 3.06 7.18 6.38 3.37

36°C 9.48 8.62 2.22 9.17 8.45 2.41 8.85 8.28 2.61 8.53 8.09 2.83 7.87 7.57 3.07 7.34 7.14 3.39

21°C 8.05 5.97 2.16 7.75 5.82 2.33 7.45 5.67 2.53 7.15 5.51 2.74 6.55 5.13 2.97 6.04 4.83 3.27

24°C 8.09 7.26 2.16 7.80 7.09 2.33 7.50 6.91 2.53 7.20 6.73 2.74 6.61 6.28 2.97 6.11 5.92 3.28

16°C

27°C 8.22 8.22 2.17 7.95 7.95 2.34 7.68 7.68 2.54 7.41 7.41 2.76 6.84 6.84 2.99 6.38 6.38 3.30

30°C 8.63 8.63 2.18 8.38 8.38 2.37 8.12 8.12 2.57 7.85 7.85 2.79 7.27 7.27 3.03 6.79 6.79 3.34

24°C 8.86 5.73 2.19 8.54 5.59 2.37 8.21 5.44 2.57 7.88 5.30 2.79 7.23 4.94 3.02 6.67 4.66 3.33

27°C 8.88 6.63 2.19 8.56 6.48 2.37 8.24 6.32 2.57 7.91 6.17 2.79 7.26 5.77 3.03 6.71 5.46 3.33

860 19°C

30°C 8.96 8.16 2.20 8.64 7.98 2.38 8.33 7.80 2.58 8.01 7.60 2.80 7.38 7.10 3.03 6.85 6.69 3.35

33°C 9.15 9.15 2.21 8.88 8.88 2.39 8.61 8.61 2.60 8.33 8.33 2.82 7.71 7.71 3.06 7.21 7.21 3.38

27°C 9.72 5.60 2.23 9.37 5.48 2.42 9.02 5.34 2.62 8.66 5.20 2.84 7.95 4.86 3.08 7.35 4.58 3.39

30°C 9.74 6.91 2.23 9.39 6.78 2.42 9.04 6.63 2.62 8.68 6.48 2.84 7.97 6.07 3.08 7.37 5.75 3.40

22°C

33°C 9.77 8.10 2.24 9.44 7.96 2.42 9.09 7.79 2.63 8.73 7.62 2.85 8.03 7.14 3.09 7.44 6.77 3.40

36°C 9.86 9.14 2.24 9.55 8.98 2.43 9.22 8.78 2.64 8.89 8.56 2.86 8.21 7.99 3.11 7.66 7.52 3.43

Remark:

AFR: Air flow rate (CFM)

EWB: Entering Wet Bulb Temp. (°C)

EDB: Entering Dry Bulb Temp. (°C)

TC: Total Cooling Capacity (kW)

SC: Sensible Cooling Capacity (kW)

PI: Power Input (kW)

Notes:

1. Ratings shown are net capacities.

2. shows nominal capacities.

3. Direct interpolation is permissible. Do not extrapolate.

4. Unit is able to operate at ambient from 19°C to 46°C DB without pressure trip.

34

DAIKIN_FFRN.indb 34 12/27/2012 9:28:12 AM

Performance Data

Model: FCRN100EXV1- RR90DXV1

Cooling Mode

Outdoor temperature

AFR

EWB EDB 19°C 25°C 30°C 35°C 40°C 46°C

(CFM)

TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI

21°C 8.07 6.17 2.14 7.78 6.00 2.32 7.50 5.84 2.51 7.19 5.68 2.72 6.61 5.28 2.95 6.10 4.97 3.25

24°C 8.08 7.38 2.14 7.79 7.21 2.32 7.51 7.05 2.51 7.21 6.87 2.72 6.62 6.42 2.95 6.12 6.05 3.26

16°C

27°C 8.14 8.14 2.15 7.87 7.87 2.32 7.60 7.60 2.52 7.31 7.31 2.73 6.75 6.75 2.96 6.28 6.28 3.27

30°C 8.40 8.40 2.16 8.15 8.15 2.34 7.91 7.91 2.53 7.65 7.65 2.75 7.09 7.09 2.99 6.64 6.64 3.30

24°C 8.90 5.76 2.18 8.59 5.61 2.36 8.27 5.46 2.55 7.95 5.31 2.77 7.30 4.94 3.00 6.75 4.65 3.31

27°C 8.91 6.59 2.18 8.59 6.44 2.36 8.28 6.29 2.55 7.95 6.14 2.77 7.31 5.74 3.00 6.76 5.44 3.31

740 19°C

30°C 8.92 8.13 2.18 8.61 7.95 2.36 8.31 7.78 2.56 7.99 7.59 2.77 7.36 7.10 3.01 6.83 6.72 3.32

33°C 9.03 9.03 2.18 8.73 8.73 2.36 8.45 8.45 2.56 8.16 8.16 2.78 7.55 7.55 3.02 7.06 7.06 3.34

27°C 9.79 5.63 2.22 9.45 5.50 2.40 9.11 5.36 2.60 8.75 5.21 2.82 8.05 4.86 3.06 7.45 4.58 3.37

30°C 9.80 6.87 2.22 9.46 6.72 2.40 9.11 6.57 2.60 8.76 6.41 2.82 8.05 6.00 3.06 7.45 5.69 3.37

22°C

33°C 9.80 8.02 2.22 9.46 7.87 2.40 9.12 7.71 2.60 8.76 7.55 2.82 8.06 7.09 3.06 7.47 6.73 3.38

36°C 9.83 9.09 2.22 9.51 8.91 2.40 9.18 8.73 2.61 8.84 8.53 2.83 8.16 8.00 3.07 7.58 7.58 3.39

21°C 8.40 6.43 2.16 8.09 6.26 2.34 7.79 6.10 2.53 7.47 5.93 2.75 6.85 5.52 2.98 6.32 5.19 3.28

24°C 8.42 7.81 2.16 8.12 7.62 2.34 7.82 7.44 2.53 7.50 7.25 2.75 6.89 6.77 2.98 6.37 6.37 3.29

16°C

27°C 8.52 8.52 2.17 8.24 8.24 2.35 7.95 7.95 2.54 7.67 7.67 2.76 7.08 7.08 2.99 6.59 6.59 3.30

30°C 8.88 8.88 2.18 8.62 8.62 2.36 8.36 8.36 2.56 8.09 8.09 2.78 7.49 7.49 3.03 7.00 7.00 3.34

24°C 9.25 6.08 2.20 8.92 5.93 2.38 8.59 5.78 2.58 8.24 5.62 2.79 7.57 5.23 3.03 6.99 4.93 3.34

27°C 9.27 7.01 2.20 8.94 6.85 2.38 8.60 6.70 2.58 8.26 6.54 2.80 7.59 6.11 3.03 7.01 5.79 3.34

860 19°C

30°C 9.31 8.64 2.20 8.99 8.46 2.38 8.67 8.27 2.58 8.33 8.07 2.80 7.67 7.54 3.04 7.12 7.12 3.35

33°C 9.47 9.47 2.21 9.18 9.18 2.39 8.89 8.89 2.60 8.59 8.59 2.82 7.96 7.96 3.06 7.44 7.44 3.38

27°C 10.16 5.96 2.24 9.81 5.82 2.42 9.44 5.67 2.63 9.07 5.52 2.85 8.33 5.15 3.09 7.71 4.85 3.40

30°C 10.18 7.31 2.24 9.82 7.16 2.42 9.45 7.00 2.63 9.08 6.84 2.85 8.34 6.40 3.09 7.72 6.07 3.41

22°C

33°C 10.20 8.57 2.24 9.84 8.40 2.43 9.48 8.23 2.63 9.11 8.05 2.85 8.38 7.56 3.10 7.77 7.17 3.41

36°C 10.26 9.68 2.24 9.93 9.50 2.43 9.58 9.30 2.64 9.23 9.08 2.86 8.52 8.50 3.11 7.94 7.94 3.43

21°C 8.71 6.71 2.18 8.39 6.54 2.36 8.07 6.37 2.55 7.73 6.19 2.77 7.09 5.77 3.00 6.54 5.43 3.31

24°C 8.75 8.15 2.18 8.44 7.96 2.36 8.12 7.77 2.56 7.79 7.56 2.77 7.16 7.06 3.01 6.61 6.61 3.31

16°C

27°C 8.90 8.90 2.19 8.60 8.60 2.37 8.31 8.31 2.57 8.02 8.02 2.79 7.41 7.41 3.02 6.90 6.90 3.34

30°C 9.34 9.34 2.21 9.07 9.07 2.39 8.79 8.79 2.59 8.50 8.50 2.82 7.87 7.87 3.06 7.35 7.35 3.38

24°C 9.59 6.44 2.22 9.24 6.28 2.40 8.89 6.12 2.60 8.53 5.95 2.82 7.82 5.55 3.06 7.22 5.23 3.37

27°C 9.61 7.45 2.22 9.27 7.28 2.40 8.92 7.11 2.60 8.56 6.93 2.82 7.86 6.48 3.06 7.26 6.13 3.37

1030 19°C

30°C 9.69 9.17 2.22 9.35 8.97 2.41 9.01 8.76 2.61 8.67 8.54 2.83 7.98 7.98 3.07 7.41 7.41 3.38

33°C 9.90 9.90 2.23 9.61 9.61 2.42 9.32 9.32 2.62 9.01 9.01 2.85 8.35 8.35 3.10 7.81 7.81 3.42

27°C 10.52 6.30 2.26 10.14 6.16 2.45 9.76 6.00 2.65 9.37 5.85 2.87 8.61 5.46 3.12 7.95 5.15 3.43

30°C 10.54 7.76 2.26 10.16 7.62 2.45 9.78 7.45 2.65 9.39 7.28 2.88 8.63 6.82 3.12 7.98 6.46 3.43

22°C

33°C 10.58 9.10 2.26 10.21 8.94 2.45 9.84 8.75 2.66 9.45 8.56 2.88 8.69 8.02 3.12 8.05 7.61 3.44

36°C 10.67 10.27 2.27 10.34 10.09 2.46 9.98 9.86 2.66 9.62 9.62 2.89 8.89 8.89 3.14 8.29 8.29 3.46

Remark:

AFR: Air flow rate (CFM)

EWB: Entering Wet Bulb Temp. (°C)

EDB: Entering Dry Bulb Temp. (°C)

TC: Total Cooling Capacity (kW)

SC: Sensible Cooling Capacity (kW)

PI: Power Input (kW)

Notes:

1. Ratings shown are net capacities.

2. shows nominal capacities.

3. Direct interpolation is permissible. Do not extrapolate.

4. Unit is able to operate at ambient from 19°C to 46°C DB without pressure trip.

35