TP-62 TP-42 TP-50 TP-70 TP-72: Pedal Timpani Timbale À Pédale Timbal De Pedal 踏板定音鼓

TP-62 TP-42 TP-50 TP-70 TP-72: Pedal Timpani Timbale À Pédale Timbal De Pedal 踏板定音鼓

Uploaded by

lucasloudCopyright:

Available Formats

TP-62 TP-42 TP-50 TP-70 TP-72: Pedal Timpani Timbale À Pédale Timbal De Pedal 踏板定音鼓

TP-62 TP-42 TP-50 TP-70 TP-72: Pedal Timpani Timbale À Pédale Timbal De Pedal 踏板定音鼓

Uploaded by

lucasloudOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

TP-62 TP-42 TP-50 TP-70 TP-72: Pedal Timpani Timbale À Pédale Timbal De Pedal 踏板定音鼓

TP-62 TP-42 TP-50 TP-70 TP-72: Pedal Timpani Timbale À Pédale Timbal De Pedal 踏板定音鼓

Uploaded by

lucasloudCopyright:

Available Formats

PEDAL TIMPANI

TIMBALE À PÉDALE

TIMBAL DE PEDAL

踏板定音鼓

English

TP-6220 /23 /26 /29 /32

TP-4223 /26 /29 /32

TP-5020(G/H) /23 (G/H) /26 (G/H) /29 (G/H) /32 (G/H)

Français

TP-7020(H) /23(H) /26(H) /29(H) /32(H)

TP-7220 / 23 / 26 / 29 / 32

Owner’s Manual

Español

Mode d’emploi

Manual de Instrucciones

用户手册

中国语

2002TIMPANI_C(C)* Page 31 02.9.6, 3:05 PM Adobe PageMaker 6.0J/PPC

Thank you for selecting a Yamaha musical instrument.

We are confident that the instrument will bring you years of musical

enjoyment and satisfaction. Please read through this booklet care-

fully. It contains important information about your instrument's care.

Your new Yamaha instrument, like all Yamaha musical instruments,

is the result of careful planning, testing and assembly using select

materials. Proper care will ensure that your Yamaha instrument will

deliver its full and rich sound for years to come.

When using the pedal timpani for the first time after unpacking, make

sure to set it up according to the instructions of section “Before Using

The Pedal Timpani” on pages 4 and 5.

PRECAUTIONS

• Fully depress the heel of the tuning pedal after use.

• Protect the head from heat, moisture, oil, and dust. Use a soft cloth to remove

dust and other foreign matter from the head surface, and cover the head with

the head protector when not in use.

• When using plastic heads such as the one initially supplied, loosening of the

head after use is not required.

• The kettle is very sensitive to shock and must not be bumped against another

object. Also, do not forget to remove dirt using a polishing cloth from time to

time.

2002TIMPANI_E Page 2 02.12.5, 6:27 PM Adobe PageMaker 6.0J/PPC

Nomenclature & Lubrication

Head Protector

Tuning Bolt Kettle Edge

Head

Hoop

(Counter Hoop)

Tuning Indicator (Tuning Gauge)

Pointer Lock Nut

Pointer

Adjustment Knob

Kettle

PAC Adjustment Bolt

Strut

The TP-50xx (H/G) / TP-70xx (H)

series use a wing bolt on the

Caster PAC adjustment system.

Base Spring Tension

Adjustment Bolt

Tuning Pedal

Third Wheel

Caution Never put your hands etc. (removable)

under the pedal.

● Lubrication

Lubricate the moving parts of the tuning mechanism Points of lubrication

as shown in the diagram.

This should be done at least once a year, or as

needed.

* The illustrations on this page show a pedal timpani of the

TP-6200 series.

2002TIMPANI_E Page 3 02.12.5, 6:27 PM Adobe PageMaker 6.0J/PPC

Before Using The Pedal Timpani

Your Yamaha pedal timpani is equipped with a plastic head carefully mounted and tuned

(adjusted to a note) at the factory, and thus can be used after setup immediately. However,

new heads will tend to stretch gradually during shipping and storage, resulting in a tuning

deviation when you receive the instrument. Therefore, please perform the steps below to

restore the tuning to the factory setting prior to shipment:

1 The area between the kettle edge and the inner 3 If the heel of the pedal is fully lowered as in Fig.

circle of the counter hoop is called the collar. C, proceed with step 5.

Please make sure that the width of this collar is If the pedal position is as shown in Fig. D or the

uniform, as shown in the illustration titled “Cor- toe of the pedal is fully lowered, perform step 4

rect”. first.

Correct Wrong

Fig. C

Kettle Counter Kettle Counter

edge edge

Collar hoop Collar hoop

If the collar is not uniform (illustration titled

“Wrong”), keep the heel of the pedal fully de-

pressed as shown in Fig. C, and align head and

hoop as shown in the illustration titled “Correct”.

2 Make sure that the end of the wire tube is not

disengaged from the adjuster of the tuning indi- Fig. D

cator as shown in Fig. A. If it is disengaged,

insert it into the adjuster as shown in Fig. B.

Caution Never put your hands etc. under the

Fig. B pedal.

Adjuster

4 Fully depress the heel of the pedal as shown in

Fig. C. Hold the pedal in this position, as it will

Wire tube Fig. A return otherwise.

2002TIMPANI_E Page 4 02.12.5, 6:27 PM Adobe PageMaker 6.0J/PPC

Before Using The Pedal Timpani

5 Using the supplied timpani key, tighten the tun- 9 Tighten each tuning bolt by 1/8 of a turn (45°) in

ing bolts by 1/4 of a turn (90°) in the order the order shown in step 5.

shown below. It is very important to always

turn all tuning bolts by the same amount. 10 ● Toe and heel feel equal

→ Go to step 11

● Heel still feels heavier than toe

Timpani key → Repeat steps 8 through 10

● Heel feels lighter than toe

→ Head is tightened too much. Loosen the

head as described in step 7.

11 Move the pedal into an intermediate position, as

shown in Fig. D, and remove your foot from the

pedal. Confirm that the pedal stays in this posi-

tion and does not move.

26”, 29”, 32” 20”, 23” If the pedal stops in this position, adjust-

ment is complete. Return the pedal to the

position shown in Fig. C.

6 Take your foot off the pedal.

● If the toe of the pedal moves downward

● Heel still moves up → Repeat steps 8 through 10.

→ Repeat steps 4 through 6. ● If the heel of the pedal moves downward

● Heel stays down → Head is tightened too much. Loosen the

→ Go to step 7. head as described in step 7.

7 Put your foot on the pedal and fully depress it in 12 Strike the head lightly with the supplied mallet

either direction (toe and heel). etc. The standard striking point is shown below.

● Heel feels heavier than toe

→ Go to step 8. The standard striking

● Toe and heel feel equal point lies at distance

B from the kettle

→ Go to step 11. edge, which

● Heel feels lighter than toe corresponds to 1/4 to

Striking point

→ Head is tightened too much. Loosen the 1/3 of distance A

head. Keeping the heel of the pedal de- (distance between

kettle edge and

pressed, loosen the first tuning bolt by 1/ center of head).

2 turn and then retighten it by 1/4 of a

turn. Perform this operation for all other Pedal

tuning bolts in the order shown in step 5.

For note comparison a piano is most suitable.

If necessary, repeat this procedure, until

When the toe of the pedal is depressed, a higher

proper tension is obtained.

pitch is obtained.

8 Fully depress the heel of the pedal as shown in

For details on precise tuning refer to “Adjusting

The Sound Of Your Timpani” on the following

Fig. C.

page.

Note As the head will stretch over time, readjustment should be performed periodi-

cally (starting with step 7 )

2002TIMPANI_E Page 5 02.12.5, 6:27 PM Adobe PageMaker 6.0J/PPC

Adjusting The Sound Of Your Timpani

When using the pedal timpani for the first time after unpacking, make sure to set it up according

to the instructions of section “Before Using The Pedal Timpani” on pages 4 and 5.

z Head Tuning* (* Adjusting the head tension to a specific note)

1 Tuning is performed for the lowest sound (note) When loosening the tuning bolts, always

of the timpani. loosen them by double the desired amount,

For this reason, the heel of the pedal must stay and then return (retighten) them by half.

fully lowered during the tuning procedure. When the sound lies within 1 halftone

The proper lowest note (and tonal range) de- below the desired pitch after loosening

pends on the size of your timpani. For example, the tuning bolts (repeatedly, if necessary),

as shown in the figure below, the lowest sound proceed with step 3.

of a 26” timpani should be tuned to A. When

tuned properly, your Yamaha timpani will give 3 Lightly strike the head with the mallet about 2

you its full tonal range without being inch (5 cm) from the kettle edge at each tuning

overtensioned. bolt. Check at which tuning bolt the sound is

highest.

■ Standard Tonal Ranges for Yamaha Timpani

● Pitch of highest sound higher than tuning

32" (81cm) 29" (74cm) 26" (66cm) 23" (58cm) 20" (51cm) note

→ Loosen the corresponding tuning bolt by

about 1/16 to 1/8 of a turn. First loosen

the bolt by double the desired amount,

and then return (retighten) it by half. After

loosening the tuning bolt, repeat from the

Keep the heel of the pedal fully lowered during beginning of step 3.

the tuning procedure (steps 2 through 7 below) if ● Pitch of highest sound lower than tuning

not specified otherwise. note

→ Go to step 4.

2 Strike the head and check the sound. The stan-

4 Tighten the other bolts little by little (by about 1/

dard striking point is shown below.

16 to 1/8 of a turn) until the sounds at the corre-

sponding striking points match the pitch of the

The standard striking

point lies at distance highest sound. Please note that tightening of

B from the kettle one bolt will also raise the pitch at the neighbor-

edge, which corre- ing and opposite tuning bolts. Thus, after tight-

Striking point sponds to 1/4 to 1/3 of

ening the tuning bolt with the lowest sound, first

distance A (distance

between kettle edge reconfirm the sound at the other tuning bolts

and center of head). before tightening the tuning bolt with the next

lower sound. While alternately tightening the other

Pedal

bolts, do not touch the tuning bolt with the high-

● Sound lower than tuning note est sound (reference pitch).

→ Go to step 3.

● Sound higher than tuning note 5 Loosen all overtightened bolts according to the

→ Loosen tuning bolts by an equal amount procedure described in step 3. When the pitch is

in the order shown in the figure of step 5 approximately the same at each bolt, repeatedly

on page 5. depress the toe and heel of the pedal several

times.

6

2002TIMPANI_E Page 6 02.12.5, 6:27 PM Adobe PageMaker 6.0J/PPC

Adjusting The Sound Of Your Timpani

x Pedal Adjustment

6 Repeat steps 3 through 5 until the pitch at each After depressing the toe and heel of the pedal, turn

bolt is exactly the same. the spring tension adjustment bolt as described be-

low.

7 Check the sound by striking the head as de- ● Heel moves up when releasing the foot from

scribed in step 2. the pedal after depressing the heel, or heel

● Sound lower than tuning note feels heavier than toe

→ Tune the instrument by tightening all tun- → Turn the spring tension adjustment bolt to

ing bolts by an equal amount (max. 1/16 the left (counterclockwise)

of a turn). ● Toe moves up when releasing the foot from

● Sound higher than tuning note the pedal after depressing the toe, or toe feels

→ Tune the instrument by loosening all tun- heavier than heel

ing bolts by an equal amount (max. 1/16 → Turn the spring tension adjustment bolt to

of a turn) according to the procedure de- the right (clockwise)

scribed in step 3. Turning the spring tension adjustment bolt is per-

formed using the timpani key. Do not turn by too

8 Operate the pedal as described in step 5. If the many full rotations at once, but re-check the adjust-

pitch does not change, the instrument is tuned ment state every 2 turns by depressing the toe and

properly. heel of the pedal.

(If the pitch changes, repeat from step 7.)

Note Do not loosen the spring tension ad-

The instrument is now tuned to the lowest sound justment bolt by more 3 rotations at a

(note) of its tonal range. Depress the toe of the time, as the toe of the pedal tends to

pedal to change to a higher pitch (note). drop abruptly after a specific point.

9 After tuning, perform x Pedal Adjustment and Caution Never put your hands etc. under the

pedal.

then c Tuning Indicator Adjustment.

Spring tension

adjustment bolt

Spring Timpani key

● Pedal balance spring mechanism

Your Yamaha pedal timpani is equipped with a unique

pedal balance spring mechanism (a coil spring coun-

teracting the tension of the head) which allows you to

freely change the pitch (note) of the instrument at an

instant. When the pedals are moved, the pitch of the

head will change, and the balance spring ensures that

the pedal angle (pitch) will not change when you re-

move your foot from the pedal.

2002TIMPANI_E Page 7 02.12.5, 6:27 PM Adobe PageMaker 6.0J/PPC

Adjusting The Sound Of Your Timpani

c Tuning Indicator Adjustment

The tuning indicator shows to which note the pedal is ● Adjusting the Pointer Position

set. After tuning the instrument, you must set each First loosen the pointer lock nut and then turn the

note of the indicator to its proper position. adjuster as follows:

1 After you have tuned your timpani to the lowest ● Pointer is located beyond the lower rail end

note of its tonal range, make sure that the pointer when heel of pedal is lowered fully (lowest

is located within 10 mm from the pedal-side end note)

of the indicator rail. → Turn the adjuster to the left (counterclock-

* If not, adjust referring to “Adjusting the Pointer wise) until the pointer is aligned with the

Position”. lowest note of the indicator.

● Pointer moves beyond the upper rail end

2 Slide the lowest note of the indicator (“A” in case before toe of pedal reaches end of stroke,

of a 26” timpani — see “Standard Tonal Ranges or

for Yamaha Timpani” on page 6) to the position Pointer does not reach lower rail end when

where its center line coincides with the pointer. heel of pedal is lowered fully (lowest sound)

→ Turn the adjuster to the right (clockwise) to

3 Tune the instrument to the next higher pitch correct the pointer position as required.

(note) by moving the pedal, and then slide the

corresponding note on the rail to the respective After adjustment, securely tighten the pointer lock

pointer position. Repeat for each note. nut.

* The tuning indicator can be set to a desired angle

by loosening the indicator mounting screw using a

Phillips screwdriver.

Note

Indicator rail Pointer

Indicator rail

Pointer

Note

Adjuster Adjustment nut

2002TIMPANI_E Page 8 02.12.5, 6:27 PM Adobe PageMaker 6.0J/PPC

Other Features

■ Pedal Adjustment Clutch

Using the PAC, you can adjust the rotational torque ● PAC Adjustment

of the pedal to a comfortable pedal force without Use the timpani key to turn the PAC adjustment bolt

degrading the smooth pedal action. In addition, the as follows:

PAC is useful in preventing undesirable happenings Turn the PAC adjustment bolt to the right (clockwise)

such as slight movement of the pedal when the head to tighten the pedal movement.

is struck strongly causing a small change in pitch. To return the tightened pedal movement to the initial

rotational torque setting, turn the PAC adjustment

bolt to the left (counterclockwise).

* Be sure to turn the timpani key using one hand

only.

* Do not use both hands or an additional tool.

The TP-50xx (H/G) / TP-70xx (H) series use a

wing bolt on the PAC adjustment system.

Note on PAC Usage

PAC adjustment bolt • The pedal cannot be locked with the PAC,

even at its tightest position.

(Do not try to use the PAC for locking the

The PAC (Pedal Adjustment Clutch) is an original pedal, for example to prevent the toe of the

Yamaha mechanism that enables you to adjust the pedal from jumping up when the head is re-

pedal’s rotational torque (the force required to move moved.)

the pedal) by altering the amount of friction within the • The PAC adjustment bolt has limit positions in

pedal balance spring mechanism.

both turning directions. If the bolt is hard to

turn, do not force to overtighten it because this

may cause damage to the mechanism.

2002TIMPANI_E Page 9 02.12.5, 6:27 PM Adobe PageMaker 6.0J/PPC

Moving And Setup Your Timpani

The timpani can easily be moved when the third ● Attaching and Removing the Third Wheel

wheel is attached to the pedal section as shown on

the right. Attaching and removing the third wheel can Pedal Mounting plate

be performed easily.

To move the timpani on a flat surface, make sure to

hold it by the frame section on the pedal side and

push it in the direction opposite the pedal (see

illustration below).

Never hold the instrument by the counter hoop, as

this may result in a deformation of the head or the

Base

counter hoop.

Locking shaft

On gravel and stairways the instrument should not

pushed on its casters. Instead, to prevent damage, it

1) Hook the mounting plate of the wheel onto

should be lifted by its frame and carried by at least the base end, and, while pushing both ends

two persons. of the locking shaft in the direction of the

timpani, push the wheel up in the direction of

the arrow, engaging the locking shaft into

the groove of the base.

Hold the instrument by

its frame and push in

2) To remove, disengage the locking shaft by

the direction opposite

fully pushing both ends in the direction of the

the pedal.

timpani, and pull the wheel down.

To stabilize the timpani, push down the “ON”

side of the caster lock.

* The illustration shows a pedal timpani of the TP-62xx

series.

Using the Third Wheel (TP-70xx Series)

The third wheel can be easily moved in or out of

position with a single motion. To use the third

wheel, lean the tympani slightly forward to lift

After setting up the timpani, lock the other two the pedal off the ground then use your foot to

casters to stabilize the instrument during perfor- manipulate the wheel into the desired position.

mance. Also, the pedal wheel should be removed

for performance. If it is left attached, it may be

the cause of noise and will also result in different

head angles when several timpani of different

size are used.

10

2002TIMPANI_E Page 10 02.12.5, 6:27 PM Adobe PageMaker 6.0J/PPC

Replacing The Head

1 To prevent the pedal from being pulled down by 3 Place the new head with the hoop on the kettle.

the spring force, the heel of the pedal must be When using a Yamaha timpani head, its YAMAHA

kept down (this can easily be accomplished by logo must be on the side opposite the pedal.

placing a piece of wood or a softball between The hoop must be re-mounted in the same po-

the base and the pedal) while the tuning bolts sition as marked with cellophane tape in step 2.

are loosened alternately in the proper sequence. Tighten the tuning bolts alternately by hand until

the head is tensioned slightly. At this time, make

sure that head and hoop are centered on the

Softball etc. kettle.

Tighten each tuning bolt an additional 1/4 of a

turn using the timpani key. Repeat at least 4

times.

4 Adjust the timpani as described on pages 4 and

5, “Before Using The Pedal Timpani”, starting

with step 5. For precise tuning, refer to the section

“Adjusting The Sound Of Your Timpani” on

page 6.

Caution Never put your hands etc. under the

pedal.

2 After removing all tuning bolts, mark the pedal ● Interval For Head Replacement

side of the hoop with cellophane tape etc. and The maximum head life normally is approxi-

then remove the head together with the hoop. At mately 2 years and depends on the frequency

this time, be careful not to lose any of the tuning and duration of use. However, the head should

bolts and prevent dust from adhering. always be replaced before the sound quality

Also, avoid touching the tuning bolt threads, as deteriorates dramatically. If a head is left on

they are greased. and used more than two years, the following

problems may occur:

Hoop

• It may become impossible to tune the

head to the proper pitch range.

• It may become impossible to balance

the pedal.

• The main unit mechanisms themselves

may become damaged.

Cellophane tape

Pedal

When the head is slightly tensioned and its

surface looks wavy or shows dents, it is time to

* Be careful not to make any scratches in the tape replace the head with a new one.

attached to the kettle edge. If the tape is peeling or

badly damaged, it must be replaced with timpani

edge tape (Teflon™ tape).

11

2002TIMPANI_E Page 11 02.12.5, 6:27 PM Adobe PageMaker 6.0J/PPC

You might also like

- Default ControlsDocument2 pagesDefault Controlslucasloud75% (8)

- s13 Ecu Pinout Ca18detDocument1 pages13 Ecu Pinout Ca18detEduardo Junior Obando Romero0% (1)

- M44 Combo Vibraphone: 5 3/4" Dia. (18.06" Long)Document3 pagesM44 Combo Vibraphone: 5 3/4" Dia. (18.06" Long)fabianNo ratings yet

- Project Quality ManagementDocument4 pagesProject Quality ManagementSadashiw Patil100% (1)

- Golden Empire Drum & Bugle Corps: 2020 Front Ensemble Audition PacketDocument24 pagesGolden Empire Drum & Bugle Corps: 2020 Front Ensemble Audition PacketLeeNo ratings yet

- 003 PDFDocument1 page003 PDFNazareno LopezNo ratings yet

- Snareline Manual Lite: Phantom Regiment 201 9Document1 pageSnareline Manual Lite: Phantom Regiment 201 9Zach ToddNo ratings yet

- Percussion ClinicDocument8 pagesPercussion Clinicvolrosa504No ratings yet

- Franz Schmidt Symphonies Frankfurt RS Paavo JarviDocument10 pagesFranz Schmidt Symphonies Frankfurt RS Paavo JarviCarlos DaneriNo ratings yet

- Pearl2015 Price ListDocument47 pagesPearl2015 Price ListCristianNo ratings yet

- 06 Performance Grades Qual Spec Percussion 2020 230303Document51 pages06 Performance Grades Qual Spec Percussion 2020 230303Yang Che LiuNo ratings yet

- 作詞/歌:Lisa 作曲:草野華余子 高音直笛譜 = 136: Egg Head LiuDocument3 pages作詞/歌:Lisa 作曲:草野華余子 高音直笛譜 = 136: Egg Head Liu簡杰No ratings yet

- Audio Book PDFDocument13 pagesAudio Book PDFlileyangNo ratings yet

- Little Champ-Partitura - y - PartesDocument5 pagesLittle Champ-Partitura - y - PartesAlberto CabezaNo ratings yet

- Catalogo Yamaha Marching Percussion 2012Document8 pagesCatalogo Yamaha Marching Percussion 2012Daniel OropesaNo ratings yet

- Multimatum: Cont. RH On CymDocument8 pagesMultimatum: Cont. RH On CympeprintoNo ratings yet

- Repeat Six Times or More. Aiways Start PPPDocument8 pagesRepeat Six Times or More. Aiways Start PPPJulio AcostaNo ratings yet

- Anthony J. Cirone - Portraits in RhythmDocument53 pagesAnthony J. Cirone - Portraits in RhythmGuilherme FreireNo ratings yet

- Laurello - Spine 5.2 - Percussion 4 (Piano)Document16 pagesLaurello - Spine 5.2 - Percussion 4 (Piano)Henrique BatistaNo ratings yet

- Chord DictionaryDocument44 pagesChord DictionarySam EffordNo ratings yet

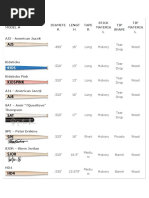

- Vic Firth ModelsDocument24 pagesVic Firth ModelsNANOMAN1994No ratings yet

- The Duel Solo For Two Solo DrummersDocument5 pagesThe Duel Solo For Two Solo DrummersyuryNo ratings yet

- La Marcha de Los PolaresDocument4 pagesLa Marcha de Los PolaresIvan100% (1)

- 8th Grade All State Band Set A: Multi-PercussionDocument1 page8th Grade All State Band Set A: Multi-Percussiontheatomizer90No ratings yet

- Evans - Timpani Head Care and TuningDocument2 pagesEvans - Timpani Head Care and Tuningoneota123No ratings yet

- Blue Book-Volume 1Document94 pagesBlue Book-Volume 1hacker boiNo ratings yet

- Time Swinging: MarimbaDocument1 pageTime Swinging: MarimbaaspoiuNo ratings yet

- Shadow Drum + Bugle Corps Front Ensemble: 2021 Technique/Philosophy ManualDocument24 pagesShadow Drum + Bugle Corps Front Ensemble: 2021 Technique/Philosophy ManualReese MNo ratings yet

- Bajo El Hechizo: Marimba, Guitar, PianoDocument24 pagesBajo El Hechizo: Marimba, Guitar, PianoGarrison Gerard100% (1)

- Percussion PDFDocument2 pagesPercussion PDFgizzy9dillespieNo ratings yet

- 4511896-Rain Dance by Alice Gomez and Marilyn Rife PDFDocument6 pages4511896-Rain Dance by Alice Gomez and Marilyn Rife PDFNazareno LopezNo ratings yet

- Technique Packet-TenorsDocument10 pagesTechnique Packet-Tenorsapi-186882135No ratings yet

- Percussionists Assemble!: The Avengers Theme Arranged For Percussion EnsembleDocument23 pagesPercussionists Assemble!: The Avengers Theme Arranged For Percussion EnsembleGloria Ieong F3C10No ratings yet

- CMB Drum Line Audition Packet 2017Document16 pagesCMB Drum Line Audition Packet 2017gizzy9dillespieNo ratings yet

- KGSDRGTFSDDocument1 pageKGSDRGTFSDandyNo ratings yet

- Estojos de PercussãoDocument32 pagesEstojos de Percussãoalexandre biondiNo ratings yet

- Eckhard Kopetzki - Three Songs For VibraphoneDocument8 pagesEckhard Kopetzki - Three Songs For VibraphoneAnita PrimoracNo ratings yet

- Peter TheWolf AllPercussionDocument5 pagesPeter TheWolf AllPercussionjoaquinNo ratings yet

- I Am Iron ManDocument4 pagesI Am Iron ManYurikoNo ratings yet

- 14 Timppercussion Excerpts2018 PDFDocument12 pages14 Timppercussion Excerpts2018 PDFDaniele DaldossNo ratings yet

- Como Organizar Um Naipe de PercussãoDocument16 pagesComo Organizar Um Naipe de Percussãoalexandre biondiNo ratings yet

- Spy City: Cymbal For OpenDocument10 pagesSpy City: Cymbal For OpenAnderson GomesNo ratings yet

- Catching Shadows pt1Document17 pagesCatching Shadows pt1Roberto FontanellaNo ratings yet

- 08 - Flam Control 95-118Document7 pages08 - Flam Control 95-118Jimmy ZambranoNo ratings yet

- Five Latin Grooves (For Working Drummers) : 1. Cha-ChaDocument2 pagesFive Latin Grooves (For Working Drummers) : 1. Cha-ChaAnonymous 9WmJ9pMweNo ratings yet

- Blood and GoldDocument16 pagesBlood and GoldLiam ConneryNo ratings yet

- Crash CymbalsDocument1 pageCrash CymbalsAlain GuilmetteNo ratings yet

- Adam Tan - SOLO no. 2 WINTERDocument4 pagesAdam Tan - SOLO no. 2 WINTERAnand DaherkarNo ratings yet

- Strive To Be Happy - Ivan TrevinoDocument9 pagesStrive To Be Happy - Ivan Trevinoangela chanNo ratings yet

- Percussive Celebration - Percussion1 - Chime Glock Whistle XyloDocument2 pagesPercussive Celebration - Percussion1 - Chime Glock Whistle Xylo陳昱豪No ratings yet

- Mudra Glockenspiel-BDDocument5 pagesMudra Glockenspiel-BDJuan Pablo Vega VargasNo ratings yet

- Matt Savage 3Document27 pagesMatt Savage 3MatíasNo ratings yet

- Mental Training in Percusion PDFDocument2 pagesMental Training in Percusion PDFJose Perez GarciaNo ratings yet

- Beethoven Overture Fidelio TimpaniDocument3 pagesBeethoven Overture Fidelio Timpanikyok5No ratings yet

- Paliev Etude PDFDocument3 pagesPaliev Etude PDFFiorella UmNo ratings yet

- 30 Day Weak Hand Training PlanDocument3 pages30 Day Weak Hand Training Plangam nguyenNo ratings yet

- Yamato Introductions of Taiko and InstrumentsDocument3 pagesYamato Introductions of Taiko and InstrumentsKotchan Lixo100% (1)

- Scherzo PetersDocument2 pagesScherzo PetersJosef SöllingerNo ratings yet

- PAS International Drum RudimentsDocument2 pagesPAS International Drum RudimentsManuel RinconNo ratings yet

- DeaneTambourineTriangle PDFDocument3 pagesDeaneTambourineTriangle PDFBartholomew Aloicious MumfreesNo ratings yet

- Well Tempered Lab Amadeus GTA MK IIVersalex Instruction Manual Rev. June 17Document11 pagesWell Tempered Lab Amadeus GTA MK IIVersalex Instruction Manual Rev. June 17yv58dn5tvdNo ratings yet

- Every Day LyricsDocument1 pageEvery Day LyricslucasloudNo ratings yet

- Sample PDFDocument1 pageSample PDFlucasloudNo ratings yet

- I Am Some Random PDFDocument1 pageI Am Some Random PDFlucasloudNo ratings yet

- Subtenly's AnalysisDocument3 pagesSubtenly's AnalysisMariyamNo ratings yet

- Chapter 1-Part 1: Half-Wave RectifiersDocument50 pagesChapter 1-Part 1: Half-Wave RectifiersWeehao SiowNo ratings yet

- Complete The Sentence WithDocument6 pagesComplete The Sentence WithCendyka KumaratunggaNo ratings yet

- USEPA - 2003 - Principles & Practices of Air Poll Control (p.1-2, 7)Document3 pagesUSEPA - 2003 - Principles & Practices of Air Poll Control (p.1-2, 7)Farhan WibiandraNo ratings yet

- Layerzero: Trustless Omnichain Interoperability Protocol: Ryan Zarick Bryan Pellegrino May 26, 2021 Caleb BanisterDocument10 pagesLayerzero: Trustless Omnichain Interoperability Protocol: Ryan Zarick Bryan Pellegrino May 26, 2021 Caleb BanisterEren OnderNo ratings yet

- HIRA For Crusher HouseDocument5 pagesHIRA For Crusher HousegondsachinpratapNo ratings yet

- In-Situ Combustion Model: Intercomp Resource Development and Engineering IncDocument22 pagesIn-Situ Combustion Model: Intercomp Resource Development and Engineering IncAliNo ratings yet

- Acca Code of Ethics (Notes)Document16 pagesAcca Code of Ethics (Notes)nurmaisarahnurazim1No ratings yet

- Tanede AcrDocument4 pagesTanede Acraderahayu100% (1)

- Lecture 4 - CS50's Web Programming With Python and JavaScriptDocument37 pagesLecture 4 - CS50's Web Programming With Python and JavaScriptrk8307068No ratings yet

- QPS Motor Starting Auto TransformerDocument2 pagesQPS Motor Starting Auto TransformerEddie TweNo ratings yet

- Francis_Katamba_English_Words-2Document3 pagesFrancis_Katamba_English_Words-2Mohammad AlamNo ratings yet

- Menstrual CycleDocument10 pagesMenstrual CycleintanNo ratings yet

- Timing Nutrition Around Training and Matches: ReplenishDocument2 pagesTiming Nutrition Around Training and Matches: ReplenishSam GillNo ratings yet

- 1964: Alaska's Good Friday Earthquake: Read More +Document21 pages1964: Alaska's Good Friday Earthquake: Read More +manish mehtaNo ratings yet

- Computerised Wheel Balancer: WB-VL-65 DSP WB-VL-65 DSPDocument2 pagesComputerised Wheel Balancer: WB-VL-65 DSP WB-VL-65 DSPShivaraj JadhavNo ratings yet

- Minerals Engineering Volume 16 Issue 12 2003 (Doi 10.1016 - J.mineng.2003.08.011) M. Lindqvist C.M. Evertsson - Prediction of Worn Geometry in Cone CrushersDocument7 pagesMinerals Engineering Volume 16 Issue 12 2003 (Doi 10.1016 - J.mineng.2003.08.011) M. Lindqvist C.M. Evertsson - Prediction of Worn Geometry in Cone CrushersAditya NugrahaNo ratings yet

- Lab 12 22235103361Document7 pagesLab 12 22235103361lucifeskNo ratings yet

- Desert Rut: by Zaggy NorseDocument10 pagesDesert Rut: by Zaggy Norsemary sueNo ratings yet

- Functional Organization of Human Body, Control of Internal Environment, Cells (R) 4Document8 pagesFunctional Organization of Human Body, Control of Internal Environment, Cells (R) 4nevmerkaNo ratings yet

- Shah JahanDocument8 pagesShah Jahananon-838010100% (1)

- Bca 1 Unit NotesDocument15 pagesBca 1 Unit NotesAnkit KumarNo ratings yet

- Laban Tayo / - / SST Pepol!!!Document161 pagesLaban Tayo / - / SST Pepol!!!anthonyNo ratings yet

- Study of Electrical Power Generation, Transmission & Distribution in BangladeshDocument111 pagesStudy of Electrical Power Generation, Transmission & Distribution in Bangladeshavocadocolor88% (16)

- Knapsack ProblemDocument11 pagesKnapsack ProblemVijay TrivediNo ratings yet

- E-Books - Ratio Proportion Indices and LogarithmDocument61 pagesE-Books - Ratio Proportion Indices and LogarithmRahul JaykerNo ratings yet

- Unisab-III-1.10 Engineering 2014-09 en 01Document322 pagesUnisab-III-1.10 Engineering 2014-09 en 01Jay Rabanera100% (2)

- FD Service ManualDocument64 pagesFD Service ManualJustin Steele0% (1)