VS1131

VS1131

Uploaded by

Stroia Constantin MariusCopyright:

Available Formats

VS1131

VS1131

Uploaded by

Stroia Constantin MariusCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

VS1131

VS1131

Uploaded by

Stroia Constantin MariusCopyright:

Available Formats

VS1131A

BOSCH/LUCAS-CAV DIESEL ROTARY INJECTION PUMP TIMING KIT

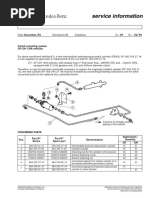

PARTS LIST

VS1079 Bosch Pump Timing Tools (1-7).

1 VS1079/01 Short Timing Adaptor

2 VS1079/02 Extension Adaptor

3 VS1079/03 M12 Thread Adaptor

4 VS1079/04 Thumbscrew

5 VS107/3 Indicator Pin

6 VS108/3 Indicator Pin

7 VS1259 M10 Thread Adaptor

8 AK9634M Dial Test Indicator

VS110 CAV/ Rotodiesel Pump Timing tools (9-13).

9 VS110/1 Main Body

10 VS110/2 Toggle

11 VS110/3 Indicator Pin

12 VS110/4 DTI Foot

13 VS110/5 Thumbscrew

INTRODUCTION

Injection pump timing is the procedure to set the correct relationship between the injection pump plunger and the corresponding engine piston on

its upward ignition stroke. This relationship is critical for optimum operation of the diesel engine. VS1079, VS110 are used together with gauge

AK9634M to check and set the fuel injection pump timing by indicating the exact point of travel of the high pressure pump element at a static TDC

position for the piston on its ignition stroke.

1. APPLICATION DETAILS

VS110 Diesel Fuel Pump Timing Tool

LUCAS/CAV . . . . . . . . . . . . . .DPC Rotary Injection Pump (Top Entry)

VS1079 Diesel Fuel Pump Timing Adaptors

BOSCH . . . . . . . . . . . . . . . . . .Type VE & EPVE Rotary Diesel Fuel Injection Pump With M8/M12

DIESEL KIKI . . . . . . . . . . . . . .Type VE Rotary Diesel Fuel Injection Pump service port entry

NIPPONDENSO . . . . . . . . . . .Type VE Rotary Diesel Fuel Injection Pump

BOSCH . . . . . . . . . . . . . . . . . .Type VE Rotary Diesel Fuel Injection Pump (with M10 service port entry)

2. SAFETY INSTRUCTIONS

p WARNING! Ensure all health and safety, local authority, and general workshop practice regulations are strictly adhered to when using tools.

7 DO NOT use tools if damaged.

3 Maintain tools in good and clean condition for best and safest performance.

3 If required, ensure the vehicle to be worked on is adequately supported with axle stands, ramps and chocks.

3 Wear approved eye protection. A full range of personal safety equipment is available from your Sealey dealer.

3 Wear suitable clothing to avoid snagging. Do not wear jewellery and tie back long hair.

3 Account for all tools, locking bolts, pins and parts being used and do not leave them in or near the engine.

p WARNING! Incorrect or out of phase camshaft timing can result in contact between the valve head and the piston crown causing possible

damage to the engine. Incorrect injection pump timing may cause excessive smoke emissions, poor starting and low power output.

p WARNING! Always refer to the vehicle manufacturers service instructions, or proprietary manual to establish the current procedure and data.

These instructions for use are provided as a guide only .

VS1131 - 0869 - (2) - 200900

3. INSTRUCTIONS FOR USE

3.1. VS1079 BOSCH INJECTION PUMPS.

VS1079 Timing Adaptor Set connects to the service port of Bosch VE Rotary Injection Pumps to set the pump static

timing position. VS1079/01 Adaptor can be used as a short reach adaptor extended by adding VS1079/02 according to

access capability around the service port area. Its M8 thread screws directly into the service port or adaptor VS1079/03

can be fitted to allow connection into M12 service ports or VS1259 for connection onto M10 service ports. VS1079 is used

with AK9634M Dial Test Indicator.

1. Locate service port, clean and remove the blanking plug.

2. Unscrew plunger end off the DTI gauge and screw in its place VS108/3 Long or VS107/3 Short

Indicator Pin whichever is appropriate to the configuration of timing adaptor being used, (short or

extended). Ensure the indicator pin threads fully up to its shoulders into the DTI.

3. Insert the dial test indicator into the timing adaptor and screw it into the service port of the pump.

IMPORTANT: Ensure that the timing tool indicator pin can remain in constant contact with the

injection pump plunger by pre-loading the dial test indicator with sufficient pre-load to cover the

full travel of the pump plunger, plus 1mm. The pre-load is shown on minor scale of indicator gauge.

4. Secure the DTI by clamping with VS1079/04 Thumbscrew.

5. Turn the engine against the normal direction of rotation until the dial indicator needle reaches its Lowest Reading.

6. Re-adjust the indicator gauge to ensure it has at least 1mm of pre-load and then zero the dial indicator gauge.

7. Turn the engine in the normal direction of rotation to the static timing point and compare the dial test indicator reading against the

manufacturers timing data, allowing for the pre-load.

3.2. VS110 DIESEL INJECTION PUMP TIMING TOOL - CAV/ROTODIESEL DPC ROTARY INJECTION PUMP, TOP ENTRY.

VS 110 is used for static timing of CAV/Rotodiesel injection pumps after servicing operations which may have affected the timing e.g. removal

of the timing belt or pump.

3.2.1. Checking the Timing.

1. Set the engine to TDC on No. 1 cylinder using the static timing points.

2. Clean top of pump, remove cap from entry port, and insert Pin VS110/3 into hole (fig.1).

3. Unscrew plunger end of AK9634M Dial Test Indicator and screw in its place Indicator Foot VS110/4. Ensure the foot threads fully up to its

shoulder into the DTI, then locate and clamp body on pump spigot (fig.2).

4. Fit Dial Test Indicator AK9634M against bell crank and pin VS110/3, and pre-load indicator gauge 1mm. Turn crankshaft 90 degrees

anti-clockwise (opposite to normal rotation).

5. Zero dial test indicator gauge.

6. Turn crankshaft slowly in the normal direction of rotation to TDC and, if called for in service instructions, insert appropriate flywheel locking

tool and/or injection pump pulley locking bolts.

7. Check that the amount of lift on the indicator gauge corresponds to the figure stamped on the load lever plate (fig.3), or on side of pump

(each pump is calibrated and marked during manufacture), allowing for pre-load.

3.2.2. Timing Adjustment.

1. Set the engine to TDC on No.1 cylinder and, if called for in service instructions, fit flywheel locking pin, injection pump pulley bolts and/or

camshaft pulley locking bolt.

2. Ensure injection pump is in the fully retarded position (tilted away from the engine).

3. Clean top of pump, remove cap from entry port (fig.1), and insert Pin VS110/3 into hole.

4. Locate and clamp body VS110 on pump spigot (fig.2).

5. Fit Dial Test Indicator AK9634M with Indicator Foot VS110/4 fitted against bell crank and pin VS110/3 and pre-load indicator gauge 1mm.

6. Remove flywheel locking pin and pulley locking bolts (if previously fitted).

7. Turn crankshaft 90 degrees anti-clockwise (opposite to normal rotation) and set the test indicator gauge dial to zero.

8. Turn crankshaft slowly in the normal direction of rotation to TDC and, if called for in service instructions, insert appropriate flywheel locking

tool and/or injection pump pulley locking bolts.

9. Turn pump until dial test indicator reading corresponds to figure stamped on load lever plate (fig.3), or on side of pump, allowing for pre-load.

10. Tighten pump retaining nuts and support bracket bolt to specified torque.

11. Remove flywheel locking pin and pulley bolts (if previously fitted) and turn crankshaft two complete turns in normal direction of rotation.

12. Refit appropriate locking pin/bolts.

13. Dial test indicator should indicate specified figure +/- 0.04mm.

IMPORTANT: Remove all locking pins and bolts.

fig. 1 fig. 2 fig. 3

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of product. WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required

for any claim. INFORMATION: Call us for a copy of our latest catalogue on 01284 757525 and leave your full name and address including your postcode.

01284 757500 01284 703534

Sole UK Distributor

Sealey Group, E-mail: sales@sealey.co.uk

Bury St. Edmunds, Suffolk.

VS1131 - 0869 - (2) - 200900

You might also like

- SI1290F Crankcase Thru-Stud Locations, Repair of Oil LeakageDocument7 pagesSI1290F Crankcase Thru-Stud Locations, Repair of Oil Leakagedavid100% (1)

- EDocument23 pagesEUliAlejandroRodriguezCorianga100% (2)

- Volvo EC210BDocument12 pagesVolvo EC210BStroia Constantin Marius78% (27)

- Deutz Allis Engine Service ManualDocument7 pagesDeutz Allis Engine Service ManualLucas Valente50% (2)

- Bosch Distributor Pump VeDocument8 pagesBosch Distributor Pump Vegire_3pich2005No ratings yet

- AP 240 enDocument6 pagesAP 240 enJoão GuardadoNo ratings yet

- Lincoln Helios (India) Limited: Operation & Maintenance ManualDocument50 pagesLincoln Helios (India) Limited: Operation & Maintenance Manualprem sagarNo ratings yet

- BVA P Series Manual Single AlumDocument12 pagesBVA P Series Manual Single AlumTitanply100% (1)

- PC-Software HMGWIN 3000: User ManualDocument30 pagesPC-Software HMGWIN 3000: User ManualStroia Constantin MariusNo ratings yet

- P D R HMG 3000: Ortable ATA EcorderDocument76 pagesP D R HMG 3000: Ortable ATA EcorderStroia Constantin MariusNo ratings yet

- Volvo L220 Atach Prod ManDocument54 pagesVolvo L220 Atach Prod ManStroia Constantin Marius0% (1)

- QRF Wa320pz-6 LowresDocument2 pagesQRF Wa320pz-6 LowresStroia Constantin MariusNo ratings yet

- Sf6 Handling ProcedureDocument3 pagesSf6 Handling ProcedureRohith R Nair100% (1)

- Service Bulletin: Engine Rattles at Cold Start-UpDocument11 pagesService Bulletin: Engine Rattles at Cold Start-UpPanayiotis PalmirisNo ratings yet

- Diesel Engine Setting/Locking Tool Kit For Vauxhall/Opel: 1. ApplicationDocument3 pagesDiesel Engine Setting/Locking Tool Kit For Vauxhall/Opel: 1. ApplicationchennieNo ratings yet

- Versa Sedan, Versa Note, and Sentra CVT Valve Body Replacement With Confirmed DTCDocument40 pagesVersa Sedan, Versa Note, and Sentra CVT Valve Body Replacement With Confirmed DTCVENDA DE PEÇAS CAMBIONo ratings yet

- Diesel Engine Setting/Locking Tool Set - Psa Dw8 Engine Model NoDocument4 pagesDiesel Engine Setting/Locking Tool Set - Psa Dw8 Engine Model NoJohanny Barrera HurtadoNo ratings yet

- Fiat SST 2Document4 pagesFiat SST 2Sajin Raj100% (1)

- VS200.V2 SealeyDocument2 pagesVS200.V2 SealeyaudioimagenNo ratings yet

- A13 055Document6 pagesA13 055AgustinNo ratings yet

- Diesel Engine Setting:Locking Tool Kit Renault dCi EnginesDocument5 pagesDiesel Engine Setting:Locking Tool Kit Renault dCi EnginesanatolieNo ratings yet

- NTB15 037dDocument36 pagesNTB15 037dALVARO ALATORRE ANo ratings yet

- Dokumen - Tips - Ve Pump Denso Repair ManualDocument32 pagesDokumen - Tips - Ve Pump Denso Repair Manualko koNo ratings yet

- VS125Document8 pagesVS125Wijnand BosNo ratings yet

- VTC Actuator FixDocument11 pagesVTC Actuator FixthemummraNo ratings yet

- VS5170 Instructions 20240220 (8)_DFC1576672Document14 pagesVS5170 Instructions 20240220 (8)_DFC1576672Ákos LengyelNo ratings yet

- NissanDocument7 pagesNissanTun Tun Win KseNo ratings yet

- Safety InstructionsDocument8 pagesSafety InstructionsnituicNo ratings yet

- A16-088 - Actuador VTC - Honda FIT 2015 2016Document11 pagesA16-088 - Actuador VTC - Honda FIT 2015 2016Carlos López100% (1)

- 1375 0009 401Document10 pages1375 0009 401juan saezNo ratings yet

- 98428000_Manual_Vulcan_Copperhead_grayscale MonitoresDocument13 pages98428000_Manual_Vulcan_Copperhead_grayscale MonitoreswendellNo ratings yet

- Fedco Mss Pumps For Swro Mss15-70 - v2 - r7Document29 pagesFedco Mss Pumps For Swro Mss15-70 - v2 - r7gulfengsolutionsNo ratings yet

- Boletim Tecnico - JF016 - Re0f10dDocument9 pagesBoletim Tecnico - JF016 - Re0f10dautomaticosbrasil100% (1)

- 3.06 ES 10K DUAL BOP ManDocument15 pages3.06 ES 10K DUAL BOP ManRafael BolivarNo ratings yet

- OwnersManChemstar 1400N 1402N 1376N 1374NDocument36 pagesOwnersManChemstar 1400N 1402N 1376N 1374NvankarpNo ratings yet

- VS5080Document5 pagesVS5080Robert MvogoNo ratings yet

- Service Bulletin S - 7: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 29.09.95Document4 pagesService Bulletin S - 7: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 29.09.95Diego ReggianiniNo ratings yet

- Product Bulletin No. - TDS Top Drive Drilling SystemDocument10 pagesProduct Bulletin No. - TDS Top Drive Drilling Systemali rezaNo ratings yet

- VS1400Document2 pagesVS1400timingtoolNo ratings yet

- LD23 Timing - Belt ProcedureDocument4 pagesLD23 Timing - Belt ProcedureNaomi Marty100% (2)

- Manual Honda ActuadorDocument11 pagesManual Honda ActuadorLuis MurrietaNo ratings yet

- SEAINSVS4411Document2 pagesSEAINSVS4411joguzmanNo ratings yet

- Balancines Admision y EscapeDocument6 pagesBalancines Admision y Escapesinger50No ratings yet

- Parts Catalogue - 621 ESDocument32 pagesParts Catalogue - 621 ESnobinmendez100% (1)

- Technical Service Bulletin: 210-2418 Ed. 4 April 2006 AllDocument7 pagesTechnical Service Bulletin: 210-2418 Ed. 4 April 2006 AllPyro KDNo ratings yet

- VS4840Document6 pagesVS4840marcNo ratings yet

- Lifting Mechanism: M7.0-1460-001 03 Rev. 1/12Document35 pagesLifting Mechanism: M7.0-1460-001 03 Rev. 1/12Coque de LunaNo ratings yet

- VW 3VWLN6161CM082257 AllSystemDTC 20221028150536Document9 pagesVW 3VWLN6161CM082257 AllSystemDTC 20221028150536hitecNo ratings yet

- Ag200l83 Service ManualDocument165 pagesAg200l83 Service ManualP FNo ratings yet

- EuroV MBE 900 Ajuste de Punterias (DDC-SVC-MAN-0206) - (00000002)Document5 pagesEuroV MBE 900 Ajuste de Punterias (DDC-SVC-MAN-0206) - (00000002)Emmanuel CuevasNo ratings yet

- Mobile Division: Service Parts ListDocument20 pagesMobile Division: Service Parts Listwag008100% (1)

- Waukesha Gas Engines: Intake / Exhaust SystemsDocument2 pagesWaukesha Gas Engines: Intake / Exhaust SystemsDiego MillanNo ratings yet

- PP 17 VKMC 06002 EN - TCM - 12-140104Document4 pagesPP 17 VKMC 06002 EN - TCM - 12-140104Montgomery HaNo ratings yet

- Start Visco T-Stop o Boos Instru Ster U Uctions Unit S: GE EA Mechan Nical Equip PmentDocument23 pagesStart Visco T-Stop o Boos Instru Ster U Uctions Unit S: GE EA Mechan Nical Equip PmentДмитрий РоманюкNo ratings yet

- 13-2-108Document5 pages13-2-108jussmeeeNo ratings yet

- R9100 R9150 R9200 New Swing PumpsDocument5 pagesR9100 R9150 R9200 New Swing Pumpsyugopuspoyo100% (1)

- PF5700 00 1.8TS Master US Dec 06Document1,654 pagesPF5700 00 1.8TS Master US Dec 06mohammedNo ratings yet

- M-0 JAN 2024 Fuel Injector ReplacementDocument5 pagesM-0 JAN 2024 Fuel Injector Replacementtech.recordsNo ratings yet

- Torrvac (D) ManualDocument26 pagesTorrvac (D) ManualMarcel SpenceNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- 14 Commissioning ProcedureDocument2 pages14 Commissioning ProcedureIonut Stavarache100% (1)

- AQ430854906684en 000101Document4 pagesAQ430854906684en 000101Yhann Karllos Alves MesquitaNo ratings yet

- Ve Pump Denso Repair Manual PDFDocument32 pagesVe Pump Denso Repair Manual PDFNikola Mitev100% (4)

- Operating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasDocument20 pagesOperating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasCarlos RondonNo ratings yet

- Operator'S Manual CL0409A91XXXXXXXDocument8 pagesOperator'S Manual CL0409A91XXXXXXXtaller.copiapoNo ratings yet

- 13-2-102Document5 pages13-2-102jussmeeeNo ratings yet

- CatalogueDocument55 pagesCatalogueStroia Constantin Marius100% (1)

- Transfluid HidrauliccouplingDocument32 pagesTransfluid HidrauliccouplingStroia Constantin Marius100% (1)

- B&J Fuel Injection 2014Document24 pagesB&J Fuel Injection 2014island140% (1)

- CatalogueTroubleshooting HY29 0022 UKDocument62 pagesCatalogueTroubleshooting HY29 0022 UKStroia Constantin MariusNo ratings yet

- Sensors EuropeDocument107 pagesSensors EuropeStroia Constantin MariusNo ratings yet

- Turbocharging Inspection 10-01Document15 pagesTurbocharging Inspection 10-01Stroia Constantin MariusNo ratings yet

- Turbo SidDocument60 pagesTurbo SidStroia Constantin Marius100% (1)

- BTNDocument68 pagesBTNStroia Constantin Marius100% (1)

- Catalog KKKDocument40 pagesCatalog KKKemboko0% (1)

- SUNTEC Pompa AL Fisa-TehnicaDocument2 pagesSUNTEC Pompa AL Fisa-TehnicaStroia Constantin MariusNo ratings yet

- Caterpillar® Engine SpecificationsDocument6 pagesCaterpillar® Engine Specificationsmaman96100% (3)

- Yuchai Yc 8 Models 2010Document6 pagesYuchai Yc 8 Models 2010Stroia Constantin Marius100% (1)

- Spec EC460B INT EN 30E4351646Document16 pagesSpec EC460B INT EN 30E4351646Stroia Constantin Marius100% (1)

- Formula To Calculate Gear Pump DisplacementDocument1 pageFormula To Calculate Gear Pump DisplacementStroia Constantin MariusNo ratings yet

- JCB Lubricant Brochure 2009Document13 pagesJCB Lubricant Brochure 2009Henwy Dickinson100% (1)

- Selection Guide Eaton1DRDocument20 pagesSelection Guide Eaton1DRStroia Constantin MariusNo ratings yet

- 2013 - 14 HydraulicsDocument122 pages2013 - 14 HydraulicsStroia Constantin Marius100% (1)

- INA CatalogueDocument110 pagesINA CatalogueStroia Constantin MariusNo ratings yet

- Bell Lubricants European EnglishDocument16 pagesBell Lubricants European EnglishStroia Constantin MariusNo ratings yet

- Cat Short BlocksDocument40 pagesCat Short Blockslucianowcap100% (3)

- Delphi Electronic Unit Injectors CatalogDocument20 pagesDelphi Electronic Unit Injectors CatalogStroia Constantin Marius100% (4)

- Princeton Barron 9Document13 pagesPrinceton Barron 9bioforlyfeNo ratings yet

- MST Plus Eng BrochureDocument16 pagesMST Plus Eng Brochurehamda100% (1)

- Salt CatalogueDocument4 pagesSalt CatalogueisosicaNo ratings yet

- 8 Ways To Achieve Efficient Combustion in Marine EnginesDocument10 pages8 Ways To Achieve Efficient Combustion in Marine EnginestomNo ratings yet

- Bryan Steam: Separable Tank Tray Type Boiler Feedwater DeaeratorsDocument2 pagesBryan Steam: Separable Tank Tray Type Boiler Feedwater Deaeratorskosmc123No ratings yet

- Zhu 2013Document8 pagesZhu 2013Rezha Maulana Kusuma ANo ratings yet

- Hydraulic SystemDocument37 pagesHydraulic Systemkunbasukiadi88% (8)

- Remove Fuel Injection Pump Housing and GovernorDocument7 pagesRemove Fuel Injection Pump Housing and GovernorAnonymous cS9UMvhBqNo ratings yet

- Dimensions (MM) : Wheelbase (A) Roof H1 H2 H1 H2 H2 H3 H2 H3 3000 3000L 3300 3950Document2 pagesDimensions (MM) : Wheelbase (A) Roof H1 H2 H1 H2 H2 H3 H2 H3 3000 3000L 3300 3950dionymackNo ratings yet

- Statistical Analysis of Fire Outbreaks in Homes and Public Buildings in Nigeria: A Case Study of Lagos State.Document10 pagesStatistical Analysis of Fire Outbreaks in Homes and Public Buildings in Nigeria: A Case Study of Lagos State.Editor IjasreNo ratings yet

- 8031 I06 DS P4A048001EDocument2 pages8031 I06 DS P4A048001EAlan VeizagaNo ratings yet

- DRRR LECTURE Revised VersionDocument15 pagesDRRR LECTURE Revised VersionJhoycelyn AngelesNo ratings yet

- April 2009Document84 pagesApril 2009Priyesh SinghNo ratings yet

- Submersible Sewage Ejector Pump: Pump Installation and Service ManualDocument8 pagesSubmersible Sewage Ejector Pump: Pump Installation and Service Manualallen_worstNo ratings yet

- Mumbai ReportDocument515 pagesMumbai ReportShailesh RathodNo ratings yet

- All Diafragms Meters Sb3500Document17 pagesAll Diafragms Meters Sb3500Ruben Romero Soto100% (1)

- Jetlube Grease PDFDocument20 pagesJetlube Grease PDFravivelamarthyNo ratings yet

- AAS) Atomic Absorption Spectroscopy-2nd Edition..Document88 pagesAAS) Atomic Absorption Spectroscopy-2nd Edition..Sarah Permata SariNo ratings yet

- Manual de Servicio para AlternadoresDocument101 pagesManual de Servicio para AlternadoresAngel Pendragon Lara0% (1)

- Practice Questions Equilibrium ElasticityDocument1 pagePractice Questions Equilibrium ElasticityAlbania weissNo ratings yet

- Tests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water LevelDocument6 pagesTests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water Levelahmed121No ratings yet

- Gasification of Wood in A Dual Fluidized Bed Gasifier: Influence of Fuel Feeding On Process PerformanceDocument15 pagesGasification of Wood in A Dual Fluidized Bed Gasifier: Influence of Fuel Feeding On Process Performancevitor_alberto_7No ratings yet

- Isuzu Diesel Engines: Standard FeaturesDocument2 pagesIsuzu Diesel Engines: Standard FeaturesJay MobNo ratings yet

- QSK50 G6 PDFDocument3 pagesQSK50 G6 PDFIrul AfandiNo ratings yet

- Recent Advances in Bioenergy Research (SSSNIRE 3rd Conference)Document496 pagesRecent Advances in Bioenergy Research (SSSNIRE 3rd Conference)Msaikia1986No ratings yet

- PCP Evaluation ExamDocument10 pagesPCP Evaluation ExamMark Dimagiba VillanuevaNo ratings yet

- PROMECH PresentationDocument38 pagesPROMECH PresentationAbu UmarNo ratings yet

- Fluid Lines & FittingsDocument6 pagesFluid Lines & FittingsPritamjit RoutNo ratings yet