100%(1)100% found this document useful (1 vote)

1K viewsSouth Bend 10LathesCatalog

South Bend 10LathesCatalog

Uploaded by

dsr200The document describes a 16-24 inch large swing lathe. It has a swing capacity of up to 25 1/2 inches over the bed and 18 1/2 inches over the saddle or cross slide. It provides eight or sixteen spindle speeds through an underneath motor drive system. The large capacity makes it suitable for machining large diameter parts like pulleys, brake drums, and similar work.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

South Bend 10LathesCatalog

South Bend 10LathesCatalog

Uploaded by

dsr200100%(1)100% found this document useful (1 vote)

1K views14 pagesThe document describes a 16-24 inch large swing lathe. It has a swing capacity of up to 25 1/2 inches over the bed and 18 1/2 inches over the saddle or cross slide. It provides eight or sixteen spindle speeds through an underneath motor drive system. The large capacity makes it suitable for machining large diameter parts like pulleys, brake drums, and similar work.

Original Title

south bend 10LathesCatalog

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The document describes a 16-24 inch large swing lathe. It has a swing capacity of up to 25 1/2 inches over the bed and 18 1/2 inches over the saddle or cross slide. It provides eight or sixteen spindle speeds through an underneath motor drive system. The large capacity makes it suitable for machining large diameter parts like pulleys, brake drums, and similar work.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

1K views14 pagesSouth Bend 10LathesCatalog

South Bend 10LathesCatalog

Uploaded by

dsr200The document describes a 16-24 inch large swing lathe. It has a swing capacity of up to 25 1/2 inches over the bed and 18 1/2 inches over the saddle or cross slide. It provides eight or sixteen spindle speeds through an underneath motor drive system. The large capacity makes it suitable for machining large diameter parts like pulleys, brake drums, and similar work.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 14

--- - - -

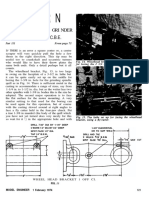

16-24-inch Large Swing Lat-he

Eight or Sixteen-Speed Drive

Reqularequipment included in. price of lathe is same as for l~in.ch Quiok Chenqe Gear Lathe as listed on page' 11.

The 16.24.inch Large Swing Lathe is a practical tool lor machining large diameter work that is not excessively heavy. It is the same as the l~inch Quick Change Gear Lathe except that the height of the centers is in.creased to take work up to 25}~'in diameter over the bed and 18h" in diameter over th.e saddle orOBS slide.

The large capacity 0.1 this lathe makes it a valuable tool for Ihe shop requiring a general purpose precision lathe for large diameter [cbs, such a1I boring jig plates,lurning and boring wheels, machining pulleys, turning brake drums, and similar work, Although this lathe has ample capacity for large awkward jobs, it is not too heavy and cumbersome tor ·efficient operation on small paris.

TJi:e underneath motor drive (patented) provides a series of eig-bt spindle speeds with a one-speed motor, or sixteen spindl» speeds wi.th. a two-speed motor, as listed below .. 71 precision belt tension adjustment is provided, The belt drive to the spindle is silent in operation and free hom gear vibration.

18-24" L .. rq" Swl"'lr L"th"" with Eight.S.;pe.ed Drive

CL199C 6 30 93 3100 2480

CL198n "7 42 99 3200 2560

CLl98E a 54 loa 3300 2640

CL19SG 10~ 18 121 3700 2980

CLl9aFl 12" 102 150 3900 3155 CL.l19C 6 30 93 3175 2555

CL119D 7 42 99 3275 2635

CI.l79E 8 54 108 3375 2'115

CL179G 10· 78 127 3175 3055

CL179H J2" 102 150 3975 3230 "C .. nlar lag Is supplied with la' and 12' bed lenglli4 ..

SpecificaHons of 16M24/1 Large Swing Lathes

CAP.ACITV Of LATHE

Swing oyer bed 26H"

Swlny over saucH. wings... .. . '24 . n

S'yi~g nver sndtllo crllSS aJrde. .. . 18 iH

Swlny over .... '!! sHlle ",iUm"t 6bl~ ~"nrd ..•..•. '1,9){"

SPI N OLE SPEEDS (apDroximnte. nol exact)

Direct Drive 8nok-GeaJ'ed

S-Ojieed drive 470. 280.175,105 sll, 36 •. n. 16

18 sp. dr .. high

• ~ •• da , . . . .900, 560. 340. 203 , 16. 70. 46, 30 IS 'p. dr., low

speed .455, 274, 110, 104 BO, 34, 24, 15

HEADSTOCK

Hola through splnl:lle " 1",'

M""lmull! toll!it copao'I:)', I"

lTH READS IWO FEEDS

Thread clliling mng.0-48 pitches

A.H'. or LH.... ...... . .. .4 to .n4 po. lnch Lonulturlinal foeds through l.lcrUon

clutDll-tii feeos R.H. 'Dr L H. .... .001!i" 1.0 .0a41· Cross-IDBtls tilrough frktion cluloh-

48 feeds. .. . . . .. . . .. .• . . . .. .. .00.06" to .. 00IS·

L.end ..... w, 29' .I!,,,m. tho"",' ..... i~' IJI a, -S thrds.

TOOL. POST

SizQ ol teul holde. ~hank... , ~ •• 1%"

Size 0' outter bit for tool holde liN ~.

MOTO A (SlII.nd.rd .Ite]

for 8-.po"d lath. (I-speed moto.1... 11 fI h.p.

For lB-spDed IBthll. (2'-8IleD~ moIDrl., .. , 2-1h.p,

SOUTH BE;i',ID 22., INDIANA. U.S.A.

SDindle nose diameter III1d thread.. • .. 2%'.6

Size!lf' centor! MOi"sl;J taper, , _No.-3

Width ."no pLllloy·step '., 2M"

largo faceplate dlameler .13! •

Small fate plole Iliamete... .. . •..•....• .. ..8~1!:

Fronl!ipln~1 e boo.lng, dlnm.te........ .... 2a

TAiLSTOCK

Siz~ of cenler, MorlRl blper. • . . • . . . . . •• . .• No. 3

Spindle travol. • . .. .. . .. . .. . . .. 5!4'

Ea.h D.nduntlDn on loll,L1I"" .plodla. ... ....!.It •

Tallsl<lok I;;n eet-nvlll' fortupa, lurnln~. . . . ... . ... 1'

COMPOUND REST

'0.0$ slide trovol wilhou! IaPD' altachmMI." .. lOW'

Cross slid. 1m ve 1 with laper anaenment. la~'

Angular hand feed 0:1 compound res! ·top slide. ' .. 3~·

13

SOUTH BEND I._ATHE WORKS

14~-inch Toolroom ~ Lathe

Precisio,n Lead Screw-Telescopic Taper Attachmen,t

T.be perlect proportions 01 this superbly enqineezed model will appeal to the most discriminating technician. It has plenty 01 power I rigidity, and .stamina for large jobs, yet it is not too heavy for economical operation on small work, Conveniently placed easy operating controls save time and effort.

Improved features of this lathe include an alloy steel headstock spindle, oarburized, hardened, groUlld, and superfinished; improved headstock bearings; double wall apron with steel gears and multiple disc friction clutch for operating power cross-feeds and power longitudillal feeds; easy reading micromeler graduated collars, and improved two-lever quick change gear box for threads and leeds.

Toolroom attachments included in price of lathe consist 01: preoision lead screw; bandwbeel type draw-in coUet attachment {without collets}; collet rack; telescopic laper attachment;

thread dial indicator; chip pan; and micrometer carriage stop.

Regular equipment included in price of lathe consists of; 4 V-belts; flat leather belt; large and small face plates; beat treated steel loot post; adjustable thread cutting slop; tool steel centers for headstock and tailstock spindles; headstock spindle sleeve; wrenches; quick change gear box; installation plan; and hook "How to Run a Lathe." Electrical equipment is not included in the price of the lathe.

Ca:taloq Bod Between Cubic Boxed Cra.ted

Lonqth Ca.ntArs Feat Weight Wtdght

Nuxnhez Feet Inches BQzod. Pounds Poc.nde

CL8185B 5 24.~. 90 26B5 21BO

CLBl85C 6 ~~~ 95 21SS 2255

CL61BSD '] lOt 2935 2330

CLBIBSE B SOh III 30B.~ 2405 Specifications of 141/z-inch Toolroom Lathes

CAPACITY OF LATHE

Swing over bed Dnd ""ddl. wings .. Swing IIVIJf 11>1111110 cross sli~e, ...

Width or cone pulley .Iop ror bell ...•... . , .21;,'

l.arye fnco plata dinmo'liII" • 13!- .. •

Small face plale dlamot... ,. , . .8h.·

Front splndle benrlng, ulameter. ..... ' ..... , ... 2%"

TAllSTOCK

Sil. of eenler, Morae taper , ... , , ...•. , .. No.3

S,JlndiB travel •• , . , , .• , , '..' ,. "~rJ:"

En.1I ~rndualion on tail&l.c~ spindle., , n.~

Tailatock lOP !!III-over for laper turning ... "" .. 'li·

THREADS ANO fEEDS

ThR~~ :~'If. ~.n~~ ,PI~oIl~ . . 4 10 224 per Inch

Lon;r.ilucilnel feedl through friction

0Iul.ol.-48 rOBd~ R,fI, or L.H .. ,. .001'6· In .084'1"

Cro ... r~ed8 through frlolion d ulcl1-

48 'feed.s ,.,'... '" .. ,. . ,00118" 10 ,0315"

Lead 8(lrBw.29' A"",. 'hrend, , , , I~· dia.-6 Ihrlts.

TOOL POST

Size ~f 1001 holdllf liha"k. • .. .. . .. 's" • lh' Size 01 cut""' bll for 1001 hoi dar .. , , ' . . • . . . •. " • sq.

MOTOR

SlQndnrd alze or molor .ettulr,ed •• , "', •... , I' • h.p,

SOUTH BEND 22, INDIANA. U,S.A.

spmDLE SPEEDS

St.ndllrd spindle speeds (appro.lma [o, nDI e"Del) T.p,1T1. of spindle, direcl bBI.I drlvll,815, 546. 360,215 t.p,rn. .f spindle, back-gear drivo ,.,130.80, 50, 311

HEADSTOCK

Hole thr.ugh spindle , , , •• .,' • ,. .1}i'

MllXlmum call 01 copatlly. ,. . . ... . • .1"

S~lndle noee dlamBtllf Dnd Ihrlllld. , , , ,2Mj"·a

Si •• 01 center, Mor:se taper" ... ,',' ,",., ,No.3

SOUTH S£ND LATHE WORKS

COMPOUND REST

Cross slide tra¥lll ...... , , , .. , , , • , , , , ,. , , ... 9~· Angular hand leed of compound reet lo-p .lIde, , • ,8H"

14

th pc sii at HI Wl

fo in fa th th bl fe

ta of

CA

SF

HI

I

51

14Y2-inch Ouick Change Gear ~e, Lathe Eight Spindle Speeds-Back-Geared-Belt Drive to Spindle

Desiqned and built to give you years of satisfactory service, this is an economical lathe to buy and to use. It has the same power and capacity as th.e toolroom model shown on the opposite page, but is less costly because it does not have the taper attachment, collet atfachmen±, and other toolroom accessories. However, any attachment that may be needed can be ordered with the lathe as an exira.

New two-lever gear box: gives you quicker, easier changes for all threads and feeds. Powerful multiple disc :w.ction clutch in apron permits engaging 0.1 disengaging power turninqend lacing feeds instantly. Direction 0:1 feed is reversed by shilting the Ieed reverse lever conveniently located at the left end of the headstock. An automatic safety interlock makes it impossible to damage the lathe or the work by engaging a second feed acoidentally when one feed is aheady in operation.

The underneath motor drive (patented) is entirely sell-con, tained and fully .enclosed. It provides an unusually wide ranqe of spindle speeds. A precision belt tension adjustment is pro-

vided. The endles.s belt drive to the spindle is silenl in operation and develops smooth, steady power, nee from gear vibration.

Regular equipment included in price 01 lathe consists of: 4 V-belts; flat leather bell; large and small la.ce plates; heattreated steel 1001 post; adjustable thread culting stop; tool steel centers for headstock and tailstock spindles; headstock spindle sleeve; wrsncltes; quick change gear box; installation plan: and hook "How to Run a Lathe." Electrical equipment is not included in price of lathe.

14 h-inch Ouick Change Gear Lat.h es with Eight~Sp"ed Drive

Ca:t:alog Bed Between Cubic BoxBd C~ e, t.,d

Lenqth Cent.nrs F""t Weiqht Weioht

Numher Feet L>ehes Boxed Pounds Pounds

CL18SB 5 24~ 81 2500 1995

CLIBSC 6 3d 85 2600 20:70

CL1BSD 7 4a!ii 91 2780 2145

CI.1SSE 8 BOLli 100 2900 2:225 Specifications of H1fz~inch Quick Change Gear Lathes

CAPACITY OF LATHE

Swlny Ovor bed anu sad[lIa wings ..•.... • ..• 14%" Swing over .,.dlll e ero ... slidl>.. . . . . . . . B%(~· SwIng liver cross snde wlthoul chip guard. .. . .1 OJ4"

SPIN OLE SPEEDS

Sbmdard splndlo speells (opptG~im.nle. not exact)

r. p.m, 01 spinliio. direct bell driY a. B7.5, &45, 350, 215 r.p.m, of ""Imlle bnck'guar drlv •..... 130.80.60,30

HEADSTOCK

Hoi. through spIndle. . •.... • ....•.....•. 1:f Mulmum collel talmclty .. . . . . . . . . . . . .• "

Snlndla nose dl.meter and Ihr.ads. . 211"-a

S·OUTH BENO L_ATI-IE: WORKS

.Size of center, MQt8~ I11per. ..••. . •...•.•.. No. 3

Widli'l 01 eone plJlI.y!l1ep lor belt. •. . . . .. . 21i."

llI'g. foco plale dlnmele. ..•. . Uy,;"

Small frule plate dlameter , .. . .. ..8>;,'

Front spindle bearlnU, dlnm_.. ...• ... . .. 2%"

TAILSTOCK

Size of conler, Moue I1lpor No.3

Spindle Ira vel. ... . . .. .5}fH Ench grad"nlion on tall.tock spindle.. ..... . . !itt" TRlIslOCk lop SIlI-o •• r lor taper lurnin9 ••• " I~I"

COMPOUND REST

Cro ss s Iid. trayeL . .. ... ....•...... . ... _ 10'

Angutar hand feed of compound resl lop alide 3~~

15

THREADS AN 0 FEE·OS

Thread culling l"~nyll-48 pilcho.

R.H. Dr L.H.. 4 10224 per InGh

LongUutllnal mM Ihrougll frlclion

cJuloh-48 feode RH. 0<" LH. .0015" 10 .0841"

Cross loe". through friotion clutr.h-

4B leeds _ _.. .. . ..0006" 10 .0315'

Lrod s.crew, 29' AI)lnQ Inrend.. l).of' draA thrda.

TOOL POST

SIze of 1001 holder shank. • .. . ~. x 1%'

Sizo of cutter bit lor 1001 holder. .. . .~'!IiI.

MOTOR

SiJuJdard slzo al moLor roqulred 1~~ h.p,

SOUTH BENO aa, INDIANA, U.S.A.

13-inch Toolroom ~ Lathe

Precision Lead .screw-Telescopic Taper Attachment

The 13-inch Toolroom Lathe is especially popular for small and medium sued jobs requiring speed and accuracy. Having 9l"eater sensitivity and speed than larger lathes, i1 will save yon time and sHort on all work within its capacity, You can also save on first cost. power, and floor space by selecting one or more of these lathes for your shop.

Equipped with the South Bend Telescopic Taper Attachment. this lathe is unsurpassed f0r turninq and boring precision tapers or cuttinq lapered screw threads. To engage the taper attachment, it is only necessary to tighten two binding screws. The telescopic oroas-Ieed screw eliminates the necessity oi disconnecting the cross- teed nut at any time. Before engaging the taper attachment. the cross-Ieed screw may be used to adjust the position 0f the culting tool. .A rigid connecting hat locks the compound rest base to the taper attachment slide block to eliminate all lost motion of ,the cross-feed screw assembly when tapers are being machined.

Toolroom attachments included in price of lathe consist of: precision lead screw; handwheel type draw-in, collet attachment (wi:lhoul collels); coUet rack; telescopic taper attachment; thread dial indicator; chip pan; andmicromeler carriage stop,

Regular equipment inoluded in price of lathe consists of: 2 V-belts; £lat leather belt; large and small face plates; healtreated sleel tool post; adjustable thread outting stop; tool steel centers for headstock and tailstock spindles; headetcck spindle sleeve; wrenches; quick change g.ear box; installation' plan; and book "How to Run a Lathe." Electrreel equipment is not included in the price of the lathe,

13-inch Und ee "eath Toolroom. Lath ... with Eiqht-Sp" .. d D~ive

c .. taioq Bed Be±wBen Cuhic Boxed Cr .. t"d

Numb .... Llutllth Oen,tm:l!":B, F ee t Wulllht Weight

Feet In,,he~ Bored Pound;; Pou:n&

CLB145R 5 281} 81 1995 1665

CL8145C 6 40;4 82 2160 1715

CLS145D 7 52),£ 90 2305 1770 Specifications of 13~inchToolroom Lathes

Wldlh 01 non. pulley step 'ror belt. , , . __ . ,1 U"

Lnr~o lac. plato ulameter .. , , , I DU'

Small Ill •• pial. ~Iamot.r. . . . .. ..,........ .8%" Fronl spindle be.vlng, dln"'e!er.... . . . . •• . ..•.. 2,liM

TAILSTOCK

Site of con lor. Mor toper .. ,. .. , No.3

Splndl. travel. . ., " .. ...• .4~K

Ench lI'"o(luntion on rallateuk eplndla , --.. ..lO"

Tolleloek top set-evar for llIp"' lutnlnu , ,. .,' I~.

CAPAC lTV OF LATHE

S ing over bed ~nd saddle WiIlY , , 1 aMI"

Swing DV saddle cross slide , ..• ,.. __ ·.iI·

SPINDLE Sf-EEllS

Sl:Jlndard spindle .pe~tJ. (npproximate, not a13,01) r.o.m. 01 81.indle, diroct belt I!rIV'L .. 94D, 628.418,270 r.p,m, of spindle, baek-gear ((rive., .. , ,. '36. 90, 60. 40

HIEADSTOCK

Hole i:l1r~ugh splndle 1!4·

Maximum collet ~pnclly..... . - .• "

Spindle nose diameler and threaa •..•. , ..• , .. ,2!";;'-6

SiUl 01' center, Moree rnper No. 3

SOUTH BEND .... A.THE WORKS

THREADS AND FEE.DS

Thread cu Ulng mngll-4B pU.chBI

1'1'. H. or L H. .. .. 4 to 224 per hwh

LlIIlgiludlnal re.d. through Iriclhm

clutch--4ll feeds R. H. III' LH, " • ,DO 16" io ,0841' c..os.-I,eed. thrDugh lriotlon tluloh-

48 foed.-. , ... '" .. .. .. , .0006" 10 .0315"

Lead 8 .. 0W, ago Acme th ... d .... , ... 1" dia.-6 thrds.

TOOL POST

Size of 1001 hnlde, shank , 1,~. x lJ.ti·

81.8 01 cutter bit IQI' tool holdllt ..•.•. , . •• . . ~,. sq.

MOTOR

Standnrd $110 01 muter rllQ"ired, . , . . . . . ...•• 1 h.llo,

SOUTH BEND 2.2., INDIANA, U.S.A.

COMPOUNO REST

Cross slide Imvel " ..•....• __ aVo·

Angular hand reed 0'1 wmpound fnllop s1ido. , .. 3W

16

..

- --~--~~- --- -_- - - --

---------~- - --

13-inch Quick Change Gear ~ Lathe Eight S.pindle Speeds-Bac:k,-Geared-Belt Drive to Spindle

The 13-inch Quick Change Gear La.the is efficient and economical for manufacturing or maintenance operations on work 01 av,e~age size. Its sensitivity and ease of operation save eftort and speed production, especially on multipl» operation jobs requiring several changes or adjustments 01 controls.

These lathes are carefully engineered Io give you years of satisfaotorY service. Large hearings and excellent facilities for oiling reduce wea:r to a minim.wn. The tlmetested pti=atic V-way construction assures permanent alignment of the head.stock, tailstock, and ca:rriage. The headstock spindle is of heattreated alloy steeL Other important parts are made of ·ID.lnilaily high quality materials selected for long service. Given the proper care, these lathes will retain their accuracy indefinitely.

Many practical attachments .for this lathe are listed In. the back of this catalog. These attachments and accessories greatly increase the usefulness ofilie lathe. They simplify tooling the

lathe for operations that mightoili,erwise require special fix. tures or machinery,

Regular equipment included in price of lathe consists of: 2 V-belts; flat leather belt; large and small lace plates; heattreated staal tool post; adjuslable thread cuttin,g stoprtoolsteel centers for headstock and tailatock spindles; headetook spindle sleeve; wrenches; qWck cha.nge geaE box; installation plan; and book "How to RUIla Lathe." Eleddcal equipment is not included in the price of the lathe.

13-in<:h Quick Change Ge ..... Lath"" with Eight-Speed Driv ..

Catalog: Bod BotWi!cn Cubic Boxod Cr.ated

Numhs"l" L..,.,g;th Oent.ers .Feet W"'qht Vl!e$ght

!',...,t .In-clu!!$I BQ'.lI:ed. P'"""",dH P"unds

CLI45A 4 1614 60 IB36 1460

CLl45B 5 28).i 69 1940 IS10

CL14SC 6 40~ 70 2045 1560

CL14SD 7 62yt 78 2150 16113 Specificati.ons for 13-inch Quick Change Gear Lathes

OAPACITY OF LATHE

s.wlng " .. " •• bOU. ~O. d: SR. drtle w. 1."9. 8,' .... " ,'as·

Swing over saddle cro ss slld •.......... , .•. .7 H

Swing oyer r,;.ro.se Rlide. without ehlp ,guard... 8, ,"

Siz. of center, Morsl lape'·. , , , ,No,·a

Width of 80ne pulley otep for belt. .. . .••..• , 1~·

Large mee ple1e dlnmeter. . . .. . ... ,...... .., lD~H Smal.1 I.ce phil. dinrneter. •• . . . . • , • . . . , , ,6%" Front spindle 1I"'ing~ dl~'metsr.... . •..•...... 2!i'"·

TAILSTOC.K

Size of esnter, Mill'll. t!lper •.•.. , No. 3

S. ~lndleIrllVe! " , .. ,. 4J4:

EnchllNldu~~on on tall.lrfck splndle........... JiG

TolI •. tocic U1p Bjlt-over lor lops, turning .. , I 1iO"

COMPOUND REST

C.oss slide Irnvel. ..•. , , , ...... ... . ..•.. 8~· .• • Angular hand I.nd ti, cOmIIOU!lU rest 'top sllda. ... 3H·

17

SPINDLE SPEEDS

Standard splndlp speeds [approxlmll.le, not e~ect)

r, p,.JI!. .f eplndlB, dlrec! nell drlv •. 940, 6:n1' 41S. 270 r, p.m, 01 .plnnle, back-SlUir drlva, , • ,1:as, SIl, SO, 40'

HEADSTOCK

Hole tllrough spindle • ,.. 1 '-fiN

lIIIa.imum collet capacity .1"

Spinello no,", diameter nnd thr ea d •............ 2J4"-8

SOUTH BE;NP I..ATHE; WORKS

THREAIlS ANIl FEE;DS

Threa.d cu'itlng ,ehge-4a pttenes

R.H. 0" L. H., . , , . • .. . .. . ...... .4 fo 224 per InDh lllnQiludinRI feB~s· through '!riclion

.• lutch'"""l8 fee.ds R.H. or LH ...... 001,&' to .1l841· 'Cro8ll-le9i1Jt Ihroughfrictlonoluloh-

4UleetiB. "" " " , .ODDS" 10 .031~

Lsad •• row, 29" A.m. th,,,,, II .. •... ,.. mIL's thrill!.

TOOL pOST

SI2.e 01 10.01: holder Mnnk ..... , ...... , .... J<:,w x 1)f' SI~1l 01 cutter bit for tool hol~er .•. , ••• ,.,., ,%," 811.

MOTOR

Standard me of molor required ...•...•••••••. T h,p.

SOUTI-I BE;ND ZZ. INDIAN ..... , U.S.A.

lO~inch Toolr-oom ;O~ Lathe

Precision .Lead Screw-Telescopic Taper At.tachrnent

This is one of OUI Hnest lO -. i.nch swing lathes. Equipped with a precision lead screw, thread dial indicator, and thread cutting !HOp, you can uaeil. with confidence for cutting screw threads on precision gimges, taps, dies, instrument parts, etc. The telescoplc taper attachment makes taper turning and boring almost as easy ea machininq suajght work

New two-lever gear box gives you quicker, easier changes for threads and feeds. Powerful multiple disc friction clutch in apron permits e,ng,aging or disengaging power turning and facing feeds instantly. Direction of feed is reversed by shifting the feed reverse lever conveniently located on the left end of the headstock. An eufometic saiety· interlock makes itimpcssible to damage the lafh.e or the work by ,engaging a second feed accidentally when one Ieed Is aheat:iy in operation.

Toolroom attachments included in price of lalhe consist of: precision lead screw; ha:ndwheel type draw-in colle! chuck

attachment (without collets}; collet. rack; telescopic taper attachment; thread dial indicator; chip pan: and. micrometer OaIriage stop.

Regular eq;uipm.enl included in price of lathe consists of:

V ·bell; flat leather belt; large and small j'ace plates: heat·trealed slael 'tool post; adjustable thread cutting stop; tool ~eel centers; spindle sleeve; wrenches; quick change gear: box; Insrallaficn plan; and hook "How to Run a Lathe," Eleotrical equipment is not included in price of lathe.

lO-inch l " Collet South Bend Took""rn Lathes wl-th Floor Lel1l'

Catalog Bad Between. Cubic Boxe.d Crated

,Longth Oo.nt&l"1; F.;u,~t W,,'qht W.,1ght

.Nu1iTLhl!r F-eat lrtoh ee B,,><ed Pounds Pounds

OLBIa7Y 3 14).( 4S 1290 990

CLS187Z 3~. 20! 48 1310 1010

CL8181A -I 2H~ 48 1330 lO30 Specifications. of lO-inch Toolroo,mFloor Lathes

CAPACITY OF lATHE

Swing D •• r b.fl'lofl ",ul!ll~ wl"9 s , , •.......... IDM" Swing over saddle cro ••• 1Id •...•...••... , .•. , .5:l--I"'

SPINDLE SPEE.OS lapproxlm"t •• nut .~a.tJ

Di'''''I. Dri.. Baalc-Cleared

High "peed!!. r.n.m 140D', B9a, 685 ~D. t60, lD5

Luw !J1uda, r.p.m 7411, 47D, 304 ISO', 85, 55'

HEADstoCK.

ColI'ol capac~ty, maximum .. , , .1;

H ... d.!Qok "plnnl. 11.1... •. .. .. . . .. ....•... . •. 1~ "' .. ,d.'DIll< 8pln!Da n088 Ihread.. . •. . :2!.i"..a Si"l.e of CAnter" MOTSA taper' .. r." ~. r _ ~ •• , ~ ••• I 'No, 2:

TH,REAOS AND FEEDS

lhreall Dulling tnng~B plloh.,

1o~ii~~3rn~i~~4il lIiroUDh fricflon" 4 to 224 ~Ilf Tnch clLtt~h--48 feedll R.H.or L_H .. , .. ;0015' to .OB30" Ol'afiS-fS8(.l.lh,uuQb frlutian dU1ch-

48 'leed.. . . •.. . . . . . . ......• 0006" 10 .0303'

Lend a<t~w 29" ADm. llirOlld ,'{" dlo.-11 thru ..

TOOL POST

Size of 1001 hold ... shank..... . . ..... ... ~'x I!;.t' Sir. Ill' ctltler bit 'for IDOl bDIII~ •....• , . • .• . xn aq.

MOTOR

Slnnda,d ·$iu or molar required •.....•.. , U h.p.

.SOUTH BEND 22, 1",01"'1'1",; U.S.A.

WI"!h 01 to"" pun~y $IBn for bell... .... . .. 1 ~,.

Lor'iflB fnCo' plate dlamat.t.. .•. • . . . B~·

Smon I,,~e plats diameter. . . . • . . . .• , ..••.• S%"

Front "Dlndle benrlny dl~m.t.'· 2Xf#

TAILSTOCK

Sil·e o·f eenter, Morse taper No.2

'Spindle travel " . . _... . 2W

Eru:h grnduatiM On IaU'\Dck !!plntUe 1/10'

Tells'ock top .et-over ror t~per lur.lng , .. 'ht

COMPOUND REST

C",,. slid. travel .. q ••• •• .. ••• , ...... _ " •• 57A" ""ngular hand fe~ ~I· compound '"61 lap $Iid •• , •.. '.2"

SOUTH BEND LATHE; Wf;lFH<:S

18

r

I

e

s

lO-inchQuick Change Gear ~ Lathe

Under.neath Motor Drive-Back~geared-Belt Drive te Spindle

Ruggedly constructed throughout, this lathe has ample power for all work within its capacity. Motor and driving mechanism are Iully enclosed. Direct belt drive '10 the spindle assures quiet, vibreticn free operation at high spindle speeds. Slow speeds for heavy cuts on large diameter work 'are driven through powerful back gears.

The tailstock spindle is graduated and the lailstock screw is fitted with a micrometer collar (or drilling to a specified depth with extreme precision. Both 'the cross-feed screw and the compound rest screw have large diameter easy reading micrometer collars for adjusting the positional the outting tool.

New two-lever gear box gives you quicker, easier changes (or threads and feeds. Powerful multiple disc fri.ction clutch in apron permits engaging or disengaging power turning and facing leeds instantly. Direction of Ieed is reversed by shifting 'the feed reverse lever conveniently Iocated on the left end of

the headstook. An automatic safety interlock makes it in'Ipossible to damage the lathe or the work by engaging a second feed accidentally when one feed is already in operation ..

Regular equipment included in price of lathe consists 01:

V-belt; fiat leather belt; large and small face plates; heattreated, steel tool post; Bdjuatable thread cutting stop; tool steel centers spiridle sleeve; wrenches; quick change gear box; installation plan; and book "How to Run a, Lathe." Electrical equipment 15 Dot included in price of lathe.

10-lm'h 1" CDU"t South Bend Quick Cbang" O ee r l.tatb .... with Floo)' L"51"

Catalog- Bed B~tWl)cn Cubic Box"d Crated

Nu.mbu l.t<>ngth CentCll"!B Feet Weight Weillht

Feet lnch"" Bo .. ed Pounds ;E'QU",a..

CL187Y 3 14~ 4~ 1230 930

CL1872 3H 20Ji 4S 1250 9SO

CL1S7A 4 26J.i 4S 1270 970

CL],67R <1M 34J.~ 48 1290 990 Specifications. of lO-inch Quick Change Gear Floor Lathes

Width ~f cone pulley step 'or boll, ........•. , . , • l'". urge Inoe plale mameler., ... ,' . """"'" 8~r Small face plato lliamarlll', •.. , " , .•.. ,. ., .6Ai"

Front spindle bearing diamellll' " , . z~f'

CAPACITY OF LATHE

Swing oyer bod ant! iladlli. wlng , , .10Jli"

Swing o~er ~R(ldIQ croso slide , , , ....•... ,5):1"

Swing over cross slide wflholIl ohlp guard •. , ••..• 6~·

SPINDLE SPEE.DS (approximate, not .... tl)

Dlreel Drive Back-G""r~d

High speeds. r.n.m ..•.. 1400, 89B. 586 250. laO. 106

Low speeds, r.p.m. .... 7~, 470, 304 130, 85. 55

HEADSTOCK

Correl clIIlacily. maximum, ......•... , ••.. ..,.,. I"

Headslllok ~lndl0 hole. ..... . ..1~·

HeadstoGk spindle nese thron".. .., ,.2!4~.,g

Sl~e 0' center. Morse lap.r .... ",.", ... " .... No. 2

SOUTH ElENO LATHE WORKS

THREADS AND FEEDS

Thread culling .nnge.-48 plteh os

R.H, or LH ,. , 4 to 224 ner Inch

longitudinal 'eeds Ihrough friction

clulch--4B 'eeds R.H. or L.H. , .... 0015" i n , 0836' Cross-feedB throuyh friction clut.h-

48 leeds .... , . . .. ... .... .. ...... OOOS' fa .0303"

Lead screw. 29" Acmo thread ...•. U" die,-tI Ihr<ls.

TOOL POST

Size of tool holdor shank , .. , .. ,Jij" ~. I!~

Sizo of cutter bit 'or tool holder , .• " ....• )4'11<1.

MOTOR

Standard alzo 01 motor r'll<Iulrod .. , ... , •• , • , •• :!Ii h.p.

SOUTH BEND ZZ. INDIANA. U.S.A.

TAILSTOCK

SIZ8 01 eentar, Mor~e laper, ,'" ......• ,No.2

Spindle trayel •. " ,.. .. .2J.t·

En,ch ul"ildu.~on on 1811.10,.1< spindle ....... , . .1/10' Tnllstoek top, ,.t-OYIII" for taper turning. ' . , . ' .. , .'~!I.'

COMPOUND REST

Cr •• , slide tray.I ....... , ... ".,.,', ..... _ ..... 6'{' Angular hand foed or compQund re$t lOp $lIdo, , , , •.. 2"'

19

'.

Toolroom attachments Included in price of lathe consist ,of: precision leadacrew; .handwheel type draw-in collet chuck attaohme:o t (wiiliout collets); collet rack; telescopic taper attachment;i:hread dial indicator; and micrometer carriage slop.

Regular equipment included in price 01 lathe coneleta of: steel hench with built-in chip pan and three drawers; V·belt; flat leather belt; large and small face plates; heat-treated steel tool post; adjustable thread cuttinq stop; tool steel centers; spindle sleeve; wrenches, quick cha:n,ge geal;' box; installation plan; and book "How to Run a Lathe." Electrical equipment is not included in price.

10-Sn,gh IN Collet South Bend 'I'eeb-eem Bench Le.t.hee

IO-inch Toolroom p~ Bench Lathe

Precision Lead Screw-Telescopic Taper Attachment

Designe,d especially for precision toolroom operations, this lathe has many improvements and refinements that will make your most difficult lathe jobs easier, The telescopic taper attachmen! is graduated in both deglees and inches per foot for machining tapers up to 3M' per foot. A rigid connecnng bar and hinding lever remove the thrust from the cross- feed nut and lock the compound rest base rigidly to the lapel attachment slide block to eliminate lost motion in the cross slide when turning or 'boring tapers.

New two-lever gear box gives you quicker, easier changes for threads and feeds. PowerfuJ multiple disc friction clutch in apron permits engaging or disengaging power turninq and facing feeds instantly. Direction of feed is reversed by shiiting the feed reverse lever conveniently located on the left end of the headstock. An automatic safety interlock makes it impossible to damage the lathe or the work by engaging a second feed accidentally when one leed is elready in operaficn.

CatalDI! Bed Between Cub:lc Boxed Crated

Langth CenterS Feet Waight Wei .. ht

NumJ:. .... F""t Inch ea Basad Pounds Ponmu

CI.8187YB 3 ~dti 56 13JO 960

CLBI87ZB 3~ 56 1360 990

CLS1S7A13 4, 26X 68 1410 1060 Specifications of lO-inch Toolroom Bench Lathes

CAPACITY OF LATHE

Swing over b B~ .n~' saddle .... In~s, ' .. ' ..... .1 OW Swing over oaddl~ Ctll~ $Ill1e,., , •.•.•.. , ,SM"

SPINDLE SPEEDS {approxlmale, not onCil

Direct D,lve Sack-Geared

High ""Beoe, r. p.rtr. . 1400. 898, 58B 250, 160. 105

Low Ipeods. r.p.m ...... 740,470,304 130, 85, 55

HEADSTOCK

Collet enpacity, I11!Iklmum , 1"

H""dflllck 8pln~l& hule, •••• . •••.. ••... . ..••. .1"'· Headstock spindle no ... Ihreade ..•........... ,2U·.:a Size of eenler, MOl •• hIIIer" .. , ..... " , ... , ... No. 2

Width or wne pulley step for belt .... " ... ,', .. , 1~· Larger.c. ulnts dinmelnr.,,, .. ,., .. ,,.,., ..... BW

Small Fac'"JlIPle dlamoto' , . , , . , , , , . , , .••• 5%"

fron·t ""In Ie bearing diameter ' .. 2!.('

TAILSTOCK

SilO of eon lor, Mor ... Inpot. , . , . No. 2. Spindle INIvel •••. '''.' ."'''''''''''''' ,2J..1!·

Elto:t! gl'lldu;rlion on III If slock spindle , , . .. .,1/10"

TaU.took top aot"over 'ror loper lurn Ing , l!{,'

COMPOUND REST

CNISS slide IraveL". " ..................•• ,8)W Angular hAnd I_I 01 wmpound res! lop elide •••••. 2"

THREADS AND FEEDS

Thrlli'd' culling flIfIge--<lB plltnBS

R.H, or L.H"" ..... " , ..... .4 10 2'24 ~.r Inch longllullInnl leods through frlcUon

efutM-'18 feeds R.H. Dr L,H ..... 0015- to .0836- Cross· feeds thNlugh friction dlllcfl-

48 feed. , ,.. . ..... , .. • .. .. . .0006" 10 .0303"

lend set.", 29' Acme thread, . , ... ,~. dln.-8 Ihrd&

TOOL POST

Sb .. allDol holder shank .•.. , , .~i· " ",,,"

Size 01 cultot bit for IDOl holder " ,MY .sq.

MOTOR

Standord 11~~ or motor uqull'ild .•....... , ••••. '" h.p.

SOUTH BEND 2.2. INDIANA, U.S.A"

SOUTH eEI'ID LATHE WORKS

20

..

ment, Most of these attachments and accessories may be purchased either with the lathe or later.

Regular equiplne~t inoluded in pdce of lathe conslsts of; sleel bench with built-in chip pan andth.ree drawers; V·belt; flat Ieathar belt; large and small face plates; heat-treated steel tool post; adjustable thread cutting stop; tool steel centers; spindle sleeve; wrenches; quick change gear box; installaticn plan; and book "How to Run a Lathe." Electrical equipment is not included in the price.

IO-inch Quick Change Gear ~~ Bench Lathe

Underneath Motor Dr~ve-Back-geared-Belt Drive to Spindle

Mounted on a substantial welded steel bench with built-in chip pan and three roomy drawers, this is one at OUT most convenient models. Contrel switch is always within easy reach and permita ·staxtingr stopping or reversing lathe spindle' instantly. Motor and ch;ivinq mechanis:m are fully enclosed in cabinet beneath lathe headstock.

New two-lever gear box. gives you quicker, easier changes for threads and feeds. Powerful multiple disc friction clutch in aplon permits engaging or disengaging power turning and faCing feeds instantly. Direction of feed is reversed by shifting the feed reverse lever conveniently located on the lefl end of the headstock. An automatic safety interlock makes it impossible 10 damage the' lathe or the work by engaging a second feed accidentally ",hen one .Ieed is already in operation.

A complete line ol practical attachments and aecessories simplifies tooling Ihe lat.he for many classes of work, including SOme, thai ~ghl: otherwise require special machinery or equip-

lO·inch 1" Con..t Sou th Bend Quick Ch_51" Q ee.e Benc:h L .. th""

Catalog Bea 8.>twe .. " Cubic Boxed Crated

Length Centers reet Wlriqht We1ll'ht

NU'ZTlhm' Filet lncholl Bcnr::od Po=ds Po"",ds

CL181YB 3 Ml3 56 1200 aso

CL187ZB 3)4 56 laSO 8aO

CL187AB 4 :l6U 6!! 1300 950

CLla'1RB Hi 34 '. 65 1350 980 Specifications 0'£ lO~inch Quick Change Gear Bench Lathes

CAPACITY OF L.ATHE

Swing ovO!' bed and SlIddle wing9 10li"

Swing n .. er saddle ClOs9 slide 5J1"

Swing over cro5ullde wilflout chip gullJ'd 6~-a·

SPI N OLE SPEEDS (~pproJ;lm~le, not exact)

Direot Drive Back-Goorad

High speeds, r.p.m. 1400. B98, 5B5 260,160.105

tow speeds. r.p.m ..... 740, 470. 30<1 130, 85. 55

HEADSTOCK

Collo! capacity, maxlmum.. ,"

H Bad.IDc!< Bplndle hole. , . .. . • .. . . . . . • .. .. t:' •.

H'Balr.(oCk Spindle, nos<> .lhteads 2 ,"-8

SIZ6 Df eenler, MDrse t8pt\l'.. . .. • • . • .. .. . .. . • .. d. 2

Width 01 cone ~tliley step tor boll. ...•..••••.••. 1',,-

Large 'aco plate dlnmeter... .B%"

Small fan plate diameter... .. 5","

Front spindle bearing dlnme[er 2j,{"

TAII.STOCK

SiztJ of canter, Moreo tIIper No.2

Splndlelrnyel.. ..• .. , 2!1i"

Each graduation on tallslook spindle 1/10'

TallslllCk tOfl set-ever for tnper turning.. • ..•... l~"

COMPOUND REST

Crossslide !raver BU'

AngulDr hand Ie~d 0' OOnll'OUR,1 rest lop allde ••.... 2"

THREADS AND F'EEDS

Threall cutling range--4B plleh ••

R.H. Dt LH... ..... .. ... 410224 pllf'lnoh

Longitudinal f06ds through friction

tMoIl-48 feeds R.H. 01' LH ...... DDI5" ill .1l83B" Cross-feeds through frleUIIIl clutch-

48 leed.. .. .. .. . .. .. .. .. .. .. .. • .. .0006" 10 .0303"

Lead .nlQw 29" Acme thread .. . %" dia.~ Ihrda.

TOOL POST

SI of tool IWllda. Bh~nk ~i· ~ .',,'

SI1.s of culfer bit for 1001 hDldor............ .}:(' sq.

MOTOR

Standard size 01 motor required !Yo( h.n,

SOUTH BEN'o 2.2. INDIANA, U.S.A.

SOUTHI BEND LATHE WORKS

21

Tailstock ill subs!l:anlially designed with long hand-scraped bearing OD. bed. Tailstock top has, set-over for laper t~q. A double plug binder locks the tailstook spindle without thrOWing it out of allgnm.ent. T;riMock spindle is graduated and is made of special quality spindle steel For drilling operations, a micrometer collar on the tailstoak spindle feed screw indicates movement of spindle in thousandths of an inch. Tailstock center is hardened and is self-ejecting. Felt wipet'S are attached !o both ends of the lailstock basa to clean and oil the bed ways.

Quick Change Gear Box supplied on Model A and Toolroom Lathes permits changtng thread cuL1:i.ng leeds, power longitudinal feeds, and power cross- teeds inslani:ly by shifting two levers. Model B and Model C Lathes have independent change gears for ohanging threads and feeds.

Carriage has Ienqbearinqs (9J16 inchea) On V.ways of lathe bed, providing a solid support for 'the cutting tool and reducing wear to a minimum. V·ways of sadqIe are hand-ecraped to match V-ways 01 lathe bed -perfectly and are fitted with felt wipers to clean and oil the bed, Carriage lock for facing operations is conveniently located on front wing of saddle.

Features, of South Bend Light Ten Lathes

Forty-Five Years of experience in designing' and building fine precislon lathes have gone into the development oI the new South. Bend Light Ten Lathe. It is a modern precision tool having the mosl recently developed improvements and refinements. The workmanship and materials used in its construction are the besl that can be obtained, and the highest standards 01 inspection are maintained thrcuqhout its manufacture.

Lathe Bed is rigidly constructed 01 a special grade of gray iron having thirty per cent steel, which produces a hard closegrained metal having unusual slIength and long wearing qualities. The time proved superior design of the bed, having three V·ways and one flat way, assures permanent precision aJignment of the headstock, tailstock, and carriage, practioally unaffected by weal,'. The bed ways are carelully precision finished the entire lenglhof the bed,

Back-Geared Heacistoch is hand-screped to the bed to assure precision alignment of the spindle with the bed ways. A wrenchless bull gear lock permits en.qaging and disengaging the back gears without the use of a wrench. The cone pulley and back gears are enclosed in a hinged cover which may be raised to permit easy shifting of the cone pulley belt to change spindle speeds. An improved spring latch reverse on the left and of the headstock permits changing the direction of power carriage feeds instantly.

Bearings for headstock spindle are replaceable bronze sleeve type, and are precision bored and burnished to a smoothness of ten microinches (.000010") * by the bearingixing process. The use 01 large sleeve bearings to carry the radial load prevents chatter marks 00 the work due to vibra:tions which might be set up by ball or roller bearings. Large oil reservoirs and an improved capillary oiling system provide iI.. complete film of clean hlter·ed oil which separates the rotating spiudle from the bearing. As long as sufficient oil is supplied to maintain an adequate oil film, there can be no metal to metal contact in this bea:ring, no wear and no friction other than the fluid friction of the lubricant. An efficient oil return system retains the oil so that only an occasional replenishing is required.

Headstock Spindle is made of a special. quality alloy spindle steel, with all bearing surfaces carburized, hardened, and ground. Journal bearing surfaces are superfinished to a smooth. ness ol five microinchea {.OOOO05")". Spindle has ball thrust bearing and lake-up nul for e1imina:ting end play.

SOUTH 'ElEND LATHE WORKS

Apron lor Model A and Model B Lathes (patented) is equipped with a worm. driven by a spline in the lead screw, and a friction clutch for operating the power cress- feeds and the power longitudinal leeds. The threads 01 the lead screw are not used lor the power lenqitudine] turning feeds. The plunger type feed chanqe knob on the front ollha apron has three positions; top for power longitudinal leeds; canter for a neutral poaiticn: and bottom for the power cross-feeds. An automatic safety in terlock prevents ecngaging h alf·l1 uts accidentally when the power tuxning or facing feeds are in operation, Apron. for Model C Lathe has power longitudinal leecia driven through the lead screw and hall-nuts, and hand operated cross-feed.

Compound Rest is graduated 180 degrees, swivels to <Uly <Ulgle, and has improved lockinq device with double binder. Compound Test screw and cross-feed screw have larqe mic:rometer collars graduated to read in thousandths 01 an inch. Dovetails are hand-scraped and have adjustable gibs. Tool POlLt is made of heat-treated steel.

CIa.

·Profilometer reading in microin.ches nne.

SOUTH BEND 22., INDIANA. U.S.A.

SPEED

High spindle speeds are essentlal tor machining small diameters, drillinq, polishing, diamond tunung' and boring, finishing plastics, machining brass, aluminum, magnesium, and many other similar operations. Slow speeds are just as important lor cuttin,g screw threads, reaming, ma.ohining large diamelets, etc, The South Bend Light Ten La.the has been designed to perform equally well over an unusually mde range of spindle speeds. The improved closecoupled horizontal motor drive (patented) provides twelve spindle speeds rang· ing from 48 10 1435 r.p.m. (approximately). Direct belt drive to the spindle assures smooth. operation at high speeds. Slow speeds are driven throuqh powerful back gears.

ACCURACY

Buill by creftsmen who take pride in thelt work, the Light Ten Lathe is capable of machining to the enoting tolerances demanded in modern industry. The workmanship and materials entering into its construction are of a quality hard to equal in a,ny other lathe, Ieg'arilless of price, The bed ways are carefully precision finished to assure accurate aliqnmen,* ef the headstock, tailstock, and carriage. All dovetails are hand-scraped and flat hearing eurtaces are grolllld, lapped, or bend-scraped, Even the beating surfaces between the hed and leers are precision qIoUlld, just to make sure that no strain will be put on the bed when the leg bolts are tightened. Ea.ch lathe is critically tested under power, and must actually machine work to close tolerances before it can be approved for shipment from the factory.

ECONOMY

The Light Ten Lathe is aconomical to buy and to use. II is the lowest priced 10· Lathe in. our line and it can be fitted with chucks, tools, and attachments at reasonable prices. The wide range of speeds and feeds available permit machining all classes of work at the. correct speed and feed lor maximum efficiency. Power consumption is held '10 a minimum by the use oi a hactional horsepower motor and an effioient drive mechanism. The Light Ten Lathe is especially suited to small toolroom and manufacturing operations, which often cannot be economioally handled on the larger and more costly heavy duty lathes,

CONVENIENCE

Large diameter hendwheels, clear- cut easy reading graduations, and a convsnient ar.rangement of controla conltlhute to the ease ol operating the new Light Ten Lathe. This reduces operator fatigue, increases efficiency and prevents mistakes ee that maximum production call be maintained on either toolroom or manuiaoturinq operations. The quick change gear hox on. Model A and Toolroom Lathes makes threads or leeds instantly available.

SPINDLE BEARINGS

The weighl 01 a needle applied point lirst will easily b(eak through an oillilm, yet the same Iilm of oil between two optically flat surfaces will support almost an infinite load. To remove the "needle points," spindles for South Bend Light Ten Lathes are superlinished to a smoothness 01 hve nucrotnches, and bearing sleeves are burnished to ten nricroinches, epprcaohlnq a surface smoothness equal to that of an optical flat. Conditions within the bearings are auohfhat an almost unbreakable film of oil is maintained at all times. This provides erlrejllely rigid support fOI: tne spindle, and the absence of metal fo melal contact eliminates wear, reduces b:iction, and assures long, trouble-free service.

DURABILITY

The South Bend Light Ten Lathe is carefu1iy engineered to give years of satisfactory service. Large bearing surfaces and excellent facilities fOI oiling, reduce wear 10 a minimum. The time tesled prismatic V-way construction assures permanent pracision alignment of the headstock, tailstock, and carriage. The headslock spindle is of heat-treated alloy steel, Other important parts are made, oI similarly hiqh quality materials selected fat long service. Given the proper care, the South Bend Light Ten will! retain its accuracy indefinitely.

SOUTH ae:ND ,22, INDIANA. U.S,A,

Light Ten Toolroom. _r::;~ Bench Lathe

Precision Lead Screw-Plain. 'Taper Attachrnen t

This is a veI)' fine precision lathe for small work in the toolroom, manufacturing plant, melntenance department or repair shop. Although it is competitively priced, it haathe same precision and many 01 the Ieatures and refinements usually found only on larger and much more expensive lathes. Its speed and ease ol handling- will save much time and etlort on work within its capacity.

Twelve spindle speeds ranging from 48 to 1435 I. p.m. (approximately) are provided by the patented horizontal motor drive, Power is supplied by a. ~>2 h.p, instant reversing motor mounted on. a cradle back: 01 the lathe. Direct drive to the spindle through a ,flat leather cone pulley belt assures smooth operation at high speeds, Slow speeds are driven through powerful hack gears, A conveniently located control lever permits starling, stopping, or reversing the rolation of the lathe spindle instantly. The quick acting belt tension release and hinged cone pulley cover make it easy to shift the belt to change spindle speeds.

Large diameter replaceable sleeve type spindle bearings provide rigid support for the heat-treated alloy steel spindle. Bearing surfaces on the spindle are cazburized, hardened, and superfinished for extreme precision and maximum durahility. The threads on the spindle nose are held to close tolerances to assure precision and interchangeability of. chucks and face plates. Spindle bearings have large oil reservoirs with

capillary wicks which supply a continucus Dow 0.1 clean filtered oil. After flowing through the bearing, the oil is collected and returned to the oil reservoir for recirculation.

Toolroom attachments included in price of lathe censlsl at: precision lead screw; haudwheel type draw-in collet chuck attachment (wilhout collets); collet tack; taper attachment; thread dial indicator; thread cut!l:ng stop; latge face plate; and micrometer c""riage stop.

RegulaT equipment included in price of lathe consists 01.: twelve-speed horizontal motor chive unit (patented); motor pulley with !!{" hole; V -beH; £lat leather belt and lacing; power feed apron (patented); g~duated compound rest; smell face plale; heat-treated steel tool post; two 60-degre.e hardened tool steel centers; spindle sleeve; w:r;enches; quick change gear hO'X; installation plan; and book "How 10 Run a Lathe." Bench and electrical equipment are not included in price of lathe.

1 9 9 a a f, Q

il '" .0

rl

.h

s:

Light Ten "roo1:raam Bend. Lathas wit:b Hcri1<ontal Mote .. Drlv ..

Le$OO £l.evtrlc"l Equipment and Ben..h

Catalog Bed BEt-tween Cubio Boxed CrB1:ed

Length Oen'ters Feet We1ghi Weight

Nutnber Feot. Inch ..... BOllOd Pound.e Pounds

CL.8670Y 3 16~ 22 6S0 520

CL8670Z 3l1i 22 22 665 536

CLB670A 4 2B'~ 22 690 550 tJ L it

a g

Specifications of Light Ten 'Toolroom. Bench Lathes

CAPACITY OF LATHE

Swinu Oyllt oed, matlmurn. . . . . . '10"

Swing over .. ddle wlnlJll 9"{·

Swing over .. ddle cro .. sllde., .. , .". " $7 "

SPI NDLE SPEEDS (apprOXimlltB. not aXlltt)

High splndlo s~s

r.~.m. of spindle. tliretl bell drive .•.. HSS, 8<1~, 002 r.p.Ol- of spindle. bilek-gear drive ••• , , 216. 185, 96 low spindle t;peod.

r.p.m, ol8plndl8, dir ... belt drlve .•... 7M, 416, 244 r.p.rn, of spindle., back-jjes, dtiv~. . . • .137, BO, 48

HEADSTOCK,

Hole lill'DU.gh .plndle" .• , .• ,', " .... " ... , ,'Ii,-

MRxlm"m collet caP"clty ... , ,', .• " .. " ... Mi~

SOUTH I3END' LATHE WORKS

Spindle nese di.meler nnuth.ends per iock, ... 11:1"-8

Sile of center, Morse toper . ,. . .. , ,.. No. 2

Width 01 con. pulley olep fo, helt .• ,. ,.;, , . l'

Large face pJIIla diameter. .. . . . . .. 7%"

Small face pia Ie diameter.. .. , 5.li\·

Front .pindle boarlng diameter , . , . • .. . .. l'HII"

TAILSTOCK

Sile of cenler, Morse taper No.2

Splnrlle !tilVoJ ••• , , , .. 2!o1iH

Each graduation o~ tall.tode splndle 1(,'

Talislock top .el-o ••• ror laper tumlng %"

COMPOUND REST

C<osoolld.ll"IIvel. ....... "' .. "' •.• , ' .... " ..•. 5H·

Atlg"I •• h.md 1.$Il 01 .o~mpoul\iI reol tap .lId8 .•.. 2)4.·

THREADS AND FEEDS

Thread outtlnu range-48 pitch os

R. H. 01' LH 4 to 224 per Inch

Lon~itudlnal feeds Ihrough !fIction

c1U1ch-48 loedi R.H. or l.H ...... 0015·lo.D8W Cr~·t81!11. Ihtougll 'rlcllon clulcll-

48 leedB RH. 0' L.H... , .•.. ,.. .0004" ID .DI!!iIi" Lead serew, 2!1" Acme IIorllad. •.•• l~' dla.-8 Lhrde.

s

SI

TOOL POST

~ 01 tool holdot shonk.. . .. , S" ~ %'

s, ... er auH.r bit lor IDol hold.,... • • • , ••. ,. )4" ...

MOTOR

H

Slnndard slz6 'Of mot.or r'equir'ed' ~

~. ,~ •.• ~'T~1ih.p.

24

SOUTH BEND .22, INDI .... N ... , u.s ......

Light Ten Model A ~ Bench Lathe

Horizontal Motor Drive-Back-Geared-Quick Change

This is an exoeptional value in a. really fine small lathe with big lathe fealures including the double tumbler quick change gear box, power feed apron (patented), superfinished spindle, graduated tailatock spindle with micrometer collar on screw, and heavy bed with. prismatic V-ways. Except for the taper attachment and other tcolroom attachments, it has most of the featu.res and refinements of the tcolrcom lathe shown on the opposite page.

Quick and easy selection oi a desired thread cuttinq, turning, or facing feed is made by placing the two levers on the gear box in the positions indicated by the direct reading index chart, Direction 01 feed is changed by shifting the spring latah reverse gear lever conveniently located on the left end of the headstock. All gears are precision cut to ~!;sure accuracy and sm a oth , quiet operation.

The patented apron construction is unsurpassed for convenience, ease of operation, and efficiency. Power feeds ale driven through worm gearing and are engaged by turning the clutch knob to the right A large oil reservoir provides ample IubrlcationIor fhe clutch and power feed gearing. The worm is driven by a spline in the lead screw so that the threads of the lead screw are used only when the half-nuts are engaged lor cutting screw threads. An automatic safety interlock makes it impossible to damage the lathe by accidentally engaging two opposing Ieeds at the same time. The large handwheel is gea.red to the rack on the lathe bed for positioning the ca:rriage

and fox hand-operated longiludmaIleeds.

Graduations on the tailstcck spindle reading In tenths oi an Inch, and on the lailstock screw micrometer collar readint;J in thouaandths of an inch permit drilling or reaming to " specified depth with extreme precision. The hardened tailstock cent.ar is. automatically ejected when the spindle is fully retracted into the tailstock barrel. An internal clutch securely locks the tails tack spindle withou t disturbinq its aligtunenl.

Regular equipment included in price of lathe consists of: twelve-speed horizontal motor drive unit (patented); motor pulley with !l4" hole; V-belt; flat leather belt and lacinq; power lead apron (patented); grad.uated compound rest; small face pla'fe; heat-treated steel tool post; two 60-cleg.Iee hardened tool steel centers; spindle sleeve; wrenohes;quick change' gear box; installation plan; and book "How to Run a Lathe." &nab. and electrical equipment are not Included in price of lathe.

L.lghl Ten MQdeJ A B..rtch l,athes wHh Horizontal Motor Driv ..

Less El"ctr!c"]' E"uipmo.nt and Bench

Cataloq Bad Between Cubic 'Boxed C.ated

Nu.=),~ Lanqth Centers Feet Weight Weight

feet Inoh~~ ·Boxed Pouhd. Pounds

CL670Y 3 16\·. 21 600 400-

CL670Z 3 ~~ 22'. 21 615 5QS

CL670A 4 28', 23 640 520

CL670R 4 ).., 3'P. 26 670 535 Specifications of Light Ten Model A Bench Lathes

Spindle nese dIameter ann threads per In"il .. Sila of center, MorS!) raner:

Width of r.One I,ulley step 'or belt Small fa •• pl.Ie dl.meter

Front splnelle bearin~ diameter .

TA.ILSTOCK

Sin of .entor. Mot'. taper .. _ No.2

Spindl. Irnvel. . . .. .. . •• . . . . . .. 2!-i'

Eaah graduation on taUBI.ok spindle 1 I11Y'

Ton.look lap Bel-over far top..- lurning ..• ' .. _ .• M"

CA.PACITY Of LATHE

Swing Qyer bed, maximum _ 11)'"

51111ng over oa(ldle wings . . .. . .91l •

Swing over saddlo cross 81lde chip guard. •. B '~h

SPI NDLE SPEEDS (apprOxlmale, no! •• act)

High SIIi ndle spued.

r.p.m. of IIPlndlo, direct belt ,Irive.. 1435. 844.502 r.p.m, of spindle, bBck-gBBr drive.... 2711, 165, 96 Low spindle spell,I,

r, p.m. of spindle, direGI hel! drive 1116. 415. 244

r .p.m. of III!IMlo. bnck-gear tlri 137, 80, 48

HEADSTOCK

Hole IhrQUJlIl splndlo.. . ':''(;'

Moulmum coIl.t ".poolty rt

SOUTH SEND LATHE WOR·KS

THREADS AND fEEDS

Thread cutting range-48 pitches

RH. or LH. . .. . . _ .4 10224 per lnah

Longltu~innl feetls through tri"li~n

clulcl\--48 feeds RH. orLH.. . .0016" to ,0S52~ C'D9S-!oods Ihrough 'rlatlDn clurnh-

48 r.ed, 'R.'H. Of LH. . . .. . .00001" t o , 0255"

Lend we ..... 29· A~m. Ihread. . . .• . U" "10.--.8 thrdll.

TOOL POST

Size of toot hoHler shank.. . . .. . ...•• . .. ~. x 1%" sr~e 01 cLlller bit fOf' 'Dol hold.... .. . .~. sq.

MOTOR

.II/'..a NO. 2. l' ... M~· ..11!liI'"

COMPOUND REST

Crose IIid. 1m .. 1 .. _ __ _ 5H"

Angular hand foed 01 !lOmpound r •• 1 top .lId •.... 2)1"

Slnndnrd sIz. 01 mDlor required .•....

".Ii h.p,

25

SOUTH BEND U. INDIANA, U.S .«.

Light Ten Model B ~ Bench Lathe

Horizontal Motor Drive-Back-Geared-Power Cross-Feeds

This is an attractively priced model, especially suited for production operations or other work which requires few changes ·of threads and feeds. It is the same as the Model A lathe shown. on the preceding page, except that it does not have the quick change gear box.

A Bel of independent change gears is supplied with each lathe for cutting various pitches of screw threads and for power longitudinal and cross-feeds. An index chart attached to the lathe shows the- arranqement 01 the g'8'!lIS for cutting 45 pitches of screw threads, 4- to 160 per inch and 26 power longitudinal feeds .0021" to .015S·. Twenty-three power cross-feeds range from .. 0009' to .0046~ ..

The pate-nted apron construction is unsurpassed for convenience, ease of operation, and efficiency. Power feeds are driven. through worm g~aring and are engaged by turning !.heclutch knob to the right. A large oil reservcir provides ample lubrication for the clutch and power feed gearing. The warm is driven by a spline in the lead screw so that the threads of the lead screw are used only when the half-nuts are engaged for cutting screw threads. An automatic safety interlock makes it impossible to damage the lathe by accidentally engaging two opposing feeds at the same time. The large handwheel is geared to the rack on the lathe bed tor positioning the carriage and for hand-operated longitudinal feeds.

Large diameter easy reading graduated collars on cross-Ieed and compound rest screws save time and effort in positioninq the outting 1001. The Compound, rest sWivel has clear cut accurately divided graduations and may be set at any anqle jar machining bevels and shari tapers. The carriage lock forlacin9 operations·is located on the right side of the froul seddle wing.

Regular equipment included in price o( lathe consists of: twelve-speed horizontal motor drive unit (patented); motor pulley With %. hole; V-helt; flat leather belt and lacing; power feed apron (patented); graduated compound rest; small [ace plate; heat-heated steel tool post; two 60-degree hardened 1001 steel centers; spindle 'sleeve; wrenches; set of change gears; installation plan; and book "How to Run a Lathe.' Bench and electrical equipment are .D<;,t included. in. price of lathe.

Light Ton Mo<lel B Bench L,..U,,,,, with H"ruontal Motor Drive L""" Elect"ica.l Equipment ...... d Banch

Catalog Bed Between Cubio Boxed Crated

J..ength CenttU'8 Feet Weight WBight

N ... rnh.". Feet lnehes Bo"ed Pounds Pounds

CL667Y 3 16K 21 585 415

CL667Z 3)i 22 21 600 490

CL667A 4 281" 23 625 50s

CL667R 4J.o1 34h, 26 655 520 Specifications of Lig:ht Ten Model B Bench Lathes

CAPACITY OF LATHE

SwillQ cvur If 011. madmurn.. ....•...... .•• . .1'0'

Swing over saddl e winDs. " .. , 91}fr"

Swing over saddl~ cross .lIne chip guarrl. .6)-(·

SPINDLE SPEEDS (approximale, not elCHot)

High sf)lndl e spows

r.e.m, of splndl •• dirBol uollllrtve 1430, 844, 502

r.n.m, of spindle, bock-genr <lrlve 276, 185.96

Low spindle speeds

r.p.m, of' wlndre. direct iJelt IlrlYe •. , .705,415.24'1 r.p.m, 01 &!llndle, bnlll<-fjenr dtlvo ...... ,137, 80,48

HEADS.OCI<,

Hole tJrrllUglI spindle rtf."

Mnxlmum cnllet Cllpacity %.

SOUTH BEND LATHE WORKS

Splnlne nose dlnmeter and threads per Inch.. 1 t ;,'-8

Si ae of center. MfH'se tnper. .. .. No.2

Wid th of cone pulley stop for bnlL 1·

5"",11 fate plato diamst6l' .SH"

Front Silintlle ~ .. ;rlng dlnmutor I"","

TAILSTOCI<,

SIz8 of center. Merse IJlpOl.... .. Nf>. 2

Splndl. ImYel. . .• .. .• . .. . . . •• . 2)rS'

ElIch gl'llduation On mil.look wln~lo .. 1,1"

TnllslDi'k top sel·oVIlf for taper turning %"

COMPOUND REST

Cro ... slitl& tl'iwel. . . • . . .. . . .. . . . .. .. . . • . .5W' Anguillt hnnd feed 01 oolT1)Jound roallop .1I~e .... 2~·

26

THREADS AND FEEDS

Thread cutting rnngfl-45 plt~Ms

R.H. or L.H.. 4 to 1611 per inch

Lonyllurlinal foeds through frlcllon

clUleh-26 fomls R.Ho, or LH •.•...• 0021" to .0165" Croos-Iews Ihrough frlolioll clulcil-

23 fonds R.H. or L.H. .,. . .. .0009' to .P046"

LBlld ""row, 29' Atmc Ihrs.,rt... . ~~. dla.-8 thrde,

TOOL POST

SilO of IDOl holder shank ~ ~ "·ii'

Size 01 cutter bit for tool holder.... •..••.. Ii" SQ.

MOTOR

Slandard 0;20 of motor reqUltB~ !.~ h.p.

SOUTH BEND 22. INOIANA. U.S.A.

You might also like

- Myford 7 Series - Inspection Sheet PDFDocument3 pagesMyford 7 Series - Inspection Sheet PDFRichardScribed100% (1)

- 12 Atlas Master Parts ListDocument33 pages12 Atlas Master Parts ListlokiNo ratings yet

- Model Stationary and Steam EnginesDocument168 pagesModel Stationary and Steam EnginesRobert Grabowski100% (3)

- Atlas Mill AccessoriesDocument1 pageAtlas Mill AccessoriesGary RepeshNo ratings yet

- Atlas 7B Know Your ShaperDocument6 pagesAtlas 7B Know Your ShaperColin FinkbeinerNo ratings yet

- The Advance Metalworking LatheDocument6 pagesThe Advance Metalworking LathePronina100% (2)

- 1946 Rusnok Mill Heads CatDocument25 pages1946 Rusnok Mill Heads CatfgrefeNo ratings yet

- Gingery's Pipe Bending MachineDocument1 pageGingery's Pipe Bending Machinegodfrey73100% (1)

- Projects For The Unimat Part 2Document95 pagesProjects For The Unimat Part 26KILLER100% (2)

- Practical Lessons In Metal Turning - A Handbook For Young Engineers And Amateur MechanicsFrom EverandPractical Lessons In Metal Turning - A Handbook For Young Engineers And Amateur MechanicsNo ratings yet

- Turning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningFrom EverandTurning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningRating: 2.5 out of 5 stars2.5/5 (2)

- Emco - Unimat 3 - Unimat 4 LathesDocument23 pagesEmco - Unimat 3 - Unimat 4 LathesEnrique Luera0% (1)

- Quick Change Gearbox: Instructions For Installation and Operation Pictorial Parts ListDocument10 pagesQuick Change Gearbox: Instructions For Installation and Operation Pictorial Parts ListfejlongNo ratings yet

- 8454 PDFDocument72 pages8454 PDFjon@libertyintegrationcom100% (3)

- Unimat3 Threading AttachmentDocument1 pageUnimat3 Threading AttachmentGelandangan GedeNo ratings yet

- Quorn User Manual PDFDocument31 pagesQuorn User Manual PDFtaiwest100% (1)

- 33 - Making Clocks PDFDocument65 pages33 - Making Clocks PDFBruno DelsupexheNo ratings yet

- MEB Issue 37 Screen Format-SDocument52 pagesMEB Issue 37 Screen Format-SPaolo Di Marco100% (1)

- SteamE MuncasterDocument29 pagesSteamE MuncasterchopenNo ratings yet

- Racing Gas Engine: Building A Twin CylinderDocument12 pagesRacing Gas Engine: Building A Twin Cylinder2n Tv100% (2)

- Quorn: Tool and Cutter GrinderDocument5 pagesQuorn: Tool and Cutter GrinderDan HendersonNo ratings yet

- MyfordDocument1 pageMyfordPeanut d. DestroyerNo ratings yet

- South Bend 9" Compound Slide Screw Fabrication For A Large Dial/Thrust Bearing Conversion by Ed Godwin 8 December, 2007Document16 pagesSouth Bend 9" Compound Slide Screw Fabrication For A Large Dial/Thrust Bearing Conversion by Ed Godwin 8 December, 2007asdfNo ratings yet

- Mini Milldiy PDFDocument6 pagesMini Milldiy PDFCelso Ari Schlichting100% (1)

- Balancing Grinder WheelsDocument8 pagesBalancing Grinder WheelsmountaineerjpNo ratings yet

- Lathe Schaublin 102n 9982Document1 pageLathe Schaublin 102n 9982FranciscoNo ratings yet

- WPS 39 Model Engineers Workshop Projects PDFDocument55 pagesWPS 39 Model Engineers Workshop Projects PDFabeeraj100% (3)

- 149-Workshop Hints & TipsDocument1 page149-Workshop Hints & TipssyllavethyjimNo ratings yet

- Quorn: Tool and Cutter GrinderDocument4 pagesQuorn: Tool and Cutter GrinderDan HendersonNo ratings yet

- OS Rotary Engine 49-PI Ype!!Document20 pagesOS Rotary Engine 49-PI Ype!!franco.didio1945No ratings yet

- Lathe Chuck Backplate FittingDocument2 pagesLathe Chuck Backplate FittingAnonymous iYKTkmhpZ100% (3)

- ChiltonDocument68 pagesChiltonAna Paula MalaquiasNo ratings yet

- Quorn: Tool and Cutter GrinderDocument4 pagesQuorn: Tool and Cutter GrinderDan HendersonNo ratings yet

- Quorn - Part 1-4Document24 pagesQuorn - Part 1-4catalin9494100% (4)

- Metal SpinningDocument4 pagesMetal SpinningfranklynNo ratings yet

- South Bend How To Make BushingsDocument12 pagesSouth Bend How To Make Bushingsjuliansimon100% (2)

- Rebuilding My Monarch 10EE LatheDocument5 pagesRebuilding My Monarch 10EE Lathesyllavethyjim100% (2)

- Ralph Patterson Tailstock Camlock 2Document13 pagesRalph Patterson Tailstock Camlock 2supremesportsNo ratings yet

- Clayton Steam Truck-Ocr PDFDocument76 pagesClayton Steam Truck-Ocr PDFbackyardcnc100% (1)

- A Rotary Sine Bar For The LatheDocument2 pagesA Rotary Sine Bar For The LatheTheodor EikeNo ratings yet

- More Tricks With The: "Quorn"Document5 pagesMore Tricks With The: "Quorn"Dan Henderson100% (1)

- Parts Price List Atlas Milli NG Machine: Atlas Press Company - Kalamazoo 13D Michigan - U.S.ADocument16 pagesParts Price List Atlas Milli NG Machine: Atlas Press Company - Kalamazoo 13D Michigan - U.S.Ataxmac100% (2)

- 02 - Vertical Milling in The Home WorkshopDocument93 pages02 - Vertical Milling in The Home Workshopj43951048No ratings yet

- Shaper Used As Surface GrinderDocument1 pageShaper Used As Surface Grinderradio-chaserNo ratings yet

- A Spark Erosion Machine: by C. R. AmsburyDocument11 pagesA Spark Erosion Machine: by C. R. AmsburyWedy Lim100% (1)

- Atlas M52 CatalogDocument36 pagesAtlas M52 Catalogbottomscraper100% (4)

- 2562 The Model EngineerDocument31 pages2562 The Model Engineerstilmix60No ratings yet

- Quorn - Part 2.CVDocument5 pagesQuorn - Part 2.CVAndy LNo ratings yet

- In The Workshop: Duplex "Document6 pagesIn The Workshop: Duplex "johnboy183No ratings yet

- Gear Cutting in Milling MachineDocument5 pagesGear Cutting in Milling MachineTrophie NilemoaNo ratings yet

- World of Model Engineering 01Document86 pagesWorld of Model Engineering 01Fransie1100% (4)

- Series 7 Lathes: Technical Support Explaining Changewheel Sets For Lathes With Changewheel Driven LeadscrewsDocument8 pagesSeries 7 Lathes: Technical Support Explaining Changewheel Sets For Lathes With Changewheel Driven LeadscrewsTomas MalyNo ratings yet

- Nano Ic EngineDocument12 pagesNano Ic EngineVinod JadavNo ratings yet

- SphericalturninglathetoolDocument14 pagesSphericalturninglathetoolFrenchwolf420No ratings yet

- BME Lecture 5 ShaperDocument6 pagesBME Lecture 5 ShaperRoop LalNo ratings yet

- Baby AceDocument16 pagesBaby AceAmy Shanley ParianoNo ratings yet

- Shop Made SlotterDocument4 pagesShop Made Slotternevadablue100% (4)