CBLM EPAS Core 2

CBLM EPAS Core 2

Uploaded by

International Technology Center IncCopyright:

Available Formats

CBLM EPAS Core 2

CBLM EPAS Core 2

Uploaded by

International Technology Center IncOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

CBLM EPAS Core 2

CBLM EPAS Core 2

Uploaded by

International Technology Center IncCopyright:

Available Formats

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 1

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 1 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 1 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 1

of 92

ELECTRONICS PRODUCT ASSEMBLY AND

SERVICING NCII

Sector : ELECTRONICS

Qualification Title/ Level : ELECTRONICS PRODUCT ASSEMBLY AND

SERVICING NCII

Unit of competency : SERVICE CONSUMER ELECTRONIC PRODUCTS

AND SYSTEMS

Module Title : SERVICING CONSUMER ELECTRONIC PRODUCTS

AND SYSTEMS

HOW TO USE THIS COMPETENCY BASED LEARNING MATERIAL

Welcome to the module in “SERVICE CONSUMER ELECTRONIC PRODUCTS AND SYSTEMS ”.This

module contains training materials and activities for you to complete.

You are required to go through a series of learning in order to complete each learning outcomes of this module.

In each learning outcomes are Information Sheets, Self Checks, operation sheets and job Sheets. Follow these

activities on your own. If you have questions, please don’t hesitate to ask your trainer for assistance.

The goal of this course is the development of practical skills. To gain these skills, you must learn basic concepts

and terminology. For most part, you’ll get this information from the information sheets and TESDA website,

www.tesda.gov.ph.

This module was prepared to help you achieve the required competency in“SERVICE CONSUMER

ELECTRONIC PRODUCTS AND SYSTEMS ”This will be the source of information for you to acquire

knowledge and skills in this particular competency independently and at your own pace, with minimum

supervision or help from your trainer.

Remember to:

Work through all the information and complete the activities in each section.

Read information sheets and complete the self check. Suggested references are included to supplement the

materials provided in this module.

Most probably your trainer will also be your supervisor or manager. He/She is there to support you and show

you the correct way to do things.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 2

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 2 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 2 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 2

of 92

You will be given plenty of opportunity to ask questions and practice on the job. Make sure you practice new

skills during regular working shifts. This way you will improve both your speed and memory and also your

confidence.

Use the Self Checks, Operation Sheets or Job Sheets at the end of each section to test your own progress.

When you feel confident that you have had sufficient practice, ask you trainer to evaluate you. The results of

your assessment will be recorded in your Progress Chart and Accomplishment Chart.

You need to complete this module before you can perform the next module

Recognition of Prior Learning(RPL)

If you can demonstrate to your trainer that you are competent in a particular skill, talk to him about having

them formally recognized so you would not have to undergo the same training again. If you have a qualification

or certificate of competency from previous training's, show it to your trainer. If the skills you have acquired are

still relevant to this module, they may become part of the evidence you can present for RPL. If you are not sure

about the level of your skills, discuss this with your trainer.

ELECTRONICS PRODUCT ASSEMBLY AND SERVICING NCII

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 3

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 3 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 3 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 3

of 92

COMPETENCY BASED LEARNING MATERIALS

LIST OF COMPETENCIES

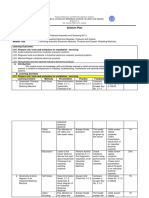

No. Unit of Competency Module Title Code

1 Assemble Electronic Products Assembling Electronic Products ELC724335

2 Service consumer electronic Servicing consumer electronic ELC724336

products and systems products and systems

3 Service industrial electronic Servicing industrial electronic ELC724337

modules, products and systems modules, products and systems

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 4

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 4 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 4 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 4

of 92

MODULE CONTENT

SERVICE CONSUMER ELECTRONIC

UNIT OF COMPETENCIES:

PRODUCTS AND SYSTEMS

SERVICING CONSUMER ELECTRONIC

MODULE TITLE:

PRODUCTS AND SYSTEMS

CONTENT:

Audio-Video products and systems

Different kinds of electrical power

Assembly Proper care and use of tools

Component

- Soldering Technology

- Reflow soldering

- Wave soldering

- Hand soldering

- RoHS and lead-free soldering

- Nonsolder Connections (terminal block

Corrective and preventive maintenance

Upgrading of technology

The role of rosters and their importance in controlling staff costs

Factors to be considered when developing rosters

Formats for the presentation of staff rosters and details to be included

Formats for the presentation of staff rosters and details to be included

Knowledge on area of operation for which roster is being developed.

Organizing information

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NOMINAL DURATION:

NC II 50 hours Issued By:

Page 5

Developed By:

of 92

LEARNING OUTCOMES: Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

At the end of this module

ASSEMBLY you MUST be able to:

AND SERVICING

NC II Issued By:

Developed By: Page 5 of

LO1. Prepare unit, tools and workplace for installation / servicing 92

LO2. Install industrial electronic modules/ products/ systems

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

LO3. Diagnose faults and defects

NC II

of industrial electronic modules/ products/systems

Issued By:

Developed By: Page 5 of

92

LO4. Maintain/Repair industrial electronic products

Document No.

LO5. Reassemble and test repaired Date

industrial electronic products

Developed:

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 5

of 92

SUMMARY OF ASSESSMENT CRITERIA:

1. Complete check-up of industrial electronic components, products and systems is conducted and defects are

identified, verified and documented against customer description.

2. Repair/maintenance history is verified in line with the company procedures.

3. Service manuals and service information required for repair/maintenance are acquired as per standard

procedure.

4. Workplace is set/prepared for repair job in line with the company requirements.

5. Necessary tools, test instruments and personal protective equipment are prepared in line with job

requirements

6. Materials necessary to complete the work are obtained in accordance with job requirements.

7. Consumer electronic products and systems are installed in accordance with manufacturer’s instructions,

requirements, and without damage to the surrounding place or environment

8. Devices are tested in accordance with standard procedures.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 6

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 6 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 6 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 6

of 92

9. Final inspections are undertaken to ensure that the installed devices conforms to technical requirements.

10. Unplanned events or conditions are responded to in accordance with established procedures

11. Work site is cleaned and cleared of all debris and left safe in accordance with the company requirements

12. Report on installation and testing of equipment is prepared according to company’s procedures/policies.

13. Systematic pre-testing procedure is observed in accordance with manufacturer’s instructions.

14. System defects/Fault symptoms are identified using appropriate tools and equipment and troubleshooting

techniques and in accordance with safety procedures

15. Test instruments required for the job are used in accordance with user manuals.

16. Circuits are checked and isolated using specified testing procedures

17. Identified defects and faults are explained to the responsible person in accordance with enterprise or

company policy and procedures

18. Control settings/adjustments are checked in conformity with service-manual specifications.

19. Results of diagnosis and testing are documented accurately and completely within the specified time.

20. Customers are advised/informed regarding the status and serviceability of the unit according to procedures.

21. Personal protective equipment is used in accordance with Occupational Health and Safety practices.

22. Electro-static discharge (ESD) protection procedure is followed in accordance with current industry

standards.

23. Defective parts/components are replaced with identical or recommended appropriate equivalent ratings

24. Repaired or replaced parts/components are soldered/mounted in accordance with the current industry

standards.

25. Control settings/adjustments are performed in conformity with service-manual specifications

26. Repair activity is performed within the required timeframe

27. Care and extreme precaution in handling the unit/product is observed as per procedures

28. Cleaning of unit is performed in accordance with standard procedures

29. Excess components and materials are disposed of based on WEEE directives and 3Rs waste management

program

30. Repaired units are reassembled according to procedures

31. Reassembled units are subjected to final testing and cleaning in conformity with manufacturer’s

specifications

32. Service completion procedures and documentations are complied with based on manual.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 7

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 7 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 7 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 7

of 92

33. Waste materials are disposed of in accordance with environmental requirements.

LEARNING OUTCOME SUMMARY

PREPARE UNIT, TOOLS AND WORKPLACE FOR

LEARNING OUTCOME 1 INSTALLATION / SERVICING

CONTENTS:

Audio-Video products and systems

- Radio receivers

- Audio recorders

Different kinds of electrical power

ASSESSMENT CRITERIA:

Assembly workplace is prepared in accordance with OH&S policies and procedures

Established risk control measures for work preparation are followed.

Work instructions are obtained and clarified based on job order or client requirements

Responsible person is consulted for effective and proper work coordination

Required materials, tools and equipment are prepared and checked in accordance with established procedures

Parts and components needed to complete the work are identified, prepared and obtained according to

requirements

CONDITION: Document No.

Date Developed:

The students/trainees must be provided

ELECTRONIC PRODUCTS with theSeptember

following:20, 2016

ASSEMBLY AND SERVICING

May include: NC II Issued By:

ESD-free

Developed By: work bench with mirror Page 8

Variable power supply Oscilloscope, digital of 92

Variable transformer High-grade magnifying glass with lamp

Soldering iron Flashlight/headlamp Document No.

Date Developed:

Hot airELECTRONIC

soldering station

PRODUCTS Cleaning brush

September 20, 2016

Table top reflow oven

ASSEMBLY AND SERVICING Soldering wire

Desoldering

NC II tools SMD soldering paste Issued By:

Page 8 of

Screwdriver (assorted) Developed By:

Stranded/solid/hook-up wires 92

Wrenches (assorted) Assorted electronic components

Allen wrench/key Assorted electronic sensors

Function/Signal generator Date Developed: Document No.

ELECTRONIC

Mufti-testers PRODUCTS

(analog/digital) September 20, 2016

Utility knife/stripper SERVICING

ASSEMBLY AND

NC II Issued By:

Pliers (assorted) Developed By: Page 8 of

ASSESSMENT METHOD: 92

Oral Questioning or Interview Document No.

Date Developed:

Practical Demonstration

ELECTRONIC PRODUCTS September 20, 2016

Third-party workplace

ASSEMBLY reports

ANDofSERVICING

on-the-job performance by the candidate

NC II Issued By:

Developed By: Page 8

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 9

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 9 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 9 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 9

of 92

LEARNING EXPERIENCES

Learning Outcome 1 : PREPARE UNIT, TOOLS AND WORKPLACE FOR INSTALLATION /

SERVICING

Learning Activities Special Instructions

Read Information Sheet 1.1 If you have some problems on Information Sheet 1-1,

don’t hesitate to approach your facilitator. If you feel

you are knowledgeable on the content of Information

Sheet 1-1, you can now answer Self-Check 1-1.

2. Answer Self Check 1.1 Compare your answer with the answer key 1-1. If you

got 100% correct answer in this self-check, you can

now move to the next information sheet. If not review

the information sheet and go over the self-check

again.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 10

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 10 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 10 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 10

of 92

INFORMATION SHEET 2.1-1

Audio-Video products and

systems

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 11

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 11 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 11 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 11

of 92

A. RADIO RECEIVER

What are the types of radio receivers?

It doesn't matter whether you are a short wave listener, an A.M. radio dx'er, into hobby electronics or amateur radio design, the

broad basic principles will still apply. Here we will briefly discuss the radio receiver basics as they apply to:

Basic crystal set.

A T.R.F. Receiver.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 12

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 12 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 12 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 12

of 92

A Superhetrodyne Receiver.

The Reflex Receiver.

This electronics tutorials site is totally free for you to use and is financed wholly by click revenue derived from our sponsors

who mainly advertise at the top of the pages and some other below. By visiting their different sites you demonstrate your very

practical support for this valuable free site and for our sponsors as well.

1. The first receiver built by a hobbyist is usually the plain old crystal radio set. If you are unfamiliar with the design then

check out the crystal radio set page.

2. The earliest receivers built were of the tuned radio frequency TRF variety. Here all the stages were made to tune

simultaneously to the received frequency. Some tuned radio frequency TRF receivers we very elaborate but suffered a number

of disadvantages overcome by the superhetrodyne principle.

3. A superhetrodyne receiver works on the principle the receiver has a local oscillator called a variable frequency oscillator or

V.F.O.

This is a bit like having a little transmitter located within the receiver. Now if we still have our T.R.F. stages but then mix the

received signal with our v.f.o. we get two other signals. (V.F.O. + R.F) and (V.F.O. - R.F).

In a traditional a.m. radio where the received signal is in the range 540 Khz to 1650 Khz the v.f.o. signal is always a constant

455 Khz higher or 995 Khz to 2105 Khz.

Several advantages arise from this and we will use our earlier example of the signal of 540 Khz:

(a) The input signal stages tune to 540 Khz. The adjacent channels do not matter so much now because the only signal to

discriminate against is called the i.f. image. At 540 Khz the v.f.o. is at 995 Khz giving the constant difference of 455 Khz which

is called the IF frequency. However a received frequency of v.f.o. + i.f. will also result in an i.f. frequency, i.e. 995 Khz + 455

Khz or 1450 Khz, which is called the i.f. image.

Put another way, if a signal exists at 1450 Khz and mixed with the vfo of 995 Khz we still get an i.f. of 1450 - 995 = 455 Khz.

Double signal reception. Any reasonable tuned circuit designed for 540 Khz should be able to reject signals at 1450 Khz. And

that is now the sole purpose of the r.f. input stage.

(b) At all times we will finish up with an i.f. signal of 455 Khz. It is relatively easy to design stages to give constant

amplification, reasonable bandwidth and reasonable shape factor at this one constant frequency. Radio design became somewhat

simplified but of course not without its associated problems.

We will now consider these principles in depth by discussing a fairly typical a.m. transistor radio of the very cheap variety.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 13

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 13 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 13 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 13

of 92

THE SUPERHETRODYNE TRANSISTOR RADIO RECEIVER

I have chosen to begin radio receiver design with the cheap am radio because:

(a) nearly everyone either has one or can buy one quite cheaply. Don't buy an A.M. / F.M. type because it will only confuse you

in trying to identify parts. Similarly don't get one of the newer I.C. types.

Just a plain old type probably with at least 3 transformers. One "red" core and the others likely "yellow" and "black" or "white".

Inside will be a battery compartment, a little speaker, a circuit board with weird looking components, a round knob to control

volume.

(b) most receivers will almost certainly for the most part follow the schematic diagram I have set out below.

(c) if I have included pictures you know I was able to borrow either a digital camera or had access to a scanner.

Important NOTE: If you can obtain discarded or broken "tranny's" (Australian for transistorised am radio receiver) by all means

do so because they are a cheap source of valuable parts. So much so that to duplicate the receiver as a kit project for learning

purposes costs about $A70 or $US45. Incredible. That is why colleges in Australia and elsewhere can not afford to present one

as a kit for students to construct.

THE REFLEX RADIO RECEIVER

Such a receiver includes a reflex amplifier and is one which is used to amplify at two frequencies - usually both the intermediate

and audio frequencies.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 14

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 14 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 14 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 14

of 92

Figure 1 - a.m. bcb radio schematic

There are no parts values shown as this schematic is purely for illustration purposes.

VIDEO RECORDER:

AUDIO SIGNAL

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 15

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 15 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 15 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 15

of 92

An audio signal is a representation of sound, typically as an electrical voltage. Audio signals have frequencies in the audio

frequency range of roughly 20 to 20,000 Hz (the limits of human hearing). Audio signals may be synthesized directly, or may

originate at a transducer such as a microphone, musical instrument pickup, phonograph cartridge, or tape head. Loudspeakers or

headphones convert an electrical audio signal into sound. Digital representations of audio signals exist in a variety of formats.

An audio channel or audio track is an audio signal communications channel in a storage device, used in operations such as

multi-track recording and sound reinforcement.

Signal flow

Signal flow is the path an audio signal will take from source (microphone) to the speaker or recording device. It is most

frequently in a recording studio setting, where the signal flow is often very long and convoluted as the electric signal may pass

through many sections of a large analog console, external audio equipment, and even different rooms.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 16

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 16 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 16 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 16

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 17

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 17 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 17 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 17

of 92

Parameters

Audio signals may be characterized by parameters such as their bandwidth, power level in decibels (dB), and

voltage level. The relation between power and voltage is determined by the impedance of the signal path, which

may be single-ended or balanced.

Audio signals have somewhat standardized levels depending on application. Outputs of professional mixing

consoles are most commonly at line level. Microphones generally output at a lower level, commonly referred to

a "mic level". Consumer audio equipment will also output at a lower level.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 18

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 18 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 18 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 18

of 92

Digital equivalent

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 19

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 19 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 19 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 19

of 92

As much of the older analog audio equipment has been emulated in digital form, usually through the development of audio

plug-ins for digital audio workstation (DAW) software, the path of digital information through the DAW (i.e. from an audio

track through a plug-in and out a hardware output) is also called an audio signal or signal flow.

A digital audio signal being sent through wire can use several formats including optical (ADAT, TDIF), coaxial (S/PDIF), XLR

(AES/EBU), and Ethernet

Audio editing software

An audio production facility at An-Najah National University

Audio editing software is software which allows editing and generating of audio data. Audio editing software can be

implemented completely or partly as library, as computer application, as Web application or as a loadable kernel module. Wave

Editors are digital audio editors and there are many sources of software available to perform this function. Most can edit music,

apply effects and filters, adjust stereo channels etc.

A digital audio workstation (DAW) consists of software to a great degree, and usually is composed of many distinct software

suite components, giving access to them through a unified graphical user interface using GTK+, Qt or some other library for the

GUI widgets.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 20

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 20 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 20 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 20

of 92

For use with music

Editors designed for use with music typically allow the user to do the following:

The ability to import and export various audio file formats for editing.

Record audio from one or more inputs and store recordings in the computer's memory as digital audio

Edit the start time, stop time, and duration of any sound on the audio timeline

Fade into or out of a clip (e.g. an S-fade out during applause after a performance), or between clips (e.g. crossfading between

takes)

Mix multiple sound sources/tracks, combine them at various volume levels and pan from channel to channel to one or more

output tracks

Apply simple or advanced effects or filters, including compression, expansion, flanging, reverb, audio noise reduction and

equalization to change the audio

Playback sound (often after being mixed) that can be sent to one or more outputs, such as speakers, additional processors, or a

recording medium

Conversion between different audio file formats, or between different sound quality levels

Typically these tasks can be performed in a manner that is non-linear. Audio editors may process the audio data non-

destructively in real-time, or destructively as an "off-line" process, or a hybrid with some real-time effects and some off-line

effects.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 21

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 21 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 21 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 21

of 92

DVD/VCD Player

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 22

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 22 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 22 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 22

of 92

Problems playing/reading certain CDs

While you may be tempted to blame *Big Brother* and some sort of diabolical copy protection scheme, I doubt

that CD dependent behavior has anything to do with a lower intelligence at work. :) More likely, it is a bad

quality control on the pressing. (This assumes your CD isn't one of those which has 85 minutes of music

squeezed into a 74 minute space. See the section: Problems with extended length discs.)

First, check for physical damage or imperfections on both sides of the CD. Even if you find nothing, trying a

replacement disc would probably be a good idea before ripping apart your CD player.

However, it may just be CD which produces an unusually low signal level.

Depending on manufacturer, the signal level from CDs can vary by quite a large amount - maybe 30 percent

(just guessing). Telarc discs were (maybe still are) particularly bad in this regard. CD-Rs are also quite variable

and generally worse than normal CDs. (See the section: Problems reading CD-Rs). If the player is somewhat

marginal to begin with (no way to really predict this), low signal level may mean either it won't recognize the

disc at all or will be subject to skipping, audible noise, and other play problems.

An internal adjustment might help but my advice would be that if it only occurs with a small percentage of CDs,

better to leave well enough alone.

However, a proper lens cleaning won't hurt! See the section: "General inspection, cleaning, and lubrication". If

you really won't sleep knowing there might be something else you can do, see the "General servo adjustment

procedure". I definitely don't recommend attempting to boost laser power - which would be considered a last

resort.

Note that newer CD players and CDROM drives may be more tolerant of damaged discs as well as CD-Rs

(which became popular only relatively recently) - you may just be expecting too much from that 15 year old

machine!

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 23

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 23 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 23 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 23

of 92

Problems with extended length discs

The specifications for the length of an audio CD is just over 74 minutes. I have seen them as long as 78 or 80

minutes which means that some of the basic CD specifications have been compromised - either the track pitch

has been reduced or the track extends closer to the outside edge of the disc - or both. If the track pitch has been

reduced, there could be tracking or audible noise problems throughout the disc. If the track extends closer to the

outer edge, there could be problems near the end of the discs. The player may not these discs at all. Any of the

following symptoms are possible:

No problems. Your player is one of those that is perfectly happy playing really long CDs. Most players will

indeed be unaffected.

The disc may be rejected resulting in the display showing 'disc' or 'error' as though damaged, improperly

inserted, or missing. In this case, the CD player's microbrain simply thinks anything with a total playing time

exceeding 74 minutes and 15 seconds is invalid.

Unless you want to redesign the player, there is nothing you can do to play these CDs. It might only require

changing a single byte in the player's firmware :-).

There may be more of a tendency for skipping, sticking, or audible noise (probably near the end though it could

happen anywhere if the track pitch has been reduced - including inability to read the disc's directory) since the

servos are operating slightly outside their normal range. The actual likelihood of these types of problems are

very slight, however.

It may be possible to adjust the servos as described in the chapter: "Servo Systems and CD Player Adjustments".

As with any adjustments, there is some risk of affecting performance for all discs - or totally messing things up.

Or, if problems only occur near the end of these discs, just don't play them to the end!

The sled on which the pickup is mounted ventures into new territory where no sled has ventured before (at least

on this player). Dirt, gummed up grease, hair, and other garbage may have collected there resulting in the sled

drive mechanism getting stuck. You may hear whirring, buzzing, or clicking as the motor attempts to move the

immovable - or nothing at all. Eventually, the player should probably shut down. In any case, kill power or

remove the batteries to prevent damage to the gears.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 24

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 24 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 24 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 24

of 92

With luck, all you need to do is move the sled manually toward the spindle by turning the proper gear (freeing it

up first, if necessary). Then clean and relube the track and gears. Hopefully, nothing is actually damaged since

locating a replacement part may prove to be a challenge.

The sled simply overran the end of the rack and the drive gear no longer is capable of returning it to more

familiar territory. You may hear some whirring, buzzing, or clicking as the gears attempt to mesh but do not

quite succeed.

Manually moving the sled so that the drive gear meshes with the rack - and then turning it a bit to be sure -

should restore operation but, of course, you should not attempt to play these extended length discs to the very

end in the future.

Problems reading CD-Rs

CD-Rs (recordable CDs, usually gold on the label side and greenish (or with newer ones like various

PlayStation discs, some other strange color) on the readout side) can be quite variable in quality. They are often

produced on a low cost writer of questionable design and calibration. It is quite common for a CD-R disc to

play/read fine on one drive and not be recognized at all on another. There may not be any relation between cost

of the CDROM drive and its reliability with CD-Rs.

Note that newer CDROM drives (and probably CD players as well) may be more tolerant of CD-Rs (as well as

of damaged normal CDs). 1X and even 4X CDROMs (as well as older CD players) predated the wide

availability of CD-Rs so they weren't designed with them in mind. As a byproduct, newer technology may be

more tolerant of bad normal CDs as well. So, there may in fact be an advantage to using high-X CDROM

drives! So, it still has nothing to do with the high-X part, just that the low level circuits are smarter!

Problems recording CD-Rs

Consistently recording high quality CD-Rs is by no means as fool-proof as reading typical CDs. Any problems

affect the recording quality permanently.

Media - there is significant variability in the quality and consistency of CD-R blanks from different

manufacturers. You may have to experiment with multiple brands to determine those that work for you in your

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 25

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 25 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 25 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 25

of 92

CD-R writer.

Recorder - there may be significant variability in the performance of various manufacturer's hardware. High

price may not translate into high quality especially considering the rapid changes in the industry.

Writing speed - while it really should not matter whether you record at 1X or 4X (or whatever your machine

supports), this may not actually be the case. If the servo systems are less stable at the higher rate, the quality of

the recorded information may suffer. Thus, writing at a slower rate may be better - or may not matter. In any

case, experimentation at different writing speeds should determine if this is an issue.

Media cleanliness - you only get one shot. A speck of dust or fingerprint - which might just decrease the signal

to noise ratio when reading a CD - can degrade the writing laser beam resulting in malformed pits (oh no, not

the dreaded malformed pit disease!). Inspect each CD-R blank before inserting it into the writer. Reject it if you

see any visible surface damage or manufacturing defects. Use clean, dry compressed air if necessary to blow off

any dust or fluff. Clean the surface as you would a CD to remove any fingerprints or smudges.

Equipment maintenance - keep the recorder clean - periodic inspection and cleaning similar to that used for CD

players may be needed if it is used in a less than ideal environment - dust, smoke, and cooking vapors can

quickly coat the lens leading to lower quality recordings. Inspect, clean, and replace (as necessary) the caddies

(if used) as well since dirty or damaged caddies can cause problems as well.

Data under-runs - where the recorder does not have an internal buffer of sufficient size (yeh, like 650 MB!), it

expects to be fed at a high enough rate to always have data available to send to the writing laser. Any failure

will likely result in incorrect data being written - and probably a ruined disk. Some recorder software will

simply abort. Even running another application like a screen saver can result in uncertainties with respect to

data availability. When in doubt or where time is available, run the recorder at a slower speed to reduce the

required datarate.

Mechanical shock - locate the recorder on a stable surface - not the top of a printer or other equipment that may

be subject to movement during the duration of a recording session. Any vibration transmitted to the optical deck

may cause a momentary shift in the position of the lens and laser beam reducing the recording quality. Bump it

hard enough and the result will be mistracking and a ruined disk.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 26

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 26 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 26 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 26

of 92

There's an area of the CD-R disc used specifically to "calibrate" the laser. Since all disks have different needs

(gold versus blue/green dye, for example) one-for-all power level won't do. If you laser has lost its power (they

DO have a very finite life) which may be due to end-of-life OR dust on the lens (always consider a lens and any

other accessible optics cleaning first!), it will FAIL this write-test and you will get what you are seeing. I would

try a different color dye CD-R disc and see if there is one type it can still write to.

From what I read, there is enough "write-space" in the laser-power-test area of the CDR for close to 1000 tests -

which is why a new drive may work fine with your rejected discs.

So, clean the lens, then try different types/colors of CD-R discs and then, if that still yields no results, write off

the drive as "got my money's worth" and use it as a reader.

Voice (almost) missing from CD playback

My first thought would be to say "how can the electronics know about the voice separately?" Well, the answer is

"it cannot". However, due to the way vocals are often recorded, this behavior is possible, if unlikely. What must

happen is for the audio output to be the difference between the left and right channels mostly cancelling the

centered vocal track but not having as much effect on the audibility of the instruments.

It is possible for this to happen as a result of a bad ground connection or an electronic fault in the analog

circuitry following the D/A stage but it is quite unlikely to be due to a problem in the optical pickup or digital

decoding - though not out of the question.

What is suggested below can happen by accident should the shield connection to the headphone or line out jack

or cable become disconnected.

Actually, it is possible. Modify a headphone so that the two ground conductors are still connected together and

to each earpiece, but no longer connected to the sleeve of the headphone jack. The two "hots" remain connected

to tip and ring on the jack. Plug it in to a portable CD player and listen to a pop or country CD with (preferably)

a solo vocalist.

The vocals will almost disappear, while the instruments will still be quite audible (although now in mono).

Normally, the lead vocals are 'centered' in the stereo imaging and are in phase on each channel. The instruments

are panned more or less left or right. When you rewire the headphones, you effectively place the two

transducers in series, and they are now wired out of phase with each other (the two "-" terminals are connected

together on what used to be the ground lead, and the two "+" terminals are connected to their respective signal

outputs from the channels - effectively since they are now in series, they are wired out of phase). Any signal

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 27

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 27 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 27 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 27

of 92

which is "identical" and "in phase" on both left and right channels tends to cancel - the vocals. Signal which is

not identical on each channel appears as the difference between the two sides - the instruments.

Some recordings are not made this way and this will have little or no effect - you may have to try a few CD's to

experience the 'phenomena'.

Problems with anti-skip buffers

Newer portable CD players often offer an extra cost option of an 'anti-skip' capability - usually about 10 seconds

of buffer memory. While there is probably little you can do to repair an electronic or logical problem with this

memory, there are a couple of points to keep in mind which may lead to the repair of problems like erratic anti-

skip performance, noise, dropouts, skipping, and other symptoms dealt with elsewhere in this document.

Anti-skip is actually implemented by reading ahead on the CD and storing up to 10 seconds of digital audio in

dynamic random access memory (DRAM). This has a direct impact on optical deck performance and power

requirements:

To read ahead, the player must actually operate at a higher than normal (1X) speed. Watching a player with this

feature, it would appear to be close to 2X. This puts a greater strain on motors and servo systems so anything in

the optics or servo alignment that is marginal - or even a dirty lens - may result in problems which do not show

up with the anti-skip feature turned off. In addition, there are likely to be more problems reading marginal CDs

or CD-Rs. See the section: CD player with skip buffer fails with some CD-Rs.

Power requirements are also greater with anti-skip on - the spindle motor and servos need to work harder and

the buffer DRAM may require greater power when being accessed. Therefore, weak batteries or an inadequate

wall adapter may result in erratic operation. If possible, try fresh batteries or a different adapter before warming

up the oscilloscope.

CD player with skip buffer fails with some CD-Rs

This was an odd problem posted to the newsgroup sci.electronics.repair:

"I am having an odd problem with my new portable cd player. It is a Panasonic with 10-second skip protection.

I made an audio compilation CD with my CD-burner. This CD works fine with my CDROM drive and home

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 28

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 28 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 28 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 28

of 92

CD player. In fact it works fine with the Panasonic UNTIL I turn on the skip protection. Then it plays for

awhile, and for no apparent reason the seconds run out and it hangs up and displays the message 'Sorry'."

Your player is having trouble tracking the CD-R. Likely causes:

The CD-R burner or software is producing discs whose layout is slightly off spec. A firmware or software

upgrade may help if available.

The CD-R burner works better with some types of blanks than others; and you've just discovered the ones it

DOESN'T work well with. Try a different brand and color.

You are using poor quality CD-R blanks which have an unacceptably high bit error rate, eccentricity of the

spiral groove, or both.

You are burning the disc as a speed which does not give the lowest error count with the media you are using -

try faster or slower. Usually 2X write speed gives the best pit structure on the widest variety of media.

Your CD-R burner is in need of calibration or laser replacement, resulting in poor pit shape. Have you tried an

OPC test to see if it is delivering the right power?

I have a Panasonic portable and have experienced the same thing with two Maxell CD-R's received in a trade.

Of the dozens of CD-R's I own, these two, burned by the same person, are the only ones that cause trouble. For

that reason I believe it is not the player but the discs that are "off".

(From: Andy Cuffe (baltimora@psu.edu).)

In skip protection mode the disc is played a double speed so it can keep the memory full. It must be having

trouble tracking these discs at the higher speed, but is able to play them at normal speed. It's either a problem

with the CD-Rs or just the way the player is.

Problems with CDROM drives

The newest CDROM drives operate at 12X speed or greater. Such performance puts significant strain on the

motors and servo systems. Even 2X speed means substantially higher demands of the electronics and power

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 29

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 29 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 29 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 29

of 92

systems. Thus, you may find that a drive will play audio CDs flawlessly but have trouble reading data files.

While there is probably little you can do to repair an electronic or logical problem without schematics - which

are almost certainly not going to be available, there are some things to keep in mind which may lead to the

repair of problems like erratic or total failure of data readback.

The first test for any CDROM problem is to force the drive to the 1X (or some slower speed than its maximum

specifications) and see if that helps. Your drive may have come with instructions/software to operate at a

selected speed.

Data readout must be flawless. Uncorrectable errors which may not be noticed for audio playback would result

in corrupted files. Thus, anything that is marginal may significantly impact performance. If it still has trouble

with data even at the 1X speed, something may be marginal or there may be a true problem in the decoding

logic or computer interface.

Multi-X performance puts a much greater strain on motors and servo systems so anything in the optics or servo

alignment that is marginal - or even a dirty lens - may result in problems which do not show up with audio CDs

played at the 1X speed. Thus, once a dirty lens is ruled out by cleaning it, some fine tuning of the servo systems

may be needed.

At the high rotation rates used with the latest drives, even the slight imbalance caused by a label that is not

uniform across the disc can result in enough vibration to affect the servo systems and result in an increase in

data transfer error rate, mistracking, or even loss of focus and shutdown. There may be no problem with the

drive itself - just the disc. It may be possible to add a small sticky label to the disc in a strategic location to

improve balance. However, if the label is not very secure, it may fly off due to centrifugal force at high rpms

and create yet another problem inside the drive. Some quick drying paint might be better. If only there were a

tire balancing type machine for CDs!

Power requirements are substantially greater at the higher speeds - the spindle motor and servos need to work

harder and even the electronics may require greater power. Therefore, weak batteries in laptop computers or

CDROM drives operated off of laptop power or an inadequate wall adapter may result in erratic operation. If

possible, try fresh batteries or a different adapter before warming up the oscilloscope.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 30

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 30 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 30 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 30

of 92

Portable CD player/CDROM drive power considerations - batteries

As with all equipment operated from a batteries, there are specific requirements that must be met for reliable

and safe operation.

Batteries must be of the proper type. Some devices will work on either Alkaline or rechargeable NiCd types.

However, since NiCds put out less voltage than fresh alkalines, there may be a selector switch or the instruction

manual may state that NiCds should not be used. Batteries should be fresh - the motors, servo systems, and

electronics in a CD player or CDROM drive can be a significant load when seeking or spinning up. A weak

battery may cause it to shutdown erratically or never be able to find the selected track. Do not mix new and used

cells. This can result in poor performance and may actually result in damage to the cells where rechargeable

(NiCd) types are involved.

Some CD players use a sealed lead-acid battery pack. For long life, these must be recharged immediately after

use. Leaving a lead-acid battery pack in a discharged condition will significantly shorten its life. And these are

not cheap! A pack for a typical Sony CD player may cost more than $20.

Portable CD player/CDROM drive power considerations - AC adapters

As with all equipment operated from a wall adapter, there are specific requirements that must be met for reliable

and safe operation:

Voltage. The CD player or other device will specify the nominal input voltage. This must be adhered to - you

cannot connect a 3 V CD player to a 12 V adapter (or auto battery, for that matter). It will become toast.

However, not all wall adapters are created equal. Some are very poorly regulated meaning that even though its

label says something like '9V', the actual output may be as much as double this (or more) with no load. This

may not be acceptable. The device may overheat or be damaged or destroyed nearly instantly. Internal

protection devices may blow (if you are lucky!). It is safest to follow the manufacturer's recommendations

(though, admittedly, they may be pushing their own brand of adapter). My rule of thumb is that if the unloaded

output voltage is within about 25% of the specified requirements, it is probably safe to use. However, when

connecting for the first time, be on the lookout for any strange behavior (or strange odors!).

Current. The required current should be stated somewhere - either on the device itself or in the instruction

manual. If only power is specified (i.e., 9 V, 4.5 W), then divide power in watts by voltage to get the current

rating in A. (1 A = 1000 mA). The adapter must be capable of putting out at least this amount of current though

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 31

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 31 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 31 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 31

of 92

a modestly higher current rating should be no problem. Using an adapter with an inadequate current rating may

result in erratic behavior or overheating and failure of the adapter.

Polarity. All the portable CD players and CDROM drives I know of operate on DC. Thus polarity is critical. Get

it backwards and at best nothing will happen but nothing will work either. However, the equipment and/or

adapter may be damaged - permanently. Internal protection devices may blow - if you are lucky.

Regulation. It is often impossible to determine whether the device expects regulated power or whether a given

AC adapter provides it without tests. There are both types. Higher voltage AC adapters (say, 6 V or above) often

tend to be just rectifier/filter capacitor types. However, low voltage adapters (e.g., 3 V) may have an IC

regulator built in.

As noted in the section: CD player is totally dead, it is easy to destroy a portable device using an improper

power adapter or a universal adapter that is configured incorrectly.

Boomboxes and compact stereo systems

These combine a stereo receiver and a single or dual cassette deck, and/or a CD player or changer, and a pair of

detachable speakers, into a single unit. Most are fairly portable but larger boomboxes and compact stereos may

require a forklift to move any great distance.

While the individual subsystems - CD player for example - are usually relatively self contained electrically

except for a common power supply, mechanically, everything tends to be jumbled together - even on units that

have an outward appearance of separate components. Both cassette transports are usually driven from a single

motor. Getting at the CD player may require removal of both cassette decks, audio amplifier, and power supply.

Working on these is not fun. As usual, take careful notes as you disassemble the unit and expect it to require

some time just to get to what you are after. Be especially careful when removing and replacing the individual

modules if printed flex cables are used for interconnections.

Refer to the relevant sections on cassette transports, loudspeakers, and power supplies for problems with these

units.

Since these do get abused - bumped, dropped, dunked, etc., bad connections, and other damage is very common.

See the sections: "Intermittent or erratic operation" as well as "Audio muting, noise, or distortion".

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 32

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 32 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 32 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 32

of 92

CD player was dropped or got wet

I have never heard of a component CD player being dropped or rained on. However, this does happen to

portables. While a service shop may not even want to tackle such a unit, it is quite possible that damage is

minimal - even for a CD player.

With a CD player that has been dropped, unplug it from the AC line or remove the batteries immediately. This

will prevent further damage should anything be shorting internally.

For one that has gotten wet, dry it immediately (you knew that!).

See the document: Audio Equipment and Other Miscellaneous Stuff for more info on restoration of abused

audio equipment.

Repairing flexible printed cables

It seems that more and more consumer devices from pocket cameras to laptop computers are being built with

miniature multiconductor flexible printed cables. Very often one or more traces to develop hairline cracks due to

repeated flexing. In addition, damage from moving circuit boards and modules during servicing is all to

common.

Needless to say, repairing any kind of flex cable is a real pain. I have succeeded by carefully scraping the plastic

off with an Xacto knife and then soldering fine wire (#30 gauge wire wrap for example) to the traces. This

presumes that the conductors on your cable will even take solder. I then cover up the joints with a flexible sealer

for electrical and mechanical protection.

However, you need to make sure that the wire you use can be flexed or that the joint is set up in such a way that

the wire does not flex much - else you will just end up with broken wires pretty quickly.

Here is another alternative if the flexing of the cable prevents the use of ordinary wire for jumpers: Find a piece

of somewhat similar flex cable cable from a dead piece of equipment. Use it to jumper across the high stress

area and then solder it to the other cable with short wires if necessary. Then coat the connections as above.

Soldering from end point to end point if possible may be preferable. Even going to only one endpoint would

reduce the risk of immediate damage and reliability problems in the future.

With multiple traces broken or damaged, you are probably better off replacing the cable entirely. With the

typical flex cables found in CD players, there is often no way to repair a large number of broken traces and

retain your sanity.

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 33

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 33 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 33 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 33

of 92

CD player whine

CD players are generally nearly silent during play (though they may make a variety of whirring and clicking

noises when loading discs, initializing, or seeking). The only sound normally eminating from inside the machine

during play might be a very faint gritty noise from the focus and tracking actuators.

Thus, a sustained whine would generally be considered abnormal.

There are two likely causes:

Worn spindle motor bearings can result in a high pitched whine. In this case, adding a drop of oil may quiet it

down temporarily but replacement will eventually be needed.

The whining noise may be the laser/chassis assembly resonating with the CD as it spins. Depending on the

model, there is a cure - adding a weight or damping material to the pickup or the chassis to change the resonant

frequency.

To confirm that this is your problem, gently rest your finger on the rotating clamper disk and/or other parts of

the optical deck while it is whining - the whine should change or disappear. If you can locate a particularly

sensitive spot, try gluing a piece of heavy rubber to this location (even if it is the clamper disk) with rubber

cement. If this solves the whine problem, confirm that discs seek and play correctly for all tracks before

buttoning it up.

For more details on Sony problems, see the section: Audio whine (not from speakers) and/or muddy sound with

Sony CD players.

(From: Joel B. Levin (levinjb@gte.net).)

If this were the problem it would be highly dependent on the CD's speed of rotation, which varies as the disc is

played. If it always happened N minutes into the disc and went away a few minutes later as the disc slowed

down (and came back if you repeated the track) I would consider that definitive of a resonance problem.

I would try lubricating the shaft of the spindle motor, and check to see if the motor brushes might be partially

shorted. (not to worry you at this early stage, but sometimes Sony pickups, especially the KSS240 and KSS212

and 213, have resonance problems, often just as the disc is coming to speed.) This is the subject of at least a

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 34

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 34 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 34 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 34

of 92

couple service bulletins. Can often be heard as a whistling tone coming from the mechanism usually

intermittent, and can be observed in the focus error and tracking error lines as a sine wave overriding what

should be essentially a random noise signal. Occasionally the resonance gets so pronounced the disc won't even

spin up.

It happens with some Pioneers as well. It's not a common symptom, but it is the pickup at fault. Look at the

focus error line and you'll see a sine wave riding on it. There is essentially a feedback loop existing between the

spindle motor/subchassis and the pickup. I've seen various attempts to damp it out but replacing the pickup fixes

it every time in my experience.

It's possible that a loose lens can result in a resonant condition so check that the lens is secure. If it falls out in

your hand, gluing it back in place should solve the whining and prevent a future problem.

Noisy CD player

CD players are not silent despite all the hype to the contrary. The focus and tracking actuators act like voice

coils in loudspeakers produce various chirps and hisses while playing a CD. When seeking, the sled motor adds

its own additional instrumental accompanyment. :)

As they say, "If it ain't broke, don't fix it." Assuming it plays CDs fine and has always been this way (or you

don't recall how it was when you first got it), leave well enough alone.

If you do decide to twiddle pots, mark their original position carefully before doing anything! The ones most

likely to have any effect are the gain controls for focus and tracking. Lowering the gain slightly (perhaps 1/8th

of a turn counterclockwise) will reduce the noise level - but may also result in more susceptibility to skipping

from vibration. Turn them too far and the disc will no longer even be recognized. These adjustments don't

generally change on their own so think several times before possibly making matters worse.

Perhaps, putting the CD player in a box padded with sound deadening insulation would be a simpler solution if

the noise bothers you!

Also see the section: CD player whine.

Objective lens popped out

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 35

of 92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 35 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 35 of

92

Date Developed: Document No.

ELECTRONIC PRODUCTS September 20, 2016

ASSEMBLY AND SERVICING

NC II Issued By:

Developed By: Page 35

of 92

Don't expect to see this one too often. However, on some Pioneer changers where the pickup is mounted upside-

down, tired pickup suspension grommets, excessive heat, age, long use with warped discs, or just bad luck, has

apparently resulted in the adhesive holding the objective lens in place to come unglued, as they say. :-) In some

cases, it is still attached but loose, which will also prevent the player from working but may be easier to fix than

one that is rolling around at the bottom of the cabinet.

The best solution is to replace the entire pickup. However, you have nothing to lose by attempting to reattach

the lens IF you can locate it AND its optical surfaces are undamaged from the ordeal. If either of these is not the

case, you will probably have to install an entire new pickup. Swapping of a lens from another player is even less

likely to work unless it uses a similar pickup from the same manufacturer and then only with great pain. But in

many instances, Murphy has taken the day off because (1) the optical surfaces are recessed and relatively well

protected from bumping into stuff and (2) there are no holes in the cases of these players for the lens to sneak

through and get lost (that is, until you remove the cover not realizing the lens is trying to escape!).

It may be essential to line up the lens in EXACTLY the same position as it was originally in terms of centering

as well as the same orientation to have any chance of success. (However, I've never actually seen this):

The lens must be centered for the return beam to be properly aligned with the photodetector array.

It is possible that some lenses are astigmatic (not circularly symmetric) to implement the focus servo (rather

than using a separate cylindrical lens or thick beam splitter mirror for this purpose). For these, the orientation is

also critical. When this is the case, there will be a reference on the lens for this purpose. On Sony pickups, for

example, there is a flat filed on one edge of the lens. (You always wondered why the lenses in all your Sony CD