Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General Application

Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General Application

Uploaded by

عصام السامرائيCopyright:

Available Formats

Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General Application

Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General Application

Uploaded by

عصام السامرائيOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General Application

Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General Application

Uploaded by

عصام السامرائيCopyright:

Available Formats

Designation: A297/A297M − 14

Standard Specification for

Steel Castings, Iron-Chromium and Iron-Chromium-Nickel,

Heat Resistant, for General Application1

This standard is issued under the fixed designation A297/A297M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. General Conditions for Delivery

1.1 This specification covers iron-chromium and iron- 3.1 Except for investment castings, material furnished to

chromium-nickel alloy castings for heat-resistant service. The this specification shall conform to the requirements of Speci-

grades covered by this specification are general purpose alloys fication A781/A781M, including any supplementary require-

--`,,,,,`,`,,``,`,,``,,`````,``,-`-`,,`,,`,`,,`---

and no attempt has been made to include heat-resisting alloys ments that are indicated in the purchase order. Failure to

used for special production application. comply with the general requirements of Specification A781/

NOTE 1—For heat-resisting alloys used for special product application, A781M constitutes nonconformance with this specification. In

reference should be made to Specification A351/A351M, A217/A217M, case of conflict between the requirements of this specification

and A447/A447M. and Specification A781/A781M, this specification shall pre-

1.2 The values stated in either SI units or inch-pound units vail.

are to be regarded separately as standard. The values stated in 3.2 Investment castings furnished to this specification shall

each system may not be exact equivalents; therefore, each conform to the requirements of Specification A957/A957M,

system shall be used independently of the other. Combining including any supplementary requirements that are indicated in

values from the two systems may result in non-conformance the purchase order. Failure to comply with the general require-

with the standard. ments of Specification A957/A957M constitutes nonconfor-

2. Referenced Documents mance with this specification. In case of conflict between the

requirements of this specification and Specification A957/

2.1 ASTM Standards:2 A957M, Specification A957/A957M shall prevail.

A217/A217M Specification for Steel Castings, Martensitic

Stainless and Alloy, for Pressure-Containing Parts, Suit- 4. Ordering Information

able for High-Temperature Service

A351/A351M Specification for Castings, Austenitic, for 4.1 The inquiry and order should include or indicate the

Pressure-Containing Parts following:

A370 Test Methods and Definitions for Mechanical Testing 4.1.1 A description of the casting by pattern number or

of Steel Products drawing (dimensional tolerances shall be included on the

A447/A447M Specification for Steel Castings, Chromium- casting drawing),

Nickel-Iron Alloy (25-12 Class), for High-Temperature 4.1.2 Grade of steel,

Service 4.1.3 Options in the specification, and

A781/A781M Specification for Castings, Steel and Alloy, 4.1.4 The supplementary requirements desired including the

Common Requirements, for General Industrial Use standards of acceptance.

A957/A957M Specification for Investment Castings, Steel

and Alloy, Common Requirements, for General Industrial 5. Process

Use

5.1 Alloys shall be made by the following processes:

1

electric-arc, electric-induction, or other approved processes.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.18 on Castings. 6. Heat Treatment

Current edition approved May 1, 2014. Published June 2014. Originally

approved in 1946. Last previous edition approved in 2010 as A297/A297M – 10. 6.1 Castings for heat-resistant service may be shipped in the

DOI: 10.1520/A0297_A0297M-14.

2

as-cast condition without heat treatment. If heat treatment is

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

required, the treatment shall be established by mutual agree-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on ment between the manufacturer and the purchaser and shall be

the ASTM website. so specified in the inquiry, contract, or order.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright ASTM International

Provided by IHS under license with ASTM

1Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/01/2015 04:42:45 MST

A297/A297M − 14

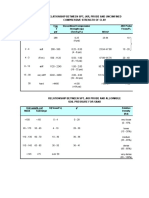

TABLE 1 Chemical RequirementsA

Grade/ Composition, % (max, except where range is given)

Type

UNS Number Carbon Manganese Silicon Phosphorus Sulfur Chromium Nickel MolybdenumB OtherC

HF 19 Chromium, 0.20–0.40 2.00 2.00 0.04 0.04 18.0–23.0 8.0–12.0 0.50

J92603 9 Nickel

HH 25 Chromium, 0.20–0.50 2.00 2.00 0.04 0.04 24.0–28.0 11.0–14.0 0.50

J93503 12 Nickel

HI 28 Chromium, 0.20–0.50 2.00 2.00 0.04 0.04 26.0–30.0 14.0–18.0 0.50

J94003 15 Nickel

HK 25 Chromium, 0.20–0.60 2.00 2.00 0.04 0.04 24.0–28.0 18.0–22.0 0.50

J94224 20 Nickel

HE 29 Chromium, 0.20–0.50 2.00 2.00 0.04 0.04 26.0–30.0 8.0–11.0 0.50

J93403 9 Nickel

HT 15 Chromium, 0.35–0.75 2.00 2.50 0.04 0.04 15.0–19.0 33.0–37.0 0.50

N08605 35 Nickel

HU 19 Chromium, 0.35–0.75 2.00 2.50 0.04 0.04 17.0–21.0 37.0–41.0 0.50

N08004 39 Nickel

HW 12 Chromium, 0.35–0.75 2.00 2.50 0.04 0.04 10.0–14.0 58.0–62.0 0.50

N08001 60 Nickel

HX 17 Chromium, 0.35–0.75 2.00 2.50 0.04 0.04 15.0–19.0 64.0–68.0 0.50

N06006 66 Nickel

HC 28 Chromium 0.50 max 1.00 2.00 0.04 0.04 26.0–30.0 4.00 0.50

J92605

HD 28 Chromium, 0.50 max 1.50 2.00 0.04 0.04 26.0–30.0 4.0–7.0 0.50

J93005 5 Nickel

HL 29 Chromium, 0.20–0.60 2.00 2.00 0.04 0.04 28.0–32.0 18.0–22.0 0.50

N08604 20 Nickel

HN 20 Chromium, 0.20–0.50 2.00 2.00 0.04 0.04 19.0–23.0 23.0–27.0 0.50

J94213 25 Nickel

HP 26 Chromium, 0.35–0.75 2.00 2.50 0.04 0.04 24–28 33–37 0.50

N08705 35 Nickel

HG10 19 Chromium, 0.07–0.11 3.0–5.0 0.70 0.040 0.03 18.5–20.5 11.5–13.5 0.25–0.45 Cu 0.50

MNN 12 Nickel, Nb(Cb)D N

J92604 4 Manganese 0.20–0.30

CT15C 20 Chromium, 0.05– 0.15 0.15– 1.50 0.15– 1.50 0.03 0.03 19.0–21.0 31.0–34.0 { Nb 0.50–

N08151 33 Nickel, 1.50

--`,,,,,`,`,,``,`,,``,,`````,``,-`-`,,`,,`,`,,`---

1 Niobium

A

Where ellipses ({) appear in this table there is no requirement, and the element need not be analyzed or reported.

B

Castings having a specified molybdenum range agreed upon by the manufacturer and the purchaser may also be furnished under these specifications.

C

Niobium (Nb) and Columbium (Cb) both designate element 41.

D

Grade HG10MNN shall have a niobium content of not less than 8 times the carbon, but not over 1.00 %.

7. Chemical Composition 8.3 Weld repairs shall be considered major when the depth

7.1 Alloys shall conform to the requirements as to chemical of the cavity after preparation for repair exceeds 20 % of the

composition prescribed in Table 1. actual wall thickness, or 1 in. [25 mm], whichever is smaller,

or when the extent of the cavity exceeds approximately 10

8. Repair by Welding in.2 [65 cm2].

8.1 Except for Grade HG10MNN, the composition of the 8.3.1 When Supplementary Requirement S7 is specified on

deposited weld metal shall be similar to the composition of the the purchase order, or inquiry, major weld repairs shall be

casting. For Grade HG10MNN, the filler metal to be used shall subject to the prior approval of the purchaser.

be established by mutual agreement between the manufacturer

and the purchaser. All weld repairs shall be subjected to the 8.4 All other weld repairs shall be considered minor and

same inspection standards as the casting. may be made at the discretion of the manufacturer without

prior approval of the purchaser.

8.2 Castings with major weld repairs shall be heat treated in

accordance with Section 6.

Copyright ASTM International

Provided by IHS under license with ASTM

2Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/01/2015 04:42:45 MST

A297/A297M − 14

SUPPLEMENTARY REQUIREMENTS

The following supplementary requirements shall not apply unless specified in the purchase order. A

list of standardized supplementary requirements for use at the option of the purchaser is included in

Specification A781/A781M or A957/A957M. Those which are ordinarily considered suitable for use

with this specification are given below. Others enumerated in A781/A781M or A957/A957M may be

used with this specification upon agreement between the manufacturer and purchaser.

--`,,,,,`,`,,``,`,,``,,`````,``,-`-`,,`,,`,`,,`---

TABLE S14.1 Tensile RequirementsA

Elongation

Tensile Yield Point, in 2

Strength, min min in.

Grade

Type [50

mm],

ksi (MPa) ksi (MPa) min,

%B

HF 19 Chromium, 9 70 (485) 35 (240) 25

Nickel

HH 25 Chromium, 12 75 (515) 35 (240) 10

Nickel

HI 28 Chromium, 15 70 (485) 35 (240) 10

Nickel

HK 25 Chromium, 20 65 (450) 35 (240) 10

Nickel

HE 29 Chromium, 9 85 (585) 40 (275) 9

Nickel

HT 15 Chromium, 35 65 (450) ... ... 4

Nickel

HU 19 Chromium, 39 65 (450) ... ... 4

Nickel

HW 12 Chromium, 60 60 (415) ... ... ...

Nickel

HX 17 Chromium, 66 60 (415) ... ... ...

Nickel

HC 28 Chromium 55 (380) ... ... ...

HD 28 Chromium, 5 75 (515) 35 (240) 8

Nickel

HL 29 Chromium, 20 65 (450) 35 (240) 10

Nickel

HN 20 Chromium, 25 63 (435) ... ... 8

Nickel

HP 26 Chromium, 35 62.5 (430) 34 (235) 4.5

Nickel

HG 19 Chromium, 12 76 (525) 33 (225) 20

10 Nickel,

MNN 4 Manganese

CT15C 20 Chromium, 33 63 435 25 170 20.0

Nickel,

1 Niobium

A

Where ellipses ({) appear in this table there is no requirement, and the element

need not be analyzed or reported.

B

When ICI test bars are used in tensile testing as provided for in this specification,

the gage length to reduced section diameter ratio shall be 4 to 1.

Copyright ASTM International

Provided by IHS under license with ASTM

3Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/01/2015 04:42:45 MST

A297/A297M − 14

S1. Magnetic Particle Examination S14.3 Tension test specimens may be cut from heat-treated

S2. Radiographic Examination castings; or from as-cast castings if no heat treatment is

S3. Liquid Penetrant Examination specified for the castings, instead of from test bars when agreed

S4. Ultrasonic Examination upon between the manufacturer and the purchaser or at the

S5. Examination of Weld Preparation option of the producer if suitable separately cast test material is

S6. Certification not available.

S7. Prior Approval of Major Weld Repairs

S14.4 Test specimens shall be the standard round 2-in.

S8. Marking

[50-mm] gage length specimen shown in Specification A370,

S14. Tension Test

unless the purchase order is for investment castings, in which

S14.1 One tension test shall be made from material repre- case, the specimen shall be in accordance with Specification

senting each heat. The bar from which the test specimen is A957/A957M.

taken shall be heat treated in production furnaces to the same

S14.5 If the results of the mechanical tests for any heat do

procedure as the castings it represents. The results shall

conform to the requirements specified in Table S14.1. not conform to the requirements specified, the castings may be

S14.2 Test bars shall be poured in separately cast keel re-heat treated and re-tested, but may not be solution treated or

blocks shown in Specification A781/A781M, unless the pur- re-austenitized more than twice.

chase order is for investment castings, in which case, test S14.6 If any test specimen shows defective machining or

material shall be poured in accordance with the requirements of develops flaws, it may be discarded and another specimen

Specification A957/A957M. substituted from the same heat.

SUMMARY OF CHANGES

Committee A01 has identified the location of selected changes to this standard since the last issue

(A297/A297M – 10) that may impact the use of this standard. (Approved May 1, 2014.)

(1) Table 1, defined ellipses in note A and re-lettered subse- (4) Supplementary requirement S9, renumbered to S14 to be in

quent footnotes. agreement with A781/A781M and A957/A957M.

(2) Table 1, added UNS numbers. (5) Table S14.1, defined ellipses in note A and re-lettered

(3) Supplementary requirements, cited A957/A957M. subsequent footnotes.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

--`,,,,,`,`,,``,`,,``,,`````,``,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

4Licensee=SAUDI ELECTRICITY COMPANY/5902168001

No reproduction or networking permitted without license from IHS Not for Resale, 02/01/2015 04:42:45 MST

You might also like

- Astm A351-A351mDocument7 pagesAstm A351-A351mJose Gregorio RodriguezNo ratings yet

- Astm A 743 PDFDocument8 pagesAstm A 743 PDFWill MottaNo ratings yet

- Astm A148Document4 pagesAstm A148Michael Skrable100% (2)

- Supplementary Specification To API Recommended Practice 582 Welding Guidelines For The Chemical, Oil, and Gas IndustriesDocument51 pagesSupplementary Specification To API Recommended Practice 582 Welding Guidelines For The Chemical, Oil, and Gas IndustriesArab WeldersNo ratings yet

- API 582 The Welding Solution PDFDocument21 pagesAPI 582 The Welding Solution PDFRemmy Torres Vega80% (10)

- 297 GR HFDocument4 pages297 GR HFAgustinus KNo ratings yet

- Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General ApplicationDocument4 pagesSteel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General ApplicationmtNo ratings yet

- Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General ApplicationDocument8 pagesCastings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General ApplicationWin DarNo ratings yet

- Astm A743 A743m 21Document5 pagesAstm A743 A743m 21Norberto GómezNo ratings yet

- Astm A743 A743m - 12Document6 pagesAstm A743 A743m - 12Joshua ZantoyNo ratings yet

- Standard Specification For Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General ApplicationDocument8 pagesStandard Specification For Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General ApplicationFayez Al-ahmadiNo ratings yet

- Norma Inox-A743.1537974-1 PDFDocument8 pagesNorma Inox-A743.1537974-1 PDFJACKROSI2009No ratings yet

- A297 A297mDocument4 pagesA297 A297mVeerrajuChowdaryNo ratings yet

- ASTM A747 - A747M-16a PDFDocument5 pagesASTM A747 - A747M-16a PDFHanda Bin AdiNo ratings yet

- Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General ApplicationDocument8 pagesCastings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General Applicationalucard375No ratings yet

- Astm A351Document5 pagesAstm A351Iksan MustofaNo ratings yet

- Steel Castings, Carbon, For General ApplicationDocument4 pagesSteel Castings, Carbon, For General ApplicationVIKAS DAHIYA100% (1)

- A351a351m 38657Document7 pagesA351a351m 38657Abhinandan AdmutheNo ratings yet

- Astm A 297 PDFDocument5 pagesAstm A 297 PDFMuhammad Harits50% (2)

- A351a351m-14 10877Document5 pagesA351a351m-14 10877Lalit PatelNo ratings yet

- Astm A560 A560m - 12Document3 pagesAstm A560 A560m - 12Leandro Dilkin ConsulNo ratings yet

- Astm A351 16Document7 pagesAstm A351 16Nguyen JohnNo ratings yet

- Steel Castings, Chromium-Nickel-Iron Alloy (25-12 Class), For High-Temperature ServiceDocument4 pagesSteel Castings, Chromium-Nickel-Iron Alloy (25-12 Class), For High-Temperature ServiceHoem ITNo ratings yet

- Astm A494 - A494m - 13Document7 pagesAstm A494 - A494m - 13raul100% (1)

- Astm A351 - A351m - 13Document5 pagesAstm A351 - A351m - 13raulNo ratings yet

- Astm A 297a 297M - 07Document4 pagesAstm A 297a 297M - 07Ramsi AnkziNo ratings yet

- Astm A 447-2011Document4 pagesAstm A 447-2011Vk Rai100% (1)

- Castings, Austenitic, For Pressure-Containing PartsDocument5 pagesCastings, Austenitic, For Pressure-Containing PartsالGINIRAL FREE FIRENo ratings yet

- A351A351MDocument5 pagesA351A351MWanderlan Rodrigues da Silva100% (1)

- Astm A216Document4 pagesAstm A216salazaralexi100% (1)

- A182 PDFDocument19 pagesA182 PDFالGINIRAL FREE FIRE100% (2)

- Castings, Nickel and Nickel Alloy: Standard Specification ForDocument7 pagesCastings, Nickel and Nickel Alloy: Standard Specification FordgkmurtiNo ratings yet

- Steel Castings, High Strength, For Structural PurposesDocument4 pagesSteel Castings, High Strength, For Structural PurposesLuis Daniel MadrigalNo ratings yet

- Astm A447-11 (2021)Document4 pagesAstm A447-11 (2021)Imane ElkodsiNo ratings yet

- Astm A962 A962m 12 PDFDocument11 pagesAstm A962 A962m 12 PDFNoel FrancisNo ratings yet

- Common Requirements For Bolting Intended For Use at Any Temperature From Cryogenic To The Creep RangeDocument11 pagesCommon Requirements For Bolting Intended For Use at Any Temperature From Cryogenic To The Creep RangeRobNo ratings yet

- A 958 - A 958M - 17Document5 pagesA 958 - A 958M - 17Eddie Michael67% (3)

- Steel Castings, Carbon, For General ApplicationDocument4 pagesSteel Castings, Carbon, For General ApplicationSofia YuliNo ratings yet

- Steel Castings, Alloy, Specially Heat-Treated, For Pressure-Containing Parts, Suitable For High-Temperature ServiceDocument3 pagesSteel Castings, Alloy, Specially Heat-Treated, For Pressure-Containing Parts, Suitable For High-Temperature ServiceRed RedNo ratings yet

- ASTM A182 - 2009aDocument18 pagesASTM A182 - 2009aLeonardo R. GonçalvesNo ratings yet

- Astm A488-A488m 2010Document18 pagesAstm A488-A488m 2010Júlio RosaNo ratings yet

- Astm A744-A744m 2010Document6 pagesAstm A744-A744m 2010Júlio RosaNo ratings yet

- ASTM A 962 - 16aDocument12 pagesASTM A 962 - 16aMarcos Verissimo Juca de Paula100% (2)

- A 962 - A 962M - 16b Material Requirement of Bolting For Cryogenic ServiceDocument12 pagesA 962 - A 962M - 16b Material Requirement of Bolting For Cryogenic ServiceThái Đạo Phạm LêNo ratings yet

- Astm A182 2015Document16 pagesAstm A182 2015Lėo GuimarãesNo ratings yet

- Alloy-Steel and Stainless Steel Bolting For High Temperature or High Pressure Service and Other Special Purpose ApplicationsDocument13 pagesAlloy-Steel and Stainless Steel Bolting For High Temperature or High Pressure Service and Other Special Purpose Applicationsprabhu2k21No ratings yet

- ASTM A182 BallDocument16 pagesASTM A182 Ballsigurdur hannessonNo ratings yet

- ASTM A 494 Nickel AlloysDocument7 pagesASTM A 494 Nickel AlloysalirezaattariNo ratings yet

- Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature ServiceDocument16 pagesForged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature ServiceRosario BarbaNo ratings yet

- Steel Castings, Carbon, For General ApplicationDocument4 pagesSteel Castings, Carbon, For General Applicationsandeep acharNo ratings yet

- A194a194m 17Document13 pagesA194a194m 17jcarlos7411No ratings yet

- A182 PDFDocument16 pagesA182 PDFExport priminoxNo ratings yet

- Carbon Steel Forgings, For General-Purpose PipingDocument3 pagesCarbon Steel Forgings, For General-Purpose PipingThiago Ribeiro da SilvaNo ratings yet

- Common Requirements For Bolting Intended For Use at Any Temperature From Cryogenic To The Creep RangeDocument13 pagesCommon Requirements For Bolting Intended For Use at Any Temperature From Cryogenic To The Creep Rangesafak kahramanNo ratings yet

- ASTM A484-2023aDocument22 pagesASTM A484-2023aTEJASH BHATTNo ratings yet

- Astm A182 A182m 22Document7 pagesAstm A182 A182m 22Adco forge & fittings pvt ltdNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Bolted Flanged Joint: Flanges, Studs & Gaskets. Recommended Practices for the Assembly of a Bolted Flange Joint.From EverandBolted Flanged Joint: Flanges, Studs & Gaskets. Recommended Practices for the Assembly of a Bolted Flange Joint.No ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Buttress Wall - R1Document110 pagesButtress Wall - R1عصام السامرائيNo ratings yet

- Form F - Application For Registration Renewal 13112019-1 PDFDocument1 pageForm F - Application For Registration Renewal 13112019-1 PDFعصام السامرائيNo ratings yet

- KDC19 Container Concept C Mk3a 17 10 19 Rev E Master S7 - ModelDocument1 pageKDC19 Container Concept C Mk3a 17 10 19 Rev E Master S7 - Modelعصام السامرائيNo ratings yet

- Geo5 OutputDocument23 pagesGeo5 Outputعصام السامرائيNo ratings yet

- Mesy Tapak BilDocument2 pagesMesy Tapak Bilعصام السامرائيNo ratings yet

- C Geo5Document23 pagesC Geo5عصام السامرائيNo ratings yet

- N (Flow/Ft.) Consistency Cqu Uncomfined Compressive JKR Probe 2 Strength (Qu) Flows/Ft. PSF (Ton/Sq - FT.) kN/m2Document8 pagesN (Flow/Ft.) Consistency Cqu Uncomfined Compressive JKR Probe 2 Strength (Qu) Flows/Ft. PSF (Ton/Sq - FT.) kN/m2عصام السامرائيNo ratings yet

- Base Plate DesignMS601a Good MahfuzDocument4 pagesBase Plate DesignMS601a Good MahfuzDavid PuenNo ratings yet

- Plaxis ValidationDocument5 pagesPlaxis Validationعصام السامرائيNo ratings yet

- Sepakat Setia Perunding SDN BHD: Design Information DimensionsDocument30 pagesSepakat Setia Perunding SDN BHD: Design Information Dimensionsعصام السامرائيNo ratings yet

- Design of Raft FoundationDocument9 pagesDesign of Raft FoundationМилош ЈанићијевићNo ratings yet

- Pac Pdpa NoticeDocument1 pagePac Pdpa Noticeعصام السامرائيNo ratings yet

- Transactionhistory PDFDocument3 pagesTransactionhistory PDFعصام السامرائيNo ratings yet

- CL - Ms Premalatha Sukumaran - 17th August 2018Document1 pageCL - Ms Premalatha Sukumaran - 17th August 2018عصام السامرائيNo ratings yet

- PhySci Gabion Elements Timeline ReportingDocument6 pagesPhySci Gabion Elements Timeline Reportingseungkwan booNo ratings yet

- Aisi e 52100 SteelDocument2 pagesAisi e 52100 SteelFelipeTadeuNo ratings yet

- Esab Weld 71T - 1 PDFDocument1 pageEsab Weld 71T - 1 PDFAbhishek AnandNo ratings yet

- Metals and Non MetalsDocument24 pagesMetals and Non MetalsSrinivas VenkataramanNo ratings yet

- Project 01-3137 - EHC - Well #4u#5 - 2015-04-27 - Normal CaseDocument2 pagesProject 01-3137 - EHC - Well #4u#5 - 2015-04-27 - Normal CaseunconformistNo ratings yet

- Architectural - Sheet Metal - CollieDocument42 pagesArchitectural - Sheet Metal - CollieWissam Alameddine100% (1)

- Exploration For PGE in IndiaDocument22 pagesExploration For PGE in IndiaAravind KumaraveluNo ratings yet

- Benefits of Stainless Steel Conduit Systems VS. PVC CoatedDocument2 pagesBenefits of Stainless Steel Conduit Systems VS. PVC CoatedWidhi ImranovichNo ratings yet

- Asme Sa-812 Specification For Steel Sheet, High-Strength, Low-Alloy, Hot-Rolled, For Welded Layered Pressure VesselsDocument3 pagesAsme Sa-812 Specification For Steel Sheet, High-Strength, Low-Alloy, Hot-Rolled, For Welded Layered Pressure Vesselslucecita1902No ratings yet

- Sa 278 PDFDocument5 pagesSa 278 PDFlucecita19020% (1)

- Stellram Turning Cutting Speeds Inch PDFDocument4 pagesStellram Turning Cutting Speeds Inch PDFAJi Syaeful BarkahNo ratings yet

- Essentra Knobs Handles and GripsDocument110 pagesEssentra Knobs Handles and GripsMarcus SteeleNo ratings yet

- The Effect of Adding Zro Nanoparticles To Fe-18Al-15Cr Alloys With Mechanical Alloying Process For Oxidation ResistanceDocument17 pagesThe Effect of Adding Zro Nanoparticles To Fe-18Al-15Cr Alloys With Mechanical Alloying Process For Oxidation ResistanceFauzan FariedNo ratings yet

- Corrosion of Galvanized Steel in SoilDocument16 pagesCorrosion of Galvanized Steel in SoilyaofuzhangNo ratings yet

- FORA 500: A 500 HB Wear Resistant SteelDocument4 pagesFORA 500: A 500 HB Wear Resistant SteelLaura BejaranoNo ratings yet

- Oe750 App NotesDocument22 pagesOe750 App Noteswael barbaryNo ratings yet

- Steel Gauge ThicknessDocument4 pagesSteel Gauge ThicknessLaplaceFourierNo ratings yet

- Element Six Road Planing PicksDocument12 pagesElement Six Road Planing PicksJackChanNo ratings yet

- Ferrous Metal AND Non-Ferrous MetalDocument38 pagesFerrous Metal AND Non-Ferrous MetalKristineNo ratings yet

- Precipitation-Hardening Bolting (UNS N07718) For High Temperature ServiceDocument4 pagesPrecipitation-Hardening Bolting (UNS N07718) For High Temperature ServiceJose Anisio SilvaNo ratings yet

- Effect of CR and ZR On The Grain Structure of Extruded EN AW 6082 AlloyDocument6 pagesEffect of CR and ZR On The Grain Structure of Extruded EN AW 6082 AlloyGÖRKEMNo ratings yet

- 2002 Thallium Review 2002 JEMEPDocument34 pages2002 Thallium Review 2002 JEMEPMINANo ratings yet

- Grade 100 Alloy ChainDocument1 pageGrade 100 Alloy ChainRameshwar PatilNo ratings yet

- Asme, Aws CodesDocument21 pagesAsme, Aws Codesemmanueljoseph100% (1)

- Astm A582 Round Bar, Flat Bar & Astm A582 Material Suppliers IndiaDocument6 pagesAstm A582 Round Bar, Flat Bar & Astm A582 Material Suppliers IndiaAVINASHRAJNo ratings yet

- SAE J403 Grade 1055: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument4 pagesSAE J403 Grade 1055: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearALEX MURPHYNo ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument25 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenNo ratings yet

- Minerals 11 01178Document16 pagesMinerals 11 01178Erwin SetiawanNo ratings yet