0 ratings0% found this document useful (0 votes)

39 viewsFabrication of Air Brake System Using The Application of Exhaust Gas in IC Engines

Fabrication of Air Brake System Using The Application of Exhaust Gas in IC Engines

Uploaded by

SHASHIKIRANThis document describes a proposed air brake system that uses exhaust gas from a two-stroke petrol engine to operate the brake plate, rather than using an air compressor driven by the engine. The exhaust gas is filtered and stored in a pneumatic tank before being used to actuate a pneumatic cylinder that applies the brakes. This system is intended to reduce the workload on the engine compared to conventional air brake systems. The key components discussed include a two-stroke petrol engine, exhaust gas collection system, pneumatic storage tank, pneumatic cylinder, and solenoid valves controlled by a central control unit to operate the brakes using stored exhaust gas pressure.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Fabrication of Air Brake System Using The Application of Exhaust Gas in IC Engines

Fabrication of Air Brake System Using The Application of Exhaust Gas in IC Engines

Uploaded by

SHASHIKIRAN0 ratings0% found this document useful (0 votes)

39 views2 pagesThis document describes a proposed air brake system that uses exhaust gas from a two-stroke petrol engine to operate the brake plate, rather than using an air compressor driven by the engine. The exhaust gas is filtered and stored in a pneumatic tank before being used to actuate a pneumatic cylinder that applies the brakes. This system is intended to reduce the workload on the engine compared to conventional air brake systems. The key components discussed include a two-stroke petrol engine, exhaust gas collection system, pneumatic storage tank, pneumatic cylinder, and solenoid valves controlled by a central control unit to operate the brakes using stored exhaust gas pressure.

Original Title

IJSRDV7I40622

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document describes a proposed air brake system that uses exhaust gas from a two-stroke petrol engine to operate the brake plate, rather than using an air compressor driven by the engine. The exhaust gas is filtered and stored in a pneumatic tank before being used to actuate a pneumatic cylinder that applies the brakes. This system is intended to reduce the workload on the engine compared to conventional air brake systems. The key components discussed include a two-stroke petrol engine, exhaust gas collection system, pneumatic storage tank, pneumatic cylinder, and solenoid valves controlled by a central control unit to operate the brakes using stored exhaust gas pressure.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

39 views2 pagesFabrication of Air Brake System Using The Application of Exhaust Gas in IC Engines

Fabrication of Air Brake System Using The Application of Exhaust Gas in IC Engines

Uploaded by

SHASHIKIRANThis document describes a proposed air brake system that uses exhaust gas from a two-stroke petrol engine to operate the brake plate, rather than using an air compressor driven by the engine. The exhaust gas is filtered and stored in a pneumatic tank before being used to actuate a pneumatic cylinder that applies the brakes. This system is intended to reduce the workload on the engine compared to conventional air brake systems. The key components discussed include a two-stroke petrol engine, exhaust gas collection system, pneumatic storage tank, pneumatic cylinder, and solenoid valves controlled by a central control unit to operate the brakes using stored exhaust gas pressure.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

IJSRD - International Journal for Scientific Research & Development| Vol.

7, Issue 04, 2019 | ISSN (online): 2321-

0613

Fabrication of Air Brake System using the Application of Exhaust Gas in

IC Engines

Nakul Gayali

Department of Mechanical Engineering

G H Raisoni College of Engineering, Maharashtra, India

Abstract— The purpose of this project named “Fabrication piston such as upstroke and down stroke due to this

Of Air Brake System Using the Application of Exhaust movement it will convert the chemical energy in power.

Gas in IC Engines” is to diminish the workload of the

engine drive to operate the air compressor, because in the

proposed model, instead of air brake the exhaust gas is

used to operate brake plate. The two stroke petrol engine is 1) Fuel Tank:

employed during this exhaust gas braking system, as a A fuel tank should be made up of plastic and it should be

result of petrol engine produces less impurities than diesel safe for flammable fluid. Plastic fuel tank must avoid

engine. This can be performed on diesel engine but with leakages and limit evaporation emission.

appropriate design. In exhaust gas braking system exhaust 2) Exhaust Gas:

gas from the engine is stored in especially pneumatic tank. In this proposed model the exhaust gas system used to

Exhaust gas pressure is used to operate the pneumatic discharge exhaust gas into atmosphere. The exhaust pipe

cylinder and brake plate. Filters and dryer are used to should be design properly to carry toxic exhaust gasses

remove impurities and moisture and then it is allowed to such as hydrocarbon, carbon monoxide (CO) and nitrogen

store in the tank. Pressure relief valve is employed to attain oxide (N2). It should be heat-resistant.

specific pressure in tank and helps to avoid damage in tank Exhaust gas can be pass through a catalytic

as well as in engine. converter to decrease air pollution and a muffler in (North

Keywords: DC Compressor, Two Stroke Petrol Engine, America) /silencer (UK, India) to diminish noise pollution

Exhaust Gas, Exhaust Gas, Pressure Relief Valve in atmosphere.

A study in 2013 by MIT indicated that 53000

I. INTRODUCTION deaths occurs per year in US because of vehicle emission.

Due to the development of roads, highways, organizations, The exhaust gas contains largest a part of most combustion

velocity of vehicles increased, because of which the safety gases that’s N2 (Nitrogen), H2O (Water vapor), CO2

of driver has diminished. We waste almost 60 percent of (Carbon di oxide). These are not toxic though CO2 led to

energy as heat. In heavy goods transportation the braking global warming. The toxic ones are CO (Carbon monoxide)

load of vehicle increases because of which primary brake and hydrocarbon CxHy because of incomplete combustion.

system is definitely overloaded and might be broken by The exhaust gases which discharged by engine to

overheating, which leads to failure in brake. Latest vehicles atmosphere can affect human being and animals health.

are built-up with hybrid system to preserves the non- The effect of inhaling exhaust gases or Air bone led to

renewable energy sources. asthma, lung cancer, cardiovascular issues, premature death

The hand brake system is used in both emergency because of size of air bone particles and they can puncture

conditions as well as parking condition. If the primary the deepest part to lungs.

Braking system fails then the hand brake can be Exhaust gas temperature gauge is used to measure

used to stop the vehicles in emergency condition. This the exhaust gas temperature of an IC engine in conjunction

model proposed both functions of primary air brake system with a thermocouple type pyrometer. By measuring exhaust

such as exhaust gas braking and also during emergency gas temperature the driver gets an idea of the vehicle air

condition. Exhaust gas braking will going to be helpful to fuel ratio.

stop the vehicles. B. Turbine and Dynamo:

High power with magnitude relation and less The function of turbine is to rotate, here we are placing

moving parts of 2 stroke petrol engine. Scrutiny to the price turbine in path of exhaust gas because of which it will start

two stroke engine is used in the proposed model. This rotating and which will rotate the dynamo as well. Dynamo

brakes uses exhaust pressure that improves the potency of meter is a device which converts kinetic energy into

engine compare to default air brake system. electric energy.

II. EQUIPMENTS USED C. Dryer:

The function of dryer in this proposed model is to dry the

A. Two Stroke Petrol Engine

moisture contain in the atmospheric air. So, that it will

The mechanical simplicity, light weight and high power to protect air tank and others from rusting.

weight quantitative relation and it completes full cycle in

every two stroke of the piston whereas in four stroke petrol D. Pneumatic Cylinder (Double Acting Single Piston):

engine piston travels four stroke so the two stroke petrol It consist of a cylinder in which the piston with single

engine is used in proposed model. The fuel tank will piston rod and reciprocate, similarly to single acting

supply the pressurized gas in an engine and by the stroke of cylinder. The bore is highly finished surface having closed

tolerances. There are two ports A and B. The pressurized

All rights reserved by www.ijsrd.com 459

fluid enter through port A due to pressure force created by pneumatic cylinder hence the brake is applied. When the

fluid A piston moves from left death center (LDC) to right pneumatic cylinder is initiated, brake plate is operated and

death center (RDC). When piston reaches to RDC flow applies the brake to the wheels.

through port A stops.

Fabrication of Air Brake System using the Application of Exhaust Gas in IC Engines

(IJSRD/Vol. 7/Issue 04/2019/117)

Now, pressurized fluid start entering port B, due to

pressure force created by fluid it moves from RDC to V. CONCLUSION

LDC. During this the fluid flows back to port A, and In this proposed model we obtained that the brake is

process continues. applied with help of engine exhaust gasses from two stroke

E. Solenoid Valve: petrol engine, It improves the efficiency of engine

compared to previous air brake system. This also reduced

It is electro mechanical valve which used to control flow of

the cost involved in the setup.it also helps to reduce the air

liquid or gas it converts the electrical signal from control

pollution by using the air filter. This can be further study

unit to mechanical movement of plunger to allow the flow

on diesel engine but with the improvement in design.

inside of valve. There are two chambers separated by

plunger when it get electric signal, the magnetic force is

produced inside because of which the plunger get attracted REFERENCES

towards the magnetic force and valves opens. [1] Srivatsan Ramarathnam, “Development of a model for

F. Control Unit: an air brake system with leaks”, (est.al)-2003.

[2] C.L. Bowlin, “Pressure control scheme for air brakes

Control unit is a part of CPU that directs the operation of

in commercial vehicle”. Apr 2006.

processors, it tells the computer memory, arithmetic/logic

unit and input output devices how to responds to programs. [3] Caiazzo, Fabio; Ashok, Akshay; Waitz, Ian A.; Yim,

It operates unit by providing timing and design. In this Steve H.L.; Barrett, Steven R.H. (November 2013).

proposed model CU operates the solenoid valves. "Air pollution and early deaths in the United States.

Part I: Quantifying the impact of major sectors in

2005". Atmospheric Environment. Elsevier. 79: 198–

208.

[4] Pulkrabek W.W., “Engineering Fundamentals of the

Internal Combustion Engine. Pearson Prentice Hall,

new Jersey”, 2004.

[5] Cengel, Yunus A., and Michaeul A. Boles.

“Thermodynamics: An Engineering Approach. 7th

Edition ed” New York: Mcgraw-Hill, 2012.

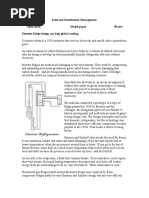

Fig. 1: Assembly of Fabrication of Air Brake System

III. USING THE APPLICATION OF EXHAUST GAS IN IC

ENGINES

SR. SR.

PART NAME PART NAME

No No

Two Stroke Petrol

1 7 Air Tank

Engine

2 Silencer 8 Solenoid Valve

3 Dryer 9 Frame

Turbine and Pneumatic

4 10

Dynamo Cylinder

5 DC Compressor 11 Braking plate

6 Battery 12 Wheel

13 Fuel Tank

IV. WORKING

A two stroke petrol engine powered by petrol produces

exhaust gas in 2nd stroke this exhaust gas is then passes

through silencer, here we have placed the turbine in path,

Depending on the flow the turbine starts rotating because

of which dynamo which is inside the turbine also starts

rotating. Dynamo meter is a device which converts kinetic

energy into electric energy. Thus, the power generated

through dynamo is stored in battery. This power is supplied

to DC compressor. Compressor is a device which

compresses the atmospheric air and stored it into the tank.

Before this the dryer is used to dry moisture in the air.

Now, when the brake is applied/pressed the 5/2 solenoid

valve is initiated and it allow the air to actuates the

All rights reserved by www.ijsrd.com 460

You might also like

- 344 Pump Intallation and Maintenance Course PreviewDocument17 pages344 Pump Intallation and Maintenance Course PreviewMostafa GimyNo ratings yet

- Air Braking System in Indian RailwayDocument22 pagesAir Braking System in Indian RailwayClassic Printers100% (1)

- Compressed Air EngineDocument12 pagesCompressed Air Enginezakibrant23No ratings yet

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- ASME VIII Div. 1 - 6 Pressure TestingDocument11 pagesASME VIII Div. 1 - 6 Pressure TestingYoucef ChorfaNo ratings yet

- Syabas Standard Drawing 01Document31 pagesSyabas Standard Drawing 01Jpmega Civil Structural100% (1)

- Design and Fabrication of Airbrake System Using Engine Exhaust GasDocument6 pagesDesign and Fabrication of Airbrake System Using Engine Exhaust Gassv lyricsNo ratings yet

- System Design and Mechanism of A Compressed Air EngineDocument5 pagesSystem Design and Mechanism of A Compressed Air Enginemuner886644No ratings yet

- Fabrication of Compressed Air Engine: Mechanical Engineering Department, Bharath University Chennai, IndiaDocument3 pagesFabrication of Compressed Air Engine: Mechanical Engineering Department, Bharath University Chennai, IndiaRohanKhuranaNo ratings yet

- Pneumatic Powered Air EngineDocument4 pagesPneumatic Powered Air EngineRegg ParkerNo ratings yet

- Development and Fabrication of Airbrake System Using Engine Exhaust GasDocument8 pagesDevelopment and Fabrication of Airbrake System Using Engine Exhaust GasretechNo ratings yet

- Compressed Air Car's TechnologyDocument14 pagesCompressed Air Car's TechnologyPravin JawarkarNo ratings yet

- Design Methodology For Compressed Air EngineDocument7 pagesDesign Methodology For Compressed Air EngineShashank SrivastavaNo ratings yet

- Design, Analysis of Flow Characteristics of Exhaust System and Effect of Back Pressure On Engine PerformanceDocument5 pagesDesign, Analysis of Flow Characteristics of Exhaust System and Effect of Back Pressure On Engine PerformanceInternational Association of Scientific Innovations and Research (IASIR)No ratings yet

- IOSRDocument6 pagesIOSRmuner886644No ratings yet

- Compressed Air Engine ISTEDocument8 pagesCompressed Air Engine ISTEVaibhavNo ratings yet

- Pneumatic Final ReportDocument11 pagesPneumatic Final ReportAbhijeet Ekhande100% (1)

- Submitted By: "Compressed Air Engine Technology"Document11 pagesSubmitted By: "Compressed Air Engine Technology"harshmehla009No ratings yet

- Chapter OneDocument8 pagesChapter OneKaleab EndaleNo ratings yet

- Bahirdar University Bahirdar Institute of ThecnologyDocument6 pagesBahirdar University Bahirdar Institute of ThecnologyKaleab EndaleNo ratings yet

- Design & Fabrication of Air Driven Engine: Sanketh S, Harsha R N, Manunath MVDocument10 pagesDesign & Fabrication of Air Driven Engine: Sanketh S, Harsha R N, Manunath MVretechNo ratings yet

- Improving The Performance of Two-Stroke Motorcycle With Tuned Adjustable Exhaust PipeDocument7 pagesImproving The Performance of Two-Stroke Motorcycle With Tuned Adjustable Exhaust PipePaul MartinNo ratings yet

- "Compressed Air Engine": Seminar ONDocument18 pages"Compressed Air Engine": Seminar ONRationallyIrrationalSamikshaNo ratings yet

- Design and Analysis of Automobile Exhaust AssemblyDocument7 pagesDesign and Analysis of Automobile Exhaust AssemblyIJRASETPublicationsNo ratings yet

- Transformation of A Piston Engine Into A Compressed Air Engine With Rotary ValveDocument5 pagesTransformation of A Piston Engine Into A Compressed Air Engine With Rotary ValveGulshan D'souzaNo ratings yet

- Solar Based Air Compressor For in Ating Tyres: July 2014Document6 pagesSolar Based Air Compressor For in Ating Tyres: July 2014Arpan BariaNo ratings yet

- Abstract - Air BikeDocument6 pagesAbstract - Air BikeNasruddin Shaikh33% (3)

- Air Bike NewDocument7 pagesAir Bike NewAnkit GargNo ratings yet

- IOSRDocument7 pagesIOSRrobsonrober83No ratings yet

- 3 Way Catalytic ConvertorDocument14 pages3 Way Catalytic Convertorpradeepa.sseNo ratings yet

- Air Brake System Using Exhaust Gas PowerPoint PresentationDocument16 pagesAir Brake System Using Exhaust Gas PowerPoint PresentationErole Technologies Pvt ltd Homemade Engineer100% (1)

- Imp 3Document8 pagesImp 3Justin JosephNo ratings yet

- Design and Fabrication of Air Brake System Using Engine Exhaust GasDocument11 pagesDesign and Fabrication of Air Brake System Using Engine Exhaust Gasscholarship cptcNo ratings yet

- Thermal Effect of Drain Gas Recirculation Arrangement Combined With Intercooler For Two WheelersDocument7 pagesThermal Effect of Drain Gas Recirculation Arrangement Combined With Intercooler For Two WheelersAlbertoNo ratings yet

- Thesis Simple Gas Turbine Engine Design PDFDocument6 pagesThesis Simple Gas Turbine Engine Design PDFdwtt67ef100% (2)

- An Overview Studyof Camless Combustion EnginesDocument6 pagesAn Overview Studyof Camless Combustion EnginesDuc DungNo ratings yet

- Irjet V10i1294Document4 pagesIrjet V10i1294kavyapatelmechNo ratings yet

- Novel Configuration For Air Flow Rationalization and Turbo Lag Reduction in CRDI EngineDocument4 pagesNovel Configuration For Air Flow Rationalization and Turbo Lag Reduction in CRDI Engineyash1239No ratings yet

- Vehicle Using Compressed AirDocument5 pagesVehicle Using Compressed AirInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Fabrication of Air Brake System Using Engine Exhaust Gas Ijariie2083Document5 pagesFabrication of Air Brake System Using Engine Exhaust Gas Ijariie2083Chetan AmrutkarNo ratings yet

- 2003 11020170 PDFDocument9 pages2003 11020170 PDFFlorian DraguNo ratings yet

- Design Analysis of Power Recovery Systems For Cabin Exhaust AirDocument8 pagesDesign Analysis of Power Recovery Systems For Cabin Exhaust AirJoe shankerNo ratings yet

- Green Engine System: Bachelor of TechnologyDocument12 pagesGreen Engine System: Bachelor of Technologymadhu kotlaNo ratings yet

- Design and Fabrication of Compressed Air Vehicle: J.Tarun Kumar B.Gowtham KumarDocument5 pagesDesign and Fabrication of Compressed Air Vehicle: J.Tarun Kumar B.Gowtham KumarankNo ratings yet

- Compressed Air VehicleDocument10 pagesCompressed Air Vehiclefelix judeNo ratings yet

- Art 20172846Document3 pagesArt 20172846Miskoncha MiskonchaNo ratings yet

- New Design For A 2 KW Capacity Cooling System Powered by Exhaust Gases of A Diesel EngineDocument9 pagesNew Design For A 2 KW Capacity Cooling System Powered by Exhaust Gases of A Diesel EngineAl-Mustaqbal Journal of Sustainability in Engineering SciencesNo ratings yet

- Air Driven Engine VehicleDocument7 pagesAir Driven Engine VehicleBharanidharan RajmohanNo ratings yet

- Energies: Experimental Investigation On The Performance of A Compressed-Air Driven Piston EngineDocument15 pagesEnergies: Experimental Investigation On The Performance of A Compressed-Air Driven Piston EngineeskewtNo ratings yet

- Air Powered EngineDocument22 pagesAir Powered Enginerashid khanNo ratings yet

- Pneumatic Vehicle Using Compressed Air-303Document7 pagesPneumatic Vehicle Using Compressed Air-303raja maneNo ratings yet

- Air Driven EngineDocument19 pagesAir Driven EngineVivek PatilNo ratings yet

- Solar Based Air Compressor For in Ating Tyres: October 2014Document6 pagesSolar Based Air Compressor For in Ating Tyres: October 2014bappah harunaNo ratings yet

- 3832 9259 2 PBDocument7 pages3832 9259 2 PBJajsjshshhsNo ratings yet

- AE Scheme of Evaluation 2023-24Document22 pagesAE Scheme of Evaluation 2023-24Thota SrinivasNo ratings yet

- Supercharger SynopsisDocument8 pagesSupercharger SynopsiskrunalNo ratings yet

- Computational Fluid Dynamics Analysis of A Turbocharger SystemDocument4 pagesComputational Fluid Dynamics Analysis of A Turbocharger Systemmuthu vNo ratings yet

- CFD_Analysis_of_Exhaust_Manifold_of_MultDocument12 pagesCFD_Analysis_of_Exhaust_Manifold_of_Multdaovuphat190303No ratings yet

- Design & Development of Hybrid Electric Jet EngineDocument5 pagesDesign & Development of Hybrid Electric Jet EngineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Valved Two Stroke EngineDocument10 pagesValved Two Stroke EngineBlaž VerdevNo ratings yet

- Reducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemFrom EverandReducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemNo ratings yet

- Compressed Air Propulsion System to Power the Car of the FutureFrom EverandCompressed Air Propulsion System to Power the Car of the FutureNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- D9R Hydraulic SystemDocument24 pagesD9R Hydraulic SystemMarta TiaNo ratings yet

- HW1ADocument3 pagesHW1ANIRVANANo ratings yet

- Gala ValveDocument2 pagesGala ValveThomas JohnNo ratings yet

- NPK P&id Rev 6.2Document40 pagesNPK P&id Rev 6.2Syahrul FitriaNo ratings yet

- Fluid Machiney Module 1Document27 pagesFluid Machiney Module 1Jacob BenningsNo ratings yet

- Catalog-MNC-14 ColorDocument76 pagesCatalog-MNC-14 Colorja.tellez97No ratings yet

- Fluid MechanicsDocument13 pagesFluid MechanicsArnold GacangNo ratings yet

- Bomba P6010Document22 pagesBomba P6010mantenimientoNo ratings yet

- Sample SM Des Turton 5Document16 pagesSample SM Des Turton 5bertha kiaraNo ratings yet

- Brayton Cycle Closed Cycle OnlyDocument2 pagesBrayton Cycle Closed Cycle OnlyAlvin LoocNo ratings yet

- Saep 311Document30 pagesSaep 311GulfamNo ratings yet

- Djedi S. Widarto, DSc. PresentationDocument28 pagesDjedi S. Widarto, DSc. PresentationtakhululumNo ratings yet

- Unusual Behavior of Propane As A Co Guest During Hydrate For - 2014 - Chemical EDocument10 pagesUnusual Behavior of Propane As A Co Guest During Hydrate For - 2014 - Chemical EadeelrehmanNo ratings yet

- Nexterra's Gasification Technology Technology Nexterra - The Next Generation of Industrial Gasification SystemsDocument1 pageNexterra's Gasification Technology Technology Nexterra - The Next Generation of Industrial Gasification Systems7kkqg42m6cNo ratings yet

- DHM Series Horizontal Multistage Pumps: WarrantyDocument4 pagesDHM Series Horizontal Multistage Pumps: WarrantysepasepasepaNo ratings yet

- Application of CFD For Designing Conventional Three Phase Oilfield SeparatorDocument8 pagesApplication of CFD For Designing Conventional Three Phase Oilfield SeparatorrahuNo ratings yet

- SafariDocument2 pagesSafariMalahayati ZamzamNo ratings yet

- Safety Data Sheet: Bromotrifluoromethane (Halon 1301, R13B1)Document5 pagesSafety Data Sheet: Bromotrifluoromethane (Halon 1301, R13B1)Rinny RojasNo ratings yet

- Answer Any One Question From This SectionDocument4 pagesAnswer Any One Question From This SectionSyakir FahmieNo ratings yet

- Gas Refrigerator Specifications, Installation, Parts, and Maintenance OverviewDocument2 pagesGas Refrigerator Specifications, Installation, Parts, and Maintenance OverviewClayton ConnerNo ratings yet

- Einstein FridgeDocument2 pagesEinstein FridgeMohanish SoniNo ratings yet

- Surge in A Centrifugal CompressorDocument33 pagesSurge in A Centrifugal CompressorTheerayoot100% (1)

- Boquillas WL - MetricDocument1 pageBoquillas WL - MetricDavid Fernando Tirado ArizaNo ratings yet

- Theory Surface TensionDocument11 pagesTheory Surface Tensionrudrakshengg.No ratings yet

- GT Air Compressor Blade - DCADocument29 pagesGT Air Compressor Blade - DCAMehulkumar PatelNo ratings yet

- Excess Flow ValveDocument2 pagesExcess Flow ValveSyed Waqas HaiderNo ratings yet

- ICFMET Conference Paper 2020.editedDocument17 pagesICFMET Conference Paper 2020.editedVijay GouthamNo ratings yet