Dimension Specification: Identification

Dimension Specification: Identification

Uploaded by

Александр ОлейникCopyright:

Available Formats

Dimension Specification: Identification

Dimension Specification: Identification

Uploaded by

Александр ОлейникOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Dimension Specification: Identification

Dimension Specification: Identification

Uploaded by

Александр ОлейникCopyright:

Available Formats

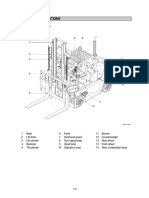

Dimension Specification

Identification

1. 1 Manufacturer HYUNDAI HYUNDAI HYUNDAI

1. 2 Manufacturer's type designation 16B-7 18B-7 20B-7

1. 3 Drive : electric(battery or mains) ,diesel, petrol ,fuel gas, manual ELECTRIC ELECTRIC ELECTRIC

1. 4 Type of operation : hand, pedestrian, standing, seated, order - picker SEATED SEATED SEATED

1. 5 Load capacity / rated load Q kg 1,600 1,750 2,000

1. 6 Load center distance c mm 500 500 500

1. 8 Load distance, center of drive axle to fork x mm 360 360 365

1. 9 Wheelbase y mm 1,355 1,440 1,440

Weights

2. 1 Service weight kg 2,995 3,195 3,300

2. 2 Axle loading, loaded front / rear kg 4,094/501 4,403/592 4,724/576

2. 3 Axle loading , unloaded front / rear kg 1,463/1,532 1,513/1,682 1,513/1,787

Wheels, Chassis

3. 1 Tires : solid rubber, superelastic, pneumatic, polyurethane SE SE SE

3. 2 Tires size, front(⅘ x width) 18x7-8 18x7-8 200/50-10

3. 3 Tires size, rear(⅘ x width ) 16x6-8 16x6-8 16x6-8

3. 5 Wheels, number front rear(x = driven wheels) 2x/2 2x/2 2x/2

3. 6 Track width, front mm 895 895 905

3. 7 Track width, rear mm 880 880 880

Basic Dimensions

4. 1 Mast / fork carriage tilt forward / backward degrees 5/7 5/7 5/7

4. 2 Lowered mast height h1 mm 2,120 2,120 2,129

4. 3 Free lift h2 mm 135 135 140

4. 4 Lift height h3 mm 3,325 3,325 3,325

4. 5 Extended mast height h4 mm 4,332 4,332 4,332

4. 7 Overhead load guard (cab) height h5 mm 1,970 1,970 1,980

4. 8 Seat height h7 mm 920 920 930

4. 12 Coupling height h10 mm 250 250 250

4. 19 Overall length I1 mm 2,931 3,016 3,031

4. 20 Length to face of forks I2 mm 2,031 2,116 2,131

4. 21 Overall width b1 mm 1,100 1,100 1,105

4. 22 Fork dimensions s / e / l mm 900x100x35 900x100x35 900x100x40

4. 23 Fork carriage ISO 2328, class / type A, B 2A x 3.9(100) x 1.8(45)

41.3(1,050) 2A 41.3(1,050) x 4.9(125)2A

x 1.8(45)

4. 24 Fork - carriage width b3 mm 980 980 980

4. 31 Ground clearance, loaded, under mast m1 mm 85 85 94

4. 32 Ground clearance, centre of wheelbase m2 mm 90 90 100

4. 33 Aisle width for pallets 1,000 x 1,200 crossways Ast mm 3,370 3,455 3,465

4. 34 Aisle width for pallets 800 x 1,200 length ways Ast mm 3,190 3,275 3,285

4. 35 Turning radius Wa mm 1,685 1,770 1,780

4. 36 Smallest pivot point distance mm - - -

Performance Data

5. 1 Travel speed, loaded / unloaded (48V) km/h 16/17 16/17 16/17

(36V) km/h 15/16 15/16 15/16

5. 2 Lift speed, loaded / unloaded (48V) mm/s 410/600 410/600 410/600

(36V) mm/s 330/500 330/500 330/500

5. 3 Lowering speed, loaded / unloaded mm/s 500/450 500/450 500/450

5. 5 Drawbar pull, S2 30 min (loaded) N - - -

(unloaded) N - - -

␍ Some of the photos may include optional equipment.

5. 6 Max. drawbar pull, S2 5 min (loaded) N 15,102 15,190 14,367

(unloaded) N 14,759 14,710 14,043

5. 7 Gradient performance, S2 3 min (loaded) % - - -

(unloaded) % - - -

5. 8 Max. gradient performance, S2 5 min (loaded) % 29.5 27.5 24.5

5. 10 Service brake - Hydr. Hydr. Hydr.

E - Motor

6. 1 Drive motor rating S2 60 min (48V / 36V) kW 4.4/3.5 4.4/3.5 4.4/3.5

FORKLIFT TRUCKS Environmentally - Friendly

6. 2 Lift motor rating at S3 - 15% (S2 10min) (48V / 36V) kW 15.8/9.9 15.8/9.9 15.8/9.9

6. 4 Battery voltage, nominal capacity K5 V /A h 48 / 505 48 / 585 48 / 585

6. 5 Battery weight (min)

Battery dimensions L / W /H

Other Details

8.1 Type of drive control

mm

kg 710

990/545/636

AC

835

990/630/636

AC

835

990/630/636

AC

16/18/20B-7 AC

PLEASE CONTACT

www.hyundai-ce.com 2010. 08 Rev 1.

The New AC Control B Series Superior Power with Optimal Performance 5o 7o

Efficient, smooth driving, ergonomically designed,

Designed with a durable frame and built to offer excellent stability and a smooth ride. AC control B series are built to meet your needs.

The newly designed AC control forklifts are built to be real workhorses.

Increased Mast tilting Angle

Utilizing the mast tilting angle of 5

degrees forward and 7 degrees

backward, the operator can rapidly

perform hydraulic functions.

Fork Safety Features

When the forks are being lowered, a down-

control valve maintains the controlled speed.

The down-safety valve prevents forks from

dropping down in case of sudden damage to

the hydraulic lines.

Wet Disc Brake System

Tilt cylinder The wet disc brake system is virtually

Control maintenance free and is enclosed to

valve

protect from dust and water.

Priority Hydraulic

valve pump

Lift cylinder Down control valve

Power steering

unit

Filter

Tank

Down safety valve Steering cylinder

State-of-the-art hydraulic System 4-Wheel Center Pivot

The latest large-capacity hydraulic system reacts quickly during The newly designed 4-wheel center

operation, and a low noise control valve increases both efficiency and pivot allows the forklift to navigate Fully Hydrostatic Power Steering

durability. with an extremely small turning A hydraulic steering system ensures

radius compared to other forklifts. smooth & precise steering which prevents

kick-back.

␍ Some of the photos may include optional equipment.

Anti-Rollback System, Faster Travel Speed & Gradeability

ZAPI’s anti-rollback system provides safe ramp operation plus Tilt Lock

exceptional ramp start capabilities.

Travel Speed (MAX)

The powerful high-output motors provide greater acceleration, better

High Technology ZAPI Controller Eliminate “almost noiseless” gradeability and faster travel speed on any tough terrain or slope. Model km/h

The efficient, 8Khz(high frequency) ZAPI controller provides smooth operation and 16B-7 17

protection for low & high voltage, overheating and fault recording. 18B-7 17 Lift Lock

20B-7 17

Features . Regeneration : Direction change, Deceleration, Braking

. The new AC motors offers a of 10% greater efficiency than traditional DC motors

Gradeability (MAX) OPSS (Operator Presence

Various performance models are available to maximize efficiency and equipped to Sensing System)

work in all types of operations Model %

Control of mast tilting, lifting and lowering

. Enhanced Efficiency 16B-7 29.5

is not possible through operation of the

- H (High) Mode, N (Normal) Mode, E (Economic) Mode 18B-7 27.5

appropriate control when the operator is

. Turtle Mode : 10km/h 20B-7 24.5 not in the seat

02 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 03

Comfortable Operation

A design based on human engineering relieves fatigue and increases

operator’s efficiency.

AC Control System Features

_Excellent Control Ability

- Various performance modes to meet all working conditions

Adjustable Steering Wheel

- Slow rolling on ramp & ramp start

Steering wheel can be adjusted by a

lever on the right-hand side for the most _Enhanced motor efficiency & Excellent regeneration

comfortable operator position.

High visibility for safe operation

The operator is able to work with increased safety and accuracy.

Horn

Easy Control Direction Lever

Finger tip control of forward and reverse

lever allows the operator to control the

equipment with minimal effort.

Perfect Fit For Long Work Cycles

An ergonomically designed operator’s compartment enables the driver to select the

most comfortable working position for increased productivity.

The Ergonomic Pedal Position

Multi-Functional Switch & Non-slip Mat

Integrated multi-functional switch

lever enables the driver to operate Based on human engineering, the

lights that includes a secondary accelerator and brake pedals are

horn position. optimally positioned for convenience

while operating the equipment. ␍ Some of the photos may include optional equipment.

Easily Adjustable, Full Suspension Seat Console Box & Cup Holder

An attractive and adjustable seat, based on a human engineering design, Self - diagnostic LCD Monitor Additional storage spaces are available on the right side for operator convenience.

provides greater comfort, safety and durability. The LCD monitor has a back-light system to

* Options : Seat belt, Arm rest, Hip restraint provide a clear view of the system’s

operation in all environments. The monitor

provides information about operation error,

system fault, battery level, hour meter and

selected performance mode. Other various

Prompt Response of functions include items such as self diagnostics and password activation. These features

Operating Control Levers are can be accessed without the need of a laptop or handset.

Only minimal operator’s effort is required

for precise, safe and productive control.

Keyboard Buttons / Performance mode

Operator can select performance mode easily according to working condition.

04 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 05

High Durability & Simple Arrangement Easy Maintenance & Serviceability

An ideal arrangement of component parts

ensures easy access and convenience for maintenance.

A concentrated fuse box for

easy inspection

Heavy Duty Single Frame

Heavy duty single type frame, designed on the basis of accurate structural analysis, guarantees

␍ Some of the photos may include optional equipment. durability and safety.

Oil Tank Port

Easy battery replacement

Battery change is easy with swing-up compartment and slotted overhead guard. Opening

and closing of battery cover is made effortless with a gas-spring assist cylinder.

Strong Overhead Guard Parking Brake Hand Grip & Large Footboard Rear Safety Lamp

The safety overhead guard meets Ratchet type parking brake requires less Wide“open”step and large hand grip offer Rear combination lamps with turn signal Steering Sensor

EEC and ANSI regulations and protects the effort from the operator to set. convenience and safety when entering lamps, tail lamp and brake lights are

operator during hazardous work. and exiting the truck. positioned for high visibility to ensure

safety.

High quality AC motors

Enclosed motors prolong durability. No brush and no commutator.

(No arc and no spark)

/ Switch

O-Ring HOSE Pump motor Battery Disconnect Lever Easy to Check Brake Oil Level

Battery Locking System ORFS (O-Ring Face Seal) High Visibility Headlights &

ORFS type hose prevents the leaking of

DC-DC Converter

hydraulic oil.

Rear Work Light DC-DC converter exceeds UL & CE

requirements to prevent short circuit,

overload and reverse polarity

06 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 07

New 7 Series

Mast Specification (16/18B-7) Load Capacity

Overall Height Maximum Free Lift (mm) Load Capacity without Load Capacity with Truck Weight

Tilt Angle (deg)

(Lowered) Fork Height side shift at 500mm LC side shift at 500mm LC (Unloaded)

Mast Type Fwd / Bwd

(mm) (mm) With Backrest Without Backrest (kg) (kg) (kg)

16B-7 18B-7 20B-7

16B-7 18B-7 16B-7 18B-7 16B-7 18B-7 16B-7 18B-7 16B-7 18B-7 16B-7 18B-7 16B-7 18B-7 16B-7 18B-7

V250 1720 1720 2525 2525 135 135 135 135 5/7 5/7 1600 1750 1500 1650 2927 3127 16B-7 V MAST 18B-7 V MAST 20B-7 V MAST

V270 1820 1820 2725 2725 135 135 135 135 5/7 5/7 1600 1750 1500 1650 2940 3140 kg 2000 V250 kg 2000 V250 kg 2500 V250

V300 1970 1970 3025 3025 135 135 135 135 5/7 5/7 1600 1750 1500 1650 2960 3160 1800

V270 1800

V270 V270

2 1600 1600 2000

* V330 2120 2120 3325 3325 135 135 135 135 5/7 5/7 1600 1750 1500 1650 2979 3179 V300 V300 V300

/

1400 1400

Stage V350 2220 2220 3525 3525 135 135 135 135 5/7 5/7 1600 1750 1500 1650 2992 3192 V330 V330 V330

1200 1200 1500

limited V370 2320 2320 3725 3725 135 135 135 135 5/7 5/7 1600 1750 1500 1650 3006 3206 V350 V350 V350

1000 1000

free V400 2470 2470 4025 4025 135 135 135 135 5/7 5/7 1600 1750 1500 1650 3029 3229

WEIGHT

WEIGHT

WEIGHT

800 V370 800 V370 1000 V370

lift

V450 2820 2820 4525 4525 135 135 135 135 5/5 5/5 1525 1750 1435 1650 3093 3293 600 V400 600 V400 V400

V500 3070 3070 5025 5025 135 135 135 135 5/5 5/5 1475 1725 1385 1635 3126 3326 400 400 500

V450 V450 V450

200 200

V550 3320 3320 5525 5525 135 135 135 135 5/5 5/5 1425 1500 1345 1420 3158 3358 V500 V500 V500

0 0 0

TF370 / TS370 1770 1770 3735 3735 763 763 1264 1264 5/5 5/5 1600 1750 1500 1650 3077 3277 500 600 700 800 900 1000 1100 1200 V550 500 600 700 800 900 1000 1100 1200 V550 500 600 700 800 900 1000 1100 1200 V550

LOAD CENTER mm LOAD CENTER mm LOAD CENTER mm

TF400 / TS400 1870 1870 4035 4035 863 863 1364 1364 5/5 5/5 1600 1750 1500 1650 3092 3292

TF430 / TS430 1970 1970 4335 4335 963 963 1464 1464 5/5 5/5 1550 1750 1450 1650 3112 3312 16B-7 TF / TS MAST 18B-7 TF / TS MAST 20B-7 TF / TS MAST

3

/ TF450 / TS450 2070 2070 4535 4535 1063 1063 1564 1564 5/5 5/5 1525 1750 1440 1650 3127 3327 kg 2000 TF370 kg 2000 TF370 kg 2500 TF370

Stage TF470 / TS470 2120 2120 4735 4735 1113 1113 1614 1614 5/5 5/5 1500 1750 1415 1650 3137 3337 1800 TF400 1800 TF400 TF400

full TF500 / TS500 2220 2220 5035 5035 1216 1216 1714 1714 5/5 5/5 1475 1725 1395 1625 3157 3357 1600 1600 2000

TF430 TF430 TF430

free 1400 1400

TF550 / TS550 2420 2420 5535 5535 1416 1416 1914 1914 5/5 5/5 1375 1425 1295 1335 3195 3395 TF450 TF450 TF450

lift 1200 1200 1500

TF600 / TS600 2620 2620 6035 6035 1613 1613 2114 2114 5/5 5/5 1000 1000 930 930 3258 3458 TF470 TF470 TF470

1000 1000

TF650 / TS650 2820 2820 6535 6535 1813 1813 2314 2314 5/5 5/5 950 950 890 890 3302 3502

WEIGHT

WEIGHT

WEIGHT

800 TF500 800 TF500 1000 TF500

TF700 / TS700 3020 3020 7035 7035 2013 2013 2514 2514 5/5 5/5 675 675 625 625 3339 3539 600 TF550 600 TF550 TF550

400 400 500

* Standard TF600 TF600 TF600

200 200

TF650 TF650 TF650

0 0 0

500 600 700 800 900 1000 1100 1200 TF700 500 600 700 800 900 1000 1100 1200 TF700 500 600 700 800 900 1000 1100 1200 TF700

LOAD CENTER mm LOAD CENTER mm LOAD CENTER mm

Mast Specification (20B-7)

Overall Height Maximum Free Lift

Tilt Angle (deg)

Load Capacity without Load Capacity with Truck Weight Various Attachments

(Lowered) Fork Height side shift at 500mm LC side shift at 500mm LC (Unloaded)

Mast Type Fwd / Bwd

(mm) (mm) With Backrest (mm) Without Backrest (mm) (kg) (kg) (kg)

20B-7 20B-7 20B-7 20B-7 20B-7 20B-7 20B-7 20B-7

V250 1729 2530 140 140 5/7 2000 1890 3239

V270 1829 2730 140 140 5/7 2000 1890 3253

V300 1979 3030 140 140 5/7 2000 1890 3272

2

* V330 2129 3330 140 140 5/7 2000 1890 3292

/ Side Shift Hinged Fork Hinged Bucket Rotating Fork Push Pull Rotating Roll Clamp Load Stabilizer

Stage V350 2229 3530 140 140 5/7 2000 1890 3305

limited V370 2329 3730 140 140 5/7 2000 1890 3318

free V400 2479 4030 140 140 5/7 2000 1890 3342

lift

V450 2829 4530 140 140 5/5 1925 1825 3406

V500 3079 5030 140 140 5/5 1850 1770 3438

V550 3329 5530 140 140 5/5 1775 1715 3471

TF370 / TS370 1779 3740 777 1278 5/5 1975 1865 3389

Carton Clamp Pallet Invert Drum Clamp Bale Clamp Load Extender Fork Positioner

TF400 / TS400 1879 4040 877 1378 5/5 1925 1825 3405

TF430 / TS430 1979 4340 977 1478 5/5 1875 1785 3425

3

/ TF450 / TS450 2079 4540 1077 1578 5/5 1850 1760 3440

Stage TF470 / TS470 2129 4740 1127 1628 5/5 1825 1745 3449

full TF500 / TS500 2229 5040 1227 1728 5/5 1775 1705 3469

Optional Items

free . Mast Dual free lift 3-Stage Mast (Max. Fork Height)(mm) . Fork

TF550 / TS550 2429 5540 1427 1928 5/5 1700 1630 3507

lift 2-Stage mast (Max. Fork Height)(mm) 16/18B-7 16/18B-7(mm)

TF600 / TS600 2629 6040 1627 2128 5/5 1350 1290 3571

16/18B-7 -3735 / 4035 / 4335 / 4535 / 4735 / 5035 / 5535 / 6035 / 6535 / 7035 -750 / 850 / 900 / 1050 / 1200 / 1350 / 1500

TF650 / TS650 2829 6540 1827 2328 5/5 1300 1240 3615 -2525 / 2725 / 3025 / 3325 / 3525 / 3725 / 4025 / 4525 / 5025 / 5525 20B-7 20B-7(mm)

TF700 / TS700 3029 7040 2027 2528 5/5 950 900 3651 20B-7 -3740 / 4040 / 4340 / 4540 / 4740 / 5040 / 5540 / 6040 / 6540 / 7040 -900 / 950 / 1000 / 1050 / 1200 / 1350 / 1500 / 1600

-2530 / 2730 / 3030 / 3330 / 3530 / 3730 / 4030 / 4530 / 5030 / 5530 . Side Shift . Overshoe : 1300mm, 1500mm, 1700mm

* Standard

3-Stage mast (Max. Fork Height)(mm) Side shift, Intergral side shift . Cold Storage : Available at -300C working area

16/18B-7 . Valve & Hose Piping . Finger Tip Control

-3735 / 4035 / 4335 / 4535 / 4735 / 5035 / 5535 / 6035 / 6535 / 7035 3 Spool Internal & 4 Spool Internal Type Enhanced operator convenience

20B-7 . Dual Voltage : 36/48 Volt . Tire

-3740 / 4040 / 4340 / 4540 / 4740 / 5040 / 5540 / 6040 / 6540 / 7040 . UL & CE : UL Type “E“ & “EE“ Solid, Non-Marking

08 HYUNDAI FORKLIFT HYUNDAI FORKLIFT 09

You might also like

- BT Cargo C3E150 - C3E160-180L - C3E200 Electric Powered Forklift 1.5-2.0 Ton Maintenance ManualDocument12 pagesBT Cargo C3E150 - C3E160-180L - C3E200 Electric Powered Forklift 1.5-2.0 Ton Maintenance ManualjoseNo ratings yet

- BT C3E 1,5-2 Ton BrochureDocument8 pagesBT C3E 1,5-2 Ton BrochureОлег СкладремонтNo ratings yet

- HyundaiDocument7 pagesHyundaiSaurabh JadhavNo ratings yet

- Toyota SWE 120Document4 pagesToyota SWE 120Igor Pancevski0% (1)

- Engine Powered Forklift: 2.0 - 3.0 Ton FDZNDocument4 pagesEngine Powered Forklift: 2.0 - 3.0 Ton FDZNrahna pristiNo ratings yet

- 20D/25D/30D/33D-7: Dimension SpecificationDocument7 pages20D/25D/30D/33D-7: Dimension SpecificationАлександр ОлейникNo ratings yet

- Lockheed Constellation From Excalibur To StarlinerDocument178 pagesLockheed Constellation From Excalibur To StarlinerDaniel Papadopol100% (2)

- Dimension Specification: Hyundai Heavy IndustriesDocument6 pagesDimension Specification: Hyundai Heavy IndustriesAdven Tius Surya SurbaktiNo ratings yet

- BT Optio OME 100H Datasheet - Toyota Material Handling EuropeDocument4 pagesBT Optio OME 100H Datasheet - Toyota Material Handling Europemirzaadilbeg9No ratings yet

- EST124 EN BrochureDocument5 pagesEST124 EN BrochureanaNo ratings yet

- Toyota 7fbestDocument8 pagesToyota 7fbestjohnNo ratings yet

- Electric Powered Forklift: WWW - Toyota-Forklifts - EuDocument8 pagesElectric Powered Forklift: WWW - Toyota-Forklifts - EuValentinNo ratings yet

- CPD1520L1 EN Brochure 6Document5 pagesCPD1520L1 EN Brochure 6nelsonpa21No ratings yet

- Original Document - Toyota MHDocument4 pagesOriginal Document - Toyota MHpambudisapto4No ratings yet

- Especificação Técnica OMEDocument4 pagesEspecificação Técnica OMEregional SULNo ratings yet

- Forlift FD 50Document7 pagesForlift FD 50luong khanhbanhNo ratings yet

- Data Sheets Still Schubstapler FM X10-25 enDocument12 pagesData Sheets Still Schubstapler FM X10-25 enMahmoud Elpop ElsalhNo ratings yet

- Cpd25l2b S en Brochure 1Document5 pagesCpd25l2b S en Brochure 1Bersanz SrlNo ratings yet

- Pedestrian Stacker Truck: W-SeriesDocument4 pagesPedestrian Stacker Truck: W-SeriesXb ZNo ratings yet

- BT 7PML20 & 24Document4 pagesBT 7PML20 & 24Laszlo SzatmaryNo ratings yet

- BT Fre 270Document4 pagesBT Fre 270Laszlo SzatmaryNo ratings yet

- Тоyota LPE200Document2 pagesТоyota LPE200DayvisonMusicNo ratings yet

- ES16 RSi EN Brochure 1Document5 pagesES16 RSi EN Brochure 1nelsonpa21No ratings yet

- CQD16-20RV2 (EN) BrochureDocument9 pagesCQD16-20RV2 (EN) BrochureAsif JavedNo ratings yet

- Ejc m10 ZT Specsheet en Au 2023 02 PDF DataDocument5 pagesEjc m10 ZT Specsheet en Au 2023 02 PDF DataManny MisaNo ratings yet

- ES16 RS EN Brochure 7Document5 pagesES16 RS EN Brochure 7The NarcissistNo ratings yet

- F.T 16waDocument5 pagesF.T 16waAsesor2 comercialNo ratings yet

- EFL302EFL352 EN Brochure 8Document5 pagesEFL302EFL352 EN Brochure 8Hoàng Anh PhạmNo ratings yet

- Reach Truck 1.2 To 2.5 Ton: 7fbre SeriesDocument12 pagesReach Truck 1.2 To 2.5 Ton: 7fbre SeriesTrung NguyễnNo ratings yet

- CPD20L2 EN Brochure1Document5 pagesCPD20L2 EN Brochure1Bersanz SrlNo ratings yet

- Lpe 200BDocument4 pagesLpe 200BMuhammad FuadNo ratings yet

- Electric Pedestrian Pallet Truck: Lift Height: 122 MM / Capacity: 2200-3500 KGDocument5 pagesElectric Pedestrian Pallet Truck: Lift Height: 122 MM / Capacity: 2200-3500 KGJose LemosNo ratings yet

- Pedestrian Stacker Truck: W-SeriesDocument4 pagesPedestrian Stacker Truck: W-SeriesXb ZNo ratings yet

- Pedestrian Stacker Truck: W-SeriesDocument4 pagesPedestrian Stacker Truck: W-SeriesXb ZNo ratings yet

- Manitou MSI MH 20 EN PDFDocument8 pagesManitou MSI MH 20 EN PDFPeterNo ratings yet

- 7 Series Engine Powered Forklift 3.5-5.0 TonDocument8 pages7 Series Engine Powered Forklift 3.5-5.0 Tonwill wuNo ratings yet

- RPL201201H251301 EN Brochure 3Document11 pagesRPL201201H251301 EN Brochure 3vitor rodriguesNo ratings yet

- Swe120-140 746896-040Document4 pagesSwe120-140 746896-040Javier RodriguezNo ratings yet

- CPD15203035L1 en Brochure 2Document7 pagesCPD15203035L1 en Brochure 2Bersanz SrlNo ratings yet

- Es10 10es - Es12 12esDocument7 pagesEs10 10es - Es12 12esLacatusu MirceaNo ratings yet

- Especificacao Tecnica SWE120 140Document4 pagesEspecificacao Tecnica SWE120 140uzcarnevskisNo ratings yet

- Catalogo Tecnico Reach Toyota BT Reflex O SeriesDocument4 pagesCatalogo Tecnico Reach Toyota BT Reflex O SeriesJesús Enrique Izarra SeminarioNo ratings yet

- ES16 RS EN Brochure 4Document5 pagesES16 RS EN Brochure 4Socma ReachstackersNo ratings yet

- Es10 10eses12 12esdmmmDocument7 pagesEs10 10eses12 12esdmmmAriel CoyosNo ratings yet

- Toyota 42-7FD40Document8 pagesToyota 42-7FD40kien nguyenNo ratings yet

- EKX 410/412/514/516k/516: Electric Order Picker/tri-Lateral Stacker (1,000/1,200/1,400/1,600 KG)Document8 pagesEKX 410/412/514/516k/516: Electric Order Picker/tri-Lateral Stacker (1,000/1,200/1,400/1,600 KG)陳品宏No ratings yet

- cpd20l1s Datasheet 1Document5 pagescpd20l1s Datasheet 1Vinicio Henrique de SouzaNo ratings yet

- Lpe200i 2017-01Document4 pagesLpe200i 2017-01VladimirNo ratings yet

- EFL302, EFL352 (EN) BrochureDocument6 pagesEFL302, EFL352 (EN) BrochureBersanz SrlNo ratings yet

- Dimension Specification: Hyundai Heavy IndustriesDocument6 pagesDimension Specification: Hyundai Heavy IndustriesАлександр ОлейникNo ratings yet

- EFL181 (EN) BrochureDocument5 pagesEFL181 (EN) BrochureBersanz SrlNo ratings yet

- Created On November 18, 2020 at 12:46:40 AM UTCDocument4 pagesCreated On November 18, 2020 at 12:46:40 AM UTChaiccdk6No ratings yet

- Catalogo Hyster R16Document16 pagesCatalogo Hyster R16Michael Reategui FindlingNo ratings yet

- Pedestrian Stacker Truck: W-SeriesDocument4 pagesPedestrian Stacker Truck: W-SeriesXb ZNo ratings yet

- MS Stacker 10-10eses12Document7 pagesMS Stacker 10-10eses12shadow companyNo ratings yet

- Ejc m10b Specsheet en Au 2022 12 PDF DataDocument6 pagesEjc m10b Specsheet en Au 2022 12 PDF Databluerose333No ratings yet

- Rre160hrDocument4 pagesRre160hrKhhg AgddsNo ratings yet

- Nuovo Traigo 9FB 80 2.0-3.5 2Document6 pagesNuovo Traigo 9FB 80 2.0-3.5 2SergioNo ratings yet

- PSE-1.2 Specsheet en 2023-07Document4 pagesPSE-1.2 Specsheet en 2023-07jackson.santosgreentechNo ratings yet

- Dimension Specification: Hyundai Heavy IndustriesDocument6 pagesDimension Specification: Hyundai Heavy IndustriesАлександр ОлейникNo ratings yet

- Forklift Trucks: Environmental - FriendlyDocument12 pagesForklift Trucks: Environmental - FriendlyАлександр ОлейникNo ratings yet

- 35/40/45D-9S, 50D-9SA Tier 3 Sales Guide: Diesel Engine Fork Lift TrucksDocument84 pages35/40/45D-9S, 50D-9SA Tier 3 Sales Guide: Diesel Engine Fork Lift TrucksАлександр ОлейникNo ratings yet

- Dimension Specification: Hyundai Heavy IndustriesDocument6 pagesDimension Specification: Hyundai Heavy IndustriesАлександр ОлейникNo ratings yet

- Dimension Specification: Hyundai Heavy IndustriesDocument6 pagesDimension Specification: Hyundai Heavy IndustriesАлександр ОлейникNo ratings yet

- 20D/25D/30D/33D-7: Dimension SpecificationDocument7 pages20D/25D/30D/33D-7: Dimension SpecificationАлександр ОлейникNo ratings yet

- Dimension Specification: IdentificationDocument7 pagesDimension Specification: IdentificationАлександр ОлейникNo ratings yet

- Dimension Specification: IdentificationDocument7 pagesDimension Specification: IdentificationАлександр Олейник0% (1)

- 15D/18D/20DA-7E: Dimension SpecificationDocument6 pages15D/18D/20DA-7E: Dimension SpecificationАлександр ОлейникNo ratings yet

- 100D/120D/135D/160D-7: Optional ItemsDocument7 pages100D/120D/135D/160D-7: Optional ItemsАлександр ОлейникNo ratings yet

- 35/40/45DS-7E 50DA-7E: Diesel Forklift TrucksDocument12 pages35/40/45DS-7E 50DA-7E: Diesel Forklift TrucksАлександр ОлейникNo ratings yet

- Please Contact: Some of The Photos May Include Optional EquipmentDocument7 pagesPlease Contact: Some of The Photos May Include Optional EquipmentАлександр ОлейникNo ratings yet

- Group 2 Specifications: 1. Major ComponentsDocument8 pagesGroup 2 Specifications: 1. Major ComponentsАлександр ОлейникNo ratings yet

- 2010-2 Service La Artcool-Gallery System 3828a20926c 20120509091718 PDFDocument76 pages2010-2 Service La Artcool-Gallery System 3828a20926c 20120509091718 PDFTamo NekoNo ratings yet

- Articulacion Central R1300GDocument3 pagesArticulacion Central R1300GJose Armando Calderon YalleNo ratings yet

- GRP 4Document12 pagesGRP 4Bethany BermoyNo ratings yet

- 2023 Digital MICHELIN Product Catalogue Passenger (Summer, All-Season, Winter)Document48 pages2023 Digital MICHELIN Product Catalogue Passenger (Summer, All-Season, Winter)Ed LiewNo ratings yet

- STAVIC Recommended Initial Parts ListDocument18 pagesSTAVIC Recommended Initial Parts ListhwachooNo ratings yet

- Miata90 97A3Document1 pageMiata90 97A3Romir ChatterjeeNo ratings yet

- Motor KasabutanDocument2 pagesMotor KasabutanWynmar ParanganNo ratings yet

- DL 600Document108 pagesDL 600timothycbautistaNo ratings yet

- INDOPACIFIC For Website PDFDocument1 pageINDOPACIFIC For Website PDFVineethRajanNo ratings yet

- Produk Katalog - Juni 2021Document15 pagesProduk Katalog - Juni 2021【88】 KuroNo ratings yet

- Homework 1Document2 pagesHomework 1Mack Bragais BonNo ratings yet

- SBL Specimen Exam 2 Pre-SeenDocument10 pagesSBL Specimen Exam 2 Pre-SeenMyo NaingNo ratings yet

- Connaect Third Edition 2009Document92 pagesConnaect Third Edition 2009Alin GiumancaNo ratings yet

- MS Subgrade PreparationDocument5 pagesMS Subgrade PreparationAnduel SelamajNo ratings yet

- Central London Bus MapDocument1 pageCentral London Bus MapGreen BengalNo ratings yet

- Chapel School: Home-Based Learning Package Week 3 Third TermDocument21 pagesChapel School: Home-Based Learning Package Week 3 Third TermZuri NoveloNo ratings yet

- E ScootersMODEL PriceDocument2 pagesE ScootersMODEL Pricemurthy6332100% (1)

- Manual Grua GROVE TM S870Document90 pagesManual Grua GROVE TM S870rogerNo ratings yet

- User Guide: Supermarine Spitfire MK XVIDocument17 pagesUser Guide: Supermarine Spitfire MK XVIPedro ValdezNo ratings yet

- Laboratorio Módulo 1Document195 pagesLaboratorio Módulo 1wilson muñoz calderonNo ratings yet

- Advantages and Disadvantages in The International Physical DistributionDocument2 pagesAdvantages and Disadvantages in The International Physical DistributionKarmen Osorio100% (1)

- Pipeline Leak Detection Training - Pipeline Leak Detection CourseDocument5 pagesPipeline Leak Detection Training - Pipeline Leak Detection CourseArifihsanNo ratings yet

- Form Penilaian Aspek Pengetahuan Elemen Kompetensi Metode Jawaban Skor Tes Tulis Tes Lisan Benar SalahDocument7 pagesForm Penilaian Aspek Pengetahuan Elemen Kompetensi Metode Jawaban Skor Tes Tulis Tes Lisan Benar SalahJony RabuansyahNo ratings yet

- ANPR Attachment Requirement1Document10 pagesANPR Attachment Requirement1syed nadeemNo ratings yet

- The Public Engagement Process For Sidewalk TorontoDocument29 pagesThe Public Engagement Process For Sidewalk TorontoBabak D.V. DaraniNo ratings yet

- 14 - Section ST - Steering SystemDocument98 pages14 - Section ST - Steering SystemAndrès LandaetaNo ratings yet

- Rawmaterials Inward ProcessDocument12 pagesRawmaterials Inward ProcessKrushna MishraNo ratings yet

- FSAE Stab Rig DataDocument37 pagesFSAE Stab Rig DataahmadNo ratings yet