Sapphire Finishing Mills Water Treatment of Textiles by Hamza Yousaf

Sapphire Finishing Mills Water Treatment of Textiles by Hamza Yousaf

Uploaded by

Hamza YousafCopyright:

Available Formats

Sapphire Finishing Mills Water Treatment of Textiles by Hamza Yousaf

Sapphire Finishing Mills Water Treatment of Textiles by Hamza Yousaf

Uploaded by

Hamza YousafOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Sapphire Finishing Mills Water Treatment of Textiles by Hamza Yousaf

Sapphire Finishing Mills Water Treatment of Textiles by Hamza Yousaf

Uploaded by

Hamza YousafCopyright:

Available Formats

Sapphire Finishing Mills

9/18/2021

Sapphire Finishing Mills

Internship Report

Submitted By Hamza Yousaf

Roll No SSP-18-CE-09

Field BS CHEMICAL ENGINEERING

Department ICET Punjab university Lahore

Semester 7th

Session 2018-2022

Report Area RO Plant, ETP & Utilities of SFML

hamza yousaf

INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

ACKNOWLEDGMENT

None, however great can lay claim to absolute originality in any branch of knowledge. No one can

deny it. Everyone is indebted to their precursors in the particular field in which they are working.

I am indebted to many individuals within my branch of knowledge and outside it. At first, I am

grateful to Almighty ALLAH, The most Beneficent and Merciful, Who gave us mind to think and

all physical abilities to work out problems and obstacles faced in life, and for giving us enough

courage and commitment to complete this internship successfully. At Sapphire, we found people

very cooperative. During my internship in Sapphire I learnt a lot and found it as an excellent

learning place. I am very thankful to Mr. Engr Umair Khalid who allowed me to work under his

supervision. At this place I would also like to thank the following persons for their guidance and

warm support throughout the internship period for helping me through thick and thin and guiding

me in best possible way.

• Mr. Engr Umair Khalid (deputy manager)

• Engr Ahmed (RO)

• Engr Bilawal (RO LAB)

• Engr Rehman (ETP)

• Engr Zain (ETP)

• Engr Ubaid (ETP LAB)

• Mr.Awais, Mr.Azhar, Mr. usama and Mr.Awais (RO lab)

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

Brief History of Sapphire Group

Sapphire Group started its operations from Kalkutta (Present Day India) before moving to

Pakistan, setting up the first spinning unit and beginning its pioneering leadership in the

industry. During, the past four decades, Sapphire has grown in the textile sector by continuously

expanding and broadening its penetration into the industry. Today it's a vertically integrated

premier textile group, manufacturing cotton yarn, fabric and garments.

The Group has the most modern and organized textile production setup with products exported

to over 35 destinations around the globe. The Group employs more than 16,000 and has a well

established infrastructure of textile management. Sapphire Group has an annual turnover of

over US $800 million with an asset base of over US $500 million. The Group has also diversified

into the power generation and dairy sectors. Sapphire Electric Company is a 234 MW combined

cycle plant in Muridke. Sapphire Dairies Private Limited operates a large mechanized dairy farm

based on 100 acres near Manga, Lahore with a herd size of 3000 and a target of 10,000 milking

cows (300,000 liters per day) by 2020.

Sapphire Group is actively involved in community welfare programs and has two primary and

secondary schools -- one run by Sapphire and other by The Citizen’s Foundation -- providing

subsidized education to the underprivileged. Every spring, Sapphire holds an eye camp for the

rural community to treat patients with cataract disease. Regular donations are given to various

health and education institutions. The Chairman of the Group, Mian Abdullah, has been

awarded the Sitara-e-Imtiaz (Star of Excellence) award by the Government of Pakistan for

contributions towards the development of the country.

SAPPHIRE FINISHING MILLS

Sapphire Finishing Mills is a woven dyeing and finishing plant of Sapphire group. It started

production in 2003. The machinery here is most modern and updated made by leading textile

machinery manufacturers. The combination of machinery and strong professional experience has

enabled Sapphire make state of the art finished fabric. Sapphire has currently geared up to

produce 2.73 million meters of quality dyed and finished apparel fabric per month. It is also

catering to the ever-growing demand of bottom weight fabric in narrow width upto 70%. The area

of Sapphire Finishing Mills is about 67 Acres.

COMPANY PROFILE

Chairman: Mr. Mohammad Abdullah

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

Chief Executive: Mr. Muhammad Yousuf Abdullah

General Manager: Mr. Azhar Naseem Pasha

Processing Manager: Mr. Tariq Jamil

Total number employees of Sapphire group: 12500

Total no. of employees in SFM: 800

Total managerial staff: 70

Monthly production Achieved: 3 million meters

Monthly production Target: 4.5 million meters

Normally, cost/ meter for processing: 15-20 rupees

Email: info@sapphire.com.pk

Website: www.sapphire.com.pk Mills

Location: 3.5 km Manga Raiwind Road, Kasur Head Office: 7-A/K, Main Boulevard,

Gulburg ΙΙ, Lahore

MISSION STATEMENT

Our mission at Sapphire Finishing Mills is to grow flexible textile manufacturing capabilities to lead

the industry in meeting evolving global demands.

“THERE ARE NO SHORT-CUTS TO LONG-TERM SUCCESS”

Solid, stable and secure

The Sapphire Group is a leader among the largest integrated textile producers in Pakistan.

keeping a lead position in our business, maintaining our values based on good business ethics,

and at the same time to contribute in the development of the community in which we work and

live in.

Why more Quality at Sapphire?

Quality lab is equipped to conduct all type of tests in accordance with American & European

testing standards. Complete range of testing equipment from James H Heal & Atlas is available

in lab. Some of the properties for which fabric is tested in house are strength, light fastness, pilling,

abrasion, color fastness, crocking, stretch & durability press rating.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

WORKING AREAS DURING INTERNSHIP

➢ RO Plant

✓ What is reverse osmosis and Osmosis

✓ Process Flow Diagram of the RO plant

✓ Brief Details of the Instruments like Different Filters (MMF & Cartridge),

Pumps(Centrifugal Pumps, Water turbine Pumps), Valves and Storage tanks

✓ Calculation of Percentage Recovery of RO Plant

✓ Working of the RO membranes Process

✓ EKOPAK PLANT

✓ EDI Process in full detail with PFD

✓ Why there is a need of EDI process

➢ RO Water Line Tracing and water conservation in Utilities and Production hall

✓ Trace the RO water line of Sapphire Finishing Mills

✓ PFD of RO Water line trace

✓ Details of the each section where RO water is using

✓ Boilers House

✓ Thermal Oil Boilers

✓ Chillers House

✓ Production House (Dyeing, washing, Naoh recovery plant, Chemical formulation

house and printing finishing sections)

➢ ETP (waste water treatment plant)

✓ What is ETP

✓ Why there is a need of ETP

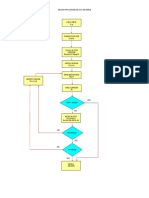

✓ PFD of the ETP with Line tracing of Process

✓ Explanation of ETP processes

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

Table of Contents

Overview of the Reverse Osmosis (RO) .................................................................................................... 8

Understanding osmosis and Reverse Osmosis .......................................................................................... 8

Reverse Osmosis ................................................................................................................................... 8

Osmosis.............................................................................................................................................. 8

TASK 1......................................................................................................................................................... 9

RO WATER PLANT OF THE SAPPHIRE FINISHING MILLS LIMITED WITH PFD AND

PROCESS DETAILS.................................................................................................................................. 9

Detail of PFD of RO Plant at Sapphire Finishing Mills.......................................................................... 11

Water Turbine Pump ............................................................................................................................... 11

Pre-Filtration Process and Pre-Treatment process .................................................................................. 12

Backwash of MMF ................................................................................................................................. 13

RO PRE-TREATMENT ......................................................................................................................... 14

RO PROCESS ......................................................................................................................................... 17

1st stage of Pressure Vessels (Membranes) of RO process ..................................................................... 17

2nd stage Pressure vessels membranes of RO process ............................................................................. 18

RECOVERY % ....................................................................................................................................... 19

EKOPAK RO PLANT .............................................................................................................................. 20

Pretreatment ............................................................................................................................................ 21

High Pressure Pump (HP) ....................................................................................................................... 22

RO PROCESS ......................................................................................................................................... 23

1st stage of Pressure Vessels (Membranes) of RO process ..................................................................... 23

2nd stage Pressure vessels membranes of RO process ............................................................................. 23

Electro De-ionization Process EDI .......................................................................................................... 24

Process Explanation ................................................................................................................................ 25

Buffer Tank 2 .......................................................................................................................................... 26

TASK 2....................................................................................................................................................... 26

RO Water Line Tracing & Consumption of the RO Water in the SFML With PFD ........................ 27

RO WATER TANK ................................................................................................................................ 28

Solid Fuel Boilers (Low Pressure Boilers) ............................................................................................. 28

Why RO water is Necessary? ................................................................................................................. 29

Scale buildup........................................................................................................................................... 29

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

System corrosion..................................................................................................................................... 29

Foaming and Priming.............................................................................................................................. 29

Energy Conservation by RO water In Boilers ........................................................................................ 30

Gas and Liquid Fuel Boilers ................................................................................................................... 30

Energy conservation by RO water .......................................................................................................... 31

Thermal Oil Boilers/Heaters ................................................................................................................... 32

Purpose of the RO water and Energy conservation ................................................................................ 32

Chillers Section ....................................................................................................................................... 33

Production Hall ....................................................................................................................................... 36

NAOH Caustic Recovery Plant (CRP) ....................................................................................................... 36

Chemical Formulation House ................................................................................................................. 37

Finishing and Recipes Production section .............................................................................................. 37

Dyeing Lab (Technical Lab) ................................................................................................................... 37

Quiring Machine and Printing Section.................................................................................................... 37

Effluent Treatment Plant (ETP) of SFML ............................................................................................. 38

Effluent Treatment Plants (ETP): ............................................................................................................ 38

What is an ETP?...................................................................................................................................... 39

Need of ETP.......................................................................................................................................... 39

Design of ETP ......................................................................................................................................... 40

Treatment Levels & Mechanisms of ETP ............................................................................................... 40

Preliminary Treatment level.................................................................................................................... 41

Primary Treatment Level ..................................................................................................................... 41

Secondary Treatment Level .................................................................................................................... 42

Methods .................................................................................................................................................. 42

Tertiary / Advanced Treatment ............................................................................................................... 42

ETP LINE TRACING PFD OF SAPPHIRE FININSHING MILLS ................................................... 43

Process Explanation ................................................................................................................................ 44

Pretreatment (Preliminary Treatment) .................................................................................................. 44

Screening ................................................................................................................................................ 44

Neutralization.......................................................................................................................................... 45

Cooling Towers....................................................................................................................................... 45

Equalization Tank 1 ................................................................................................................................ 46

Primary treatment .................................................................................................................................... 46

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

Primary Clarifier ..................................................................................................................................... 46

Secondary Treatment ............................................................................................................................... 47

Aeration tank........................................................................................................................................... 47

Secondary Clarifier ................................................................................................................................. 48

Equalization 2 ......................................................................................................................................... 48

LUCUS 4 Activated Sludge Process ....................................................................................................... 48

Advance Treatment method (Chemical method) ................................................................................... 49

Coagulation and Flocculation Tank ........................................................................................................ 49

Dissolved Air Floatation (DAF) ............................................................................................................. 49

Chlorination Tank ................................................................................................................................... 50

Sludge thickening tank & Centrifuges .................................................................................................... 50

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

Let’s start

Being a chemical Engineer Internee I performed my internship at WTP (water treatment plant).

WTP has two departments

• RO Water Plant (Pre-treatment of water)

• ETP Effluent treatment plant (Waste water treatment)

Brief Details of these two pants are in this List. Different PFDS are designed with Line Tracing of

the plants and processes for comprehensive understanding.

So, starting with the RO plant

Overview of the Reverse Osmosis (RO)

Understanding osmosis and Reverse Osmosis

Reverse Osmosis, commonly referred to as RO, is a process where you demineralize or

deionize water by pushing it under pressure through a semi-permeable Reverse Osmosis

Membrane.

Osmosis

To understand the purpose and process of Reverse Osmosis you must first understand the

naturally occurring process of Osmosis.

Osmosis is a naturally occurring phenomenon

and one of the most important processes in

nature. It is a process where a weaker saline

solution will tend to migrate to a strong saline

solution. Examples of osmosis are when plant

roots absorb water from the soil and our kidneys

absorb water from our blood.

Below is a diagram which shows how osmosis

works. A solution that is less concentrated will

have a natural tendency to migrate to a solution

with a higher concentration. For example, if you

had a container full of water with a low salt concentration and another container full of water

with a high salt concentration and they were separated by a semi-permeable membrane,

then the water with the lower salt concentration would begin to migrate towards the water

container with the higher salt concentration.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

Reverse Osmosis is the process of Osmosis in reverse.

Whereas Osmosis occurs naturally without energy

required, to reverse the process of osmosis you need to

apply energy to the more saline solution. A reverse osmosis

membrane is a semi-permeable membrane that allows the

passage of water molecules but not the majority of

dissolved salts, organics, bacteria and pyrogens. However,

you need to 'push' the water through the reverse osmosis

membrane by applying pressure that is greater than the naturally occurring osmotic

pressure in order to desalinate (demineralize or deionize) water in the process, allowing

pure water through while holding back a majority of contaminants. The water that makes

it through the RO membrane is called permeate or product water and usually has

around 95% to 99% of the dissolved salts removed from it.

TASK 1

RO WATER PLANT OF THE SAPPHIRE FINISHING MILLS

LIMITED WITH PFD AND PROCESS DETAILS

RO water is the basic need of every industry. As, day by day underground water conditions

is going to be worsen. The TDS and TSS level of the water is so high that water can’t be

use direct into the equipment for any process. Water containing different impurities like

organic and inorganic salts, TDS and TSS. Different tests are performed to check the

quantity of the impurities like

• Chloride test

• Total Hardness test

• PH test

• Conductivity test

• Alkalinity test

• P Alkalinity Test

• M alkalinity

• Silica test

• Iron test

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

• Calcium test

• Magnesium test

• Phosphorus test

These tests help us to check the water condition before using in any process. Without water

any process is not possible. So, there is a need of Process of the Water treatment. For

water treatment there are many methods like

• RO Process

• Ion exchange Method

• Softening method

• EDI Method

These methods are use to demineralize the water before using in any process to avoid the

following problems

• Scaling

• Fouling

• Pitting

• Corrosion

• Erosion

• PH control

These problems reduce the efficiency of any equipment and its life also. High maintenance

and operational cost are the result of these problems. Sapphire finishing mills has designed

the RO water treatment Plant according to their requirement of 108m 3/hr capacity. For

different equipment and processes different water quality is required like for cogeneration

plant conductivity should be 0.07 µs/cm so that’s why EKOPAK plant is here to reach this

conductivity. Details of this plant are explained comprehensively with process flow diagram

that is generated by the RO Water plant line tracing. Each and every equipment

specifications working and processing details are also given in details below.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

Detail of PFD of RO Plant at Sapphire Finishing Mills

Here is a complete detail of the Process flow diagram of the RO water plant of SFML.

Water Turbine Pump

There are four turbines working to lift underground water to the Raw water tank. These turbine

pumps are of different capacities and are named as Turbine no 1,2,3 and 4 in plant. The Purpose

of these water turbine Pumps is to suck the Underground water which is about 80 feet down the

earth to the Raw Water Storage tank of the Plant.

• Operating at 900

• Capacity of Turbine no 1, 2 and 4 is per 150 m3/hr

• Capacity of turbine no 3 is 100 m3/hr

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

• Conductivity of Turbines water in Storage Tank is 2000-

2200 µs/cm.

• PH range is 8 – 9

Water of these turbines 1st come into the Raw water common

header. Then header distribute the water into Raw water storage

tank. Water of turbine no 1 is also distributing to the Colony and

mini filter plant. Remaining water of other Turbines and Turbine

no 1 is supplying to the Raw Water Storage tank.

Pre-Filtration Process and Pre-Treatment

process

In RO plant 1st stage is pre-filtration of raw water. As, Raw is stored in the Raw water storage

Tank. Here a centrifugal pump is used to lift the water from Raw water Storage tank to the Pre

filtration process. Pre-filtration process is used to remove the suspended contaminant from Raw

water and to remove the fouling causing agents in the water. Pre-Filtration Process comprises of

following stages.

1. Multi-media filter (MMF)

2. 5 Microns Cartridge Filter

3. 1 Microns Cartridge Filter

Here is the complete detail of Pre-Filtration process

I. Multi-Media Filter (MMF) /sand Filter - B

Centrifugal pump is lifting the Raw water from the raw water storage tank into MMF. Before the

MMF a butterfly Valve is installed to Regulate the Flow of Raw water into MMF. Then pressure

transmitter is also present in the feed line. Inlet pressure of the MMF Is 1.9 Bar.

Purpose

A Multi-Media Filter is used to help prevent fouling of an RO system. Fouling occurs when

contaminants accumulate on the membrane surface effectively plugging the membrane.

There are many contaminants in municipal feed water that are naked to the human eye and

harmless for human consumption, but large enough to quickly foul (or plug) an RO system.

Fouling typically occurs in the front end of an RO system and results in a higher pressure

drop across the RO system and a lower permeate flow.

Fouling can be caused by the following:

1. Particulate or colloidal mater (dirt, silt, clay, etc.)

2. Microorganisms (bacteria, viruses etc). Bacteria present one of the most common fouling

problems since RO membranes in use today cannot tolerate a disinfectant such as

chlorine

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

Working

At this inlet pressure water is showering from the top of the MMF with the help of nozzles. By this

water is equally distributed in the MMF tank. In MMF

multi stages (layers) are used to filter the raw water.

Multi layers are of Anthracite(charcoal), Sand, Garnet

and filtration Gravels. At the bottom of the MMF

strainer nozzles are using to provide the support to the

filtration layers of different materials in MMF. On the

supporting strainer the 1st layer is of the material which

have high gravity value. On this layer on upward side

the layer which have low gravity is used and so on in

upward direction. 20 – 25 microns size of TSS are

trapped in the filter media and filtrate passed out the

media layer.

Before entering the feed water in the MMF tank vacuum is removed with the help of vent valve

which is present on the top of the MMF. Then Raw water is shower on the 1st layer of filtration

media passing through different filtration layers and large particles or suspended contaminants

trapped in these layers while clear water is passed through the bottom of MMF. Outlet pressure

of Product water of the MMF is 1.6 Bar.

Specifications

• 20 – 25 Microns Size of particles trapped in this MMF

• Capacity of the Sand Filter-B is 73 m3/hr

• Empty weight 4500kg

• Design Pressure 6 Bar

• ∆p Limit is 0.5 Bar

Backwash of MMF

A backwash is performed by reversing the flow of water through the Multi Media Filter bed to

remove the suspended solids TSS that are trapped in the bed. When pressure difference exceeds

the value of 0.5 bar then backwash is applied. This is very important process for the filtration

media. As pressure difference causes the low filtration rate and Scaling fouling problems in MMF.

So, Backwash is applied to avoid these situations. Hence the TSS which are on the filter are drain

by backwash.

II. Cartridge Filter 5 micron

After MMF next stage of pre filtration process is to pass the filter water form the cartridge filter of

5micron size. The inlet pressure of the cartridge filter is 1.6 Bar.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

Purpose

Prefiltration (cartridge filtration) is perhaps the most

important part of a satisfactory performance of RO

unit after the RO membranes themselves. The ability

of depth and cartridge filters to remove suspended

particulates, colloids and larger color causing

organics (NOM) from the feed stream greatly

impacts the performance and longevity of any RO

equipment and specifically the high performance

units.

5micron - Will remove most particles visible to the

naked eye. Cartridge filters can be composed of a number for materials. Some may be made from

wound strands of a material such as polypropylene. Cartridge filters can screen out twice as much

dirt and debris as a sand filter. Its larger filtration area allows the water to progress through

the cartridge removing smaller particles. Maintenance is much easier in that there is no need for

a back-washing step.

Working

Feed water enter from the center of the Cartridge filter at pressure of 1.6 bar. There are 18 filters

in the CF. water at pressure passes through the filters here unwanted TSS trapped. Particles of

size larger than 5 microns trapped here while other remaining water molecules passes through

the filters. Hence filter water of 8 filters then come out of the CF from the bottom. The outlet

pressure is 1.2 Bar. Pressure drops occur due to filtration.

Specifications

• Filter made up of Polypropylene PP

• No of filters are 18

• Size 5 Microns

• No need of backwash

RO PRE-TREATMENT

Proper pretreatment using both mechanical and chemical treatments is critical for an RO

system to prevent fouling, scaling and costly premature RO membrane failure and frequent

cleaning requirements. Below are some pretreatment solutions for RO systems that can

help minimize fouling, scaling and chemical attack. After the cartridge filter of 5 microns the

pressure of water is 1.2 bar here two chemicals are added in the feed water stream before

entering into the cartridge filter of 1 micron. These chemicals are Anti-Scalent and Biocide. There

is a special purpose of adding these chemicals into main feed line.

Anti-Scalent

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

As the name shows that it is against the scaling. This chemical prevents the scales formation in

the membranes of pressure vessels. As certain dissolved (inorganic) compounds become

more concentrated (remember discussion on concentration factor) then scaling can occur

if these compounds exceed their solubility limits and precipitate on the membrane surface

as scale. The results of scaling are a higher pressure drop across the s ystem, higher salt

passage (less salt rejection), low permeate flow and lower permeate water quality. An

example of a common scale that tends to form on an RO membrane is calcium carbonate

(CaCO3) . These started to deposit on the walls of the Pressure vessels and membranes. Hence,

destroy the vessels and membranes. Performance and life of the membranes get low due to

scales formation. For this reason, the Anti-scalent dosing is important continuously in the Feed

water stream.

Working

Anti-scalants and scale inhibitors increase the solubility limits of troublesome inorganic

compounds. By increasing the solubility limits, you are able to concentrate the salts further

than otherwise would be possible and therefore achieve a higher recovery rate and ru n at

a higher concentration factor. Anti-scalants and scale inhibitors work by interfering with

scale formation and crystal growth. The choice of anti-scalant or scale inhibitor to use and

the correct dosage depends on the feed water chemistry and RO syste m design.

Biocide

Biocide is also a chemical which is dosed in the feed water stream. As virus, fungi and Algae are

of small size. Membrane pore size is of 0.0001micronmeter

• Bacteria size range is 0.4 to 1 micron meter

• Virus size range is 0.2 to 1 micron meter

• Colloids size range is 0.001micron meter

• Salt NACL size range 0.0007micron meter

These contaminants can’t pass through the membranes in pressure vessel. Only water molecules

passes through membrane other TSS separate out. To kill these Bacteria and Viruses Biocide is

used. This Biocide controls the growth of Bacteria fungi and viruses in the pipes and vessels.

CIP Tank

CIP stands for the Clean in Place is the method to clean the interior of vessels, pipes, equipment’s

and filters Without major disassembly. CIP is commonly use for the piping, Tank and filters For

the Nominal system performance CIP cleaning is necessary.

Basically, this tank is connected to the Main feed line. There is a butterfly valve and NRT valve

(non-return valve) is used in the line. This line is connected to main feed line before the cartridge

filter of 1 micron. The tank is full of RO product water of conductivity 35-40(µs/cm) and Biocide

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

chemical is dose with it when plant is shut down. When pressure difference in the pressure

vessels exceeds the limit then shut down applied and water from CIP tank is taken into the vessels

to avoid the Fungi, Algae growth in the membranes of the pressure vessels. CIP controls the

growth of TSS like Fungi, Algae etc.

III. Cartridge filter of 1 micron

Water enters at 1.2 bar pressure I cartridge filter of 1 micron size the working of this filter is same

as the cartridge filter of 5 micron but the major difference is the filter size. Here the size is 1 micron

meter the unwanted particles TSS and TDS of size larger than 1micron meter trapped here hence

remaining small size molecules passes through this filter. The outlet pressure is 1.1 bar. No of

filters in the CF is 18 and of size of 1microns meter. Basically, this is also used to control the

fouling in membranes.

Specifications

• Size of Filters is 1micron meter

• No of filters 18

• Filters are made up of the PP polypropylene

• No need of backwash

High Pressure Pump (HP)

The high pressure pump is the heart of the desalination process—

every desalination plant must have at least one high pressure pump.

The main purpose of this pump is to overcome the osmotic pressure

for the Reverse osmosis through the membranes of the pressure

vessels. Before the Pump the pressure guage and the pressure

transmitter is installed. The inlet pressure is 1.1 Bar. The Pump is

centrifugal pump it is used because of easier operation, maintenance

and scalability to larger capacities. To deal with high pressure multi-

stage impellers are used in the pump. Water inter into the pump by

suction head Motor is connected by shaft with the impeller water

enters into the impeller hence out at the diffuser head with high kinetic energy this kinetic energy

converts into the high pressure of 1.9 bar. As the pump is operating at 45HZ it can run on

maximum 50Hz. The running of the Pump depends on the overcoming of the Osmotic pressure.

If pressure drops increase more Pressure will be needed so pump will run at high speed.

Pump specifications

• Capacity of pump is 90m3/hr

• Frequency range 50Hz

• Type is vertical type centrifugal pump

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

• R.P.M IS 2960

RO PROCESS

Now the RO process starts it basically comprises of double stages for maximum recovery of the

water. RO process ratio is 6:3. Detail of RO process is given below.

1st stage of Pressure Vessels (Membranes) of RO process

Treated Feed Water from the HP Pump at 1.9 bar passes through the Globe valve. Globe valve

is use to regulate the high pressure flow of water. Then water at high pressure enters the 1st stage

of pressure vessels which are 6 in number. These pressure vessels comprise of Membranes.

There are 6 membranes in one pressure vessel. Membranes are made up of poly amide polymer.

Membranes are spiral in shape wounded around the pipe.

When water enters into the vessel then it enters into the membranes TSS and TDS like viruses,

bacteria are trapped here in membrane as concentrate the outlet pathway of the concentrate is

separate. The water molecules that pass through the membrane enters into the central pipe and

come out of the pipe as permeate from other end. Hence the Permeate of the 6 pressure vessels

membranes (1st stage) comes in to the product line. While the reject or concentrate of these

Membranes send to the next stage of pressure vessels which are 3 in number for more

purification.

Specifications of RO process

• No of Pressure Vessels of 1st stage 6 and 2nd stage is 3

• No of membranes in each Vessel 6

• Length of 1 membrane is 40 inches

• Diameter of 1 membrane is 8 inches

• Capacity of each vessel is 9m3/hr

• Capacity of 1st stage of RO process is = 9 x 6 = 54m3/hr

• Ratio of membranes is 6:3

• Conductivity 35-40 µs/cm

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

2nd stage Pressure vessels membranes of RO process

The reject or concentrate of the 1st stage membranes comes into the 2nd stage membranes. 2nd

stage RO process contains 3 pressure vessels. In a two-stage system the concentrate (or

reject) from the first stage then becomes the feed water to the second stage. The permeate

water is collected from the first stage is combined with permeate water from the second

stage. Additional stages increase the recovery from the system. The reject of the 2 nd stage

is send to the Raw water tank for again use.

Specifications of 2 nd stage are same as the 1 st stage like membranes number and size.

The only difference is the number of pressure vessels to recover the water as much as

possible. The conductivity of permeate water is 35-40 µs/cm. This conductivity is suitable to

use for the Boilers, Chillers, thermal oil Boilers and other production unit sections.

Working of RO process

Reverse Osmosis works by using a high pressure pump to increase the pressure on the

salt side of the RO and force the water across the semi-permeable RO membrane, leaving

almost all (around 95% to 99%) of dissolved salts behind in the reject stream. The amount

of pressure required depends on the salt concentration of the feed water. The more

concentrated the feed water, the more pressure is required to overcome the osmotic

pressure.

The desalinated water that is demineralized or

deionized, is called permeate (or product)

water. The water stream that carries the

concentrated contaminants that did not pass

through the RO membrane is called the reject

(or concentrate) stream.

As the feed water enters the RO membrane

under pressure (enough pressure to overcome

osmotic pressure) the water molecules pass through the semi-permeable membrane and

the salts and other contaminants are not allowed to pass and are discharged through the

reject stream (also known as the concentrate or brine stream), which goes to drain or can

be fed back into the feed water supply in some circumstances to be recycled through the

RO system to save water. The water that makes it through the RO membrane is called

permeate or product water and usually has around 95% to 99% of the dissolved salts

removed from it.

Specifications

Filter feed water quantity : 146 M3/hour

Product water(permeate quantity): 106 M3/hour

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

Blend water quantity : 14 M3/hour

Recovery : 80%

Rejection : 20%

Feed water temp. : 28C

Mode of operation : Automatic

Buffer 1 & RO water Storage Tank

The Buffer 1 is the storage tank of RO water. The water from the RO process send to RO

water storage tank which is under the RO plant. This tank level always on maximum as for

emergency conditions. The Water from the RO water storage tank Lift up by the Centrifugal

pump to the Buffer 1 tank.

•

Capacity of Buffer 1 is 250m 3

•

Capacity of RO storage tank is 1100m 3

When the water level of the underground water tank is full then water after the RO process

directly send to the Buffer 1 by the centrifugal pump. The RO water is filled in tank from the

top side. Then from the bottom there is outlet side. Pump makes the suction of Buffer 1

water and discharge to the other sections of the Industry like Boiler house, Chillers house,

Thermal oil Boilers house and production hall.

RECOVERY %

Percent Recovery is the amount of water that is being 'recovered' as good permeate water.

Another way to think of Percent Recovery is the amount of water that is not sent to drain

as concentrate, but rather collected as permeate or product water. The higher the recovery

% means that you are sending less water to drain as concentrate and saving more

permeate water. However, if the recovery % is too high for the RO design then it can lead

to larger problems due to scaling and fouling. The % Recovery for an RO system is

established with the help of design software taking into consideration numerous factors

such as feed water chemistry and RO pre-treatment before the RO system. Therefore, the

proper % Recovery at which an RO should operate at depends on what it was designed

for. By calculating the % Recovery you can quickly determine if the system is operating

outside of the intended design. The calculation for % Recovery is below:

𝑝𝑒𝑟𝑚𝑒𝑎𝑡𝑒 𝑓𝑙𝑜𝑤

%Recovery = 𝑥 100

𝑓𝑒𝑒𝑑 𝑓𝑙𝑜𝑤

49.3

= 𝑥100 = 74.6%

66

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

For example, if the recovery rate is 75% then this means that for every 100 gallons of feed

water that enter the RO system, you are recovering 75 gallons as usable permeate water

and 25 gallons are going to drain as concentrate. Industrial RO systems typically run

anywhere from 50% to 85% recovery depending the feed water characteristics and other

design considerations.

EKOPAK RO PLANT

EKOPAK is basically a company name. The RO plant is manufactured by the EKOPAK

company so it is called EKOPAK RO plant. As, in industry for power generation there is an

need of the Cogeneration plant. In Sapphire Finishing Mill there is a cogeneration plant of

5.5MV. Here in this plant a High pressure boiler is using for running the turbine to produce

the 5.5MV of energy. The Industry need of Power is 5MV. So it I fulfilling the industry

requirements of Power demand.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

The Steam producing by the Cogeneration plant is of 65 Bar pressure and t he capacity of

the HP Boiler to produce steam is 55tonn/hr. Industry need of the steam is 50-55Tonn/hr.

So, for this HP Boiler there is a need of special treatment for its feed water. We can’t use

the Water of high conductivity or TDS that will directly effect the Turbine. As Silicon in the

water and other TDS like chloride etc are very dangerous for the turbine. So, low

conductivity water is required for the Cogeneration plant that’s why this plant is in the

industry to treat the water to low conductivity of 0.07 µs/cm. Now here is a detail of EKOPAK

RO plant detail.

Buffer TANK 1

From the buffer tank 1 the water of conductivity 35-40 µs/cm is taken to the EKOPAK plant.

There is a centrifugal pump which takes suction from the which take the suction from the buffer

tank one and discharge in to the EKOPAK RO plant as a feed water.

Pretreatment

Before entering the into RO membranes there is a need of pretreatment of water to avoid scaling

and fouling problems. Pretreatment comprises of the following stages.

• Caustic dosing

• Cartridge Filter

Dosing of caustic

Caustics, for a few process applications, can be injected to increase the RO feed PH. Typically

the only caustic injected is sodium hydroxide [NaOH] based on its cost, its availability, and its

solubility in water. Caution is required in raising the feed pH as it can decrease the solubility of

iron, manganese, and calcium carbonate as measured by an increasing LSI.

The most common process application that uses a caustic feed involve 2nd pass RO systems. In

a 2-Pass RO, the permeate from a 1st pass RO becomes the feed to the 2nd pass. The 2nd pass

RO “polishes” the 1st pass permeate to quality levels as good as. Caustic is introduced into the

2nd pass feed for 4 reasons:

• At a pH of 8.2 and higher, all carbon dioxide gas is converted into the bicarbonate ion.

The bicarbonate ion will be rejected by the RO.

• Carbon dioxide, being a gas, would pass through the RO into the permeate stream

unimpeded.

• The carbon dioxide would become an undesirable load to downstream polishing mixed

beds. Certain TOC constituents are better rejected at a higher pH.

• Silica rejection and solubility are higher at elevated pH levels (particularly above pH 9).

Boron rejection is higher at elevated pH levels (particularly above a pH of 9)

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

➢ Cartridge filter of 5microns meter size

Prefiltration (cartridge filtration) is perhaps the most important part of a satisfactory performance

of RO unit after the RO membranes themselves. The ability of depth and cartridge filters to remove

suspended particulates, colloids and larger color causing organics (NOM) from the feed stream

greatly impacts the performance and longevity of any RO equipment and specifically the high

performance units.

5micron - Will remove most particles visible to the naked eye. Cartridge filters can be composed

of a number for materials. Some may be made from wound strands of a material such as

polypropylene. Cartridge filters can screen out twice as much dirt and debris as a sand filter. Its

larger filtration area allows the water to progress through the cartridge removing smaller particles.

Maintenance is much easier in that there is no need for a back-washing step.

Working

Feed water enter from the center of the Cartridge filter at pressure of 1.6 bar. There are 18 filters

in the CF. water at pressure passes through the filters here unwanted TSS trapped. Particles of

size larger than 5 microns trapped here while other remaining water molecules passes through

the filters. Hence filter water of 8 filters then come out of the CF from the bottom. The outlet

pressure is 1.2 Bar. Pressure drops occur due to filtration.

Specifications

• Filter made up of Polypropylene PP

• No of filters are 18

• Size 5 Microns

• No need of backwash

High Pressure Pump (HP)

The high pressure pump is the heart of the desalination process—every desalination plant must

have at least one high pressure pump. The main purpose of this pump is to overcome the osmotic

pressure for the Reverse osmosis through the membranes of the pressure vessels. Before the

Pump the pressure guage and the pressure transmitter is installed. The Pump is centrifugal pump

it is used because of easier operation, maintenance and scalability to larger capacities.

To deal with high pressure multi-stage impellers are used in the pump. Water inter into the pump

by suction head Motor is connected by shaft with the impeller water enters into the impeller hence

out at the diffuser head with high kinetic energy this kinetic energy converts into the high pressure

of 1.9 bar. As the pump is operating at 45HZ it can run on maximum 50Hz. The running of the

Pump depends on the overcoming of the Osmotic pressure. If pressure drops increase more

Pressure will be needed so pump will run at high speed.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

Pump specifications

• Capacity of pump is 90m3/hr

• RPM is

• Frequency range 50Hz

• Type is vertical type centrifugal pump

CIP Feed

Basically, this tank is connected to the Main feed line. There is a butterfly valve and NRT valve

(non-return valve) is used in the line. This line is connected to main feed line before the cartridge

filter of 1 micron. The tank is full of RO product water of conductivity 35-40(µs/cm) and Biocide

chemical is dose with it when plant is shut down. When pressure difference in the pressure

vessels exceeds the limit then shut down applied and water from CIP tank is taken into the vessels

to avoid the Fungi, Algae growth in the membranes of the pressure vessels. CIP controls the

growth of TSS like Fungi, Algae etc

RO PROCESS

Now the RO process starts it basically comprises of double stages for maximum recovery of the

water. RO process ratio is 5:2. Detail of RO process is given below.

1st stage of Pressure Vessels (Membranes) of RO process

Treated Feed Water from the HP Pump at 1.9 bar passes

through the Globe valve. Globe valve is use to regulate

the high pressure flow of water. Then water at high

pressure enters the 1st stage of pressure vessels which

are 5 in number. These pressure vessels comprise of

Membranes. There are 6 membranes in one pressure

vessel. Membranes are made up of poly amide polymer.

Membranes are spiral in shape wounded around the pipe.

When water enters into the vessel then it enters into the membranes TSS and TDS like viruses,

bacteria are trapped here in membrane as concentrate the outlet pathway of the concentrate is

separate. The water molecules that pass through the membrane enters into the central pipe and

come out of the pipe as permeate from other end. Hence the Permeate of the 5 pressure vessels

membranes (1st stage) comes in to the product line. While the reject or concentrate of these

Membranes send to the next stage of pressure vessels which are 2 in number for more

purification.

2nd stage Pressure vessels membranes of RO process

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

The reject or concentrate of the 1st stage membranes comes into the 2nd stage membranes. 2nd

stage RO process contains 2 pressure vessels. In a two-stage system the concentrate (or

reject) from the first stage then becomes the feed water to the second stage. The permeate

water is collected from the first stage is combined with permeate water from the second

stage. Additional stages increase the recovery from the system. The reject of the 2 nd stage

is send to the Raw water tank for again use.

Specifications of 2 nd stage are same as the 1 st stage like membranes number and size.

The only difference is the number of pressure vessels to recover the water as much as

possible. The conductivity of permeate water is 9 µs/cm. Then further EDI is use to low the

conductivity value to 0.07 µs/cm.

Specifications of RO process

• No of Pressure Vessels of 1st stage 5 and 2nd stage is 2

• No of membranes in each Vessel = 6

• Length of 1 membrane is = 40 inches

• Diameter of 1 membrane is = 8 inches

• Capacity of each vessel is = 9m3/hr

• Capacity of 1st stage of RO process is = 9 x 5 = 45 m3/hr

• Ratio of membranes is 5:2

• Conductivity 9.97 µs/cm

• PH = 6.61

Electro De-ionization Process EDI

Electro-deionization (EDI) is a water treatment technology that utilizes electricity, ion exchange

membranes and resin to deionize water and separate dissolved ions (impurities) from water. It

differs from other water purification technologies in that it is done without the use of chemical

treatments and is usually a polishing treatment to reverse osmosis (RO). There are also EDI units

that are often referred to as continuous electro-deionization (CEDI) since the electric current

regenerates the resin mass continuously. CEDI technique can achieve very high purity, with

conductivity below 0.1 μS/cm.

Working Principle

The typical EDI installation has the following components:

anode and cathode, anion exchange membrane, cation

exchange membrane and the resin. The most simplified

configuration consist in 3 compartments, to increase the

production these number can be increased.

The cations flow towards the cathode and the anions flows

toward the anode. Only anions can go through the anion

exchange membrane and only cations can go through the

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

cation exchange membrane. This configuration allows anions and cations to only flow in one

direction because of the membranes and the electric force, leaving the feed water free of ions,

(deionized water).

The concentration flows (right and left of the feed flow) are rejected and they can be wasted,

recycled, or use in another process. The purpose of the ion exchange resin is to maintain stable

conductance of the feed water. Without the resins, the conductance will drop dramatically as the

concentration of ions is decreasing. Such drop off of conductance makes it very difficult to

eliminate 100% of the ions, but using resins makes it possible.

Process Explanation

• RO 1 permeate comes into the EDI section at conductivity of 9.6 μS/cm . PH is 6.61 and

temperature is 29.50C.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

• Then there is Butterfly valve to regulate the flow. CIP Feed inlet is also in the line here.

• RO 1 permeate divides into to stream as RO1 Product and RO1 Reject. These two lines

enters in the EDI Vessels.

• EDI vessels are 3 in number. Both RO1 Product and RO1 Reject enters into the 3 EDI

vessels. Here in vessels EDI process occurs which has explained above in working

principle.

• EDI vessels are numbered as EDIX01,EDIX02,EDIX03. R01 product in is Named as FT01

and Reject in as FT02.

• After the EDI process the Permeate and reject of each vessels comes out. Permeate

named as EDISV03,EDISVO5,EDISVO7. Same as Reject lines are

EDISV04,EDISVO6,EDISVO8.

• Permeate of all 3 vessels comes in the single line then there is conductivity meter in the

path to measure the conductivity. Here conductivity value is 0.07 μS/cm.

• Permeate is pumped to the Buffer tank 2 . Buffer tank 2 capacity is 250m 3. This water is

then send to the cogeneration boilers for the stream and power generation.

• Reject line is drained with conductivity of the 33 μS/cm.

Buffer Tank 2

The permeate of the EKOPAK EDI plant directly going to the buffer tank 2. Buffer tank 2 supply

water to the CO-generation plant with the help of the pump. There are two Pumps one is standby

pump. In this way water is supplying to the cogeneration plant for steam and electricity

Generation.

• Capacity of the Tank is 250m3/hr.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

Task 2

RO Water Line Tracing & Consumption of the RO Water in the

SFML With PFD

RO water is stored in the RO water tank and Buffer tank 1 and Buffer Tank 2 after RO processing.

This RO water is for different use in the industry. Below is the complete detail of the different

sections of the SFML where RO water is using and for which purpose it is using. There is a

complete Process Flow Diagram which is made by the RO water line tracing in the industry. By

this PFD one may understand the pathway of RO water in SFML. Here is a PFD of the RO Water

line.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

RO WATER TANK

Ro water tank is of 1100m3 capacity is always fully completed with RO water to use for the Industry

different sections like in utilities and Production hall. This water has 35-40 conductivity. Different

sections has different purposes to use this water not the Raw water. Basically for the other

sections it is working like feed RO water tank. There is a Pump to lift this water to Utilities Section

and Production Hall. Buffer tank 1 line is also given in RO water main line because some how

problems may be with Raw water tank happens so in emergency cases this line will directly use

for this purpose this line is given to main RO water line.

From Pump 4 inches line originate and take this water to other sections. Buffer tank 1 line also

join this line after the pump.

Solid Fuel Boilers (Low Pressure Boilers)

There are Two solid fuel boilers known as Gatebac

Boilers. Both have the capacity of generating 50

tonn/hr of steam. These two boilers are Running of

the solid fuels like coal and straws. Industry demand

of the steam can be fulfill by these two boilers. There

are serving as Standby boilers. Main steam and

energy is generating in Co-Generation plant. Some

how issues happens then these standby boilers run

to meet the steam demand of the energy.

• These are water tube boilers as they are Low pressure boilers.

• Operating at 9 Bar of the pressure.

• Capacity of each is 25tonn/hr steam generation.

For the Boiler basic Feed is the water. As purpose of boiler is to convert the Water into the Steam.

So, here water is the basic need of the boiler. So, what problems a Raw or untreated water can

cause are listed here.

Problems Associated by Untreated water

Calcium and magnesium: causes scaling of the boiler feed water.

- Silica: known to cause hard scaling. Silica needs to be reduced to low levels to avoid any

operating issues.

- Iron and manganese: can damage downstream equipment and have an affect on the quality

of the water.

- Copper: decreases the efficiency of boiler feed equipment when deposited in high-pressure

turbines.

- Magnesium: has the ability to stick to the inside of the boiler, also causing scaling.

- Hardness: causes scaling on boiler piping.

- Aluminum: can react with silica to increase scaling.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

- Dissolved gases: can cause severe corrosion to the boiler due to oxygen and carbon dioxide

presence.

Why RO water is Necessary?

An Ro water line of 4” is given to these gatebac boilers. Having pretreatment for a boiler is

necessary to keeping your plant operating safely and efficiently. Installing a reverse osmosis

system in place will lower operating costs of the boiler, as well as reduce the blow down times,

formation of scale and corrosion.

Scale buildup

Scaling is a deposit formed on the inside of piping and heat transfer surfaces when the water is

heated and impurities precipitate or settle out leaving

behind extremely hard deposits.

Some common feed water contaminants that cause scaling include:

• Silica

• Iron

• Calcium

• Magnesium

• Aluminum

System corrosion

Corrosion in boilers, or the breakdown of the metal elements of the device, can happen for a

variety of reasons. The most common reason is the presence of dissolved oxygen and carbon

dioxide, which eat away at areas of the boiler causing system stress

and cracking. The higher the boiler pressures, the more severe the

corrosion. When chlorides are present at an unacceptable level,

chloride stress cracking can also occur.

Corrosion typically occurs in the parts of the boiler that are heated

the most, where high temperatures and cracking in the metals

accelerate the breakdown of the materials. There are several types

of corrosion that can occur in a boiler, and the type you might

encounter can depend on the proper pH, level of oxygen, amount

of solids, and overall design of the boiler.

Foaming and Priming

Foaming and priming in a boiler occurs when there are high amounts of dissolved solids present

at the water surface. When the steam is generated, these impurities bubble up (foaming) and

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

evaporate with the steam (priming), latching on to superheaters and turbines, decreasing their

efficiency. Foaming is the production of persistent foam or bubbles in boilers, which do not break

easily. Foaming is due to presence of substances like oils (which greatly reduce the surface

tension of water).

Priming and foaming usually happen simultaneously. It’s best to avoid them because:

1. they can cause dissolved salts to deposit on superheater and turbine blades, reducing

system efficiency

2. they might allow dissolved salts to enter other parts of the system, thereby reducing the

service life of the affected machinery

Energy Conservation by RO water In Boilers

• Reduce fuel costs through lower heat loss and increased boiler cycles. Reducing the total

dissolved solids (TDS) in the RO product water can increase the boiler’s cycles of

concentration. The boiler will also have a cleaner heat transfer surface and is more

efficient.

• Improve operation and steam purity. Steam quality is improved because you are providing

better quality feedwater to the boiler. Any control valves, pumps, or compressors that have

direct steam contact are less prone to failure. There are no concerns with contaminated

products because the steam is pure.

• Reduce chemical costs. The amount of boiler feed chemicals required to prevent

condensation corrosion is less due to lower alkalinity in the boiler makeup water.

• Control return-line corrosion. Corrosion is one of the main reasons for boiler down time.

Maintaining the proper pH and alkalinity levels will help control corrosion.

• Extending equipment life. Oxygen, iron, and copper levels should be very low and pH

should be maintained between 8.5 and 9.5 to protect the boiler system.

Gas and Liquid Fuel Boilers

There are 3 boilers in this House. This is also the part of Utilities section. These are Low Pressure

Boilers. Boilers data is Given Below

LOOS Boiler

• 25 tonn/hr Steam Generation capacity

• Fire tube boiler

• Run on Gas and Furnace oil

• Operating Pressure is 9 bar

• Number of Tubes around about 500.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

DDFC Boilers

• These are 2 in number

• Capacity of each is 15tonn/hr of steam generation(15+15=30tonn/hr)

• Both can operate at gas and furnace oil.

• Operating pressure is 9bar

• Low pressure Boilers

• Number of tubes are around about to 300 In each.

These boilers have the tendency to generate the 55tonn/hr of steam according to the requirement

of the industry. Here is the RO water line is taken from that is coming as 4” line from RO water

tank. The line entering in this boiler house is of 2” size. 1st this enters into the Feed water tank of

the boilers. Where a Different chemcials are dosing into the Feed water tank for different purposes

like

• Sulphite for the Oxygen removal

• Phosphate as Anti scalent

• Amion for the TDS control

After dosing the water is feed to the boilers. They also serving as standby boilers. Water treatment

is necessary before feeding into the boiler. Though it is fire tube or Water tube both needs treated

water. Different Problems associated with the Untreated water are explained previously in Solid

fuel boilers in detail with the solution of RO process.

• Corrosion problem

• Fouling problem

• Scaling

• Foaming

Energy conservation by RO water

• It is already explained as it reduces the boilers running cost by improving its efficiency.

Improve operation and steam purity. Steam quality is improved because you are providing

better quality feedwater to the boiler. Any control valves, pumps, or compressors that have

direct steam contact are less prone to failure. There are no concerns with contaminated

products because the steam is pure.

• Reduce fuel costs through lower heat loss and increased boiler cycles. Reducing the total

dissolved solids (TDS) in the RO product water can increase the boiler’s cycles of

concentration. The boiler will also have a cleaner heat transfer surface and is more

efficient

Economizer

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

• Waste gases from the Boilers are known as the Vent gases. The temperature of these

gases is very high that can be used to pre heat the water in economizer. This is the Energy

conservation Rule is using here in Boilers.

• Waste gases transfer their heat to the feed water and hence energy is not lost here it being

used to pre heat the water in economizer to 1200c. Economizer increases the boiler

efficiency.

Thermal Oil Boilers/Heaters

From the main RO water line of 4”. A line of 2” is taken into the Thermal Oil Heaters House. There

is a special purpose of this RO water line here which will explain after the explanation of thermal

oil Boilers or heaters.

Name of the boilers are Basuki Boilers. Here, Thermal oil that

is using as heating medium in the industry is heated in the

heaters to 265 degree centigrade. The Working and purpose

of this Thermal oil is same as Steam that si for heat transfer

in different sections of the industry in close loop. As steam is

using in open loops also but thermal oil is always use in close

loop. Temperature of heated oil before entering in production

hall is 2650c while the temperature of the Thermal oil coming

back of the Production hall in close loop is 2550c.

Purpose of the RO water and Energy conservation

These Basuki boilers are running on the solid fuels like coal etc. So, vent gases are leaving the

boilers are of high temperature. Temperature of these gases is reducing by the use Economizer.

In Economizer RO water is showered from the top and vent gases moves in counter direction.

Here energy of vent gases is taken up by the water and temperature of the Ro water raises too

the 900c.

By this heat transfer temperature of vent gases which is 3000c drops to the 1500c. Hence energy

conservation is using here. This preheated water then sent to the Gatebac boilers in this way

Efficiency of the boilers is maintained and Energy remains conserved. As only Ro water can be

use for the boilers running so that’s why RO water is just preheating here for the other utilities

section whenever they needed. Otherwise, they are not using this RO water.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

Chillers Section

Here Ro water is coming in 2” pipe line. Basically, there

are 3 Cooling towers and chillers each connected with its

own is present for the heat transfer purposes. Water is the

basic need in this section as it is using as heat transfer

medium by the process of evaporation the chillers cools

the water more after cooling towers then by ducts the cool

water Is supplied to every part of the industry where heat

exchangers are using to blow the hot air on the cool water

line in this way air becomes cool by heat transfer and using

in every office. This is the best example of the energy

conservation also. As, water is using in close loop here.

Water is used in cooling systems as a heat transfer medium and frequently also as the final point

to reject heat into the atmosphere by evaporating inside cooling towers. Depending on the quality

of available fresh water supply, waterside problems develop in cooling water systems from:

• Scaling

• Corrosion

• Dirt and dust accumulation

• Biological growth

Any of these problems – or more usually a combination of them – result in costly unscheduled

downtime, reduced capacity, increased water usage, high operation and maintenance costs,

expensive parts replacements, and acid cleaning operations which reduce the life of the cooling

system.

Critical Parameters

The critical parameters for cooling water are: conductivity, total dissolved solids (TDS), hardness,

pH, alkalinity.

Conductivity and Total Dissolved Solids (TDS)

Conductivity is a measure of the ability of water to conduct electrical current and it indicates the

amount of the dissolved solids (TDS) in water. Pure distilled water will have a very low conductivity

(low minerals) and sea water will have a high conductivity (high minerals). Dissolved solids

present no problem with respect to the cooling capacity of water, since the evaporation rate of

seawater, which has 30,000ppm total dissolved solids, is only 1% less than that of distilled water.

The problem with dissolved solids is that many of the chemical compounds and elements in the

water will combine to form highly insoluble mineral deposits on the heat transfer surfaces

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

generally referred to as “scale”. The scale stubbornly sticks to the surfaces, gradually builds up

and begins to interfere with pipe drainage, heat transfer and water pressure.

PH

pH is a measure of how acidic/basic water is. The range goes from 0 - 14, with 7 being neutral.

pHs of less than 7 indicate acidity, whereas a pH of greater than 7 indicates a base. Control of

pH is critical for the majority of cooling water treatment programs. In general, when pH points to

acidic environment, the chances for corrosion increase and when pH points to alkaline

environment, the chances for scale formation increase.

Alkalinity

The pH values above 7 signify alkalinity. At pH values less than 8.3, most of the alkalinity in the

water is in the bicarbonate form, and scale formation is normally not a problem.

Hardness

The amount of dissolved calcium and magnesium in water determines its "hardness." The total

hardness is then broken down into two categories

o The carbonate or temporary hardness

o The non-carbonate or permanent hardness

Hardness particularly the temporary hardness is the most common and is responsible for the

deposition of calcium carbonate scale in pipes and equipment. Technically any bivalent metal ion

such as iron, manganese or tin would constitute hardness, but calcium and magnesium are the

two most prevalent forms.

What is scale?

Scale is a hard deposit of predominantly inorganic material on heating transfer surfaces caused

by the precipitation of mineral particles in water. As water evaporates in a cooling tower or an

evaporative condenser, pure vapor is lost and the dissolved solids concentrate in the remaining

water. If this concentration cycle is allowed to continue, the solubility of various solids will

eventually be exceeded. The solids will then settle in pipelines or on heat exchange surfaces,

where it frequently solidifies into a relatively soft, amorphous scale.

Problems & Factors

Scale, in addition to causing physical blockage of piping, equipment, and the cooling tower, also

reduces heat transfer and increases the energy use.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

The principle factors responsible for scale formation are:

1. As alkalinity increases, calcium carbonate- the most common

scale constituent in cooling systems - decreases in solubility

and deposits.

2. The second—more significant—mechanism for scale

formation is the in-situ crystallization of sparingly soluble

salts as the result of elevated temperatures and/or low flow velocity. Most salts become more

soluble as temperature increases, however, some salts, such as calcium carbonate, become

less soluble as temperature increases. Therefore, they often cause deposits at higher

temperatures.

3. High TDS water will have greater potential for scale formation.

CORROSION INHIBITION

Next to scale, the next most important concern is the

prevention of “corrosion”. Corrosion is defined as the

destruction or loss of metal through chemical or

electrochemical reaction with its surrounding environment.

Mild steel is a commonly used metal in the cooling water

system that is most susceptible to corrosion. Other metals in

general, such as copper, stainless steel, aluminum alloys also

do corrode but the process is slow.

Corrosion Problems

Common problems arising from corrosion are reduction in heat transfer and water flow resulting

from a partial or complete blockage of pipes, valves, strainers, etc. Also, excessive wear of moving

parts, such as pump, shaft, impeller and mechanical seal, etc. may resist the movement of the

equipment. Hence, thermal and energy performance of heat exchange may degrade.

Factors

Many factors affect the corrosion rates in a given cooling water system. Few important factors

are:

1. Dissolved Oxygen - Oxygen dissolved in water is essential for the cathodic reaction to take

place.

2. Alkalinity & Acidity - Low alkalinity waters have little pH buffering capability. Consequently, this

type of water can pick up acidic gases from the air and can dissolve metal and the protective

oxide film on metal surfaces. More alkaline water favors the formation of the protective oxide

layer.

hamza yousaf | INSTITUTE OF CHEMICAL ENGINEERING PUNJAB UNIVERSITY LAHORE

Sapphire Finishing Mills September 18, 2021

3. Total Dissolved Solids - Water containing a high concentration of total dissolved solids has a