Minimize Evaporation Losses by Calculating Boiloff Gas in LPG Storage Tanks

Uploaded by

aegean227Copyright:

Available Formats

Minimize Evaporation Losses by Calculating Boiloff Gas in LPG Storage Tanks

Uploaded by

aegean227Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Minimize Evaporation Losses by Calculating Boiloff Gas in LPG Storage Tanks

Uploaded by

aegean227Copyright:

Available Formats

Minimize evaporation losses by calculating boiloff gas in LPG storage tanks

SIGN UP Gas Processing & LNG is Produced by Gulf Publishing Holdings LLC

HOME NEWS SUPPLEMENT WEBCASTS ADVERTISE ENERGY WEB ATLAS

Minimize evaporation losses by calculating

boiloff gas in LPG storage tanks

S. Shiva Shamekhi and N. Ashouri, Faradast Energy Falat Co., Tehran, Iran

Liquefied petroleum gas (LPG) is stored and transported in tanks as a cryogenic liquid, at a

temperature below its boiling point near atmospheric pressure. Due to heat entering the cryogenic

tank during storage and transportation, a portion of the LPG continuously evaporates, creating a gas

called boiloff gas (BOG). BOG causes evaporation losses in the LPG supply chain over time.

It is imperative to minimize vaporization and displacement losses due to the economic and safety

problems that can result from such losses. The amount of BOG depends on the design and operating

conditions of LPG plants. In the LPG supply chain, BOG can be reliquefied or sent to the flare and

burned. The evaluation of BOG in a storage tank in all operating scenarios is important for the correct

selection and design of a BOG compressor.

Different sources exist for the generation of BOG. These sources include heat leaks from ambient air

around the storage tank, heat ingress due to the dissipation of pumping power inside the tanks, heat

leaks from pipelines, flash vapor generated by liquid rundown and displaced vapor from the tank due

to liquid filling (known as the piston effect).

In this study, boundary conditions and parameters have been implemented to accurately estimate the

amount of BOG that evaporates at the C3 and C4 refrigeration and loading facilities at the Bandar

Abbas gas condensate refinery in Iran.

Study outline. The produced propane and butane from propane/butane splitter units are cooled

down in the propane/butane refrigeration unit via open-cycle refrigeration, and then run down to the

associated refrigerated tanks and stored at atmospheric pressure before being exported to overseas

markets via propane/butane carrier ships.

As shown in Fig. 1, butane rundown is subcooled at the required temperature level in two exchangers 1D 5D 1M 3M 1Y 2Y

in series, both utilizing propane. The chilled butane is then sent to the storage tanks. Commodity Last Change

Crude Oil WTI 57.40 +0.14

Natural Gas (Henry Hub) 2.770 +0.053

Copyright © 2018. All market data is provided by Barchart

Solutions. Futures: at least a 10 minute delay. Information is provided 'as is' and

solely for informational purposes, not for trading purposes or advice. To see all

http://www.gasprocessingnews.com/features/201602/minimize-evaporation-losses-by-calculating-boiloff-gas-in-lpg-storage-tanks.aspx[25/2/2019 1:19:31 μμ]

Minimize evaporation losses by calculating boiloff gas in LPG storage tanks

exchange delays and terms of use, please see disclaimer.

FEATURED COLUMNS

Editorial Comment

-Adrienne Blume

This year could be the largest ever for LNG

export project final investment decisions

(FIDs).

Fig. 1. Propane refrigeration BOG production. EWAnalysis: Impact of technology on

gas transmission management—Part 2

-Bob Andrew

Propane is divided into two streams. One stream flows to the first exchanger and is flashed, and the This article is the second in our “Impact of

other stream is sent to the high-pressure C3 suction drums and then flashed in the second Technology” series; the first was “Impact of

exchanger. Liquid propane from the suction drum is utilized in the second exchanger, and relevant technology in gas processing plants—Part 1,”

flashed vapor is sent to medium-pressure C3 suction drums and then to the low-pressure C3 suction which appeared in the October/November 2018

drums. issue of Gas Processing & LNG.

Liquid propane flashes to lower pressure levels in medium- and low-pressure suction drums before

being pumped to refrigerated storage tanks. Propane vapors result from the rundown product

pressure reduction, and flashes at the different pressure levels are compressed in two parallel, three- GasPro 2.0: A Webcast

stage centrifugal compressors, before being condensed in a C3 air cooler and a C3 compressor Symposium

condenser. Liquid propane is collected in a C3 accumulator and flashed again to the high-pressure

suction drum to restart the cycle. Register Now

Boiloff vapors from propane tanks are sent to the low-pressure suction drums and then to the first The global LNG industry is

compressor stage. No vapors develop from butane tanks due to the subcooling of the stored liquid becoming increasingly

product. interconnected as grassroots

export projects get off the

Two tanks each are used for C3 and C4 storage. Since the boiloff calculation method can be used for ground. Another technology

both types of storage tanks, calculations are described for only one of the C3 storage tanks. route for processing gas into

fuels—GTL—is attracting

Operating modes. To load propane and butane to the ship, it is necessary to cool down the pipelines renewed attention due to

at the lowest possible temperature, with the aim of reducing BOG production during the entrance to improving economics. Small-

the ship compartments. Three steps are needed: preloading, loading and holding. Pre-loading scale solutions for both LNG

includes two parts—the initial phase and the final phase—to achieve cooling of the pipeline with low and GTL are at the forefront

flowrates and appropriate pipeline temperature, respectively. of new technological

developments, while major

As a general rule, each tank follows three steps during normal operation: projects using more

conventional technologies

Filling mode: The tank receives the product from the process unit at rundown flowrates.

continue to start up around

During the filling mode, it is necessary to prepare the tank for ship loading; in project

the world.

documentation, this operation is called preloading.

Emptying mode: When the ship is ready to receive the products (i.e., when the pipeline is at

During this webcast, we will

proper temperature, parcels are at proper temperature, loading arms are connected, etc.),

focus on LNG, GTL, gas

then it is possible to transfer the product from tank to ship. This operation is called loading.1

processing technology

Holding mode: The tank is full of product and ready for ship loading, but the ship has not yet

developments and

arrived or is not ready for loading. This operation is called holding.

deployments, operations,

To load propane to the ship, it is necessary to cool down the two pipelines at the lowest possible small-scale solutions,

temperature, with the aim of reducing BOG production when products enter the ship compartments. transportation, trading,

Therefore, some days before the carrier ship arrives, circulation from the storage tank to the jetty and distribution, safety, regulatory

back to the tank is started. This process is applied when the pipelines are in equilibrium with the affairs, business analysis and

external temperature. more.

The preloading mode is the most critical operating mode from the point of view of BOG production, October 25, 2018 08:30 AM

due to the great quantity of hot fluid trapped in the pipeline. For this reason, it is necessary to avoid a CDT

too-rapid displacement of the fluid to prevent abnormal overdesign of the BOG compressor.

Register Now

One of the major sources of boiloff production in liquefied gas handling is rollover, which can result in

a boiloff rate several times greater than normal, causing rapid over pressurization while venting a

considerable quantity of vapors to atmosphere. When the liquid layer adjacent to a liquid surface

becomes denser than the layers beneath due to boiloff of lighter fractions from the tank, stratification

develops and causes rollover due to rapid mixing as a result of density inversion. An effective solution

is the mixing of the liquid in the tanks. For this purpose, two circulating pumps are placed inside the

tank: one is always circulating the liquid and the other is used for cooling the transfer line.

Calculation methods. BOG evaluation in all operating scenarios of the tank is important for the

correct definition of the flowrates to the BOG compressors.

http://www.gasprocessingnews.com/features/201602/minimize-evaporation-losses-by-calculating-boiloff-gas-in-lpg-storage-tanks.aspx[25/2/2019 1:19:31 μμ]

Minimize evaporation losses by calculating boiloff gas in LPG storage tanks

BOG is produced under the following conditions:

1. Heat absorbed from ambient air by refrigerated storage tanks

2. Heat absorbed from ambient air by lines (rundown lines, pipelines)

3. Heat produced by the operation of pumps (loading, circulation, rundown)

4. Vapor displacement due to liquid inlet in the tank

5. Rapid variation of barometric pressure.

Total BOG flowrate can be calculated with Eq. 1:

BOGTotal = BOGTank + BOGTransferLine + BOGLoadingSystem +

BOGElectricalMotor + BOGATM + BOGCirculationSystem + (1)

BOGVaporDisplacement + BOGCompensationEffect

Note: The contribution of BOG due to rapid atmospheric pressure variation is not considered, and is

negligible when compared to the other contributions. Also, the compensation effect due to outflow of

liquid from the tank is not considered.

BOG is calculated utilizing simulation software. The thermophysical properties of propane are

collected in Table 1. Required information for the calculation of BOG is presented in Table 2.

Calculations for the contribution to BOG by heat absorbed in tanks are shown in Eqs. 2 and 3.

(2), (3)

Heat ingress by storage tank is equal in the three cases of holding, preloading and loading. Equations

for the contribution to BOG by the transfer system are shown in Eqs. 4–9.

http://www.gasprocessingnews.com/features/201602/minimize-evaporation-losses-by-calculating-boiloff-gas-in-lpg-storage-tanks.aspx[25/2/2019 1:19:31 μμ]

Minimize evaporation losses by calculating boiloff gas in LPG storage tanks

(4), (5), (6), (7)

(8), (9)

where:

QNormal=21.3 m3/h

QMax=67.5 m3/h

Head=88.2 m

η=0.68 (ηShaft 0.75 × ηMotor 0.9)

ΔP=SG × ΔH

The ΔH transfer line is calculated by HYSYS.

BOG pertaining to lines (circulation, loading and transfer line) can be calculated manually using Eqs.

10–14.2

(10), (11), (12), (13), (14)

Calculations for the contribution to BOG by the circulation system are shown in Eqs. 15–20.

(15), (16), (17)

http://www.gasprocessingnews.com/features/201602/minimize-evaporation-losses-by-calculating-boiloff-gas-in-lpg-storage-tanks.aspx[25/2/2019 1:19:31 μμ]

Minimize evaporation losses by calculating boiloff gas in LPG storage tanks

(18), (19), (20)

where:

QNormal=225 m3/h

Head=339 m

η=0.63 (ηShaft 0.7 × ηMotor 0.9)

Calculations for the contribution to BOG by the loading system are shown in Eqs. 21–26.

(21), (22)

(23), (24), (25), (26)

where:

QLoading=1,250 m3/h

Head=365.5 m

η=0.72 (ηShaft 0.8 × ηMotor 0.9)

Calculations for the contribution to BOG by electric motors are shown in Eqs. 27–28.

(27), (28)

where:

Power of loading pump = 904.3 kw

Power of circulation pump = 172.7 kw.

The calculation for the contribution to BOG by vapor displacement is shown in Eq. 29.

(29)

Rundown flowrate definitions include:

The normal flowrate is 21.3 m3/h on the transfer pump when the system is in holding mode

The maximum pump flowrate is 67.5 m3/h for the transfer pump when the system is in

preloading mode (initial phase)

http://www.gasprocessingnews.com/features/201602/minimize-evaporation-losses-by-calculating-boiloff-gas-in-lpg-storage-tanks.aspx[25/2/2019 1:19:31 μμ]

Minimize evaporation losses by calculating boiloff gas in LPG storage tanks

ρ is determined by the simulator and is derived from flashing before entrance to the storage

tanks.

The results for the different operating modes experienced by storage tanks are shown in Table 3.

Takeaway. The calculations described represent a simple approach for engineers to estimate

produced BOG ratio in cryogenic systems for LPG and LNG. The BOG ratio can be calculated

manually or with the use of a process simulator. GP

ACKNOWLEDGMENT

The author thanks the board of directors and the process division of Faradast Energy Falat Co., the

general contractor of Bandar Abbas Gas condensation refinery, for its support.

NOMENCLATURE

λ Latent heat

α Vapor fraction

η Pump shaft efficiency

W Mass flow

Kp Average heat flux through the pipe, W/m2

Ap Piping external surface area, including insulation, m2

H Enthalpy

Kt Vaporization coefficient, considered equal to 0.001 for C3/C4

Vt Geometrical volume of tank, m3

ρ Density

Kf Thermal conductivity of ambient air, W/km

Kins Thermal conductivity of insulation, W/km

LITERATURE CITED

1

Chen, C. C., “Fine-tune refrigerated LPG loading line operation,” Hydrocarbon Processing, August

2005.

2Wordu, A. A. and B. Peterside, “Estimation of boiloff gas from refrigerated vessels in liquefied natural

gas plant,” International Journal of Engineering and Technology, Vol. 3, No. 1, January 2013.

3

Adom, E., et al. “Modelling of boiloff gas in LNG tanks: A case study,” International Journal of

Engineering and Technology, Vol. 2, No. 4, 2010, pp. 292–296.

S. Shiva Shamekhi is a process engineer in the process engineering department of

Faradast Energy Falat Co. She is working on a mega-size project for a gas

condensation refinery in Tehran, Iran. She holds BSc and MSc degrees from Amirkabir

University of Technology in Iran. Her areas of specialization include basic design of

refrigeration plants and detailed design of gas and petrochemical plants. She can be

reached at S.Shamekhi@fefalat.com or s.shamekhi@gmail.com.

N. Ashouri is the process lead engineer in the process engineering department of

Faradast Energy Falat Co. He is working on a mega-size project for the Bandar Abbas

gas condensate refinery in Iran. He has 16 years of experience in the design of oil and

gas refineries. Mr. Ashouri holds an MSC degree in process engineering from the Iran

University of Technology. He can be reached at N.Ashouri@fefalat.com.

| Projects |

Contact Us |

About Us |

Site Map |

Gulf Energy Info |

World Oil |

Hydrocarbon Processing |

Construction BoxScore |

Webcasts |

White Papers |

Newsletter

Sign-Up |

Advertise |

US Directory |

Subscribe Free |

Gastech-Show-Daily |

Please read our Term and Conditions, Cookies Policy, and Privacy Policy before using the site. All material subject to strictly enforced copyright laws.

© 2019 Gulf Publishing Holdings LLC.

http://www.gasprocessingnews.com/features/201602/minimize-evaporation-losses-by-calculating-boiloff-gas-in-lpg-storage-tanks.aspx[25/2/2019 1:19:31 μμ]

You might also like

- Autoplatine SP: Converting Tools and ProductionNo ratings yetAutoplatine SP: Converting Tools and Production205 pages

- General Design Specification: 076971C 0000 JSD 1700 01 B 1/59No ratings yetGeneral Design Specification: 076971C 0000 JSD 1700 01 B 1/5959 pages

- Cargo Tank Inerting Prior To Gassing Up - LPG Tanker ProcedureNo ratings yetCargo Tank Inerting Prior To Gassing Up - LPG Tanker Procedure8 pages

- Fixed Speed Submersible Turbine Pump Installation For Fixed or Variable LengthsNo ratings yetFixed Speed Submersible Turbine Pump Installation For Fixed or Variable Lengths16 pages

- Systems Techniques Computational Methods: Computer-Aided Design, Engineering, and ManufacturingNo ratings yetSystems Techniques Computational Methods: Computer-Aided Design, Engineering, and Manufacturing7 pages

- Gas As A Marine Fuel - An Introductory Guide-SGMF (2019)No ratings yetGas As A Marine Fuel - An Introductory Guide-SGMF (2019)68 pages

- We're Going Global: The Impact of Product TemperatureNo ratings yetWe're Going Global: The Impact of Product Temperature6 pages

- C15 Recommendations Manifolds Refrigerated Liquefied Natural Gas Carriers - Ed. 19940% (1)C15 Recommendations Manifolds Refrigerated Liquefied Natural Gas Carriers - Ed. 199412 pages

- Amspec Techtalk A Stands For API Gravity 4No ratings yetAmspec Techtalk A Stands For API Gravity 45 pages

- 382.003 Final Drawing For Tank Cleaning HeaterNo ratings yet382.003 Final Drawing For Tank Cleaning Heater37 pages

- LNG Marine Loading Arms and Manifold Draining Purging and Disconnection Procedure PDFNo ratings yetLNG Marine Loading Arms and Manifold Draining Purging and Disconnection Procedure PDF15 pages

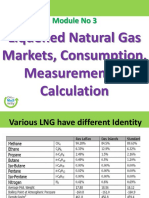

- Module No 3: Liquefied Natural Gas Markets, Consumption, Measurement & CalculationNo ratings yetModule No 3: Liquefied Natural Gas Markets, Consumption, Measurement & Calculation30 pages

- Bureau Veritas Issues FSU, FSRU Conversion GuidelinesNo ratings yetBureau Veritas Issues FSU, FSRU Conversion Guidelines1 page

- Sea Transport of Liquid Chemicals in Bulk PDF100% (1)Sea Transport of Liquid Chemicals in Bulk PDF131 pages

- Effect of H2-Injection On The Thermodynamic and Transportation Schouten2004No ratings yetEffect of H2-Injection On The Thermodynamic and Transportation Schouten20048 pages

- MANOUSOS P - Potable Water Analysis ReportNo ratings yetMANOUSOS P - Potable Water Analysis Report3 pages

- SGS-OI-Safe Talk-Heat Stress and Ramadan-A4-EN-004No ratings yetSGS-OI-Safe Talk-Heat Stress and Ramadan-A4-EN-0044 pages

- Astm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your AdvertisementNo ratings yetAstm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your Advertisement28 pages

- Commissioning Procedure - LPG Liquid ReceivingNo ratings yetCommissioning Procedure - LPG Liquid Receiving5 pages

- Introductiontogastransportation 161222145926 PDF100% (1)Introductiontogastransportation 161222145926 PDF26 pages

- BP Shipping Questionnaire: New Build VesselNo ratings yetBP Shipping Questionnaire: New Build Vessel15 pages

- The noble Polish family Doliwa. Die adlige polnische Familie Doliwa.From EverandThe noble Polish family Doliwa. Die adlige polnische Familie Doliwa.No ratings yet

- Finite Element Method and Thermo-Viscoplastic Cutting Model in Manufacturing SystemsNo ratings yetFinite Element Method and Thermo-Viscoplastic Cutting Model in Manufacturing Systems24 pages

- CO2 Utilization Developments in Conversion ProcessesNo ratings yetCO2 Utilization Developments in Conversion Processes18 pages

- A New Equation of State For Carbon DioxideNo ratings yetA New Equation of State For Carbon Dioxide89 pages

- General Construction Rules FOR Underground SystemsNo ratings yetGeneral Construction Rules FOR Underground Systems25 pages

- In Place+Structural+Strength+and+Fatigue+Analysis+for+Floating+Platform+TopsidesNo ratings yetIn Place+Structural+Strength+and+Fatigue+Analysis+for+Floating+Platform+Topsides11 pages

- Manual Operation Maintenance Vibration SwitchNo ratings yetManual Operation Maintenance Vibration Switch20 pages

- Service Manual: Washing Machine Toploader AWE 6316No ratings yetService Manual: Washing Machine Toploader AWE 631620 pages

- The Current Indian Advertising IndustryNo ratings yetThe Current Indian Advertising Industry15 pages

- TRN-2023-015 (FJLC-R1, R2, R3, Car, NHQ)No ratings yetTRN-2023-015 (FJLC-R1, R2, R3, Car, NHQ)4 pages

- Timers Star Delta Types DAC01, PAC01: Product Description Ordering Key DAC 01 C M24No ratings yetTimers Star Delta Types DAC01, PAC01: Product Description Ordering Key DAC 01 C M243 pages

- 978 3 031 50176 0 PyroFurnaceContainmentNo ratings yet978 3 031 50176 0 PyroFurnaceContainment189 pages

- General Design Specification: 076971C 0000 JSD 1700 01 B 1/59General Design Specification: 076971C 0000 JSD 1700 01 B 1/59

- Cargo Tank Inerting Prior To Gassing Up - LPG Tanker ProcedureCargo Tank Inerting Prior To Gassing Up - LPG Tanker Procedure

- Fixed Speed Submersible Turbine Pump Installation For Fixed or Variable LengthsFixed Speed Submersible Turbine Pump Installation For Fixed or Variable Lengths

- Systems Techniques Computational Methods: Computer-Aided Design, Engineering, and ManufacturingSystems Techniques Computational Methods: Computer-Aided Design, Engineering, and Manufacturing

- Gas As A Marine Fuel - An Introductory Guide-SGMF (2019)Gas As A Marine Fuel - An Introductory Guide-SGMF (2019)

- We're Going Global: The Impact of Product TemperatureWe're Going Global: The Impact of Product Temperature

- C15 Recommendations Manifolds Refrigerated Liquefied Natural Gas Carriers - Ed. 1994C15 Recommendations Manifolds Refrigerated Liquefied Natural Gas Carriers - Ed. 1994

- LNG Marine Loading Arms and Manifold Draining Purging and Disconnection Procedure PDFLNG Marine Loading Arms and Manifold Draining Purging and Disconnection Procedure PDF

- Module No 3: Liquefied Natural Gas Markets, Consumption, Measurement & CalculationModule No 3: Liquefied Natural Gas Markets, Consumption, Measurement & Calculation

- Bureau Veritas Issues FSU, FSRU Conversion GuidelinesBureau Veritas Issues FSU, FSRU Conversion Guidelines

- Effect of H2-Injection On The Thermodynamic and Transportation Schouten2004Effect of H2-Injection On The Thermodynamic and Transportation Schouten2004

- SGS-OI-Safe Talk-Heat Stress and Ramadan-A4-EN-004SGS-OI-Safe Talk-Heat Stress and Ramadan-A4-EN-004

- Astm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your AdvertisementAstm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your Advertisement

- The noble Polish family Doliwa. Die adlige polnische Familie Doliwa.From EverandThe noble Polish family Doliwa. Die adlige polnische Familie Doliwa.

- Finite Element Method and Thermo-Viscoplastic Cutting Model in Manufacturing SystemsFinite Element Method and Thermo-Viscoplastic Cutting Model in Manufacturing Systems

- CO2 Utilization Developments in Conversion ProcessesCO2 Utilization Developments in Conversion Processes

- General Construction Rules FOR Underground SystemsGeneral Construction Rules FOR Underground Systems

- In Place+Structural+Strength+and+Fatigue+Analysis+for+Floating+Platform+TopsidesIn Place+Structural+Strength+and+Fatigue+Analysis+for+Floating+Platform+Topsides

- Service Manual: Washing Machine Toploader AWE 6316Service Manual: Washing Machine Toploader AWE 6316

- Timers Star Delta Types DAC01, PAC01: Product Description Ordering Key DAC 01 C M24Timers Star Delta Types DAC01, PAC01: Product Description Ordering Key DAC 01 C M24