A.Typical Roadway Section: Pavement Design Parameters

A.Typical Roadway Section: Pavement Design Parameters

Uploaded by

rickCopyright:

Available Formats

A.Typical Roadway Section: Pavement Design Parameters

A.Typical Roadway Section: Pavement Design Parameters

Uploaded by

rickOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

A.Typical Roadway Section: Pavement Design Parameters

A.Typical Roadway Section: Pavement Design Parameters

Uploaded by

rickCopyright:

Available Formats

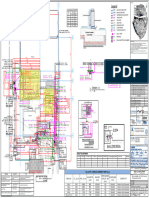

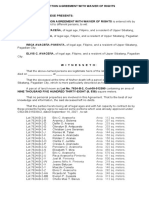

PAVEMENT DESIGN PARAMETERS

CATCH BASIN DIMENSIONS TABLE FOR SHOULDER SLOPE ITEM DESIGN REQUIREMENTS

910 The Performance Period 20 years (for PCCP)

"e" "s"

Design Traffic : ESAL

H 230

3 3 Design Reliability : R

PIPE INLET CATCH BASIN

(Dimension Centimeter) A 113 4 3 Standard Deviation : S o

Meter A D B 92 5 2

PCCP Modulus of Rupture : S c

0.910 113 150

D 150 6 1 PCCP Modulus of Elasticity : E c

1.520 136 210

7 0 Subgrade Design : CBR

C 150

Effective Roadbed Resilient Modulus : M R

8 -1

C

L 2.50 (for - Line) Subbase Elastic Modulus : ESB

SHOULDER CARRIAGEWAY SHOULDER Provide x Subbase Thickness

Rounding Slope 3.80 (for 2 - Lines)

6.70 (m) SLOPE ROUNDING Effective Modulus at Sub-grade Reaction : K (pci.)

1.50 3.35 3.35 1.50 0.50 HEIGHT OF SLOPE (m) Drainage Coefficient : Cd

0 to 4.50 Load Transfer Coefficient : J

OVER 4.50 Loss of Support : Ls'

K CORRECTED

Design Slab Thickness, D = , Adopt. D =

B

ITEM 104 - EMBANKMENT Item 500(a & b) -

16mm dia. STD. DEF. BARS SPACED AT RCCP

Item 505(5) - Grouted Riprap,

0.60m O.C. X 0.60m CUT BARS Item

Class506

"A"- Stone Masonry

ITEM 311 - PCCP 0.15m THICK

ITEM 200 - AGGREGATE SUB-BASE COURSE (0.20m THICK MINIMUM) Item 500(a&b) -

ITEM 200 - 1.50 m. SHOULDERING Item 505(5) - Grouted Riprap, RCCP

ITEM 103(3) -

AGGREGATE SUB-BASE COURSE

A A'

Class "A" FOUNDATION FILL

B'

ITEM 405 - STRUCTURAL CONCRETE, CLASS "A"

ITEM 622(1) - BIO-ENGINEERED COCO FIBER EROSION CONTROL NET

ITEM 622(3) - BIO-ENGINEERED EROSION CONTROL SYSTEM (VEGETATION)

0.50.

H- variable

ITEM 102 - EXCAVATION

0.60

ITEM 622(2) - BIO-ENGINEERED COCO LOGS/FASCINE EROSION CONTROL SYSTEM

Shoulder

0.10

0.60

0.30 3.80 0.30 0.30 1.15 1.50 1.15 0.30

TYPICAL ROADWAY SECTION FOR CONCRETE Item 506 - Stone

PLA SECTION A -

H 0.20 D +2t 0.20

SHOWING NORMAL CROWN WITH EXCAVATION & EMBANKMENT Masonry N :

scale A'

scale :

nts nts

SCALE NTS 0.40 1.60 0.50

0.60 m

m.

SECTION B-

min. DETAIL OF RCCP HEAD WALLS DETAIL OF FOUNDATION FILL

SCALE : B'scale : scale :

NTS nts nts

H

2

NOTE: DETAIL OF STONE MASONRY

STONE MASONRY (Item 506) SCALE : CONCRETE SHOULDER GROUTED RIPRAP SURFACE

30.00 m 30.00 m NTSSoil

Prior to construction, conduct 0.15 m. THK. LINING 0.20 m. THK. 3.90 1

D

3

0.50 2.90 0.50

(RROW) (RROW) Investigation in accordance with the 1

3D

standard Testing Requirement along the 0.30 m 1

alignment of Stone Masonry Wall to verify 0.15m 0.50m CL CL

3D

SHOULDER CARRIAGEWAY SHOULDER

the actual Soil Bearing Capacity of the D

13.40 foundation bed. The required allowable 0.20m

(m) Soil Bearing Capacity(qa) = 196. kpa. 0.30 m

0.75m 0.60m 0.30m 0.50m

1.50 3.35 3.35 1.50 1.15 2.90 1.15

0.30 0.30

variable

2:1 0.15m

D TRANSVERSE BARS SPACED

0.15m 0.15m @ 300MM O.C. PLAN

0.30

0.50 3.0% 1.50% 1.50% 3.0%

0.30 0.30 0.80m DETAIL OF CATCH BASIN

SCALE : NTS

ITEM 200 0.30 m. THK.

CONC. SHOULDER

H DETAIL OF CONCRETE LINED CANAL D 0.15 M THK.

S =% H 0.600 1 1 1

I.E, SCALE NTS 3D 3D 3 D

0.600 COMPACTED

0.30.m 0.30.m GRANULAR FILING

0.40 m

min 1-Line 2.50 0.30.m

Item 103(6) - Pipe Culvert and Drain excavation 0.60m O.C. (DOWEL BARS) 0.50 1.50 0.50 0.50.m

0.40 H/2 A D A 0.600

m Item 500 - RCPC 0.600 CL

H H-

Item 311(a) - PCCP (0.28 m. thk.)

0.30

Item 300 - Aggregate Surface Course ( 0.15 m. IE.

thk. ) (0.

SPOT DETAIL LONGITUDINAL JOINT TIE BAR

Item 200 - Agg. Subbase Course 0.30.m

SCALE 1:100m

30 m. thk. ) 102 -

Item

Excavation

Item 103(3) - Foundation 0.30m O.C. PLAIN 1.15 1.50 1.15 A D A

DOWEL BARS 0.30 0.30

Fill

Item 506 - Stone

Item 505 (5)- Grouted Riprap, Class "A"Masonry

SECTION

"A"

3.35 m.

LANE SHOWING TRANSVERSE

CONSTRUCTION JOINT @ LOCATION

A.TYPICAL ROADWAY OF WEAKENED PLANE JOINT

4.0m

SECTION L

0.60m O.C. DEFORMED

3.35 m.

TIE BARS

LANE SHOWING

TRANSVERSE

CONSTRUCTION JOINT

@ MIDDLE THIRD OF

NORMAL JOINT

4.50m 4.50m 4.50m INTERVAL

TYPICAL ROAD CONCRETE PAVEMENT PLAN

SCALE 1:80m

PROJECT & LOCATION : SHEET CONTENTS : DESIGNED : SUBMITTED : REVIEWED: RECOMMENDING APPROVAL : APPROVED : SET NO.: SHEET NO.:

(Sgd.) TOMAS H. LACIERDA, JR.

REPUBLIC OF THE PHILIPPINES ROAD UPGRADING (GRAVEL TO PAVED) BASED ON GRAVEL ROAD - TYPICAL ROADWAY SECTION Engineer II

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS STRATEGIES, TRAFFIC BENCHMARK FOR UPGRADING TO PAVED ROAD

- TYPICAL ROAD CONCRETE PAVEMENT PLAN DRAWN :

OFFICE OF THE DISTRICT ENGINEER STANDARD (HDM-4 PROJECT ANALYSIS)

- TYPICAL ROADWAY SECTION WITH BIO-ENGINEERED EROSION (Sgd.) GIL M. RUIZAL TRS

ZAMBOANGA DEL SUR 2nd DISTRICT ENGINEERING OFFICE

IMELDA-BAYOG-KUMALARANG-LAPUYAN-

- PAVEMENT PARAMETERS Engineer II (Sgd.) AMINODIN P. MANIRI (Sgd.) CAYAMOMBAO D. DIA (Sgd.) NENITA A. ROBLES, CESO IV (Sgd.) JORGE U. SEBASTIAN, JR. CESO III 3

GUIPOS, ZAMBOANGA DEL SUR

MARGOSATUBIG ROAD ZAMBOANGA DEL SUR

CHECKED :

Engineer V

3 28

Section 1 : K1739+560.00 - K1740+967.00 OIC-District Engineer Chief, Planning and Design Division Assistant Regional Director Regional Director

(Sgd.) NORMAN C. CARPIO

Section 2 : K1743+667.00 - K1743+880.0 0 Engineer III

Chief, Planning and Design Section Date : Date : Date : Date :

You might also like

- 202440236811BA OmotoyeDocument1 page202440236811BA Omotoyeleeyemzy17No ratings yet

- Thin Cyclinder Student Guide (A)Document27 pagesThin Cyclinder Student Guide (A)Daniel MabengoNo ratings yet

- KH21029 00 GN DD FG501Document1 pageKH21029 00 GN DD FG501AHMED TAHERNo ratings yet

- FW SstdeDocument1 pageFW SstdeJan Michael VecillesNo ratings yet

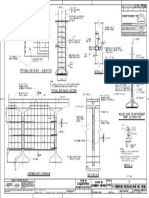

- BPS-STR-201-R1-Foundation Plan Other Details For Compound WallDocument1 pageBPS-STR-201-R1-Foundation Plan Other Details For Compound Wallsri projectssNo ratings yet

- Contoh DWG Assembly and DetailDocument1 pageContoh DWG Assembly and DetailZulkarnain ZulkarnainNo ratings yet

- Clay Tiles Shop Drawing - SDDocument1 pageClay Tiles Shop Drawing - SDAhmed MohamedNo ratings yet

- WPE DSC ESM SR1 017 0masterDocument1 pageWPE DSC ESM SR1 017 0mastercankawwasNo ratings yet

- First Floor-Daimond 0°Document1 pageFirst Floor-Daimond 0°tarique1370No ratings yet

- Detalles Constructivos para La Red de Agua PotableDocument4 pagesDetalles Constructivos para La Red de Agua PotableRoberto Cabrera MillerNo ratings yet

- Basement DDA Car ParkingDocument1 pageBasement DDA Car Parkingrajen raghwaniNo ratings yet

- 090-2100-MMM-DET-20082-01Document1 page090-2100-MMM-DET-20082-01bruce.thomason2020No ratings yet

- RW SFB 22 - 2Document1 pageRW SFB 22 - 2Yong TonghannNo ratings yet

- UPTŽ (G.15.11) - Nacrt Armature Kampade CC G.002 - K2Document1 pageUPTŽ (G.15.11) - Nacrt Armature Kampade CC G.002 - K2Kenan BegagicNo ratings yet

- KAAR COW PW IC NTU FZS DWG STR 24633 Rev.01 PDFDocument1 pageKAAR COW PW IC NTU FZS DWG STR 24633 Rev.01 PDFSatyanarayana MukkuNo ratings yet

- Project S-302: Inking, Length Measure, Area MeasureDocument2 pagesProject S-302: Inking, Length Measure, Area MeasureNoviantoNo ratings yet

- DMH5Document1 pageDMH5Keyvin dela CruzNo ratings yet

- Sys 01Document1 pageSys 01dheeraj.b.firefoxNo ratings yet

- General Drawing Exchanger N°1Document1 pageGeneral Drawing Exchanger N°1calinvasco190670No ratings yet

- Notes: Subject-Building Construction Topic - Wall CladdingDocument1 pageNotes: Subject-Building Construction Topic - Wall CladdingPiyush SinglaNo ratings yet

- RHP1P2 BW TGC 4TV 00 SD DR 00001Document1 pageRHP1P2 BW TGC 4TV 00 SD DR 00001Waqar KhanNo ratings yet

- 8det Vigas Sepsi-modelDocument1 page8det Vigas Sepsi-modelMatheusNo ratings yet

- Total WT: Parent: Proj # Customer Name: Project Name: Project Location: 08720 D1 GAD8720D1A1 Preliminary: Not Approved For ConstructionDocument7 pagesTotal WT: Parent: Proj # Customer Name: Project Name: Project Location: 08720 D1 GAD8720D1A1 Preliminary: Not Approved For ConstructionGustavoNo ratings yet

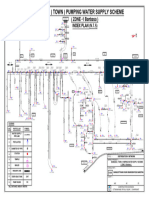

- BANBASA TOWN WATER SUPPLY LAYOUT ZONE - 1.-ModelDocument1 pageBANBASA TOWN WATER SUPPLY LAYOUT ZONE - 1.-Modelannapurnastore66No ratings yet

- BANBASA TOWN Index Plan Zone-1 .-ModelDocument1 pageBANBASA TOWN Index Plan Zone-1 .-Modelshubham kumarNo ratings yet

- Ifc Ar 8005 00Document1 pageIfc Ar 8005 00harshasudarshani31No ratings yet

- 0012DK9770 2186 B-Za 1001 (En-Ru)Document2 pages0012DK9770 2186 B-Za 1001 (En-Ru)Ninad AcharyaNo ratings yet

- It5 ElecDocument1 pageIt5 Elecmanhasr80No ratings yet

- 5tbuk04 Bujv SD 720 El DWG 10105Document1 page5tbuk04 Bujv SD 720 El DWG 10105sacseventNo ratings yet

- 66 KV Substation Earthmat DrawingDocument1 page66 KV Substation Earthmat Drawingelectrabiz.infraNo ratings yet

- Prestressed Concrete Sheet PilingDocument1 pagePrestressed Concrete Sheet PilingNaresh GajNo ratings yet

- Submission DWG of Pushpa Revised-ModelDocument1 pageSubmission DWG of Pushpa Revised-ModeldesigngalleriasNo ratings yet

- 1963 - IR Invercargill - TENDER - 6Document1 page1963 - IR Invercargill - TENDER - 6huan liuNo ratings yet

- Slop E: RestrictedDocument1 pageSlop E: Restrictedcon.sup.amchfcNo ratings yet

- Bautista - A4Document1 pageBautista - A4Wilfredo MinaNo ratings yet

- (Steps Going To Deck Roof) : LegendDocument1 page(Steps Going To Deck Roof) : LegendLowie Torres TonioNo ratings yet

- Ambala DDP 2025Document1 pageAmbala DDP 2025armaansaab511No ratings yet

- Detail B Optional End Block - Elevation: CaliforniaDocument1 pageDetail B Optional End Block - Elevation: CaliforniaProfessor PuppiesNo ratings yet

- SD - R05 - Oscars County - Parandwadi - 2 - 2023.04.18Document1 pageSD - R05 - Oscars County - Parandwadi - 2 - 2023.04.18mahesh navaghaneNo ratings yet

- Ilide - Info Caterpillar Gas Engine 3516 Schematic Diagram PRDocument2 pagesIlide - Info Caterpillar Gas Engine 3516 Schematic Diagram PRTamNo ratings yet

- Ee PlanDocument1 pageEe PlanPaul MendozaNo ratings yet

- 0-8936-2 Golden Triangle Polymers Company LLCDocument1 page0-8936-2 Golden Triangle Polymers Company LLCLester MuscaNo ratings yet

- Obtuse Corner Acute and Perpendicular Corner: Match The Slope of The GirderDocument1 pageObtuse Corner Acute and Perpendicular Corner: Match The Slope of The GirderProfessor PuppiesNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNo ratings yet

- Rear Elevation Front Elevation: MercadoDocument1 pageRear Elevation Front Elevation: MercadoLADY NICOLE STA. MARIANo ratings yet

- F-A1-0112 - Penthouse Floor-OverallDocument1 pageF-A1-0112 - Penthouse Floor-Overallnithankarthik920No ratings yet

- Me-0007 (1) - 231004-Grille Schedules Sheet 1Document1 pageMe-0007 (1) - 231004-Grille Schedules Sheet 1humcanopNo ratings yet

- !CivilDrawings 20220519Document81 pages!CivilDrawings 20220519rimshaNo ratings yet

- 06 30 Roof Framing GatchalianDocument1 page06 30 Roof Framing Gatchalianjaylvasquez01No ratings yet

- Irrigation Control Cable LayoutDocument4 pagesIrrigation Control Cable Layoutalivesince1091No ratings yet

- Fabrication Materials: Saudi Arabian Oil CompanyDocument31 pagesFabrication Materials: Saudi Arabian Oil CompanyD7mey XNo ratings yet

- NCGM XX XX D Aec DR 930 1103Document1 pageNCGM XX XX D Aec DR 930 1103yusufuNo ratings yet

- D - 01S190517-G Rev07 - AS BUILT-1Document1 pageD - 01S190517-G Rev07 - AS BUILT-1גרבר פליקסNo ratings yet

- 07Document1 page07camilo andres cutiva caraballoNo ratings yet

- 5 Bed HOUSE PLANDocument1 page5 Bed HOUSE PLANallanNo ratings yet

- HSR or DDD STR Cwa GL S01 D01 WSB 401 1002 ADocument1 pageHSR or DDD STR Cwa GL S01 D01 WSB 401 1002 AMamadoNo ratings yet

- Cont. On: Fabrication MaterialsDocument7 pagesCont. On: Fabrication MaterialsD7mey XNo ratings yet

- BG2D-Sheet - FP-702 - PELAN BUMBUNG BAWAH, PELAN BUMBUNG, KERATAN A-A & KERATAN B-B-Layout1Document1 pageBG2D-Sheet - FP-702 - PELAN BUMBUNG BAWAH, PELAN BUMBUNG, KERATAN A-A & KERATAN B-B-Layout1Alexander SNo ratings yet

- Petronas Carigali SDN BHD: Document Review StatusDocument1 pagePetronas Carigali SDN BHD: Document Review StatusMohd KhaidirNo ratings yet

- BW Tok JiringDocument4 pagesBW Tok JiringHakimi ZulkifliNo ratings yet

- Instant Assessments for Data Tracking, Grade K: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade K: Language ArtsNo ratings yet

- Instant Assessments for Data Tracking, Grade 5: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 5: Language ArtsNo ratings yet

- Legend: Vicinity MapDocument1 pageLegend: Vicinity MaprickNo ratings yet

- PARTITION AGREEMENT WITH WAIVER OF RIGHTS (Lot 7624-B-2)Document2 pagesPARTITION AGREEMENT WITH WAIVER OF RIGHTS (Lot 7624-B-2)rickNo ratings yet

- Structural Analysis and Design Report: Copra Consolidation and TradingDocument37 pagesStructural Analysis and Design Report: Copra Consolidation and TradingrickNo ratings yet

- Construction Notes: Section of FascineDocument1 pageConstruction Notes: Section of FascinerickNo ratings yet

- Summary of Quantities:: (As To Plan)Document1 pageSummary of Quantities:: (As To Plan)rickNo ratings yet

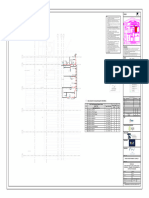

- Water Pipe Line Layout Plan: Private Room Private Room Private RoomDocument1 pageWater Pipe Line Layout Plan: Private Room Private Room Private RoomrickNo ratings yet

- Imelda-Bayog-Kumalarang-Lapuyan-Margosatubig Road: Department of Public Works and HighwaysDocument1 pageImelda-Bayog-Kumalarang-Lapuyan-Margosatubig Road: Department of Public Works and HighwaysrickNo ratings yet

- HOUSE - in Building A Structure Mathematics Is One of The Key Factor, It Should'veDocument1 pageHOUSE - in Building A Structure Mathematics Is One of The Key Factor, It Should'verickNo ratings yet

- Rice SummaryDocument30 pagesRice SummaryrickNo ratings yet

- Math10 q1 Mod6 Finding The NTH Term of A Geometric Series and Geometric Means v1.5Document22 pagesMath10 q1 Mod6 Finding The NTH Term of A Geometric Series and Geometric Means v1.5rickNo ratings yet

- Computer Education 7 Learning Module: Pagadian Diocesan SchoolsDocument2 pagesComputer Education 7 Learning Module: Pagadian Diocesan SchoolsrickNo ratings yet

- Location Plan: Pagadian CityDocument1 pageLocation Plan: Pagadian CityrickNo ratings yet

- Call For Papers - 1st AnnouncementDocument3 pagesCall For Papers - 1st Announcementeliz_kNo ratings yet

- Generation XDocument19 pagesGeneration XJm Ihza MahendraNo ratings yet

- Mobile Management SystemDocument9 pagesMobile Management SystemNaga Sai Anitha NidumoluNo ratings yet

- Speaking Part 2 Improving Lexical ResourceDocument9 pagesSpeaking Part 2 Improving Lexical ResourceMandar SutarNo ratings yet

- BDocument4 pagesBAnonymous JwAC4yPNo ratings yet

- Chart 1Document1 pageChart 1BAGUIO CATSNo ratings yet

- Learning From Real-World Building Structural CollapseDocument46 pagesLearning From Real-World Building Structural CollapseSemon AungNo ratings yet

- Book SummaryDocument2 pagesBook Summaryapi-547292340No ratings yet

- Basic Civil and Mechanical EngineeringDocument28 pagesBasic Civil and Mechanical EngineeringRAJARAMNo ratings yet

- Eaton 216376 M22 K10 en - GBDocument6 pagesEaton 216376 M22 K10 en - GBEmmanuel Astaroth PaizaNo ratings yet

- PhysicsDocument18 pagesPhysicsSheraz Khan100% (1)

- Origin Effects Cali76 SE Stacked Edition Instruction ManualDocument8 pagesOrigin Effects Cali76 SE Stacked Edition Instruction ManualCesar BrunoNo ratings yet

- NJS3 - DatasheetDocument2 pagesNJS3 - DatasheetSERGIO GIRABELNo ratings yet

- Coo - Electrical Form For C.O. TempDocument2 pagesCoo - Electrical Form For C.O. TempShopmore PhilippinesNo ratings yet

- TNFD Management and Disclosure Framework v0-3 BDocument31 pagesTNFD Management and Disclosure Framework v0-3 BPorshe56No ratings yet

- Cables For EE342 CourseDocument7 pagesCables For EE342 Coursemahmab70No ratings yet

- The Phenomenology of The Impostor PhenomenonDocument15 pagesThe Phenomenology of The Impostor PhenomenonTyaz ArizkaNo ratings yet

- Thesis Sheffield UniversityDocument6 pagesThesis Sheffield Universitylauramartinmanchester100% (1)

- Limit and Limit and Continuity Preparation Tips For IIT JEE - askIITiansContinuityDocument8 pagesLimit and Limit and Continuity Preparation Tips For IIT JEE - askIITiansContinuityaskiitianNo ratings yet

- An Introduction To Gage R&RDocument4 pagesAn Introduction To Gage R&RShiguo LiuNo ratings yet

- Curriculum Development4Document12 pagesCurriculum Development4Teacher SallyNo ratings yet

- FireDepartmentTwo toneToneOutDocument5 pagesFireDepartmentTwo toneToneOutla1450No ratings yet

- J, DL ¿ MSS - KL Ixl, Amh (Cloud Computing)Document5 pagesJ, DL ¿ MSS - KL Ixl, Amh (Cloud Computing)Madhara SamaraweeraNo ratings yet

- Applicatn of Polynomial Functions in Real Life (Architecture and Engineering)Document7 pagesApplicatn of Polynomial Functions in Real Life (Architecture and Engineering)Lemuel Blaya100% (4)

- CV SazzedDocument2 pagesCV SazzedWali Ahmed KhanNo ratings yet

- Report SampleDocument15 pagesReport Sample153-B RAKSHITHANo ratings yet

- A Case Study On Rapido: India's Largest Online Bike Service ProviderDocument7 pagesA Case Study On Rapido: India's Largest Online Bike Service ProviderKandula ArchanaNo ratings yet

- Access Audit Proforma CPWDDocument15 pagesAccess Audit Proforma CPWDPrashantNo ratings yet