0 ratings0% found this document useful (0 votes)

137 viewsHSE Risk Assessment For Trial Trench: PROJECT: Contract

HSE Risk Assessment For Trial Trench: PROJECT: Contract

Uploaded by

Sasi KumarThis risk assessment identifies 8 hazards associated with a trial trench project including collapse of trench sides, striking existing underground services, unsafe access and egress, vehicular access, underground services like electricity and water, dust from trial pit operations, existing site contamination, and risks from third parties. For each hazard, the document evaluates the risk level without and with control measures, outlines prevention methods, and identifies the responsible person to implement controls. The overall goal is to reduce risk levels through inspections, permits, protective equipment, training, and following established safety procedures.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

HSE Risk Assessment For Trial Trench: PROJECT: Contract

HSE Risk Assessment For Trial Trench: PROJECT: Contract

Uploaded by

Sasi Kumar0 ratings0% found this document useful (0 votes)

137 views3 pagesThis risk assessment identifies 8 hazards associated with a trial trench project including collapse of trench sides, striking existing underground services, unsafe access and egress, vehicular access, underground services like electricity and water, dust from trial pit operations, existing site contamination, and risks from third parties. For each hazard, the document evaluates the risk level without and with control measures, outlines prevention methods, and identifies the responsible person to implement controls. The overall goal is to reduce risk levels through inspections, permits, protective equipment, training, and following established safety procedures.

Original Title

TRIAL TRENCH

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This risk assessment identifies 8 hazards associated with a trial trench project including collapse of trench sides, striking existing underground services, unsafe access and egress, vehicular access, underground services like electricity and water, dust from trial pit operations, existing site contamination, and risks from third parties. For each hazard, the document evaluates the risk level without and with control measures, outlines prevention methods, and identifies the responsible person to implement controls. The overall goal is to reduce risk levels through inspections, permits, protective equipment, training, and following established safety procedures.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

137 views3 pagesHSE Risk Assessment For Trial Trench: PROJECT: Contract

HSE Risk Assessment For Trial Trench: PROJECT: Contract

Uploaded by

Sasi KumarThis risk assessment identifies 8 hazards associated with a trial trench project including collapse of trench sides, striking existing underground services, unsafe access and egress, vehicular access, underground services like electricity and water, dust from trial pit operations, existing site contamination, and risks from third parties. For each hazard, the document evaluates the risk level without and with control measures, outlines prevention methods, and identifies the responsible person to implement controls. The overall goal is to reduce risk levels through inspections, permits, protective equipment, training, and following established safety procedures.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

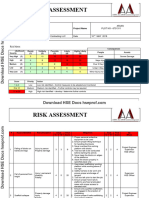

HSE Risk Assessment for Trial TrenchPROJECT: Contract: RM 12B

Risk Risk Responsible

No Hazard Consequence Risk Rating Level Prevention Risk Rating Leve Person

Without WithControls l

ControlsMeas Measures

ures

l S RR L S RR

Collapse of Death Site Engineer must be on site Site Engineer

1 sides Serious 5 4 20 Checking of slope stability by site ,Supervisor ,

Injury, engineer 5 1 5 Foreman,

Delays in Soil conditions must be followed MR safety

specific work by site engineer Officer

Excavation site must be inspected

ER daily

Trench boxes to be installed

where necessary

Steps Excavation to be taken

more than 1.5 Meter

Excavated Materials to be Kept

Minimum 1 Meter From Trench

Edge

Site Engineer

- Injury to Site engineer must be on site supervisor,

Striking personnel Necessary excavation permits foreman

2 existing -Electric shock 5 4 20 ER from local authority 3 1 3 L safety

services -Burn Location of existing services must Officer

-Damage to be identified before work

drain commences, and information on

ground condition to be given.

Existing services to be detected

us detector

Provide Training To Worker

Selecting the competent Person

to the concern work

Two ladders to be positioned for

access and egress

Ladders to be secured at the top

Unsafe access -Death and to extend at least one meter site Engineer

3 and egress -Serious injury 5 4 20 ER over the top of the trench 4 1 4 MR ,Supervisor ,

and falling -Delays in Workers should be properly Foreman

into specific works trained and supervised on site. safety

excavation Usage of PPE (helmet ,safety Officer

shoes ,high visibility jacket )-

Temporarily access bridge must

have handrail-Excavation site

must be fenced

PROJECT: Contract: RM 12B

Risk Rating Risk Risk Responsible

No Hazard Consequence Without Level Prevention Risk Rating Leve Person

ControlsMeas WithControls l

ures Measures

l S RR L S RR

4 Vehicular Vehicular 2 2 4 MR Exercise caution, Traffic Sign 1 2 2 LR site Engineer

Access Accident boards ,Supervisor ,

Use flashing lights and dipped Foreman

head lights, be aware of safety

surroundings. Officer

Adhere to site speed limits.

Plant will not divert from

identified access routes.

5 Underground Explosion, 5 2 10 HR Check Service Drawings and 3 1 3 LR site Engineer

Services injury, death, locate services as per method ,Supervisor ,

.Electricity / equipment statement, Foreman

Water. etc. damage. Detect the services using cable safety

detector

Officer

Wear PPE, exercise caution. All

trial trenches to be scanned with

Radio Detection cable avoidance ,

Model No C.A.T4

6 Trial Pit Inhalation 2 2 4 MR Wear PPE where necessary, 2 1 2 LR site Engineer

Operation - normal dust minimization ,Supervisor ,

Dust procedures if required (Watering). Foreman

Wear Mask safety

Officer

7 Existing Unknown, 1 3 3 LR Exercise caution. Wear 1 2 2 LR site Engineer

Contaminatio suspected low PPE, maintain personal hygiene ,Supervisor ,

n on-Site standards. Foreman

safety

Officer

8 Risk Arising Other site 1 3 3 LR Exercise caution, use vehicles 1 2 2 LR site Engineer

from 3rd plant with flashing lights and dipped ,Supervisor ,

Parties movements head lights. Foreman

Be aware of surroundings and ,Operator

other site plant movements.

safety

Officer

10 Heat Stroke High Body 5 3 15 Reduce activity levels and/or 2 2 4 LR site Engineer

Temperature heat exposure. ,Supervisor ,

(over 40Degree Drink fluids regularly. Foreman

ER

Celsius has hot, Workers should check on each safety

dry, red skin; a other to help spot the

Officer

faint pulse; a symptoms which often precede

headache or heat stroke.

dizziness; in

later stages, a

person may

pass out and

have

convulsions.

PROJECT: Contract: RM 12B

Risk Risk Responsible

No Hazard Consequence Risk Rating Level Prevention Risk Rating Leve Person

Without WithControls l

ControlsMeas Measures

ures

l S RR L S RR

11 UN- Injury to a 3 2 6 MR 3 1 3 LR site Engineer

Authorized member of the Provide the appropriate fencing ,Supervisor ,

entry by public and/or barricades as per site risk Foreman

others safety

assessment. Officer

Apply appropriate signage and

pedestrian control.

Devise and implement system

for site inspection and security.

Ensure security and equipment

suitable to minimize vandalism

Provide Warning sign boards.

You might also like

- ACoRN Acute Care of At-Risk Newborns A Resource and Learning Tool For Health Care Professionals 2nd EditionDocument473 pagesACoRN Acute Care of At-Risk Newborns A Resource and Learning Tool For Health Care Professionals 2nd EditionGerardo Fernandez100% (2)

- Decking Risk AssessmentDocument4 pagesDecking Risk AssessmentReagan MukeboNo ratings yet

- SUMMER WORK PLAN (For Gulf Countries)Document13 pagesSUMMER WORK PLAN (For Gulf Countries)Zubair Khan0% (1)

- Tarpaulin Installation MSDocument6 pagesTarpaulin Installation MSBilal100% (1)

- Pit Risk AssessmentDocument40 pagesPit Risk Assessmentapi-282994970No ratings yet

- Premala Hse ManualDocument7 pagesPremala Hse ManualLuqman Osman100% (1)

- Work Method Statements For Reed SelectDocument53 pagesWork Method Statements For Reed SelectInoe InaeNo ratings yet

- Summer SafetyDocument44 pagesSummer SafetySatya NaiduNo ratings yet

- Iverson v. The HeightsDocument11 pagesIverson v. The HeightsKGW NewsNo ratings yet

- EMT Past Papers 1122Document6 pagesEMT Past Papers 1122Ansar Ali100% (1)

- Workers Welfare Standards Qatar 2022 v2Document12 pagesWorkers Welfare Standards Qatar 2022 v2Ali ImamNo ratings yet

- AG Night Work Safety Operating ProcedureDocument7 pagesAG Night Work Safety Operating ProceduresharathNo ratings yet

- Hse Management PlanDocument23 pagesHse Management PlanDavis EzieNo ratings yet

- Labour ActDocument45 pagesLabour ActGajendra JoshiNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Ramadan (Fasting) Health and Safety AwarenessDocument9 pagesRamadan (Fasting) Health and Safety AwarenessMuhammad RidwanNo ratings yet

- Risk Assessment For Installation of LV Power Cables and WiresDocument9 pagesRisk Assessment For Installation of LV Power Cables and WiresMohammed Amer Pasha100% (1)

- Excavation Safety Awarness Campaign Report - OCT 2022Document11 pagesExcavation Safety Awarness Campaign Report - OCT 2022Reyaz Mallick100% (1)

- T-4.196.224 Road MarkingDocument4 pagesT-4.196.224 Road MarkingYuvaraj Ponraj100% (1)

- Traffic Diversion PlanDocument17 pagesTraffic Diversion Planaryannet100% (2)

- Excavation Shoring and Protection ProcedureDocument7 pagesExcavation Shoring and Protection ProcedureREBAA HatemNo ratings yet

- DML Method Statement of Guardrail InstallationDocument1 pageDML Method Statement of Guardrail InstallationFarisa sayuti100% (1)

- Method Statement of Road Sub Base Amd BaseDocument7 pagesMethod Statement of Road Sub Base Amd BaseBrian Colon50% (2)

- 004 Risk Assessment of Sewerage Water NetworkDocument6 pages004 Risk Assessment of Sewerage Water NetworkprabhuNo ratings yet

- Role of Safety OfficerDocument12 pagesRole of Safety OfficerJerry Consorte100% (1)

- ED2 SampleDocument53 pagesED2 SampleadelNo ratings yet

- Vwa Traffic MGT ChecklistDocument1 pageVwa Traffic MGT ChecklistAnonymous ANmMebffKRNo ratings yet

- Saline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentDocument12 pagesSaline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentBhavanishankar ShettyNo ratings yet

- Safe Job Procedure For Erecting Tube and Clamp and All Around Scaffolding June 2014Document7 pagesSafe Job Procedure For Erecting Tube and Clamp and All Around Scaffolding June 2014Abel DemNo ratings yet

- Safe - Work - Method - Statement - Roof - Truss - Installation V1.0Document8 pagesSafe - Work - Method - Statement - Roof - Truss - Installation V1.0hurairamughal666No ratings yet

- HSE Management System ArenscoDocument22 pagesHSE Management System ArenscoJaber AmariNo ratings yet

- A-2.2-21-17-01 - Bentonite MixerDocument1 pageA-2.2-21-17-01 - Bentonite MixerNisanth ThulasidasNo ratings yet

- Fall Protection PlanDocument14 pagesFall Protection PlanPrince EugoNo ratings yet

- Balama HSSE PlanDocument18 pagesBalama HSSE Planosvaldo marioNo ratings yet

- Inspection Report Offshore Oilboom Asset Saka Pangkah, LTDDocument13 pagesInspection Report Offshore Oilboom Asset Saka Pangkah, LTDsayajaswadiNo ratings yet

- EHS Approved Agency For Testing & Certification of Fire Fighting EquipmentDocument8 pagesEHS Approved Agency For Testing & Certification of Fire Fighting Equipmenttp101267No ratings yet

- Scaffolding SafetyDocument4 pagesScaffolding Safetyrguy3223No ratings yet

- Fall Protection Program: Reviewed: May 2011Document20 pagesFall Protection Program: Reviewed: May 2011Marvin ReggieNo ratings yet

- Workplace Safety and Health (Safety and Health Management System and Auditing) Regulations 2009Document12 pagesWorkplace Safety and Health (Safety and Health Management System and Auditing) Regulations 2009alexNo ratings yet

- I Safe TrainingDocument61 pagesI Safe TrainingiddsubraNo ratings yet

- Groundwater Recharge SK SharmaDocument30 pagesGroundwater Recharge SK Sharmasweta jadhavNo ratings yet

- UAE Law No. - 21 - of 2005 Concerning Waste Management in Abu Dhabi Emirate EngDocument9 pagesUAE Law No. - 21 - of 2005 Concerning Waste Management in Abu Dhabi Emirate EngwholenumberNo ratings yet

- Saubhagya Raebareli: Sensitivity: LNT Construction Internal UseDocument1 pageSaubhagya Raebareli: Sensitivity: LNT Construction Internal UseL&T Ltd.No ratings yet

- OrganogramDocument1 pageOrganogramNadeem PervaizNo ratings yet

- Suppliers H&S Pre Qualification QuestionnaireDocument6 pagesSuppliers H&S Pre Qualification QuestionnaireJoe GrantNo ratings yet

- Worker WelfareDocument2 pagesWorker WelfareNibu P ShajiNo ratings yet

- MS Road MarkingDocument2 pagesMS Road MarkingMuhammad NaumanNo ratings yet

- Chemical Inventory Records-LAUNDRY Nov'19Document10 pagesChemical Inventory Records-LAUNDRY Nov'19mukhtarNo ratings yet

- Safty Managemnt at Construction SiteDocument17 pagesSafty Managemnt at Construction Sitesvaroop architects100% (1)

- Welding Gas-ArgonDocument6 pagesWelding Gas-ArgonArpit MaheshwariNo ratings yet

- Hazard Profile Pipe Laying (Water Sewer) January 2010Document11 pagesHazard Profile Pipe Laying (Water Sewer) January 2010Mumtaz Ahmed Ghumman100% (2)

- Emergency Response Procedures: Toolbox TalksDocument2 pagesEmergency Response Procedures: Toolbox TalksmahlasbarlasNo ratings yet

- CEMP Construction Environmental Management Plan CLAREMONTROADDocument10 pagesCEMP Construction Environmental Management Plan CLAREMONTROADThomas StovoldNo ratings yet

- Scaffold Erection and DismantlingDocument5 pagesScaffold Erection and DismantlingFosu DicksonNo ratings yet

- JMS For MroDocument9 pagesJMS For Mroalexius lucasNo ratings yet

- Manual LiftingDocument1 pageManual Liftingusama666100% (1)

- Risk Assessment: Resin Anchored BoltsDocument80 pagesRisk Assessment: Resin Anchored BoltsAkhmad MuflihNo ratings yet

- Racking Inspection Template Checklist: Sales@therackinginspector - Co.ukDocument1 pageRacking Inspection Template Checklist: Sales@therackinginspector - Co.ukAlexis Carcamo MuñozNo ratings yet

- Occupational Health & Industrial Hygiene ProgramsDocument11 pagesOccupational Health & Industrial Hygiene ProgramsSatya NaiduNo ratings yet

- Risk Assessment Form - KingGroveDocument12 pagesRisk Assessment Form - KingGroveeric chenNo ratings yet

- DM HSD GU35 URAS2 Technical Guidelines For Usage of Rope Access System V2.1Document20 pagesDM HSD GU35 URAS2 Technical Guidelines For Usage of Rope Access System V2.1Natalie BlackmoreNo ratings yet

- ASMI-OSHMS-PR-11 - Communication and Consultation ProcedureDocument6 pagesASMI-OSHMS-PR-11 - Communication and Consultation ProcedureJHUPEL ABARIALNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- You Are Looking So CuteDocument5 pagesYou Are Looking So CuteSasi KumarNo ratings yet

- I Love You PanniDocument6 pagesI Love You PanniSasi KumarNo ratings yet

- HSE Internal Data Record Kumar DB 01Document16 pagesHSE Internal Data Record Kumar DB 01Sasi KumarNo ratings yet

- An Introduction To Oil and Gas ProductionDocument6 pagesAn Introduction To Oil and Gas ProductionSasi KumarNo ratings yet

- RA Excavation For Trial TrenchDocument9 pagesRA Excavation For Trial TrenchSasi KumarNo ratings yet

- Slideshare DownloadDocument18 pagesSlideshare DownloadSasi KumarNo ratings yet

- Submittal Transmittal Sheet #: Project Name DB52-TH16-PQN-001 00 Submittal Title: Prequalification For ANTI TERMITEDocument1 pageSubmittal Transmittal Sheet #: Project Name DB52-TH16-PQN-001 00 Submittal Title: Prequalification For ANTI TERMITESasi KumarNo ratings yet

- RA Excavation For ExcavationDocument13 pagesRA Excavation For ExcavationSasi KumarNo ratings yet

- Incentive Program - GenericDocument16 pagesIncentive Program - GenericSasi Kumar100% (1)

- Monthly Fire Safety InspectionDocument1 pageMonthly Fire Safety InspectionSasi KumarNo ratings yet

- Labour Work ReportDocument4 pagesLabour Work ReportSasi KumarNo ratings yet

- Risk Assesment For GRP Pipe LayingDocument3 pagesRisk Assesment For GRP Pipe LayingSasi Kumar71% (7)

- BHP Risk Assessment Dalf r1Document18 pagesBHP Risk Assessment Dalf r1Sasi KumarNo ratings yet

- Hope Notes (Semi Final)Document3 pagesHope Notes (Semi Final)Benjamin OrdenizaNo ratings yet

- رنا عبدالله الصبيح كيس ستديDocument23 pagesرنا عبدالله الصبيح كيس ستديرنا عبداللهNo ratings yet

- Thermal Regulation: Mary Frances D. PateDocument17 pagesThermal Regulation: Mary Frances D. PateWinny Shiru MachiraNo ratings yet

- Tech Report Heat Waves and Health. Usa.2019Document53 pagesTech Report Heat Waves and Health. Usa.2019JKM UKMNo ratings yet

- Lite Ls04naDocument104 pagesLite Ls04naAdrián Zigo DresingNo ratings yet

- Soal Dan Kunci Jawaban TO 3 - Kemampuan Bahasa InggrisDocument16 pagesSoal Dan Kunci Jawaban TO 3 - Kemampuan Bahasa InggrisTracy KerehNo ratings yet

- Summative Test P.E HEALTH 12Document2 pagesSummative Test P.E HEALTH 12John Lester GenizeraNo ratings yet

- Plug & Play: Owner'S ManualDocument28 pagesPlug & Play: Owner'S ManualMiguel SanchezNo ratings yet

- LAS 3-Management of PoisonDocument6 pagesLAS 3-Management of PoisonSenemela GonzalesNo ratings yet

- RA For Block WorkDocument4 pagesRA For Block WorkMd.Imtayaj AhmadNo ratings yet

- Heater MaintenanceDocument44 pagesHeater MaintenanceBryant ClarkNo ratings yet

- FeverDocument9 pagesFeverIgnatius Ivan PutrantyoNo ratings yet

- Thermal ComfortDocument192 pagesThermal ComfortMusical Black DiaryNo ratings yet

- Altered Body TemperatureDocument27 pagesAltered Body TemperatureAnusikta PandaNo ratings yet

- Observes Personal Safety Protocol To Avoid Dehydration, Overexertion, Hypo - and Hyperthermia During MVPA Participation Weeks 1 To 10 PEH11FH-Ik-t-10 6. DemonstratesDocument15 pagesObserves Personal Safety Protocol To Avoid Dehydration, Overexertion, Hypo - and Hyperthermia During MVPA Participation Weeks 1 To 10 PEH11FH-Ik-t-10 6. DemonstratesEvangeline Bercasio IINo ratings yet

- Army - fm21 10 - Field Hygiene and SanitationDocument162 pagesArmy - fm21 10 - Field Hygiene and SanitationMeowmix100% (4)

- Activity Hazard AnalysisDocument43 pagesActivity Hazard AnalysisShawn James100% (4)

- SCIED3.CIERVO - Bsed Sci1-A.laboratory 3 - The Body's FrameworkDocument6 pagesSCIED3.CIERVO - Bsed Sci1-A.laboratory 3 - The Body's FrameworkIrica Mae CiervoNo ratings yet

- Brain TemperatureThermal2010 KiyatkinDocument16 pagesBrain TemperatureThermal2010 KiyatkinIvica PutrićNo ratings yet

- HomeostasisDocument25 pagesHomeostasisJoey II Delos ReyesNo ratings yet

- Alterations in Body TemperatureDocument108 pagesAlterations in Body TemperatureJosephine George JojoNo ratings yet

- Neonatal Temp Reg CeDocument9 pagesNeonatal Temp Reg CeMatthew RyanNo ratings yet

- Summer Presentation Eng ArabicDocument24 pagesSummer Presentation Eng ArabicUsman AhmedNo ratings yet

- Q1 P.E. 12 M2Document8 pagesQ1 P.E. 12 M2Roy MaglalangNo ratings yet

- Heat Stress HSE PresentationDocument23 pagesHeat Stress HSE PresentationEtibar AliyevNo ratings yet