Hhaannddlleebbaarr Kkiitt: P/N 2882919-XXX, 2882920, 2882921, 2882922, 2882923, 2883297-XXX

Hhaannddlleebbaarr Kkiitt: P/N 2882919-XXX, 2882920, 2882921, 2882922, 2882923, 2883297-XXX

Uploaded by

Anthony ColemanCopyright:

Available Formats

Hhaannddlleebbaarr Kkiitt: P/N 2882919-XXX, 2882920, 2882921, 2882922, 2882923, 2883297-XXX

Hhaannddlleebbaarr Kkiitt: P/N 2882919-XXX, 2882920, 2882921, 2882922, 2882923, 2883297-XXX

Uploaded by

Anthony ColemanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Hhaannddlleebbaarr Kkiitt: P/N 2882919-XXX, 2882920, 2882921, 2882922, 2882923, 2883297-XXX

Hhaannddlleebbaarr Kkiitt: P/N 2882919-XXX, 2882920, 2882921, 2882922, 2882923, 2883297-XXX

Uploaded by

Anthony ColemanCopyright:

Available Formats

HANDLEBAR KIT

P/N 2882919-XXX, 2882920, 2882921, 2882922,

2882923, 2883297-XXX

IMPORTANT

Due to the technical nature of this kit, Indian®

insists that this installation be performed by a

certified Indian Motorcycle® Technician.

A P P L I C AT I O N

Verify accessory fitment at www.indianmotorcycle.com.

BEFORE YOU BEGIN

Read these instructions and check to be sure all parts and tools are accounted for. Please retain these

installation instructions for future reference and parts ordering information.

KIT CONTENTS

Full installation of this kit will require one of the following additional parts (sold separately):

• Heated Grip Kit PN: 2883442

• Non-Heated Grip Kit PN: 2883441

• Accessory Grip Kit (If accessory grip installed) PN: Various

Full installation of this kit will require the following additional part (sold separately):

• Adhesive Kit PN: 2883462

Kit PN 2882923-XXX shown; Other kits similar except as noted below.

This Kit includes:

Instr 9928169 Rev 01 2017-03 Page 1 of 16

REF QTY PART DESCRIPTION PART

NUMBER

1 1 Handlebar, Cruiser Beach, Polished Stainless Steel (Kit PN 2882921-410) -

Handlebar, Cruiser Beach, Gloss Black (Kit PN 2883448-266) -

Handlebar, Cruiser Mid-Ape, Polished Stainless Steel (Kit PN 2882920-410) -

Handlebar, Cruiser Mid-Ape, Gloss Black (Kit PN 2883449-266) -

Handlebar, Cruiser Pullback, Polished Stainless Steel (Kit PN 2882919-410) -

Handlebar, Touring Mid-Rise, Polished Stainless Steel (Kit PN 2882923-410) -

Handlebar, Touring Mid Rise, Gloss Black (Kit PN 2883450-266) -

Handlebar, Touring Pullback, Polished Stainless Steel (Kit PN 2882922-410) -

Handlebar, Springfield, Buckhorn, Chrome (Kit PN 2883297-156) -

Handlebar, Springfield, Buckhorn, Gloss Black (Kit PN 2883297-266) -

2 1 Cable, Clutch (Only in Kit PN 2882923-410, 2883450-266, 2882920-410, 7082079

2883449-266)

3 2 Cable Tie, Black (Not Shown) 7081504

4 4 Film, Protection, Clear (Only in kits PN 2882923-410 & 2883450-266) 5814472

1 Instructions 9928169

TOOLS REQUIRED

• Safety Glasses • Socket Set, Hex Bit, Metric

• Camera, Digital (Recommended) • Socket Set, Metric

• Hammer, Soft Face (Optional) • Socket Set, Torx® Bit

• Hex Key Set, Metric • Torque Wrench

• Pick Tool Set • Wrench Set, Metric

• Pliers, Side Cutting • Vice, Bench (Optional)

• Screwdriver, Phillips

CONSUMABLES REQUIRED

• Gloves, Chemical Resistant • Solvent Wipe (99% Isopropyl Alcohol)

• Multi-Purpose Grease (If replacing clutch cable) • Tape, Electrical

I M P O R TA N T

Your Indian Handlebar Kit is exclusively designed for your vehicle. Please read the installation instructions

thoroughly before beginning. Installation is easier if the vehicle is clean and free of debris. For your safety,

and to ensure a satisfactory installation, perform all installation steps correctly in the sequence shown.

A S S E M B LY T I M E

• Without Clutch Cable: Approximately 60 minutes

• With Clutch Cable: Approximately 90 minutes

Instr 9928169 Rev 01 2017-03 Page 2 of 16

I N S TA L L AT I O N I N S T R U C T I O N S

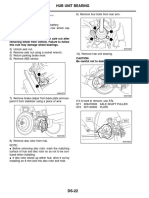

3. Remove and retain three fasteners C and

WARNING

withdraw head light assembly D far enough to

Clutch cable must be routed, installed and disconnect electrical connector. Remove head

adjusted correctly to function properly. Note how light assembly and set aside.

cable is route and secured before removing.

Permanent cable damage may result if inner cable

is bent or twisted during procedure. If cable is

incorrectly routed, installed or adjusted, serious

injury or death may occur.

IMPORTANT

Protect all finished surfaces during these

operations.

1. Turn key or ignition switch to “OFF” position

and remove key. If equipped with keyless fob,

remove fob from proximity of vehicle.

2. Place motorcycle in an upright position on a flat

level surface with front wheel secured in a wheel 4. Unplug handlebar connector E.

vise. TIP

F R O N T B O D Y W O R K R E M O VA L Tie a piece of string or wire to connector before

pulling handlebar out of fairing to ease re-routing

FAIRING MODELS of harness during install.

1. Take photos of wire routing from a front view

and a rear view for reference during re-

assembly.

2. Remove and retain two screws A from head light

bezel B. Pull firmly outward to remove head

light bezel K.

5. To make certain wiring is plugged into correct

terminal during re-assembly, ensure wiring is

labeled on both ends of each terminal. There

are a total of seven terminals coming from

handlebars (four right hand / three left hand).

6. Remove seat as per owner’s manual.

Instr 9928169 Rev 01 2017-03 Page 3 of 16

7. Remove and retain rear console mounting screw NON-FAIRING MODELS

F. 1. Remove windshield assembly, if equipped.

2. Remove and retain two fasteners A from top of

nacelle assembly.

8. Turn handlebars and pull front of the console

Gforward to release it from grommet H at front

mounting location.

3. Remove and retain two fasteners B from each

side of nacelle assembly. Disconnect turn

signals C and light bar bracket (if installed-not

shown) and set aside to prevent damage.

TIP

Photograph wire routing for assembly reference.

9. Unplug harnesses (switches). Remove back of

leather strap J from plastic retainer K on fuel

tank as if removing a shirt button. Remove

console from motorcycle and place on a cloth to

protect from damage.

Instr 9928169 Rev 01 2017-03 Page 4 of 16

4. Rotate headlight bucket assembly D forward H A N D C O N T R O L S R E M O VA L

and lower. Pull rear portion of nacelle assembly

RIGHT HAND CONTROLS REMOVAL

E back to expose handlebar riser F.

1. Starting with lower screw, remove and retain two

screws A and remove master cylinder assembly

B. Carefully hang master cylinder assembly so

that it remains level.

5. Loosen front handlebar clamp fasteners G (Do

not remove screws) and rotate handlebar up

until rear portion of nacelle E can be removed.

2. Remove and retain two screws C from RH switch

cube cover D and separate halves of cover.

6. Disconnect auxiliary light switch (if equipped)

and remove rear portion of nacelle.

3. Remove and retain two screws E from inner half

of RH switch F. Rotate switch side upward and

remove entire assembly. Disconnect wire

connectors from switch cube F.

4. Slide RH throttle tube/grip from handlebar.

Instr 9928169 Rev 01 2017-03 Page 5 of 16

LEFT HAND CONTROLS REMOVAL 3. Unplug clutch switch connector L from LH

switch assembly M by using a small pick to

1. Loosen two screws G. Slide and carefully rotate

release retaining tab. Remove and retain two

clutch handle assembly H enough to gain

screws G and clutch handle assembly H.

access to screws J on back of switch housing

Remove clutch cable from handle and set clutch

K. Use extra caution with clutch handle wire. handle assembly aside.

IMPORTANT

Do Not over-rotate clutch handle assembly around

handlebar or damage to clutch electrical wires will

occur.

4. Remove and retain two screws N from inner half

of LH switch M. Rotate switch side upward and

remove entire assembly. Disconnect wires from

switch cube M.

2. Remove and retain two screws J from LH switch

cube cover K and separate halves of cover.

Instr 9928169 Rev 01 2017-03 Page 6 of 16

5. Remove grip by placing rubber strap wrench 2. Protect clutch release arm C with a shop towel.

around LH grip P and twisting grip to break Rotate release arm inward. Disconnect clutch

adhesive free. Twist grip back and forth while cable D from release arm.

pulling outward. Use a soft hammer if needed to

move handle. Discard LH grip.

NOTE

Removal of LH grip will destroy grip and it should

not be reused.

3. Withdraw clutch cable D from mounting boss

located on primary cover.

C L U T C H C A B L E R E M O VA L

If clutch cable not required, skip to “Handlebar

Removal and Installation” section

1. Remove and retain side stand bumper bolt A

and clutch cable E-clip B.

4. Note routing of clutch cable through frame.

5. Loosen, but do not remove, two screws E, bolt

F and nut G, screws H and Jsecuring LH frame

downtube K to engine and steering head. Do

not remove fasteners.

Instr 9928169 Rev 01 2017-03 Page 7 of 16

6. Remove and retain screw L and P-clamp M. 2. Carefully remove cable clip D and remove

clutch cable E.

FAIRING MODELS

C L U T C H C A B L E I N S TA L L AT I O N

1. Turn handlebars fully right to access cable A.

Carefully pry cable A from wire clip B and IMPORTANT

remove cable. Do not kink, bend, or twist inner cable or outer

cable casing during installation.

1. Route new clutch cable w in same manner as

removed.

2. Torque LH frame downtube K fasteners E, F,

G, H, and J, to specification.

TORQUE

E, F, G, H, and J = 45 ft. lbs. (61 Nm)

NON-FAIRING MODELS

1. Remove and retain four screws A and washers

B from rear of nacelle and separate headlight

housing C from nacelle.

Instr 9928169 Rev 01 2017-03 Page 8 of 16

3. Install retained screw L and P-clamp M. Torque 7. At release arm end of cable, pull inner cable

screw to specification. until fully extended. Be sure upper end of cable

casing is seated in lever perch at handlebar end.

TORQUE

8. Apply multi-purpose grease to lower barrel end

84 in. lbs. (9.5 Nm) of cable.

9. Protect clutch release arm C with a shop towel.

4. Apply multi-purpose grease to lever end of Rotate release arm inward until cable w can be

cable barrel and install it in clutch lever at installed in release arm C.

handlebar.

10. Install clutch cable E-clip B at mounting boss.

5. Install cable casing in lever perch at handlebar. Install side stand bumper and bolt A. Torque

6. Install new cable w in mounting boss located on bolt to specification.

primary cover.

TORQUE

84 in. lbs. (9.5 Nm)

Instr 9928169 Rev 01 2017-03 Page 9 of 16

11. Apply protective film r to surface of dash in 2. Remove and retain two front and two rear cap

areas where clutch cable and brake line route screws E. Remove cap F and risers G from

and may come into contact with painted handlebar.

surfaces.

12. Route clutch cable as per routing noted during

removal. Reinsert cable into applicable clips

and replace cut cable ties.

NON-FAIRING MODELS

1. Reinstall headlight housing C to nacelle. Install

four retained screws A and washers B to rear of

nacelle. Torque to specification.

TORQUE

75 in. lbs. (8 Nm)

3. Pull left and right hand wiring harnesses and

from switch housing wiring slots in handlebar,.

TIP

Feed excess wire into center slot of handlebar

while simultaneously pulling from switch housing

end.

ACCESSORY HANDLEBAR INSTALLATION

1. Insert right hand switch housing wiring harness

into right hand switch housing wiring slot in

handlebar and pull all terminals out of center

wiring slot in handlebar. Pull harness taut until

H A N D L E B A R R E M O VA L A N D I N S TA L L AT I O N switch housing is located adjacent to wiring slot.

Repeat for left hand switch housing wiring.

HANDLEBAR REMOVAL

TIP

1. Remove and retain two screws A and two

washers C from under handlebar risers. Ensure Use a small piece of electrical tape to hold wire

rubber inserts B (retained by screws A) do not terminals together, assist in sliding wires through

fall out. Carefully slide handlebar and riser handlebars.

assembly out of triple clamp frame C. (Fairing/

Nacelle not shown for clarity)

Instr 9928169 Rev 01 2017-03 Page 10 of 16

2. Install risers G and riser cap F onto accessory H A N D C O N T R O L S I N S TA L L AT I O N

handlebar q. Center handlebar wire opening to

riser cap. Rotate handle bars to align clocking RIGHT HAND CONTROLS

marks with separation line of risers G and riser 1. Install new RH throttle tube/grip on handlebar.

cap F as shown with arrow. Loosely install two

front and two rear cap screws E. Torque front TIP

two cap screws to specification. Do not torque “Indian®” name should be horizontal when grip

rear cap screws at this time. properly installed. Rotate grip while sliding on to

ensure it is fully seated.

TORQUE

18 ft. lbs. (24 Nm)

2. Orient throttle housing F with pin in rear half of

housing and hole in bar as shown. Ensure to line

3. Carefully slide accessory handlebar q and riser up slots in throttle tube to throttle housing F.

assembly into triple clamp frame D. Ensure

rubber inserts B are installed. Install two

retained bolts A and washers C (removed in

step 1. of previous section), Torque to

specification. Route handlebar wiring towards

front.

TORQUE

60 ft. lbs. (81 Nm)

4. Torque rear cap screws E to specification.

TORQUE

18 ft. lbs. (24 Nm)

Instr 9928169 Rev 01 2017-03 Page 11 of 16

3. Close throttle housing F and reinstall two 6. Reinstall brake master cylinder assembly B

screws E. Torque screws to specification. using two retained screws A. Align dimple in

handlebar with center of assembly halves as

TORQUE shown with arrow. Starting with top screw,

10 in. lbs. (1 Nm) torque screws to specification.

TORQUE

70 in. lbs. (8 Nm)

4. Twist throttle fully backward and forward to

ensure throttle is properly seated and there is no

dragging. If dragging repeat steps 1 through 3

of this section. 7. Twist throttle fully backward and forward to

5. Reinstall RH switch cube cover D using two ensure throttle is properly seated and there is no

dragging. If dragging repeat steps 1 through 6

retained screws C. Ensure that all wiring is held

of this section.

within switch cube D and not pinched. Torque

screws to specification. LEFT HAND CONTROLS

TORQUE 1. Slide left grip onto handlebar while handlebar is

10 in. lbs. (1 Nm) clean and dry. Install inner portion of switch M

and align grip q. Hold grip in place, remove

switch M and make a mark on handlebar

aligned with tab on grip shown with arrow.

Remove switch and grip.

Instr 9928169 Rev 01 2017-03 Page 12 of 16

2. Spray three sprays worth of primer into grip 5. Quickly reinstall outer switch assembly M with

opening and allow 5 minutes for primer to dry. two retained screws N. Switch assembly notch

should fit over tab on grip flange as shown with

IMPORTANT arrow. Rotate and adjust grip to fit properly.

The next three steps need to be completed Torque screws to specification.

quickly, once adhesive dries, adjustment of grip

will not be possible. Read and understand ALL TORQUE

steps before proceeding. 10 in. lbs. (1 Nm)

3. Apply a thick bead of adhesive (PN 2883462) 15

mm into grip 360° around the grip. Spin LH grip

onto handlebar until grip bottoms out against

handlebar end. Quickly rotate grip so Indian®

name is horizontal and tab is aligned with mark

made in step 1 of this section. Wipe any excess

glue from handlebar or grip after grip is fully

seated.

6. Loosely reinstall clutch handle assembly H

using two retained screws G. Reinstall clutch

wire connector L to switch assemblyM.

4. Quickly orient switch housing M with pin in rear

half of housing and hole in bar as shown. Ensure

to line up slots on LH Grip to switch housing M

as shown.

Instr 9928169 Rev 01 2017-03 Page 13 of 16

7. Reinstall LH switch cube cover K using two C L U T C H L E V E R F R E E P L AY

retained screws J. Ensure that all wiring is held

1. With handlebars pointing straight ahead,

within switch cube K and is not pinched. Ensure measure clutch lever free play at point shown

clutch wire is not pinched by housing. Torque with arrow.

screws to specification.

MEASUREMENT

TORQUE

Clutch Lever Free Play: .019-.059 inch (0.5-1.5

10 in. lbs. (1 Nm) mm)

8. Align dimple in handlebar with center of clutch 2. Compare measurement to specification. If

handle assembly H halves as shown with arrow. adjustment is required, proceed to Step 3.

Starting with top screw, torque screws G to 3. Locate clutch cable adjuster boot A and pull it

specification. back to expose jam nut and barrel adjuster.

TORQUE

70 in. lbs. (8 Nm)

4. Hold cable and loosen adjuster jam nut.

5. Turn cable adjuster in or out until clutch free

play is correct.

IMPORTANT 6. Tighten adjuster jam nut. Torque to

specification.

Allow motorcycle to sit for a period of 24 hours to

allow glue to dry and set properly. TORQUE

48 in. lbs. (5.5 Nm)

7. Slide adjuster boot back over adjuster assembly.

Instr 9928169 Rev 01 2017-03 Page 14 of 16

F R O N T B O D Y W O R K R E - A S S E M B LY 6. Insert headlight bezel by inserting bezel

features into rubber grommets in fairing. Install

FAIRING MODELS retained two flange screws and torque to

1. Route handlebar wiring through fairing in same specification.

routing as referenced in fairing frame. Plug in

TORQUE

handlebar connector E.

36 in. lbs. (4.0 Nm)

TIP

Use piece of string or wire to connector left in

fairing during removal to pull wiring through NON-FARING MODELS

fairing. 1. Insert rear portion of nacelle and connect

auxiliary light switch (if equipped).

2. Loosen front handlebar clamp fasteners G (Do

not remove screws) and rotate handlebar up

until rear portion of nacelle E can be fully

installed.

2. Replace any cut cable ties with new cable ties.

3. Turn handlebar left and right, lock-to-lock, and

determine if any resistance from wire binding. If

resistance is felt or wire interference is found,

determine cause and re-bundle wires as

3. Re-position handlebar to rider preference (If

necessary. Check clearances between hand

needed).

controls and fuel tank. Adjust height if

necessary. 4. Torque front handlebar clamp fasteners to

specification.

4. Re-connect headlight.

5. Install headlight assembly into fairing by TORQUE

installing three aluminum spacers, headlight 18 ft. lbs. (24 Nm)

assembly, three washers then three hex screws.

Torque to specification.

5. Rotate headlight bucket assembly D into place.

TORQUE

84 in. lbs. (9.5 Nm)

TIP

Insert hex screw and washer into top mounting

hole of headlight assembly. Install an aluminum

spacer onto top hole and loosely install screw into

fairing. This will allow placement of the other two

aluminum spacers prior to installing the remaining

washers and screws.

Instr 9928169 Rev 01 2017-03 Page 15 of 16

6. Loosely install turn signals C and auxiliary light 8. Turn handlebar left and right, lock-to-lock, and

bar (if equipped-not shown) and connect determine if any resistance from wire binding. If

electrical terminals. Rotate front nacelle and resistance is felt or wire interference is found,

headlight into place and loosely install two determine cause and re-bundle wires as

retained fasteners B into each side of nacelle necessary. Check clearances between hand

assembly. Do not torque fasteners at this time. controls and fuel tank. Adjust height if

necessary.

9. Torque turn signal/auxiliary lightbar (if

equipped)/nacelle side fasteners B (installed in

step 2 of this section) to specification.

TORQUE

18 ft. lbs. (24 Nm)

10. Install windshield assembly, if equipped.

7. Install two retained fasteners A into top of

nacelle assembly. Torque to specification.

TORQUE

36 in. lbs. (4 Nm)

FEEDBACK FORM

A feedback form has been created for the installer to provide any comments, FEEDBACK FORM

questions or concerns about the installation instructions. The form is viewable on

mobile devices

by scanning the QR code or by clicking HERE if viewing on a PC.

Instr 9928169 Rev 01 2017-03 Page 16 of 16

You might also like

- Download Ethics For European Psychologists 1st Edition Geoff Lindsay ebook All Chapters PDFDocument81 pagesDownload Ethics For European Psychologists 1st Edition Geoff Lindsay ebook All Chapters PDFririteruj100% (8)

- Chastity ContractDocument3 pagesChastity ContractBritny Smith100% (1)

- 2006-2011 Yaris OEM Cruise Control DIY 20110315Document34 pages2006-2011 Yaris OEM Cruise Control DIY 20110315juanNo ratings yet

- 1989 Garden Way Tomahawk Chipper Technical Manual WMDocument12 pages1989 Garden Way Tomahawk Chipper Technical Manual WMgodiboNo ratings yet

- BMW Paddle Instalação e AtivaçãoDocument32 pagesBMW Paddle Instalação e AtivaçãoNicolas MNo ratings yet

- Shimano Tiagra 4600Document1 pageShimano Tiagra 4600Florian JurinNo ratings yet

- Shimano Ultegra 6700 Shifters Double Owners ManualDocument2 pagesShimano Ultegra 6700 Shifters Double Owners ManualTimNo ratings yet

- Fog Lamps Install (Mazda5)Document9 pagesFog Lamps Install (Mazda5)Joshby BimmerNo ratings yet

- 44Vvpppp Aauuddiioo Aam Mpplliiffiieerr Kkiitt: Aapppplliiccaattiioonn Bbeeffoorree Yyoouu BbeeggiinnDocument5 pages44Vvpppp Aauuddiioo Aam Mpplliiffiieerr Kkiitt: Aapppplliiccaattiioonn Bbeeffoorree Yyoouu BbeeggiinnTodor NakovNo ratings yet

- Montaz GPS Mazda 6 InstrukcjaDocument12 pagesMontaz GPS Mazda 6 InstrukcjaartserwisNo ratings yet

- Fax 001Document14 pagesFax 001daniel ignatNo ratings yet

- Janome 990D Sewing Machine Service ManualDocument49 pagesJanome 990D Sewing Machine Service ManualiliiexpugnansNo ratings yet

- Dixon ZTR 428-429 Technical DataDocument10 pagesDixon ZTR 428-429 Technical Datatecsbrain100% (1)

- Lexus LS 400-R1 Without Ride Light InstructionsDocument6 pagesLexus LS 400-R1 Without Ride Light InstructionsstrutmastersNo ratings yet

- BT PDFDocument12 pagesBT PDFvadim vadimNo ratings yet

- Ranger FBDocument8 pagesRanger FBfakihhabib01No ratings yet

- Kia Sportage Remote StartDocument22 pagesKia Sportage Remote StartJONATHAN100% (1)

- Spindle Belt ReplacementDocument3 pagesSpindle Belt ReplacementAshNo ratings yet

- CGen GY6 50cc Service Manual PDFDocument199 pagesCGen GY6 50cc Service Manual PDFSharkykzn0% (1)

- 501-05 Interior Trim and Ornamentation 2016 Mustang Removal and InstallationDocument35 pages501-05 Interior Trim and Ornamentation 2016 Mustang Removal and InstallationdreamopenerNo ratings yet

- Timing Belt Replacement 2008 Audi A4 20tdiDocument2 pagesTiming Belt Replacement 2008 Audi A4 20tdiJustinas RackauskasNo ratings yet

- GS150&200 Engine Service GuideDocument51 pagesGS150&200 Engine Service GuideMiguel LemosNo ratings yet

- DIXO1993 USen 304Document8 pagesDIXO1993 USen 304Per RenlundNo ratings yet

- 2013-07-24 001855 Sedona Trailer Wiring 2Document3 pages2013-07-24 001855 Sedona Trailer Wiring 2bibNo ratings yet

- Seat Belt, Srs AirbagDocument16 pagesSeat Belt, Srs AirbagJipsonCuevaNo ratings yet

- PT-V4-Installation-Royal-Enfield-Himalayan-EFI-2021-without-choke-minDocument29 pagesPT-V4-Installation-Royal-Enfield-Himalayan-EFI-2021-without-choke-minRaj Kumar NaniNo ratings yet

- Complete the _odis engineer brush hidden function modification_90-154Document65 pagesComplete the _odis engineer brush hidden function modification_90-154takemie002No ratings yet

- Janome Four DBL Sewing Machine Service ManualDocument29 pagesJanome Four DBL Sewing Machine Service ManualiliiexpugnansNo ratings yet

- Dedacciai Ran-Eng 2016Document14 pagesDedacciai Ran-Eng 2016pk50sNo ratings yet

- Hyundai Accent Sport ShifterDocument13 pagesHyundai Accent Sport ShiftermariuskidNo ratings yet

- Paddle Shift Install Instructions V5aDocument9 pagesPaddle Shift Install Instructions V5apenavi5687No ratings yet

- 2009 FIT - Ignition Coil and Spark Plug Removal/InstallationDocument8 pages2009 FIT - Ignition Coil and Spark Plug Removal/Installationbcr888No ratings yet

- Drifter Hd700 Service Manual Vol.2Document71 pagesDrifter Hd700 Service Manual Vol.2Gee K ToubulukwaNo ratings yet

- 2008 Hollow Gram SL Crank Owners Manual Supplement enDocument16 pages2008 Hollow Gram SL Crank Owners Manual Supplement engregclimbsNo ratings yet

- evotech_performance_frame_sliders_ducati_monster7972017Document12 pagesevotech_performance_frame_sliders_ducati_monster7972017luis angelNo ratings yet

- Front Axle: SectionDocument24 pagesFront Axle: SectionMihai IavorschiNo ratings yet

- Bumpers - F-Type - X152Document109 pagesBumpers - F-Type - X152sebaducatorNo ratings yet

- Ignition Switch - 4. HeadlightDocument6 pagesIgnition Switch - 4. HeadlightRodrigo SalgueroNo ratings yet

- 9 SuspensionDocument72 pages9 SuspensionFranciscoJavierChamizoMartinNo ratings yet

- SM - 29 - Fenders, Engine Hood - BMW M3 1992-1998Document6 pagesSM - 29 - Fenders, Engine Hood - BMW M3 1992-1998Hermawan 0103No ratings yet

- Type V BarDocument4 pagesType V BarJason HackNo ratings yet

- INSTRUCTIONSDocument10 pagesINSTRUCTIONSzozo0424No ratings yet

- MSA5T0205A11496Document4 pagesMSA5T0205A11496anibalbelltNo ratings yet

- Crestline Dampening Systems: Installation InstructionsDocument73 pagesCrestline Dampening Systems: Installation InstructionsSergey PhilippovNo ratings yet

- Aiwa Tvc2121Document43 pagesAiwa Tvc2121Safran NuhNo ratings yet

- Audiovox Rampage ACC-56 OM IMDocument20 pagesAudiovox Rampage ACC-56 OM IMRyan OfstieNo ratings yet

- Body & Trim: Go To Table of Contents Go To Quick Reference IndexDocument48 pagesBody & Trim: Go To Table of Contents Go To Quick Reference IndexLevin Tan HtNo ratings yet

- Camera Backup Mopar Install 82211346Document17 pagesCamera Backup Mopar Install 82211346sua woschNo ratings yet

- Engine Overhaul: EngineremovalDocument11 pagesEngine Overhaul: EngineremovalRinso PietersmaNo ratings yet

- Chrome Handlebar Switch Cap Kits: GeneralDocument5 pagesChrome Handlebar Switch Cap Kits: GeneralPhillAv1No ratings yet

- Suzuki GSX-R1000 2009-2010Document6 pagesSuzuki GSX-R1000 2009-2010Mr. TNo ratings yet

- MSA5T0205A11495Document5 pagesMSA5T0205A11495anibalbelltNo ratings yet

- Manitou Hyd Pump Repair ManualDocument48 pagesManitou Hyd Pump Repair ManualArdian Makhmud100% (2)

- Uconnectweb InstallationSheetsDocument166 pagesUconnectweb InstallationSheets#1973#No ratings yet

- MSA5T0205A11494Document4 pagesMSA5T0205A11494anibalbelltNo ratings yet

- Strida SX Etc ZadelhouderDocument43 pagesStrida SX Etc Zadelhouder5j2pw94027228No ratings yet

- Steering Column SwitchesDocument3 pagesSteering Column SwitchesToua YajNo ratings yet

- Aiwa Tv-c1400 Chassis Cp-005aDocument27 pagesAiwa Tv-c1400 Chassis Cp-005apetricabogdanNo ratings yet

- 76 - Exterior Interior TrimDocument36 pages76 - Exterior Interior Trimsaravanakumar.rkNo ratings yet

- Operating & Maintenance InstructionsDocument7 pagesOperating & Maintenance InstructionsVAN VIET NGONo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- Lesson7 - ActivityDocument3 pagesLesson7 - ActivityKaye Ann BulaoNo ratings yet

- Butuan Local Shelter Plan 2014-2023Document158 pagesButuan Local Shelter Plan 2014-2023Jerika Marie ArceoNo ratings yet

- English7 Q4 W6 Mod6Document16 pagesEnglish7 Q4 W6 Mod6Glaiza MentoyNo ratings yet

- Balance ExerciseDocument16 pagesBalance ExerciseArkiearkie PaglumotanNo ratings yet

- Empowerment Technologies: Quarter 2 - Module 11: Research Content For Social Advocacy in Developing An ICT ProjectDocument20 pagesEmpowerment Technologies: Quarter 2 - Module 11: Research Content For Social Advocacy in Developing An ICT ProjectArlene Flor100% (1)

- Anti-Red Tape Act of 2007 - RA 9485Document5 pagesAnti-Red Tape Act of 2007 - RA 9485Rudy OrteaNo ratings yet

- WC200118 MSDSDocument4 pagesWC200118 MSDSNhox XuNo ratings yet

- Understaning Model RiskDocument16 pagesUnderstaning Model RiskPeter LiNo ratings yet

- West Haven High SchoolDocument1 pageWest Haven High SchoolEditor, Hartford CourantNo ratings yet

- I. Weekly Objectives: School Grade Level Teacher Learning Area Teaching Dates and Time QuarterDocument2 pagesI. Weekly Objectives: School Grade Level Teacher Learning Area Teaching Dates and Time QuarterMarfe Montelibano100% (1)

- Capital PunishmentDocument4 pagesCapital PunishmentEric ZuluNo ratings yet

- Ovate Pontic Esthetic Enhancement of The Anterior RestorationsDocument3 pagesOvate Pontic Esthetic Enhancement of The Anterior RestorationsmadalinaNo ratings yet

- Lingkod - Pursuing Discipline-Based and Interest-Based ApproachesDocument31 pagesLingkod - Pursuing Discipline-Based and Interest-Based ApproachesJames Geronimo LopezNo ratings yet

- ASCE 52 - Guide For Design of Steel Transmission TowersDocument73 pagesASCE 52 - Guide For Design of Steel Transmission TowersFelipe DornellesNo ratings yet

- Case Study Presentation Using The Nutrition Care ProcessDocument6 pagesCase Study Presentation Using The Nutrition Care ProcessSethNo ratings yet

- Early Childhood Lesson Plan 1st Grade - Spiders New HomeDocument6 pagesEarly Childhood Lesson Plan 1st Grade - Spiders New Homeapi-430433942100% (1)

- Container Can Be Defined As Isolation With Some Resource LimitsDocument8 pagesContainer Can Be Defined As Isolation With Some Resource LimitssrinivasthNo ratings yet

- Greene Et Al 2016Document76 pagesGreene Et Al 2016Valentina Muñoz OyarzúnNo ratings yet

- Samsara and NirvanaDocument5 pagesSamsara and NirvanaMarya Fanta C LupuNo ratings yet

- Jesus Christ The Son of Mary: and His Most Blessed MotherDocument36 pagesJesus Christ The Son of Mary: and His Most Blessed MotherTyba314No ratings yet

- AoW 09 - The Library of Last Resort - 5eDocument6 pagesAoW 09 - The Library of Last Resort - 5eRoberto PadronNo ratings yet

- Deblurring Images, Matrices, Spectra, and Filtering (Fundamentals of Algorithms)Document145 pagesDeblurring Images, Matrices, Spectra, and Filtering (Fundamentals of Algorithms)Zengben HaoNo ratings yet

- Show FileDocument4 pagesShow Filesawan raiNo ratings yet

- TCC PDIC QuizzerDocument4 pagesTCC PDIC QuizzerVandixNo ratings yet

- Medical ManualDocument144 pagesMedical ManualDevinder Singh50% (2)

- Protection of Himalayan Biodiversity - n4Document70 pagesProtection of Himalayan Biodiversity - n4sohag the prime caressNo ratings yet

- Design Secure & Compliant Roles For Oracle ERP & HCM CloudDocument33 pagesDesign Secure & Compliant Roles For Oracle ERP & HCM CloudRajvirNo ratings yet

- Depresión 5Document24 pagesDepresión 5Luz Maria RojasNo ratings yet