100%(1)100% found this document useful (1 vote)

47 viewsChecklist For Scaffolding 2

Checklist For Scaffolding 2

Uploaded by

Aejaz MujawarThe document is a checklist for inspecting scaffolding with 36 points to check for scaffold safety including ensuring scaffold platforms can safely support work, using scaffold tag systems, providing fall protection such as guardrails and toe boards, properly securing materials, inspecting scaffold components, and restricting the height and movement of mobile scaffolds.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Checklist For Scaffolding 2

Checklist For Scaffolding 2

Uploaded by

Aejaz Mujawar100%(1)100% found this document useful (1 vote)

47 views2 pagesThe document is a checklist for inspecting scaffolding with 36 points to check for scaffold safety including ensuring scaffold platforms can safely support work, using scaffold tag systems, providing fall protection such as guardrails and toe boards, properly securing materials, inspecting scaffold components, and restricting the height and movement of mobile scaffolds.

Original Title

CHECKLIST FOR SCAFFOLDING 2

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The document is a checklist for inspecting scaffolding with 36 points to check for scaffold safety including ensuring scaffold platforms can safely support work, using scaffold tag systems, providing fall protection such as guardrails and toe boards, properly securing materials, inspecting scaffold components, and restricting the height and movement of mobile scaffolds.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

100%(1)100% found this document useful (1 vote)

47 views2 pagesChecklist For Scaffolding 2

Checklist For Scaffolding 2

Uploaded by

Aejaz MujawarThe document is a checklist for inspecting scaffolding with 36 points to check for scaffold safety including ensuring scaffold platforms can safely support work, using scaffold tag systems, providing fall protection such as guardrails and toe boards, properly securing materials, inspecting scaffold components, and restricting the height and movement of mobile scaffolds.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

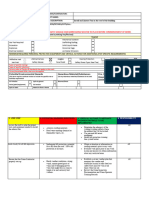

CHECKLIST FOR SCAFFOLDING

Name of Site : Inspected By :

Date : Sub-Contractors Name :

Sl. No. Points Observation Measures

1. Is site having a practice of providing suitable

and sufficient scaffolds so that the work could

safely be done at a height

2. Is site engaging suitable / properly trained /

experienced workmen for constructing /

dismantling / shifting scaffolding works

3. Are scaffold platforms designed/constructed

with a safety factor of minimum four

4. Is Scaffold Tag System is in use

5. Is there a safe means of access to the

working platform

6. Are scaffold structures having a solid base

avoiding pavements & manhole covers etc

7. Is the scaffolding structure free from

excavation pit/proper distance is maintained

8. Is verticality of the structure properly

maintained

9. Are ties for scaffold structure properly

maintained (vertical as well as horizontal

position)

10. Is there a provision of toe boards/guardrails

and are they secured

11. Whether planks used for working platforms

are wooden/metallic

12. If wooden plank, whether thickness is

maintained as per standard or not, viz.

a. For 1.5 M span - 1.5” thick

b. For 2.6 M span - 2.0” thick

13. Is there a system of inspecting the scaffolds

by a competent person at least once a week

and also after every prolonged interruption in

the work

14. Is there a system of inspecting materials of

scaffolds on each occasion before erection?

15. Is there a system of inspecting scaffolds at

every spell of bad weather/heavy wind

condition

16. Is overhanging of the working platform

restricted to less than 50mm/four times the

thickness of the board

17. Is awareness of workmen on the importance

of load distribution on a given working

platform palpable

18. Is there a check for the condition and correct

usage of fittings for scaffolds

19. Is the width of a working platform properly

maintained according to usage, viz.

a. Minimum 600mm for footing only and not

for deposit of materials

b. Minimum 800mm for footing and deposit

of materials

c. Minimum 1050mm when used for heavier

loads or to support higher platforms

20. Are all the materials stored on the platforms

properly secured or not?

21. Whether planks are tied using proper binding

wires

22. Are openings in working platform kept safely

covered/fenced

23. Do wheels used for scaffold tower of

appropriate SWL with locking arrangements

24. Are mobile scaffolds used on a firm and level

surface

25. Does the height of mobile scaffolds exceed

four times the smaller base dimension

26. Are all materials stacked on the platform

properly secured while in motion

27. Is the safety rule:

Not to ride on a scaffold while in motion,

violated

28. Is there a system of checking for obstructions

before the tower is moved

29. Is there an access tower exceeding 9.6mm

free-standing without support

30. Are suitable/correct lifting tackles (wire-

ropes/chains/shackles) selected for

suspension & used

31. Are all the suspension gears correctly spaced

and connected

32. Is there a system of using manila rope/coir

rope for suspension at any place where such

rope would be liable to damage by

heat/flames/sharp edges etc.

33. Are all precautionary measures taken to

prevent contact between arc welding

apparatus and suspension ropes

34. Is there a provision of guardrails, toe boards

35. Is hanging platform secured

36. Is there a provision of anchoring safety belts -

lanyards to be tied to guy ropes

You might also like

- Small Practice and The Sole PractitionerDocument241 pagesSmall Practice and The Sole PractitionerJeronimo Bedel100% (8)

- SSR 2012 PDFDocument550 pagesSSR 2012 PDFArshad Hussain100% (2)

- Jsa Setting Crane and Lifting GeneratorDocument2 pagesJsa Setting Crane and Lifting GeneratorSeppy Fajriani100% (1)

- PDM Handbook For ROADDocument93 pagesPDM Handbook For ROADabegail fuentesNo ratings yet

- Daily Scaffold Safety Checklist - BLANK PDFDocument1 pageDaily Scaffold Safety Checklist - BLANK PDFSajid MahmoodNo ratings yet

- SOP Material InstructionsDocument1 pageSOP Material Instructionspankajbhatt376100% (1)

- Proposed Delivery For PAU/AHU Method Statement SEC/MS/3-25Document4 pagesProposed Delivery For PAU/AHU Method Statement SEC/MS/3-25Zin Ko NaingNo ratings yet

- Housekeeping, Management & Holding Construction MaterialsDocument7 pagesHousekeeping, Management & Holding Construction MaterialsMohamed AbdelfatahNo ratings yet

- HSEP 13 8 A1 Fall Prevention System Requirement Rev 5Document5 pagesHSEP 13 8 A1 Fall Prevention System Requirement Rev 5mojgfdNo ratings yet

- Winner Double Width Aluminium Scaffolding Assembly ProcedureDocument17 pagesWinner Double Width Aluminium Scaffolding Assembly ProceduresrcNo ratings yet

- SWP - Lifting ContainersDocument2 pagesSWP - Lifting Containersmapulengmofokeng01No ratings yet

- Job Safety Analysis For Refurbishment of Porta CabinsDocument5 pagesJob Safety Analysis For Refurbishment of Porta CabinsShaheer Ahmed50% (2)

- BSA Alert 13.69 Fall of Materials From ScaffoldingDocument1 pageBSA Alert 13.69 Fall of Materials From ScaffoldingsubhanmusadiqNo ratings yet

- Scaffolding SafetyDocument4 pagesScaffolding Safetyrguy3223No ratings yet

- ESAB 6010: Safety Data SheetDocument14 pagesESAB 6010: Safety Data SheetHusam AhmedNo ratings yet

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaNo ratings yet

- Frames Erection ProcDocument18 pagesFrames Erection Procrobby_hipNo ratings yet

- Monthly Ispection CheklistDocument2 pagesMonthly Ispection CheklistYashpal Singh100% (1)

- Shuttring & Deshuttring Work JsaDocument4 pagesShuttring & Deshuttring Work JsaAKBAR ALINo ratings yet

- MJ164 RIP SAW Operation ManualDocument36 pagesMJ164 RIP SAW Operation ManualEduardo Lopez CastilloNo ratings yet

- 4 Sample Work at Height PermitDocument2 pages4 Sample Work at Height Permitlam dinhNo ratings yet

- Safety Policy 2007-10Document2 pagesSafety Policy 2007-10Bob SilvaNo ratings yet

- Chisels Risk AssessmentDocument1 pageChisels Risk AssessmentTawfik Mohamed Abu Zaid100% (1)

- Safe Job Procedure For Erecting Tube and Clamp and All Around Scaffolding June 2014Document7 pagesSafe Job Procedure For Erecting Tube and Clamp and All Around Scaffolding June 2014Abel DemNo ratings yet

- Assignment JHADocument7 pagesAssignment JHACarlos DauzNo ratings yet

- Application To Perform Work - Grass CuttingDocument2 pagesApplication To Perform Work - Grass CuttingRauf Huseynov0% (1)

- SDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Scaffold CampaignDocument9 pagesScaffold CampaignAdel SukerNo ratings yet

- Pneumatic Tool Maintenance ChecklistDocument1 pagePneumatic Tool Maintenance ChecklistAaditya SankaleNo ratings yet

- Method Statement - h4Document10 pagesMethod Statement - h4Shoaib SyedNo ratings yet

- Safety in Engineering IndustryDocument8 pagesSafety in Engineering Industryzombie100% (1)

- DM Code of Construction Safety 195-292 PDFDocument98 pagesDM Code of Construction Safety 195-292 PDFDANo ratings yet

- BarricadeDocument13 pagesBarricadeMonica Isabel Borlagdatan PerezNo ratings yet

- 27j Scaffold PermitDocument1 page27j Scaffold PermitMohammed MinhajNo ratings yet

- Jsa For PaintingDocument3 pagesJsa For PaintingNabi AkramNo ratings yet

- PPE Checklist: PT Thermax International IndonesiaDocument1 pagePPE Checklist: PT Thermax International Indonesiaadam rizkiNo ratings yet

- Cantilever Loading Platform DismantlingDocument30 pagesCantilever Loading Platform DismantlingLuffy D KaizokuNo ratings yet

- Company Name: Sacffold Location Completed By: Date: TimeDocument1 pageCompany Name: Sacffold Location Completed By: Date: Timesadashiv puneNo ratings yet

- Step 2 Who Might Be Harmed and How?: What Are You Already Doing? Step 3: What Further Action Is Necessary?Document6 pagesStep 2 Who Might Be Harmed and How?: What Are You Already Doing? Step 3: What Further Action Is Necessary?Xozan100% (1)

- Hazard and Risk RegistersDocument18 pagesHazard and Risk RegistersWole OyefisayoNo ratings yet

- JSP 42 Use of Power ToolsDocument6 pagesJSP 42 Use of Power ToolsMuhammad AtifNo ratings yet

- Tata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data SheetDocument6 pagesTata Bluescope Steel Limited, Jamshedpur.: Liquefied Petroleum Gas Material Safety Data Sheetsujit5584No ratings yet

- Safety Toolbox Talk IdeasDocument2 pagesSafety Toolbox Talk IdeasWendell Ryan OninezaNo ratings yet

- Crane SafeDocument3 pagesCrane SafetalabiraNo ratings yet

- E 28 GP 001 Working at Heights - Scaffolding StandardsDocument20 pagesE 28 GP 001 Working at Heights - Scaffolding StandardsMounir Boutaghane100% (1)

- Guarding Floor and Wall Openings and Holes: OSHA Standard 1910.23Document8 pagesGuarding Floor and Wall Openings and Holes: OSHA Standard 1910.23Osama MaherNo ratings yet

- EHS Annexure C-1 ExcavationDocument5 pagesEHS Annexure C-1 ExcavationDoita Dutta Choudhury100% (1)

- Rebar Impalement Hazards TBT FINAL July 2017Document2 pagesRebar Impalement Hazards TBT FINAL July 2017amizan100% (1)

- Use of Full Body Harness With LanyardDocument3 pagesUse of Full Body Harness With LanyardSn Ahsan100% (1)

- TDS - Mastertop 1740Document3 pagesTDS - Mastertop 1740Venkata RaoNo ratings yet

- Rainy Weather Toolbox TalkDocument3 pagesRainy Weather Toolbox Talkm.rehanhseNo ratings yet

- Site Safety ChecklistDocument5 pagesSite Safety ChecklistFAISAL RAZANo ratings yet

- Final SOP For Hydro TestDocument2 pagesFinal SOP For Hydro TestBhaskar KolichelimaNo ratings yet

- Job Safety Analysis: Gas Powered ChainsawDocument4 pagesJob Safety Analysis: Gas Powered ChainsawJuztin NovalNo ratings yet

- RH SILO LIFTING PLAN Rv.1Document4 pagesRH SILO LIFTING PLAN Rv.1Rod Kenneth LubongNo ratings yet

- Fall Protection Program: Reviewed: May 2011Document20 pagesFall Protection Program: Reviewed: May 2011Marvin ReggieNo ratings yet

- Fire Safety SeminarDocument57 pagesFire Safety SeminarMarlon BernardoNo ratings yet

- HousekeepingDocument3 pagesHousekeepingomarfortnite2011No ratings yet

- TSTI FormDocument2 pagesTSTI FormJinu ThomasNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- IM-09-A4 Scaffolding ChecklistDocument2 pagesIM-09-A4 Scaffolding ChecklistVishnu SNo ratings yet

- Checklist For Scaffolding: Project: SL# Description Observation Yes/No/ NA Remarks & RecommendationsDocument4 pagesChecklist For Scaffolding: Project: SL# Description Observation Yes/No/ NA Remarks & RecommendationsDeshbandhu Aman PandeyNo ratings yet

- Checklist For Scaffolding: Construction of Srr2-Construction Management ServicesDocument3 pagesChecklist For Scaffolding: Construction of Srr2-Construction Management ServicesChayank TiwariNo ratings yet

- Fire hydrantDocument28 pagesFire hydrantAejaz MujawarNo ratings yet

- EHS Requirements for Demolition ContractorDocument15 pagesEHS Requirements for Demolition ContractorAejaz MujawarNo ratings yet

- New XLSX WorksheetDocument2 pagesNew XLSX WorksheetAejaz MujawarNo ratings yet

- Safe Work ProcedureDocument24 pagesSafe Work ProcedureAejaz MujawarNo ratings yet

- 50 HSE TerminologiesDocument52 pages50 HSE TerminologiesAejaz MujawarNo ratings yet

- 0940 Sms Template Safety AlertDocument2 pages0940 Sms Template Safety AlertAejaz MujawarNo ratings yet

- Notes For Advance Diploma in Industrial Safety: Sub: Environmental Management (23112)Document122 pagesNotes For Advance Diploma in Industrial Safety: Sub: Environmental Management (23112)Aejaz MujawarNo ratings yet

- Iso 45001 - 2018 ChecklistDocument17 pagesIso 45001 - 2018 ChecklistAejaz MujawarNo ratings yet

- Work Permit FormatDocument12 pagesWork Permit FormatAejaz Mujawar0% (1)

- Mrs. Nagma Aejaz Mujawar Kadamwak Wasti, Loni Kalbhor, Taluka Haveli, Loni Kalbhor, Near Pyasa Hotel, Haveli, Pune, Maharashtra, 41 2201 7620063293Document33 pagesMrs. Nagma Aejaz Mujawar Kadamwak Wasti, Loni Kalbhor, Taluka Haveli, Loni Kalbhor, Near Pyasa Hotel, Haveli, Pune, Maharashtra, 41 2201 7620063293Aejaz MujawarNo ratings yet

- Hse Risk AssessmentDocument6 pagesHse Risk AssessmentAejaz MujawarNo ratings yet

- 1ig2 Forms Electronic SubmissionDocument20 pages1ig2 Forms Electronic SubmissionAejaz MujawarNo ratings yet

- Ans Sheet Chemical 23111Document96 pagesAns Sheet Chemical 23111Aejaz MujawarNo ratings yet

- Electrical Safety ProtocolDocument27 pagesElectrical Safety ProtocolAejaz MujawarNo ratings yet

- Building and Other Construction Workers Rules 2007Document144 pagesBuilding and Other Construction Workers Rules 2007Aejaz MujawarNo ratings yet

- Ans Sheet IHOC 23115Document85 pagesAns Sheet IHOC 23115Aejaz MujawarNo ratings yet

- AAT GulfJobPaper 2 OctDocument3 pagesAAT GulfJobPaper 2 OctAejaz MujawarNo ratings yet

- Building and Other Construction Workers Rules 2007Document338 pagesBuilding and Other Construction Workers Rules 2007Aejaz MujawarNo ratings yet

- TRIAA Elisiya Safety Observation 05-05-2022Document7 pagesTRIAA Elisiya Safety Observation 05-05-2022Aejaz Mujawar33% (3)

- Online RTE Reservation 2022-2023: Application DetailsDocument3 pagesOnline RTE Reservation 2022-2023: Application DetailsAejaz MujawarNo ratings yet

- Case StudyDocument65 pagesCase StudyAhmad Zuwairisyazwan100% (1)

- Mechanical Technical Office Engineer-1Document2 pagesMechanical Technical Office Engineer-1Ahmed ElswefyNo ratings yet

- Kone-The Monospace Launch in GermanyDocument11 pagesKone-The Monospace Launch in GermanyAakanksha Gulabdhar MishraNo ratings yet

- Job Description Project Engineer - Rocvolt PositionDocument2 pagesJob Description Project Engineer - Rocvolt Positionajaya PAINo ratings yet

- Cal/Osha Pocket Guide For The Construction IndustryDocument91 pagesCal/Osha Pocket Guide For The Construction IndustryBojie AbogadieNo ratings yet

- BT 2011 08Document32 pagesBT 2011 08Zain IhsanNo ratings yet

- MasterFlow 932 AN - MBSDocument144 pagesMasterFlow 932 AN - MBSaelgerm97No ratings yet

- Civil Engineering and Other ProfessionDocument21 pagesCivil Engineering and Other ProfessionKyla Dela CruzNo ratings yet

- FO-M2 Parts List (Complete)Document776 pagesFO-M2 Parts List (Complete)trung vothaiNo ratings yet

- FT0019Document2 pagesFT0019rmimo1993No ratings yet

- Sika AG FS Dec-18Document165 pagesSika AG FS Dec-18PratikNo ratings yet

- Aswar Al Andalus Profile 2024Document66 pagesAswar Al Andalus Profile 2024md bahaNo ratings yet

- DPWH Cost EstimationDocument63 pagesDPWH Cost EstimationKm TrinidadNo ratings yet

- Precast BrochureDocument12 pagesPrecast BrochureNicholasOmodingNo ratings yet

- UL CertComplianceCP25WB+Document4 pagesUL CertComplianceCP25WB+Bariul MusabbirNo ratings yet

- Build Beyond Imagination: Eik Engineering SDN BHDDocument20 pagesBuild Beyond Imagination: Eik Engineering SDN BHDdanangNo ratings yet

- Certificate For Completion of Building Construction.Document2 pagesCertificate For Completion of Building Construction.Arka Architects & AssociatesNo ratings yet

- SPektek Material Bugs CafeDocument26 pagesSPektek Material Bugs CafenurulerwinNo ratings yet

- Procurement Guide: Selecting A Contractor/Project Developer: 1. OverviewDocument7 pagesProcurement Guide: Selecting A Contractor/Project Developer: 1. OverviewCarlos LinaresNo ratings yet

- Thunderbolt Model Comparison EnglishDocument1 pageThunderbolt Model Comparison EnglishJOHAN MANUEL CALLOMAMANI BUENDIANo ratings yet

- Estimating Tracking 2017Document147 pagesEstimating Tracking 2017munnaaftab02No ratings yet

- Construction Methods and EquipmentDocument9 pagesConstruction Methods and EquipmentAngelica GicomNo ratings yet

- Application For Building PermitDocument5 pagesApplication For Building PermitmanuNo ratings yet

- ITC Construction Management Plan - Building D1Document38 pagesITC Construction Management Plan - Building D1richu rasheedNo ratings yet

- Project Fact SheetDocument62 pagesProject Fact SheetkiranNo ratings yet

- ALQ ALABRAJ PresentationCIVIL - Pipeline, Piping, Storage Tank PDFDocument95 pagesALQ ALABRAJ PresentationCIVIL - Pipeline, Piping, Storage Tank PDFSaleh Salman100% (1)

- GETO Aluminium Formwork SystemDocument30 pagesGETO Aluminium Formwork SystemGary TruitaNo ratings yet