Technical Data Sheet: Random Copolymer Esenttia 07R87

Technical Data Sheet: Random Copolymer Esenttia 07R87

Uploaded by

Roberto De Mesa PCopyright:

Available Formats

Technical Data Sheet: Random Copolymer Esenttia 07R87

Technical Data Sheet: Random Copolymer Esenttia 07R87

Uploaded by

Roberto De Mesa POriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Technical Data Sheet: Random Copolymer Esenttia 07R87

Technical Data Sheet: Random Copolymer Esenttia 07R87

Uploaded by

Roberto De Mesa PCopyright:

Available Formats

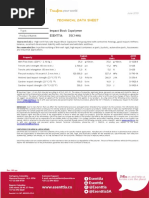

December, 2016

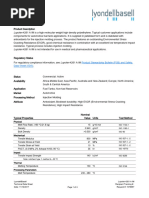

TECHNICAL DATA SHEET

Type: Random Copolymer

Product Name: ESENTTIA 07R87

Characteristics: Random Copolymer Polypropylene with controlled rheology, high cleanness and lot to lot consistency, very

good optical properties and gauge control, without slip and antiblock additives, ideal for special films formulations.

Recommended for: BOPP, Cast and TWQ Films heat seal co-extruded layer, conventional film properties modifier, injection

molding general purpose applications.

English SI ASTM

Property

Units Units Test

Melt Flow Index (230°C - 2.16 Kg.) 7.0 g/10min. 7.0 g/10min. D-1238 B

Tensile yield strength (50 mm/min.) 2950.0 psi 20.3 MPa D-638

Tensile yield elongation (50 mm/min.) 15.0 % 15.0 % D-638

Flexural modulus 1% secant (1.3 mm/min.) 87000.0 psi 599.8 MPa D-790-1A

Notched Izod Impact strength (23 °C/73 °F) 1.5 ft-lb/in 80.1 J/M D-256-A

Gardner impact strength (23 °C/73 °F) 275.0 lb-in 31.1 J D-5420 A

@ Type I specimen, 3.2 mm thick injected according with ASTM D 4101 09 method. Values shown are averages and should be taken as a guide and not to be

interpreted as product specifications. Only the properties and values mentioned on the Certificate of Analysis are considered as guarantee of the product.

These values may shift as additional data are accumulated; ESENTTIA shall not be under a duty to notify you any changes to the specifications, therefore we

advise the receiver to ask for a new declaration periodically.

IMPORTANT: The information contained herein corresponds to typical values and should be considered as a guide in the behavior and applicability of our resins

and it is based on the data available to us and is believed to be correct as the date of publication, however we make no warranty, expressed or implied,

regarding the accuracy of these data or the results to be obtained from user thereof or for any printing errors. Only the properties and values mentioned on the

Certificate of Quality are considered as guarantee of the product. In view of the many factors that may affect processing and application, these data do not

relieve processors from the responsibility of carrying out their own tests and experiments; neither do they imply any legally binding assurance of certain

properties or of suitability for a specific purpose. It is the responsibility of those to whom we supply our products to ensure that any proprietary rights and

existing laws are observed. ESENTTIA declines all responsibility that may arise directly or indirectly, from the use of such information nor do we offer any

warranty or immunity against patent infringement.

NOTICE REGARDING MEDICAL APPLICATIONS RESTRICTIONS: ESENTTIA do not recommend any of its products or sample products for use in (A) in any

commercial or development applications which is intended for contact with human internal body fluids or body tissues, regardless of the length of time

involved. (B) In any cardiac prosthetic device applications, regardless of the length of time involved, including without limitation, pacemaker leads and devices,

artificial hearts, heart valves, intra-aortic balloons and control systems and ventricular bypass assisted devices. (C) As a critical component in any medical

device that supports of sustains human life: and (D) specifically by pregnant women or in any applications designed specifically to promote or interfere with

human reproductions.

ESENTTIA does not endorse or claim suitability of their products for specific medical applications. It is the responsibility of the medical device or

pharmaceutical manufacturer to determine that the ESENTTIA’s product is safe, lawful, and technically suitable for the intended use. ESENTTIA MAKES NO

WARRANTIES, EXPRESS OR IMPLIED, CONCERNING THE SUITABILITY OF ANY ESENTTIA’s PRODUCT FOR USE IN MEDICAL APPLICATIONS.

Recommendations before using ESENTTIA’s products: We suggest when using ESENTTIA’s products for the first time, making test in the appropriate industrial

quantities to examine the possibilities of using our products in all stages of your processing. This declaration applies to the material as it leaves its production

facilities and does not cover any additive, pigment, etc., subsequently included by the converter. It is responsibility of the customer to obtain all necessary

information relating to the third party materials and ensure that ESENTTIA’s products when used together with these materials are suitable for the customer’s

particular purpose. If your final application will be exposed to outdoor, you must add the appropriate additives to ensure the performance of the Product. No

liability can be accepted in respect of the use of ESENTTIA’s products in conjunction with others materials.

NOTE: Food contact articles or articles which will be subjected to any kind of treatment such as sterilization and ozonation, a FDA certificate should have to

be requested www.esenttia.co or contacting our Customer Service. ESENTTIA shall not be under a duty to notify you any changes to the regulations.

STORAGE: Storage time of natural materials longer than 6 months may have a negative influence on the quality of the final product (for example brightness). It

is recommended to convert all materials latest within 6 months of production.

The product should be stored in dry conditions at temperatures below 40 °C and protected from UV-light. Improper storage can initiate degradations, which

results in odor generation and color changes and can have negative effects on the physical properties of the product. If polymer is stored in conditions of high

humidity and fluctuating temperatures, then atmospheric moisture can condense inside the packing. If it happened, it is recommended the pellets to be dried

before use. During storage polypropylene should not be exposed to UV radiation. Producer does not take responsibility for any damages caused by adverse

storage.

Unless otherwise agreed in writing, the exclusive remedy for all claims is replacement of the product or to reimburse of the purchase price at ESENTTIA’s

option, and in no event shall ESENTTIA be liable for special, consequential, incidental, punitive, or exemplary damages.

ESENTTIA’s products do not have additives with metals or other substances on purpose of oxi-degradation. These additives and the decomposition and

disintegration of polypropylene caused by oxi-degradation phenomenon can cause environmental pollution, decrease the package performance and increase

migration of package constituent to food, compromising resin approval regarding the requirements of Legislations, Recommendations or Communications

related. The use of these additives with ESENTTIA products implies immediate loss of performance guarantee described in this technical data sheet.

Rev.: ING 160 POLIPROPILENO DEL CARIBE S. A. • Cra 10a. No. 28‐49 Piso 27 Bogotá, D,C ‐ Colombia

http: //www.esenttia.co • PBX. (571) 596 0220 • Fax. (571)560 1593 • Nit. 800.059.470‐5

Certificados ISO 9001:2000 y 14001.Homopolímeros y Copolímeros Random e Impacto. ICONTEC CO‐028‐1/AA017‐1

You might also like

- 6640 SIP-SPLASH 640 June-12Document2 pages6640 SIP-SPLASH 640 June-12ShaikhRizwanNo ratings yet

- Petrochemicals FlowchartDocument1 pagePetrochemicals FlowchartKartik Desai50% (4)

- PP 05C05 ESENTTIA - TDSDocument1 pagePP 05C05 ESENTTIA - TDStonwellington84No ratings yet

- PP 08H85DB-BC ESENTTIA - TDSDocument1 pagePP 08H85DB-BC ESENTTIA - TDStonwellington84No ratings yet

- Technical Data Sheet: Impact Block Copolymer Esenttia 35C14NADocument1 pageTechnical Data Sheet: Impact Block Copolymer Esenttia 35C14NAMary HudsonNo ratings yet

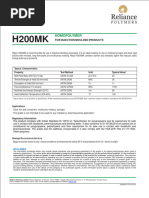

- Re H200MKDocument1 pageRe H200MKnisargpatel766No ratings yet

- Filmtec SW30-8040Document2 pagesFilmtec SW30-8040PT Deltapuro IndonesiaNo ratings yet

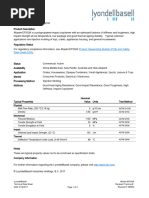

- LyondellBasell Moplen EP332KDocument3 pagesLyondellBasell Moplen EP332Klcesaksham23No ratings yet

- Arcol Polyol 1003 - en - 05557291 13603857 13603859Document2 pagesArcol Polyol 1003 - en - 05557291 13603857 13603859fernandoincesaNo ratings yet

- Acothane Twin Pack: Product DescriptionDocument3 pagesAcothane Twin Pack: Product DescriptionpazhanivelmuruganNo ratings yet

- Hyperseal - Expert 60Fc: One Component Fast Curing, High Hardness, Chemical Resistant Polyurethane SealantDocument2 pagesHyperseal - Expert 60Fc: One Component Fast Curing, High Hardness, Chemical Resistant Polyurethane Sealantsasikumar durairajanNo ratings yet

- Moplen HP648NDocument1 pageMoplen HP648Nphanplastic299No ratings yet

- ANSTAT 400565-K (1)Document1 pageANSTAT 400565-K (1)tuantdtNo ratings yet

- Ra R120MKDocument1 pageRa R120MKyansyafNo ratings yet

- Bản sao của BETASEAL™ 1858-1-gb TDSDocument3 pagesBản sao của BETASEAL™ 1858-1-gb TDSManh Nguyen TheNo ratings yet

- 3SU15000AA100AA0 Datasheet enDocument3 pages3SU15000AA100AA0 Datasheet enJorge Gonzalez GarciaNo ratings yet

- 3M™ Heavy Duty 20 Spray Adhesive - 20241019Document3 pages3M™ Heavy Duty 20 Spray Adhesive - 20241019Arunkumar SubramaniyanNo ratings yet

- JV060U Ing Rev.10Document2 pagesJV060U Ing Rev.10nicolas yoris marcoglieseNo ratings yet

- ALTECH PE-HD A 2010/550 GF10: Technical Data SheetDocument2 pagesALTECH PE-HD A 2010/550 GF10: Technical Data SheetPhung LucNo ratings yet

- TDS F18030Document2 pagesTDS F18030ShashankShethNo ratings yet

- Technical Data Sheet Moplen EP548PDocument3 pagesTechnical Data Sheet Moplen EP548Pantonio.sevelarNo ratings yet

- Purell ACP 6031 D Technical Data SheetDocument3 pagesPurell ACP 6031 D Technical Data SheetPiyush A JoshiNo ratings yet

- Lupolen 4261 BasellDocument4 pagesLupolen 4261 Basellmaria.goncalvesNo ratings yet

- Lldpe Ga564189Document3 pagesLldpe Ga564189xy2zjgNo ratings yet

- Ms 35Document7 pagesMs 35Omar AkramNo ratings yet

- Marlex HGX-030Document1 pageMarlex HGX-030jahangiralam201676No ratings yet

- Dow Kt10000ueDocument2 pagesDow Kt10000ueChu ChuNo ratings yet

- LDPE - Technical Data Sheet - ASTM - Purell PE 3020DDocument2 pagesLDPE - Technical Data Sheet - ASTM - Purell PE 3020Dmohamed.gamalNo ratings yet

- Filmtec™ Membranes: Product Data SheetDocument3 pagesFilmtec™ Membranes: Product Data Sheetcello loNo ratings yet

- 1001321-K AMSTAT 321Document1 page1001321-K AMSTAT 321tuantdtNo ratings yet

- Astm Lupoy ns5000c - EngDocument2 pagesAstm Lupoy ns5000c - EngJosh DineshNo ratings yet

- 3SU15000AA100AA0 Datasheet enDocument3 pages3SU15000AA100AA0 Datasheet ensuadNo ratings yet

- CM-18_30FDocument2 pagesCM-18_30FSammy CostaNo ratings yet

- Makrofol LM297 H M 040007 - en - 80425619 05614625 09201143Document3 pagesMakrofol LM297 H M 040007 - en - 80425619 05614625 09201143Bob ZhangNo ratings yet

- Dowlex 2006GDocument2 pagesDowlex 2006GVõ HạnhNo ratings yet

- Filmtec™ Fiberglassed Elements For Light Industrial Systems: Product Data SheetDocument4 pagesFilmtec™ Fiberglassed Elements For Light Industrial Systems: Product Data SheetfasihulNo ratings yet

- TapTec TT 3012 600 PDS 45 D03596 enDocument2 pagesTapTec TT 3012 600 PDS 45 D03596 enLam PhiNo ratings yet

- UPP_TDS_HP650P_EnglishDocument1 pageUPP_TDS_HP650P_Englishabdullah110514No ratings yet

- Technical Data Sheet: Powder PropertiesDocument2 pagesTechnical Data Sheet: Powder PropertiesJoshNo ratings yet

- Adsyl 6093Document1 pageAdsyl 6093phanplastic299No ratings yet

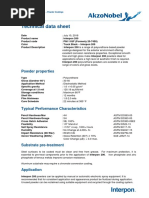

- AkzoNobel - YL003QF - Interpon ACE 2010Document3 pagesAkzoNobel - YL003QF - Interpon ACE 2010vuquangdien.polyme8288No ratings yet

- Dow KT 10000 UeDocument2 pagesDow KT 10000 UeLuca GuadagnoNo ratings yet

- Filmtec BW30-400Document3 pagesFilmtec BW30-400sales.dowtecindonesiaNo ratings yet

- Reliance Ldpe Heavy Duty Non Slip 0 5 Mfi J22fa002eDocument2 pagesReliance Ldpe Heavy Duty Non Slip 0 5 Mfi J22fa002eakshayNo ratings yet

- Proesive R3HT P Powder - March 2020Document2 pagesProesive R3HT P Powder - March 2020Kingsley BaptistaNo ratings yet

- Sigmarine 28Document3 pagesSigmarine 28aangNo ratings yet

- Moplen HP562TDocument1 pageMoplen HP562Tphanplastic299No ratings yet

- Teldene®: Technical Data SheetDocument2 pagesTeldene®: Technical Data SheetRoberto LujánNo ratings yet

- 5083 BANNOH 2000 QD Rev (1409)Document2 pages5083 BANNOH 2000 QD Rev (1409)Trịnh Minh KhoaNo ratings yet

- Data Sheet ECP PP R20TKDocument2 pagesData Sheet ECP PP R20TKĐình Long TrịnhNo ratings yet

- 3SU15500AA100AA0 Datasheet enDocument3 pages3SU15500AA100AA0 Datasheet enYgor BarretoNo ratings yet

- Isoplast Industrial ResinsDocument1 pageIsoplast Industrial ResinsJou0411No ratings yet

- Upp Tds Ep548s EnglishDocument1 pageUpp Tds Ep548s EnglishRula SiuNo ratings yet

- TDS_H030SGDocument2 pagesTDS_H030SGanil singhNo ratings yet

- Softell TKG 300N C12616Document3 pagesSoftell TKG 300N C12616Anass El IdrissiNo ratings yet

- Moplen HP648UDocument1 pageMoplen HP648Uphanplastic299No ratings yet

- pp-1030-rtp-199-x-70815-astmDocument2 pagespp-1030-rtp-199-x-70815-astmQuang Quốc NguyễnNo ratings yet

- Teldene®: Technical Data SheetDocument2 pagesTeldene®: Technical Data SheetLFCV5No ratings yet

- Adsyl 6089Document1 pageAdsyl 6089phanplastic299No ratings yet

- Lacqare Technical DataDocument3 pagesLacqare Technical DataMahmoud MassadNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Certificado de Calidad 1Document1 pageCertificado de Calidad 1Roberto De Mesa PNo ratings yet

- RobustDocument247 pagesRobustRoberto De Mesa PNo ratings yet

- ATTANE™ 4404G: Ultra Low Density Polyethylene ResinDocument3 pagesATTANE™ 4404G: Ultra Low Density Polyethylene ResinRoberto De Mesa PNo ratings yet

- XZ 89495.00Document2 pagesXZ 89495.00Roberto De Mesa PNo ratings yet

- Linear Low Density Polyethylene SLL318: DescriptionDocument1 pageLinear Low Density Polyethylene SLL318: DescriptionRoberto De Mesa PNo ratings yet

- Linear Low Density Polyethylene LL318: DescriptionDocument1 pageLinear Low Density Polyethylene LL318: DescriptionRoberto De Mesa PNo ratings yet

- ELITE™ AT 6111: Enhanced Polyethylene ResinDocument3 pagesELITE™ AT 6111: Enhanced Polyethylene ResinRoberto De Mesa PNo ratings yet

- Certene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneDocument1 pageCertene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneRoberto De Mesa PNo ratings yet

- Exceed™ 2718CB: Metallocene Polyethylene ResinDocument2 pagesExceed™ 2718CB: Metallocene Polyethylene ResinRoberto De Mesa PNo ratings yet

- Tricolene LLB1918ADocument1 pageTricolene LLB1918ARoberto De Mesa PNo ratings yet

- ELITE™ 5230G: Enhanced Polyethylene ResinDocument3 pagesELITE™ 5230G: Enhanced Polyethylene ResinRoberto De Mesa PNo ratings yet

- Pa003en Rev05 PP5231HMDocument1 pagePa003en Rev05 PP5231HMRoberto De Mesa PNo ratings yet

- Paper Recycling ProcessDocument2 pagesPaper Recycling ProcessFranky Varah50% (2)

- 08mod Phytochrome 10 2017Document16 pages08mod Phytochrome 10 2017berkimia (berkimia.com)100% (1)

- Having It Out With MelancholyDocument4 pagesHaving It Out With Melancholychandraippa2No ratings yet

- Protect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationDocument4 pagesProtect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationBurak YILMAZNo ratings yet

- Intermolecular Forces WorksheetDocument3 pagesIntermolecular Forces WorksheetMark John Dumaslan100% (1)

- Textile Fibres Classification PPT 1Document43 pagesTextile Fibres Classification PPT 1tutu1990100% (4)

- Specification For VOCDocument3 pagesSpecification For VOCThilan SenarathneNo ratings yet

- Ultrasound Assisted PTC Catalyzed Saponification of PDFDocument6 pagesUltrasound Assisted PTC Catalyzed Saponification of PDFThamyres BerniNo ratings yet

- Official Soldier GD Paper ASC Centre No 2 South Bangalore 28 March 2021 English Efbd8cc87441729a2b90bee4999f4b43Document9 pagesOfficial Soldier GD Paper ASC Centre No 2 South Bangalore 28 March 2021 English Efbd8cc87441729a2b90bee4999f4b43lambish2016No ratings yet

- Highly Scalable Synthesis of MoS2 Thin Films With Precise ThicknessDocument5 pagesHighly Scalable Synthesis of MoS2 Thin Films With Precise ThicknessDr. Anupam GiriNo ratings yet

- Chap 5 Single-Multiple Stage LeachingDocument29 pagesChap 5 Single-Multiple Stage Leachingqemaismail100% (1)

- Mock Test - 2024 - Test-1A - Paper-1 - Code-ADocument14 pagesMock Test - 2024 - Test-1A - Paper-1 - Code-AsunilsuthartopprNo ratings yet

- API Procedure For Inspection of Chemical Cargo by InspectorsDocument31 pagesAPI Procedure For Inspection of Chemical Cargo by Inspectorsdassi99No ratings yet

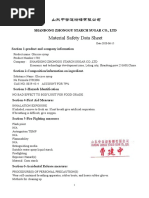

- Glucose Syrup MSDS (Shandong Zhonggu) PDFDocument3 pagesGlucose Syrup MSDS (Shandong Zhonggu) PDFMinjdeDiosNo ratings yet

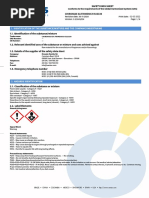

- Ventós: 1. Identification of The Substance/Mixture and The Company/UndertakingDocument6 pagesVentós: 1. Identification of The Substance/Mixture and The Company/UndertakingOctavian CoifanNo ratings yet

- C12200Document3 pagesC12200xgiorg100% (1)

- Trickling FilterDocument10 pagesTrickling FilterAbdullahNo ratings yet

- Recommend An Article: Home ArticlesDocument3 pagesRecommend An Article: Home ArticlesKumar GalipellyNo ratings yet

- Environment - Nitrogen CycleDocument5 pagesEnvironment - Nitrogen CycleMugal AslamNo ratings yet

- Technical Data:: Oasis Epoxy TL 8758Document2 pagesTechnical Data:: Oasis Epoxy TL 8758Maurice DavisNo ratings yet

- Catalog Ky Thuat Ray Dien An Toan PDFDocument20 pagesCatalog Ky Thuat Ray Dien An Toan PDFDuctoanNo ratings yet

- VB Citricacid Technology enDocument6 pagesVB Citricacid Technology enGospodin RajkovićNo ratings yet

- Degradation of Bunker C Fuel Oil by White-Rot Fungi in Sawdust Cultures Suggests Potential Applications in BioremediationDocument15 pagesDegradation of Bunker C Fuel Oil by White-Rot Fungi in Sawdust Cultures Suggests Potential Applications in Bioremediationaxe123anishNo ratings yet

- BedCide - Dairy HygieneDocument2 pagesBedCide - Dairy HygieneYasir6732No ratings yet

- Astm E84Document19 pagesAstm E84Mohd AshrafNo ratings yet

- ETON Filter Design FormulaDocument12 pagesETON Filter Design FormulaArun GuptaNo ratings yet

- GPS PLAS factory Vietnam 2024Document19 pagesGPS PLAS factory Vietnam 2024Ryan NguyenNo ratings yet

- Proceeding: The 3 International Seminar On Chemistry 2014Document8 pagesProceeding: The 3 International Seminar On Chemistry 2014Adhitya PT. SIGNo ratings yet