Solenoid Valve ST-SA-series: 2/2-WAY Semi-Direct Operated Normally Closed

Solenoid Valve ST-SA-series: 2/2-WAY Semi-Direct Operated Normally Closed

Uploaded by

Vicente Moll ZamoranoCopyright:

Available Formats

Solenoid Valve ST-SA-series: 2/2-WAY Semi-Direct Operated Normally Closed

Solenoid Valve ST-SA-series: 2/2-WAY Semi-Direct Operated Normally Closed

Uploaded by

Vicente Moll ZamoranoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Solenoid Valve ST-SA-series: 2/2-WAY Semi-Direct Operated Normally Closed

Solenoid Valve ST-SA-series: 2/2-WAY Semi-Direct Operated Normally Closed

Uploaded by

Vicente Moll ZamoranoCopyright:

Available Formats

ST-SA SERIES

JP FLUID CONTROL

SOLENOID VALVES

2/2-WAY

SEMI-DIRECT OPERATED

NORMALLY CLOSED

Solenoid Valve ST-SA-series

The ST-SA is a semi-direct operated 2/2-way solenoid Series Standard (ST)

valve. The valve is normally closed. The valves have an

Function 2/2 way

orifice of 10.5mm and can be used from a zero pressure

difference. The body material can be brass or stainless Operation Semi-direct (S)

steel with a NBR, EPDM or FKM seal. The ST-SA solenoid Position Normally Closed (A)

valves are compatible with all coils from the CS1-series.

Body Material Brass (B) / SS 316 (S)

NBR (N) -10..+80°C

Example of product code Seal &

EPDM (E) -30..+130°C

Media Temperature

FKM (F) -10..+120°C

Thread BSPP / NPT (N)

Ambient Temperature Max +50°C

Min. Pressure Difference 0 bar

Max. Pressure 16/10 bar (AC/DC)

Coil series CS1

230V AC 50/60Hz (230AC)

Dimensions

24V AC 50/60Hz (024AC)

Voltage

24V DC (024DC)

12V DC (012DC)

Insulation Class Class F

Power 15 W

Duty Cycle 100% ED

Connector EN 175301-803 (formerly DIN 43650A)

Protection Class IP 65 (with cable plug)

2 2

Circuit Diagram

1 1

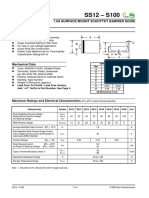

Pipe Body Orifice Kv (m3/h)

1/4" (014) Brass (B) 10.5 mm (105) 1.25

1/4" (014) Stainless Steel (S) 8 mm (080) 1.02

3/8" (038) Brass (B) 10.5 mm (105) 1.43

3/8" (038) Stainless Steel (S) 8 mm (080) 1.02

1/2" (012) Brass (B) 10.5 mm (105) 1.49

1/2" (012) Stainless Steel (S) 8 mm (080) 1.02

MANUAL-ST-SA English www.jpfluidcontrol.com 1

ST-SA SERIES

JP FLUID CONTROL

SOLENOID VALVES

100

1. TECHNICAL SPECIFICATIONS

1.1. Principle of operation

A solenoid valve is a valve for neutral, clean liquids and gases, which is

electrically controlled with the aid of a solenoid. 2/2 way means that the

Water flow (l/min)

valve has two ports (input / output) and two positions (closed / open). The

valve is normally closed, this means that the valve is closed when de-

energized.

Semi-direct operated solenoid valves combine the properties of both direct

and indirect operated solenoid valves. The force that is required to open

and close the diaphragm is supplied by both the solenoid plunger as well as

the pressure of the medium. This allows them to work from zero bar

pressure differential. Furthermore, they can control a high flow rate with a

relatively small solenoid core. They can be used in only one flow direction.

This type of solenoid valves is used in systems that require a reasonable flow

rate, but the pressure difference between input and output is low or

unknown. 10

0.5 2.5 4.5 6.5 8.5 10.5 12.5 14.5

1.2. Area of application dp (bar)

Body material 1/4" 3/8" 1/2" SS

The ST-SA series is available with a brass or stainless steel body material.

Body material Allowed media

Brass (ASTM #37800) Neutral and non-corrosive media. 1.4. Duty cycle

Stainless Steel (S316) Suitable for aggressive media and The solenoid valve is suitable for continuous use. High switching

corrosive media like seawater. frequencies and high pressures can reduce the lifespan.

Diaphragm

The ST-SA series is available with several materials. In the following table a

1.5. Compliance

concise overview is presented of compatible media. The coils are CE marked and comply with the LVD Directive (2006/95/EC)

Diaphragm Temperature Allowed Not allowed and Directive (2004/108/EC), provided that the cables and connectors

media are properly connected.

FKM -10°C..120°C Most fuels Glycol-based brake

and oils, fluids, ammonia gas, 1.6. Type label

cold water, hot water and steam,

detergents, low molecular weight The properties of both the valve and the coil are displayed on a label on

compresse organic acids (such as the coil. In the figure below, an example is shown.

d air. acetic acid.

EPDM -30°C..130°C Water and Oils, fats, fuels,

steam, solvents.

alcohol. JP FLUID CONTROL

NBR -10°C..80°C Neutral Fuels, strong acids,

media, like brake fluid. ST-SA012B105E PRODUCT C ODE

air, cold Normally Closed POSITION

VALVE

water, Pipe: 1/ 2" PIPE CONNECTION

hydraulic Seal: EPMD SEAL MATERIAL

oil. Pressure: 0 – 16 bar WORKING PRESSURE

Orifice: 10.5 mm ORIFICE

1.3. Flow chart Coil: CS1-230AC

PRODUCT C ODE C OIL

COIL C E-MARK

230V~50Hz IP-65 PROTEC TION GRADE

In the flow chart, the flow of water from 20°C is shown as a function of

the positive pressure difference across the valve. The flow rate is VOLTAGE

expressed in liters per minute and the pressure in bar. The graph shows

different pipe diameters. The stainless steel valves (SS) of the ST-SA

series have a lower flow rate due to a smaller orifice.

1.7. Exploded view

In the figure below is an exploded drawing of the ST-SA series is

displayed.

MANUAL-ST-SA English www.jpfluidcontrol.com 2

ST-SA SERIES

JP FLUID CONTROL

SOLENOID VALVES

# Brass (B) Stainless Steel adequate ventilation to facilitate heat dissipation. Make sure

(S)

the solenoid valve is not in contact with or in the vicinity of

1 SS 302 SS 302

flammable materials. Ensure that the product is protected

2 SS 302 SS 302 from frost. Frost may damage the product and/or block the

moving parts, causing the product to malfunction.

3 PA PA

► Operations may only be performed when the system is not

4 Epoxy Epoxy pressurized, electrically disconnected and cooled down.

► Turn off the power supply before performing any work on the

5 Top: 430F Top: 430F solenoid valve to prevent the risk of electrical shock and to

Rest: SS 304 Rest: SS 304

6 NBR/EPDM NBR/EPDM

prevent activation of the solenoid valve.

/FKM /FKM ► The product is only safe when properly installed and operated

7 SS 302 SS 302 by qualified persons. Please read the safety instructions and

technical documentation carefully before installation, use or

8 430F 430F

servicing. Always observe applicable and generally accepted

9 SS 302 SS 302 safety

Measures.

10 NBR/EPDM NBR/EPDM

/FKM /FKM

► Ensure a safe startup after installation or maintenance.

11 Brass #37800 SS 316 ► Water hammer is a typical consequence of a high flow rate

and pressure in pipes with small diameters. There are several

solutions to this problem:

► Reduce the pressure with a pressure reducing

valve before the solenoid valve.

► Increase the pipe diameter if possible.

► Dampen the water hammer by using a flexible

hose or buffer before the solenoid valve.

1.2. Installation

Clean fluids and gases

The solenoid valve can be used in combination with clean liquids or

gases. Make sure that the pipe may contain dirt before installing the

2. GENERAL SAFETY INSTRUCTIONS valve. It is recommended to install a filter (500 µm) before the solenoid

valve.

► This product is not a safety device and may not be used as

such. Mounting the valve

► The product may not function properly as a result of dirt, Be aware of the direction of flow of the medium when installing the

wear, damage (for example, by dropping) or improper use. valve. Solenoid valves with an arrow on the housing must be connected

Therefore, the product should not be used in applications in the indicated direction. The pipes on both sides of the valve must be

where a malfunction can cause danger or damage. securely fastened. Use a wrench for both valve and pipe while tightening,

► Check the compatibility of the medium used, temperature to prevent unnecessary stresses in the system. The solenoid valve must

and other operating conditions with the materials and be fixed via the provided connection points. Only exert force at the

specifications of the product. It is the responsibility of the designated areas on the body such as the hexagon; never to the coil or

user to select the right product for the application. armature. Avoid vibration in the pipes. Use a suitable sealant for

► This product is not intended or approved for medical threaded connections of the solenoid valve. Avoid the entry of sealing

applications, food and/or application in gas appliances. material in the valve, this can lead to malfunctioning of the valve.

► Solenoid valves can only be used with clean liquids or gases.

It is recommended to install a filter before the solenoid valve. Position

► Never exceed the limits for pressure, temperature or voltage It is recommended to install the solenoid in vertical position with the coil

as indicated on the product and/or in the technical facing upwards. This reduces the probability of the collection of debris in

documentation. the solenoid valve. When the solenoid valve is mounted at an angle, it is

► The temperature of a solenoid valve coil can rise during recommended to deviate maximally 90° from the vertical position.

operation; this is normal. Overheating will cause smoke and a

burning smell. In this case, the power supply must

immediately be disconnected.

► A solenoid valve opens and closes quickly. Improper use can

cause pressure waves (fluid hammer) in the pipes with

possible damage as a consequence.

► Beware of electric shock when working with electrical

equipment.

3. INSTALLATION AND MAINTENANCE

1.1. Safety instructions before starting

► It is recommended to install the product in a dry

environment. In moist environments, make sure that no

moisture can penetrate the coil, actuator or connector.

Ensure that the solenoid valve is installed in an area with

MANUAL-ST-SA English www.jpfluidcontrol.com 3

ST-SA SERIES

JP FLUID CONTROL

SOLENOID VALVES

Maximum angle 90°.

OUT

Installation of the cable plug

IN

► Always connect the earth (3), which is provided with a ground

fault at voltages above 50V. Never use liquid or gas for

Check the flow direction with the help of the indications on the grounding electrical equipment. The power supply is

valve body.

connected to terminals (1) and (2). The polarity does not

matter.

► Verify the voltage and frequency before connecting the coil.

► When mounting the connector, make sure that no moisture

can ingress between the coil and connector. The connector

screws should be fastened with a torque of 0.5Nm.

3 1

2

1 2

3

Only exert force at the designated faces , never at the coil or

armature.

Installation of the coil

► Make sure the coil is labeled with the valve characteristics.The

device can be damaged by the use of unsuitable tools.

► The temperature of the coil increases during use, this is normal.

Overheating will cause smoke and a burning smell. In this case, the

power supply must be shut down immediately.

► The coils can be rotated if the coil nut is loosened. After the

determination of the correct position, the nut should be fastened

with a torque of 5Nm.

Connector: EN 175301-803 (formerly DIN 43650A).

The poles (1) and (2) should be connected to the power supply , polarity

is not important. Pole (3) is the earth. Connect the connector

thoroughly to avoid ingress of moisture. Ensure that drops in cannot

slip along the cable and enter the connector.

Connecting the power supply

► Never connect power to the coil when it is not not attached

to the solenoid valve! The coil may burn out.

► Only connect power if you are sure that there is no pressure

in the system and no hazardous situations can occur.

MANUAL-ST-SA English www.jpfluidcontrol.com 4

ST-SA SERIES

JP FLUID CONTROL

SOLENOID VALVES

Product Code Housing Seal

4. SPARE PARTS ST-SA-N-REV Brass NBR

ST-SA-E-REV Brass EPDM

The coil can be replaced. The product codes of the coil are shown in the

ST-SA-F-REV Brass FKM

table below.

ST-SA-SN-REV Stainless Steel NBR

Product Code Voltage

ST-SA-SE-REV Stainless Steel EPDM

CS1-230AC 230V AC 50Hz

ST-SA-SF-REV Stainless Steel FKM

CS1-024AC 24VAC 50Hz

CS1-024DC 24V DC

Follow the drawing in 1.7 for the correct assembly of the solenoid valve.

CS1-012DC 12V DC

The diaphragm, springs and plunger of the solenoid valve can be

replaced. The product codes of the diaphragms are shown in the table 5. DISPOSAL

below:

The removal of the product should be performed in accordance with the

applicable laws. Keep in mind the media that are still present in the valve.

This manual can be downloaded from www.jpfluidcontrol.com Modifications reserved © JP Fluid Control

This document has been prepared with great care. JP Fluid control assumes no responsibility for any errors that may appear in this document. No rights can be derived from this document.

MANUAL-ST-SA English www.jpfluidcontrol.com 5

You might also like

- Northvolt Ett SkellefteåDocument10 pagesNorthvolt Ett SkellefteåFrancisco de Asís Galván DíazNo ratings yet

- GC32 9138 00Document221 pagesGC32 9138 00Sutti Karthik S JNo ratings yet

- Manual CM Ia enDocument5 pagesManual CM Ia enJose Luis GallegoNo ratings yet

- Manual ST Da enDocument5 pagesManual ST Da enSky FooNo ratings yet

- Manual TW enDocument5 pagesManual TW enRobertoNo ratings yet

- Asco Series Nt320 Nuclear CatalogDocument4 pagesAsco Series Nt320 Nuclear CatalogJota JotaNo ratings yet

- Direct Acting: Solenoid Valve 2/2 - NC (Normally Closed) G 1/4Document2 pagesDirect Acting: Solenoid Valve 2/2 - NC (Normally Closed) G 1/4aqma2No ratings yet

- BY1K Screw Clamp Terminal BlocksDocument20 pagesBY1K Screw Clamp Terminal Blocksphong vi100% (1)

- 210 прямого действияDocument2 pages210 прямого действияAlexanderNo ratings yet

- Fellbach EV-500 Namur NewDocument4 pagesFellbach EV-500 Namur Newman2mu2001No ratings yet

- IR Accessories Solenoid S 390 3W USA Product Page EnglishDocument2 pagesIR Accessories Solenoid S 390 3W USA Product Page EnglishClaudiaHernandezMesaNo ratings yet

- Bermad: 3-Way SolenoidDocument2 pagesBermad: 3-Way SolenoidLuís G. MorenoNo ratings yet

- R53 April 2015Document4 pagesR53 April 2015EIJAZ SONS International FZENo ratings yet

- Finder Relays Series 59Document4 pagesFinder Relays Series 59Thaymara ArantesNo ratings yet

- 1 22 080 Bexh120 R - DatasheetDocument3 pages1 22 080 Bexh120 R - DatasheetIbrahim NagiNo ratings yet

- EYP (E, F, H, ML, MU, N Series)Document8 pagesEYP (E, F, H, ML, MU, N Series)AsalAjaNo ratings yet

- SX310 WTE Diode PDFDocument4 pagesSX310 WTE Diode PDFHưng HQNo ratings yet

- 8230-GS3 - Data Sheet-3Document7 pages8230-GS3 - Data Sheet-3marvin barahonaNo ratings yet

- 1.0A Surface Mount Schottky Barrier Diode: Add "-LF" Suffix To Part Number, See Page 4Document4 pages1.0A Surface Mount Schottky Barrier Diode: Add "-LF" Suffix To Part Number, See Page 4Nando AguilarNo ratings yet

- Przekaźniki 2P Seria 40Document18 pagesPrzekaźniki 2P Seria 40onufrywilczurNo ratings yet

- CSF-81T en 2014Document1 pageCSF-81T en 2014NGUYEN VINHNo ratings yet

- Finder Catalogo 95.15.2SMA - Relay Socket, Through Hole, Through Hole, 8 PinsDocument16 pagesFinder Catalogo 95.15.2SMA - Relay Socket, Through Hole, Through Hole, 8 PinsJMSNo ratings yet

- Waterproof Toggle: Dual SealDocument4 pagesWaterproof Toggle: Dual Sealvendry vidiantoroNo ratings yet

- CATEN - 58Series-Finder RelayDocument11 pagesCATEN - 58Series-Finder RelayjaneeshNo ratings yet

- 1 22 080 Bexh120 R - DatasheetDocument3 pages1 22 080 Bexh120 R - DatasheetNehal MohamedNo ratings yet

- SMT4000_240621Document4 pagesSMT4000_240621박박장호No ratings yet

- RTD Temperature Sensor, Type SPT: TYPE SPT100-X-xx, With Class B (1/3-DIN) Pt100 ElementDocument4 pagesRTD Temperature Sensor, Type SPT: TYPE SPT100-X-xx, With Class B (1/3-DIN) Pt100 ElementMohamed BenounaNo ratings yet

- Datasheet Chi Tiết VavleDocument3 pagesDatasheet Chi Tiết VavlePhong PhanhungNo ratings yet

- Automation - Series 83 Valve Position MonitorDocument2 pagesAutomation - Series 83 Valve Position MonitorJair MargaritocNo ratings yet

- MTW-5408-2_24V-504A AS BUILTDocument22 pagesMTW-5408-2_24V-504A AS BUILTskumariitkgpNo ratings yet

- Pressure Gauges: AshcroftDocument1 pagePressure Gauges: AshcroftrialendentawahyunanNo ratings yet

- BMT-Rev oDocument2 pagesBMT-Rev oRaj Saurabh PandeyNo ratings yet

- Series 83 DelMonitor Limit Switch BoxDocument2 pagesSeries 83 DelMonitor Limit Switch BoxProcess Controls & ServicesNo ratings yet

- Integral: Rotary SwitchesDocument3 pagesIntegral: Rotary SwitchesabcNo ratings yet

- Features: 20 Series - Modular Step Relays 16 ADocument4 pagesFeatures: 20 Series - Modular Step Relays 16 ADejana NeznamNo ratings yet

- Venta VG311F 65-150C Specification SheetDocument4 pagesVenta VG311F 65-150C Specification Sheetdhea risqi pentanaNo ratings yet

- Level Gauges - SNK/SNKK Series: SpecificationsDocument1 pageLevel Gauges - SNK/SNKK Series: SpecificationsAbraham Del cid FloresNo ratings yet

- Astm A75Document4 pagesAstm A75gefNo ratings yet

- Solenoid valves 3_2 series 8320Document4 pagesSolenoid valves 3_2 series 8320Morhaf AlwannousNo ratings yet

- Differential Pressure Gauge Model D201: Max. Static Pressure 400 BarDocument2 pagesDifferential Pressure Gauge Model D201: Max. Static Pressure 400 BarYuri SeifaneNo ratings yet

- Asco Valve 8262h 8263h GP Spec r3Document4 pagesAsco Valve 8262h 8263h GP Spec r3Anonymous 6VCG1YRdNo ratings yet

- DZ158 CatalogueDocument4 pagesDZ158 CatalogueThinura SamarawickramaNo ratings yet

- Finder reley 20-seriesDocument4 pagesFinder reley 20-seriesVitalii LytvynovNo ratings yet

- Mor Smitt DBV relayDocument1 pageMor Smitt DBV relayRichard SyNo ratings yet

- WPS-3 (Repair)Document2 pagesWPS-3 (Repair)engr.lutforrahman.bdNo ratings yet

- Finder 41 Series RelayDocument6 pagesFinder 41 Series RelayInderjeet chouhanNo ratings yet

- 1.0A Surface Mount Schottky Barrier Rectifier: SMA/DO-214AC Dim Min Max A B C D E F G H All Dimensions in MMDocument3 pages1.0A Surface Mount Schottky Barrier Rectifier: SMA/DO-214AC Dim Min Max A B C D E F G H All Dimensions in MMLêĐìnhDanhNo ratings yet

- Arita - Ci Butterfly Lever + Limith SwitchDocument2 pagesArita - Ci Butterfly Lever + Limith Switchshinyivalve247No ratings yet

- Catalog Series 320 8320 Solenoid Valve Asco North Americas enDocument4 pagesCatalog Series 320 8320 Solenoid Valve Asco North Americas enluthfie4uNo ratings yet

- 429 cat pageDocument1 page429 cat pagebryantorres010No ratings yet

- Finder Relays Series 4CDocument5 pagesFinder Relays Series 4CJavid SalamovNo ratings yet

- Finder Relays Series 62Document9 pagesFinder Relays Series 62Thong Dang SyNo ratings yet

- SS Case Brass Pressure Gauge - Economical - India Pressure GaugeDocument6 pagesSS Case Brass Pressure Gauge - Economical - India Pressure GaugeIndiapressure gaugeNo ratings yet

- Ycms35 - Item 1-2 CatalogueDocument4 pagesYcms35 - Item 1-2 CatalogueChinhNo ratings yet

- GLOBE VALVE - 2019 UpdatedDocument28 pagesGLOBE VALVE - 2019 UpdatedAlan MokNo ratings yet

- Data Sheet: Tembreak 2 S1000-Se MCCB: Max in (A) of FrameDocument3 pagesData Sheet: Tembreak 2 S1000-Se MCCB: Max in (A) of FrameTosikur RahmanNo ratings yet

- Product Data Sheet WB14 - ENDocument10 pagesProduct Data Sheet WB14 - ENJairo Javier Díaz MontenegroNo ratings yet

- Protek Electronics - MCCB Data SheetDocument3 pagesProtek Electronics - MCCB Data SheetHoney BeeNo ratings yet

- Lincoln baso48SPDocument2 pagesLincoln baso48SPbunkerfaust2No ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- WS603 Operation ManualDocument17 pagesWS603 Operation ManualOliver SuttonNo ratings yet

- Electrical Networks, Network ElementsDocument11 pagesElectrical Networks, Network ElementsMansi NegiNo ratings yet

- St. Paul University at San Miguel: Influence of Modern Engineering in Modern House Designs: A Qualitative StudyDocument10 pagesSt. Paul University at San Miguel: Influence of Modern Engineering in Modern House Designs: A Qualitative StudyCANo ratings yet

- Dual Operational AmplifierDocument5 pagesDual Operational AmplifierPablo Diego Cecere CasadoNo ratings yet

- Titan Software Engineer JDDocument2 pagesTitan Software Engineer JDNakul kankarwalNo ratings yet

- #04 Custom Design SynopsysDocument32 pages#04 Custom Design Synopsysquangzippo2002No ratings yet

- Skyjack SJ 61 T, SJ 66 TDocument1 pageSkyjack SJ 61 T, SJ 66 TjohnNo ratings yet

- Spampots Ceas08Document10 pagesSpampots Ceas08Elverton FazzionNo ratings yet

- Car 145 QuestionsDocument4 pagesCar 145 QuestionsVikash PalNo ratings yet

- A6V12053780 - PSDS - Remote Access Type 2 - Automatically Renewab - enDocument6 pagesA6V12053780 - PSDS - Remote Access Type 2 - Automatically Renewab - enCristian OrtizNo ratings yet

- Banking ProductsDocument9 pagesBanking Productsbeena antuNo ratings yet

- New Bios 2G Hydrotreatment Unit-Cartagena, Spain Supply and Fabrication of Reformer Steel Casing, Structures and StackDocument2 pagesNew Bios 2G Hydrotreatment Unit-Cartagena, Spain Supply and Fabrication of Reformer Steel Casing, Structures and StackAHMED KHAMISNo ratings yet

- T6TR 50 Watt User DocumentationDocument144 pagesT6TR 50 Watt User DocumentationDeny MuspitaNo ratings yet

- Annotated Bibliography For PortfolioDocument7 pagesAnnotated Bibliography For Portfolioapi-241345614No ratings yet

- Data Centre Network OptimizationDocument24 pagesData Centre Network OptimizationPoonam KilaniyaNo ratings yet

- Painel Aud A3Document4 pagesPainel Aud A3Canal do VacãoNo ratings yet

- Fourth Semester Core Course Paper: Microprocessors Architecture and ProgrammingDocument44 pagesFourth Semester Core Course Paper: Microprocessors Architecture and ProgrammingSANAL KUMARNo ratings yet

- 2 - Engineering-Consultancy-Qualification-StandardsDocument2 pages2 - Engineering-Consultancy-Qualification-StandardsDaniyar KussainovNo ratings yet

- Olive ManualDocument19 pagesOlive ManualSócrates GómezNo ratings yet

- XINDAK PA-1 Instructions ManualDocument11 pagesXINDAK PA-1 Instructions ManualmilexconsultNo ratings yet

- Book 005 LaMeres Quickstart To Verilog CoverNtocDocument10 pagesBook 005 LaMeres Quickstart To Verilog CoverNtocphamminhduc862003No ratings yet

- Ds 4 WindowsDocument1 pageDs 4 WindowsJuma FNNo ratings yet

- Gap AnalysisDocument4 pagesGap AnalysisATTALLH100% (2)

- Curriculum Vitae of Ansgar NeuenhoferDocument4 pagesCurriculum Vitae of Ansgar NeuenhoferVijay KumarNo ratings yet

- EKC 315A Danfoss Rs8cS302Document16 pagesEKC 315A Danfoss Rs8cS302davebigelow42No ratings yet

- 9 Class Chapter No 01Document19 pages9 Class Chapter No 01Muhammad Sikandar DarNo ratings yet

- NEC Guide To Article 695 and Fire PumpsDocument10 pagesNEC Guide To Article 695 and Fire Pumpsalf.powerchinaNo ratings yet

- BK 2250 2270 UputstvoDocument368 pagesBK 2250 2270 UputstvoNebojsa CurcicNo ratings yet