100%(5)100% found this document useful (5 votes)

1K viewsDesign Calculation of 61kld STP

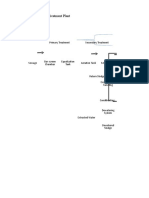

This document provides the design calculations for a 61 KLD sewage treatment plant. It details the sizing and parameters for the major unit processes, including a bar screen chamber, pre-treatment tank, buffer tank, sequencing batch reactor tank, filter feed/contact clarification tank, dual media filter, activated carbon filter, chlorination, treated water tank, and return activated sludge pumping. Key design considerations addressed include flow rates, detention times, oxygen requirements, filtration rates, and pump capacities. The plant is designed to treat domestic wastewater to meet specified discharge standards.

Uploaded by

Aminur RahmanCopyright

© © All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100%(5)100% found this document useful (5 votes)

1K viewsDesign Calculation of 61kld STP

This document provides the design calculations for a 61 KLD sewage treatment plant. It details the sizing and parameters for the major unit processes, including a bar screen chamber, pre-treatment tank, buffer tank, sequencing batch reactor tank, filter feed/contact clarification tank, dual media filter, activated carbon filter, chlorination, treated water tank, and return activated sludge pumping. Key design considerations addressed include flow rates, detention times, oxygen requirements, filtration rates, and pump capacities. The plant is designed to treat domestic wastewater to meet specified discharge standards.

Uploaded by

Aminur RahmanCopyright

© © All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

You are on page 1/ 4

DESIGN CALCULATION OF 61KLD STP

FOR

WORK NAME - Design, Manufacture, Supply, Inspection,

Installation, Testing and Commissioning of

Prefabricated Modular Type Sewage Treatment Plant 61

KLD including O& M for 5 years at Construction of

Command Control Centre, Auditorium & Convention

Centre and Tribal Museum at ABD area in Rourkela,

Odisha.

EXECUTING AGENCY

Engineering Projects (India) Limited

Contractor - JRMS Engineering Works

Designed by - JRMS Engineering Works

DESIGN PARAMETERS

PARAMETER INFLUENT SEWAGE QUALITY TREATED WATER QUALITY /AS PER TD

S /AS PER TD

QUANTITY UNIT QUANTITY UNIT

pH 6.5-8.5 mg/l 6.5-8.5 mg/l

BOD 250-300 mg/l <10 mg/l

COD 400-500 mg/l <50 mg/l

TSS 300-400 mg/l <10 mg/l

O&G 10 to 20 mg/l <10 mg/l

DESIGN CALCULATION OF STP UNIT

1). Bar screen chamber

Design flow = 0.7 m3/sec

Assume detention time = 30sec

Volume of receiving chamber = 0.35 m3

Chamber size = 1m x 0.6m x 0.6m

Adopting screen of bar for Fine screen - 10mm, Opening 10 mm

Adopting screen of bar for Coarse Screen 8mm, Opening 6 mm

2). Pre-Treatment Tank

Avg. Flow Rate = 61m3/d /24 = 2.541cum/hr.

Detention Time – 4.29hr.

Operating time - 24hr.

Tank Volume – 10.925 cum

Tank Size – 1.9 x 2.5 x 2.3mtr(SWD)+0.3mtr F.B

3). Buffer Tank

Avg. Flow Rate = 61m3/24 = 2.541cum/hr.

Operating time - 24hr.

Tank Volume – 4.6 cum

Tank Size – 0.8 x 2.5 x 2.3mtr(SWD)+0.3mtr F.B

4). SBR Tank

A) Design of SBR tank

Design Flow = 61 m3/day

Inlet BOD = 250 mg/lt

Assume F/M ratio - 0.20 for design calculations

Volume Tank = Q(Flow/day) x BOD(mg/l) / MLSS x F/M

= (61 x 250) / (0.2 x 4000) = 19.06 say 19 m3 .

Designed by - JRMS Engineering Works

So, provide a Reactor of 19m3 effective volume + Free board

Size of Tank: 3.3x 2.5 x 2.3(SWD) + 0.3m F.B.

A) Calculation of Reaction time

Operating hour - 20hr

Retention time = Tank Volume/Flow m3/hr = 19/3.05 = 6.22 say 6.0hr/batch

B) Oxygen requirement for Removing of Bod - 2.0kg O2 per Kg Of Bod

In our design of 61kld or 0.061mld:

Organic Load: Inlet bod (250mg/l, As per TD) = 250x0.061 = 15.25kg/day (Total Bod load)

O2 Required – 15.25x1.5 = 22.875 say 23kg O2/day =23/20hr=1.15kg/hr

Assume the Oxygen transfer efficiency of disc type diffuser - 3.0%

Total SWD of the reactor = 2.3 m

Overall Efficiency = 2.3 x 3.0 = 6.9 %

Oxygen to be supplied = 1.15 / 0.069 = 16.66 say 17 Kg /Hour

Air contains:

23% O2 (23kg O2 / 100kg Air)

Density of Air 1.225kg/m3

Air required will be - O2 requirement / (O2 % in Air x Density of Air) = 17 kg O2 per hr / 0.23kg O2 x1.225 kg m3 =

60.33 say 60cum/hr

4). Filter Feed Tank/CC Tank

Avg. Flow Rate = 3.05cum/hr.

Detention Time – 1.5hr.

Operating time - 20hr.

Tank Volume – 4.575 say 4.6cum

Tank Size – 0.8*2.5*2.3mtr(swd)+0.3mtr free board

DESIGN CALCULATION OF TERTIARY UNIT

5). Dual Media Filter

Assuming 20 Hours of operation in a day average flow rate = 3.05 Cum /h

Considering one DMF with the period of filtration of 20 hr/ day

Flow rate = 3.05 m3/hour

Filter type = Vertical type sand filter

Rate of Filtration = 20 m3/m2.hour

Cross section area of Filter = 3.05/15= 0.203 m2

Filter dia. = 0.496 m

Provide Filter size= 0.5 m dia. x 1.2 m ht – 1 nos

6). Activated Carbon Filter

Assuming 20 Hours of operation in a day average flow rate = 3.05 Cum /h

Considering one ACF with the period of filtration of 20 hr/ day

Flow rate = 3.05 m3/hour

Filter type = Vertical type CARBON filter

Rate of Filtration = 20 m3/m2.hour

Cross section area of Filter = 3.05/15= 0.203 m2

Filter dia. = 0.496 m say 0.5m

Provide Filter size= 0.5 m dia. x 1.2 m ht – 1 nos

Designed by - JRMS Engineering Works

8). Chlorination

Dosing throughput flow - 61m3/day

Design maximum chlorine Dose - 10ppm/1000 = 0.01kg/cum

Total chlorine dose per day - 61cumx0.01cum/kg = 0.61kg/cum

Chlorine Strength - 15%

Total chlorine dose per day - 0.61/0.15 = 4.06 say 4.0kg

9). Treated Water Tank

Avg. Flow Rate = 3.05cum/hr.

Detention Time – 1.5hr.

Operating time - 20hr.

Tank Volume – 4.575 say 4.6cum

Tank Size – 0.8x2.5x2.3mtr(swd)+0.3mtr free board

10). Return Activated Sludge

Assume Ras Ratio - 0.25

Total Ras Quantity - 61m3 x 25/100 = 15.25cum/day = 0.762 cum/hr

Required Pumps

A. Providing 2 Nos. sewage transfer pumps (one working and one standby)

Capacity : 3.05m3/hr @ 10 m head

Type : Centrifugal pumps

Solid handling capacity : Up to 10 mm

Purpose : To pump the sewage from the Buffer tank to SBR tank.

B. Provide 1 No. Sludge Transfer pump

Capacity : 1m3/hr @ 20 m head

Type : Centrifugal pumps

Solid handling capacity : Up to 25 mm

Purpose: To pump the sludge from the SBR tank to Sludge drying bed

C. Provide 2 Nos Filter feed pumps

Capacity : 3.05 @ 30 m head

Type : Centrifugal pumps,

Solid handling capacity : Up to 5 mm

Purpose : To pump the treated effluent from the FF/CC tank through Sand & Carbon filters.

Designed by - JRMS Engineering Works

You might also like

- Manuale Di Istruzioni Instruction Manual: Automatic Control Console Compression Machine100% (1)Manuale Di Istruzioni Instruction Manual: Automatic Control Console Compression Machine152 pages

- 18.12.2019 Proposal For 70 KLD Etp On UasbrNo ratings yet18.12.2019 Proposal For 70 KLD Etp On Uasbr24 pages

- 3.1 Final Process Design of 6 MLD - Stp.sbr.No ratings yet3.1 Final Process Design of 6 MLD - Stp.sbr.8 pages

- Design of 100KLD STP Using MBBR TechnoloNo ratings yetDesign of 100KLD STP Using MBBR Technolo9 pages

- Design Calculations: Design Calculation For 97.5 M /HR WTP 10% (1)Design Calculations: Design Calculation For 97.5 M /HR WTP 16 pages

- Construction of STP - 350 KLD For CPMF - Part 1100% (2)Construction of STP - 350 KLD For CPMF - Part 19 pages

- Operation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreNo ratings yetOperation & Maintenance Manual: Vishwasri-Oak Park Coimbatore17 pages

- 1295 - Offer 50 KLD Package Type STP 27.08.2022 - Removed100% (1)1295 - Offer 50 KLD Package Type STP 27.08.2022 - Removed11 pages

- Filters Pressurized Filters Pressure Filter 200100% (1)Filters Pressurized Filters Pressure Filter 2002 pages

- 45 KLD STP PROPOSAL VRANDAVAN GREENS PDFNo ratings yet45 KLD STP PROPOSAL VRANDAVAN GREENS PDF9 pages

- Tech City-STP 100 KLD Price Comparison (03092016)No ratings yetTech City-STP 100 KLD Price Comparison (03092016)10 pages

- Techno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridNo ratings yetTechno-Commercial Offer 100 KLD STP, Betul Based On MBBR Hybrid9 pages

- Free Design Calculations For STP and ETP by Richa Environmental Services PVT LTD PDF100% (1)Free Design Calculations For STP and ETP by Richa Environmental Services PVT LTD PDF6 pages

- Design Calculation Sand Filter: Basis Data Taken For The Design of The Multi Layer Sand Filter100% (1)Design Calculation Sand Filter: Basis Data Taken For The Design of The Multi Layer Sand Filter1 page

- STP (200kld) - Technical Datasheet 17.02.23100% (2)STP (200kld) - Technical Datasheet 17.02.23150 pages

- Activated Sludge Calculations With Excel Quiz0% (1)Activated Sludge Calculations With Excel Quiz2 pages

- Plant Capacity: 15 MGD Technology: Moving Bed Biological Reactor (MBBR)100% (2)Plant Capacity: 15 MGD Technology: Moving Bed Biological Reactor (MBBR)12 pages

- How To Design and Calculate The Tube Settler75% (4)How To Design and Calculate The Tube Settler6 pages

- Techno-Commercial Offer 120KLD TM Based On SBR Technology, VrindavanNo ratings yetTechno-Commercial Offer 120KLD TM Based On SBR Technology, Vrindavan9 pages

- Details of Filter Unit (Psf+Mf+Acf) For Techno Commercial OfferNo ratings yetDetails of Filter Unit (Psf+Mf+Acf) For Techno Commercial Offer3 pages

- Techno-Commercial Offer For 600 KLD STP MBBRNo ratings yetTechno-Commercial Offer For 600 KLD STP MBBR9 pages

- Techno Commercial Proposal For 50KLD STP For Bhakti Enterprises100% (1)Techno Commercial Proposal For 50KLD STP For Bhakti Enterprises21 pages

- Annexure 15 - Tool For Water Treatment Plant Design100% (2)Annexure 15 - Tool For Water Treatment Plant Design3 pages

- Bio Treat - For Effective Removal of BOD, COD & Foul OdorNo ratings yetBio Treat - For Effective Removal of BOD, COD & Foul Odor4 pages

- Material Requirement For Producing 1 Cum of Nominal Concrete MixNo ratings yetMaterial Requirement For Producing 1 Cum of Nominal Concrete Mix6 pages

- Foundation Size Calculation Tree Area 12kilonewton (Load Per SQMTR) Load/Sbc (8) Result (Ei Result SQRT Korle Foundation Size Bar Hye Jabe)No ratings yetFoundation Size Calculation Tree Area 12kilonewton (Load Per SQMTR) Load/Sbc (8) Result (Ei Result SQRT Korle Foundation Size Bar Hye Jabe)2 pages

- Optimizing Pumping Solutions For HVAC ApplicationsNo ratings yetOptimizing Pumping Solutions For HVAC Applications27 pages

- Republic of The Philippines Department of Education Region Ix, Zamboanga Peninsula Schools Division of Zamboanga Del NorteNo ratings yetRepublic of The Philippines Department of Education Region Ix, Zamboanga Peninsula Schools Division of Zamboanga Del Norte2 pages

- CP1 (2020) Verifying Space Heating Flow RatesNo ratings yetCP1 (2020) Verifying Space Heating Flow Rates8 pages

- Compressor Data Sheet Rev3 - Updated by EFXNo ratings yetCompressor Data Sheet Rev3 - Updated by EFX9 pages

- Durco Mark 3 In-Line: Asme (Ansi) B73.2 Vertical In-Line Chemical Process PumpsNo ratings yetDurco Mark 3 In-Line: Asme (Ansi) B73.2 Vertical In-Line Chemical Process Pumps8 pages

- Service Repair Manual - Hyundai 110D-9, 130D-9, 160D-9 Forklift PDF DownloadNo ratings yetService Repair Manual - Hyundai 110D-9, 130D-9, 160D-9 Forklift PDF Download532 pages

- Data Sheet NKZ3-80H: Classification Shaft SealNo ratings yetData Sheet NKZ3-80H: Classification Shaft Seal4 pages

- Brochure - SPM 2002 Iron Products - 3-25-21No ratings yetBrochure - SPM 2002 Iron Products - 3-25-2120 pages

- SEN00322-04 50 Disassembly and AssemblyNo ratings yetSEN00322-04 50 Disassembly and Assembly72 pages

- Manuale Di Istruzioni Instruction Manual: Automatic Control Console Compression MachineManuale Di Istruzioni Instruction Manual: Automatic Control Console Compression Machine

- Design Calculations: Design Calculation For 97.5 M /HR WTP 1Design Calculations: Design Calculation For 97.5 M /HR WTP 1

- Operation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreOperation & Maintenance Manual: Vishwasri-Oak Park Coimbatore

- 1295 - Offer 50 KLD Package Type STP 27.08.2022 - Removed1295 - Offer 50 KLD Package Type STP 27.08.2022 - Removed

- Techno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridTechno-Commercial Offer 100 KLD STP, Betul Based On MBBR Hybrid

- Free Design Calculations For STP and ETP by Richa Environmental Services PVT LTD PDFFree Design Calculations For STP and ETP by Richa Environmental Services PVT LTD PDF

- Design Calculation Sand Filter: Basis Data Taken For The Design of The Multi Layer Sand FilterDesign Calculation Sand Filter: Basis Data Taken For The Design of The Multi Layer Sand Filter

- Plant Capacity: 15 MGD Technology: Moving Bed Biological Reactor (MBBR)Plant Capacity: 15 MGD Technology: Moving Bed Biological Reactor (MBBR)

- Techno-Commercial Offer 120KLD TM Based On SBR Technology, VrindavanTechno-Commercial Offer 120KLD TM Based On SBR Technology, Vrindavan

- Details of Filter Unit (Psf+Mf+Acf) For Techno Commercial OfferDetails of Filter Unit (Psf+Mf+Acf) For Techno Commercial Offer

- Techno Commercial Proposal For 50KLD STP For Bhakti EnterprisesTechno Commercial Proposal For 50KLD STP For Bhakti Enterprises

- Annexure 15 - Tool For Water Treatment Plant DesignAnnexure 15 - Tool For Water Treatment Plant Design

- Troubleshooting the Sequencing Batch ReactorFrom EverandTroubleshooting the Sequencing Batch Reactor

- Bio Treat - For Effective Removal of BOD, COD & Foul OdorBio Treat - For Effective Removal of BOD, COD & Foul Odor

- Material Requirement For Producing 1 Cum of Nominal Concrete MixMaterial Requirement For Producing 1 Cum of Nominal Concrete Mix

- Foundation Size Calculation Tree Area 12kilonewton (Load Per SQMTR) Load/Sbc (8) Result (Ei Result SQRT Korle Foundation Size Bar Hye Jabe)Foundation Size Calculation Tree Area 12kilonewton (Load Per SQMTR) Load/Sbc (8) Result (Ei Result SQRT Korle Foundation Size Bar Hye Jabe)

- Optimizing Pumping Solutions For HVAC ApplicationsOptimizing Pumping Solutions For HVAC Applications

- Republic of The Philippines Department of Education Region Ix, Zamboanga Peninsula Schools Division of Zamboanga Del NorteRepublic of The Philippines Department of Education Region Ix, Zamboanga Peninsula Schools Division of Zamboanga Del Norte

- Durco Mark 3 In-Line: Asme (Ansi) B73.2 Vertical In-Line Chemical Process PumpsDurco Mark 3 In-Line: Asme (Ansi) B73.2 Vertical In-Line Chemical Process Pumps

- Service Repair Manual - Hyundai 110D-9, 130D-9, 160D-9 Forklift PDF DownloadService Repair Manual - Hyundai 110D-9, 130D-9, 160D-9 Forklift PDF Download