Structure of Bridge. No. 3

Structure of Bridge. No. 3

Uploaded by

Ravpreet SinghCopyright:

Available Formats

Structure of Bridge. No. 3

Structure of Bridge. No. 3

Uploaded by

Ravpreet SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Structure of Bridge. No. 3

Structure of Bridge. No. 3

Uploaded by

Ravpreet SinghCopyright:

Available Formats

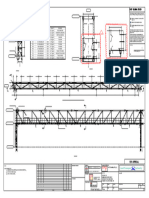

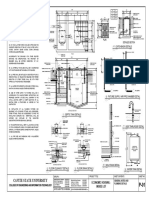

6000(SQ) 6000(SQ) 700(SQ)

250 NOTES:

700(SQ) 6464(SK) 450(SQ) 6464(SK) 754(SK)

754(SK) a4 g a2 485(SK) TBL 1. ALL DIMENSIONS ARE IN MM & ALL LEVELS ARE IN METER UNLESS OTHERWISE SPECIFIED.

A

tst-800

2. ALL DIMENSIONS AND LEVELS SHOULD BE VERIFIED AND RECONCILED

FILL SIDE

FILL SIDE BEFORE EXECUTION.

tst

08

b j1 3. GRADE OF CONCRETE - RCC M:35 FOR RCC BOX AND

07

h1 M-25 FOR RCC RETURN WALL

10

'g' BARS

HAUNCH h3

4. GRADE OF STEEL Fe-500 CONFORMING TO IS 1786:2008 TO BE USED .

600 X 600

10 5. M10 GRADE PCC 100 THK. LEVELING COURSE SHALL BE PROVIDED BELOW FOUNDATION FOR RETURN WALL AND 150mm

'a1' / 'a3' BARS THICK LEVELING COURSE FOR RCC BOX.

tht

ht

'g' BARS

8a 7a

SLOPE 1:12

STRAIGHT

CLS CLS 6. CLEAR COVER 50 MM FOR REINFORCEMENT.

g j4 'e' BARS 7. ALL RCC SURFACES COMING IN CONTACT WITH SOIL SHOULD BE PAINTED WITH BITUMEN OR COALTAR OF APPROVED

a1 e f e QUALITY @ 1.454KG/SQ.M

ht-6000

a3 11 8. TOLERANCE SHALL BE FOLLOWED AS PER CONCRETE BRIDGE CODE.

cht

cht

j3

8a 9. BED SLOPE SHALL BE ADJUSTED AS PER SITE CONDITION BY COMPETANT AUTHORITY, IT SHOULD BE MINIMUM 1 IN 100.

tsb

08

tiw 10. ENGINEER INCHARGE AT SITE SHOULD ENSURE THAT THE FOUNDATION PRESSURE SHOULD NOT BE MORE THA THE

7a

150 TH PCC (M-15) 07 BEARING CAPACITY OF SOIL..

B 09

H = 10544

tsv SECTIONAL ELEVATION OF WALL 11. ALL OVERLAPS AND ANCHORAGE SHALL BE 50 x DIA OF BARS & NOT MORE THAN 50% BARS SHALL BE LAPPED AT ONE

TBL SECTION.

tsv

11544

09

12. 75 Ų DIA PVC PIPES AS WEEP HOLES ARE TO BE PROVIDED IN RETURN WALL AT 1000 MM C/C (STAGGERED VERTICALLY &

tsv

150 THK. WEARING

h2 COURSE HORIZONTALLY).

12

13. MINIMUM SBC AT FOUNDING LEVEL SHALL BE 16.0 MT./Sq.M. FOR RETURN WALL. IT SHALL BE ENSURED AT SITE BY SITE

d1 h4

'g' BARS

c

03 ENGINEER.

tsb-900

d2 01 01 14. FOUNDATION PRESSURE FOR RCC BOX IS 21.6 t/sq.m. IT SHALL BE ENSURED AT SITE BY SITE ENGINEER.

j2

CLS

'a4' BARS 15. BACK FILL MATERIAL SHOULD BE AS PER CLAUSE 7.5 OF IRS SUBSTRUCTURE AND FOUNDATION CODE.

'g' BARS

06

16. ANGLE OF REPOSE OF BACKFILL SHALL NOT BE LESS THAN 35 DEGREE.

06 05 17. THIS DRAWING SHOULD NOT BE REFERRED FOR ANY OTHER LOCATION.

'b' BARS

18. ALL CONCRETE WORK SHALL BE MECHANICALLY MIXED AND VIBRATED.

300mm THICK BOULDER FILLING 150mm SAND FILLING 150mm THICK LEVELLING COURSE (M-10)

tiw 19. CURING SHALL BE DONE AS PER CLAUSE NO.8.4 OF IRS CONCRETE BRIDGE CODE.

OLS

OLS

02 2

20. MIX DESIGN SHALL BE APPROVED BY ENGINER-IN-CHARGE.

04 21. ALL RCC AND CC WORKS SHALL BE DONE IN

REINFORCEMENT DETAIL ACCORDANCE WITH SPECIFICATION LAID DONE RAILWAY APPROVAL

'a2' BARS

OF RETURN WALL ROAD LEVEL IN IRS CONCRETE BRIDGE CODE.

HAUNCH

1000X1000 22. DO NOT COUNT NO. OF BARS FROM DRAWING.

CLS

TYPE DIA OF BARS & SHAPE & DIMENSION DIA OF BARS & SHAPE & DIMENSION

TYPE

1000

SPACING ARE IN MM SPACING ARE IN MM 23. DESIGN CRITERIA.

CHIEF ENGINEER/CON- I

290

2830

25mm dia @ 200 C/C 200 i) IRS BRIDGE RULES INCORPORATING A & C SLIP NO. 33 S. E. C. RLY. BILASPUR

4

200 280

29

7600

25mm dia @200 C/C 46 970 ii) IRS CONCRETE BRIDGE CODE INCORPOARTING A &

TYPE SPACING ARE IN MM 250

290 C SLIP NO. 7

2830 32mm dia @ 200 C/C 1000

01 iii) IRS BRIDGE SUBSTRUCTURE AND FOUNDATION

290

25mm dia @200 C/C 4736 25mm dia @ 200 C/C 25 Ø @ 150 C/C CODE INCORPORATING A & C SLIP NO.

tew

200 24

24 Dy CE/CON/D&D

2830

7600

iv) EXPOSURE CONDITION - MODERATE

66

25mm dia @200 C/C SECTION OF TOP SLAB 02 25 Ø @ 150 C/C S. E. C. RLY. BILASPUR

200

25

1000

2830 32mm dia @ 200 C/C 290

v) SEISMIC ZONE - III

2780

2780

tsv

ALONG BARREL, ALONG SPAN

25mm dia @200 C/C 14820 03 12 Ø @ 125 C/C 3400 1220 3380 vi) STANDARD OF LOADING - 25T

10mm dia @200C/C,200C/C

ALONG BARREL, ALONG SPAN

14820 vii) THIS DRAWING IS PREPARED BASED ON RDSO DRG 10154/6R

20mm dia @ 100 C/C 8000

10mm dia @200C/C,200C/C 04 12 Ø @ 125 C/C

DY CE/CON

'g' BARS

20mm dia @ 100 C/C 14820

ALONG BARREL, ALONG SPAN

10mm dia @200C/C,200C/C

SECTION OF RETURN WALL 150mm THICK WEARING S. E. C. RLY. BILASPUR

ALONG BARREL, ALONG SPAN 05 10 Ø @ 150 C/C & 250 C/C COAT

20mm dia

2873

10mm dia @200C/C,200C/C

2873

@ 100mm C/C

CLS

32mm dia @200C/C

14820 'c' BARS 06 12 Ø @ 150 C/C

'g' BARS

450

28mm dia @200 C/C 4736 75 25mm dia

@ 100mm C/C 10mm dia AXEN/CON/BR DESIGN

900

07 25 Ø @ 200 C/C 75 @ 100mm C/C

7600

S. E. C. RLY. BILASPUR

DK

'd1' BARS

16mm dia @ 100 C/C BOTTOM SLAB

225

100mm DIA. 10mm dia

tiw 75 TOP SLAB @ 100mm C/C

7600

32 Ø @ 200 C/C 32mm dia

800

OLS

7a P.V.C. PIPE GOOD FOR CONSTRUCTION

12mm dia @ 200 C/C @200C/C

@ 1000 C/C 300 25t.LOADING

150mm THICK LEVELLING COARSE

20mm dia 450

CONNECTING RAILWAY : nf{k.k iqoZ e/; jsyos

10mm dia @100 C/C 28418 08 16 Ø @ 200 C/C @200C/C

225

'd2' BARS DETAIL OF 'A' DIVISION:

NOTATION BILASPUR

(SCALE:1:50) DETAIL OF 'B' SECTION:

TBL 8a 12 Ø @ 200 C/C KHARSIA - DHARAMJAYGARH

CLS

TOTAL BARREL LENGTH OF BOX (SCALE:1:50)

OLS CLIENT :

OVERALL SPAN

CLS CLEAR SPAN 12 Ø @ 150 C/C PROJECT :

09

ht STRUCTURAL DRAWING FOR PROPOSED CONSTRUCTION OF BR. NO.03

HEIGHT OF BOX INCLUDING WEARING COAT.

( 2x 6.0mx6.0m RCC BOX) AT CH: 2519.783m IN CONNECTION WITH FEEDER

cht HEIGHT OF BOX ABOVE WEARING COAT. 10 10 Ø @ 150 C/C LINE CONNECTING BAROUD SIDING OF SECL WITH KORICHHAPAR

tst THICKNESS OF TOP SLAB STATION OF CERL

tsb THICKNESS OF BOTTOM SLAB 10 Ø @ 200 C/C IN

tew

CONSULTANTS

THICKNESS OF END WALL 11

tew

tiw

tht

THICKNESS OF INTERMEDIATE WALL

TOTAL HEIGHT OF BOX SECTION OF BOTTOM SLAB

HORIZONTAL & 200 C/C IN

VERTICAL cuity

INFRASTRUCTURE MANAGEMENT SERVICES LLP

1st Floor, 1-7-16, Plot No. 64, JSN Colony, St.No. 8, Habsiguda, Hyderabad-500007

12 32 Ø @ 200 C/C e-mail : acuityinfra2020@gmail.com

PREPARED BY/CONSULTANT AUTHORIZE SIGNATORY OF C.G.M./CERL JGM / C DRG. NO: AIMS/IRCON/STRUCT/R-01 SHEET No. 1/1

ACUITY INFRASTRUCTURE INDEPENDEDNT ENGINEER IRCON INTERNATIONAL LTD IRCON INTERNATIONAL LTD

MANAGEMENT SERVICES LLP BILASPUR BILASPUR SCALE :1:50 ISSUED Dt: 18-06-2021

You might also like

- Overhead Gantry Sign BoardDocument1 pageOverhead Gantry Sign Boardrao shoaib100% (7)

- Turning TorsoDocument25 pagesTurning TorsoEmime Lee100% (4)

- 06 PCI Design Handbook 8th Edition - Content and Updates PDFDocument21 pages06 PCI Design Handbook 8th Edition - Content and Updates PDFJes Arvin Ocampo ZapantaNo ratings yet

- Ec2-05 - Fifth Floor Plan Auxiliary LayoutDocument1 pageEc2-05 - Fifth Floor Plan Auxiliary LayoutSEDFREY DELA CRUZNo ratings yet

- DMF&ACF GA DrawingDocument1 pageDMF&ACF GA DrawingKELVIN TECHNOLOGIESNo ratings yet

- Turap (1) - ModelDocument1 pageTurap (1) - ModelEristian GunadiNo ratings yet

- Miscellaneous Details: Schedule of Loads: Pp-1 (Unit 1 & 2)Document1 pageMiscellaneous Details: Schedule of Loads: Pp-1 (Unit 1 & 2)Lhewiz BrionesNo ratings yet

- Triode Electronics Jcm800 2204 50W LayoutDocument1 pageTriode Electronics Jcm800 2204 50W LayoutDimce BusinoskiNo ratings yet

- ARP ST DWG C1 1301 00 002 - 4 - - 承台详图Document1 pageARP ST DWG C1 1301 00 002 - 4 - - 承台详图joeshon ngNo ratings yet

- Ficha Tecnica Autohormigonera Dieci L3500Document2 pagesFicha Tecnica Autohormigonera Dieci L3500REINALDO ANTONIO NAVARRO BLANCONo ratings yet

- Fourth Floor LVL Framing Plan & Beam - Slab DetailDocument1 pageFourth Floor LVL Framing Plan & Beam - Slab DetailMOHD IMRANNo ratings yet

- Two Storey Duplex PDFDocument3 pagesTwo Storey Duplex PDFJoseph Tolentino0% (1)

- Quep Foundation 1Document1 pageQuep Foundation 1Yaw KrahNo ratings yet

- 225KL - 18M-Blank-1Document1 page225KL - 18M-Blank-1Tarun SinghalNo ratings yet

- Latest Lighting Gantry Steel Structure Shopdrawing - 20231016-5Document1 pageLatest Lighting Gantry Steel Structure Shopdrawing - 20231016-5jmr76803No ratings yet

- DDCSMP1 DD Dep Ar DW 37078 - A2Document1 pageDDCSMP1 DD Dep Ar DW 37078 - A2Het NandaniNo ratings yet

- 714 - Om4000Document2 pages714 - Om4000Edson LemosNo ratings yet

- Asb (1ST Floor) Rain Water Pipe Installation Plan R0 OkeDocument4 pagesAsb (1ST Floor) Rain Water Pipe Installation Plan R0 OkeGus Neo BaleagungNo ratings yet

- Planta - Perfil Vilcabamba-Pp 3+000-4+000Document1 pagePlanta - Perfil Vilcabamba-Pp 3+000-4+000Raul PomaNo ratings yet

- B014 0 Soporte de Losa Cisterna Nivel 8.89Document1 pageB014 0 Soporte de Losa Cisterna Nivel 8.89莱欧No ratings yet

- B014 B Soporte de Losa Cisterna Nivel 8.89Document1 pageB014 B Soporte de Losa Cisterna Nivel 8.89莱欧No ratings yet

- 12-Post Tension (PT) SlabDocument20 pages12-Post Tension (PT) Slabmohd.riyazuddin SiddiqueNo ratings yet

- Longitudinal Section On XX: Vagu FlowDocument1 pageLongitudinal Section On XX: Vagu Flowtheekshika.infra.consultantsNo ratings yet

- Section X-X Section Y-Y: Typical Plan of Proposed Construction of Tower Wagon Shed (8-WHEELER)Document1 pageSection X-X Section Y-Y: Typical Plan of Proposed Construction of Tower Wagon Shed (8-WHEELER)Manoj H MNo ratings yet

- L&T Construction: Typical Grade Slab DetailDocument1 pageL&T Construction: Typical Grade Slab DetailPowerhouse ShaftNo ratings yet

- Notes: Epc Contract For Tyra Redevelopment Project - WHRPDocument1 pageNotes: Epc Contract For Tyra Redevelopment Project - WHRPaung aungNo ratings yet

- Cad Floor Plan-A2Document1 pageCad Floor Plan-A2raymond erasmoNo ratings yet

- Ciclotron Pop Line 350hDocument1 pageCiclotron Pop Line 350hLuis FerreiraNo ratings yet

- Golsta - Southland Abidjan - Shop DWG LatestDocument47 pagesGolsta - Southland Abidjan - Shop DWG LatestSouleymane KoneNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Gabriel PulidoNo ratings yet

- 21760329-E501-PS000-0405-00Document1 page21760329-E501-PS000-0405-00ataraxia57No ratings yet

- BEAM DETAILING For G+2 Comercial BuildingDocument1 pageBEAM DETAILING For G+2 Comercial BuildingAkib KhanNo ratings yet

- Shop Drawing Air Kotor, Air Bekas, Vent R5 Denah 27052024-Layout1Document1 pageShop Drawing Air Kotor, Air Bekas, Vent R5 Denah 27052024-Layout1bhuanamargaNo ratings yet

- A-2 Enlarge Plan & SectionDocument1 pageA-2 Enlarge Plan & SectionarjayymerleNo ratings yet

- WWTF Plan Key Plan: M.H. M.HDocument1 pageWWTF Plan Key Plan: M.H. M.HGwen BautistaNo ratings yet

- NP p1b Teth DWG Civ 0112.01.ifr RNCDocument6 pagesNP p1b Teth DWG Civ 0112.01.ifr RNCSipaseut OudomsoukNo ratings yet

- Maddy 4Document1 pageMaddy 4madhuvanthis21No ratings yet

- Front Elevation Section Thru A-A Section Thru B-BDocument1 pageFront Elevation Section Thru A-A Section Thru B-BNathaniel DreuNo ratings yet

- ID-002 GROUND FLOOR SETTING OUT LAYOUT-ModelDocument1 pageID-002 GROUND FLOOR SETTING OUT LAYOUT-ModelAamerNo ratings yet

- JCM8002203 StockDocument1 pageJCM8002203 StockSergio RiveroNo ratings yet

- Hoisting Hook Detail: Elevator PlanDocument1 pageHoisting Hook Detail: Elevator Planywb ecsNo ratings yet

- R.C Wall-Drainage Around New Canteen Building at TWK-DetailsDocument2 pagesR.C Wall-Drainage Around New Canteen Building at TWK-DetailsmohammedNo ratings yet

- F003 76-10526-Detail DesignDocument1 pageF003 76-10526-Detail DesignMazen IsmailNo ratings yet

- LOTO Drawing PPB FIlterDocument1 pageLOTO Drawing PPB FIlterWibisono SternNo ratings yet

- SD Ec CGC ST 233 Rev0Document1 pageSD Ec CGC ST 233 Rev0Ahmed Salah El DinNo ratings yet

- Title: Dual Hot Air Soldering Station 898D: Alex BaruthDocument1 pageTitle: Dual Hot Air Soldering Station 898D: Alex BaruthJaricsa Bernaola100% (1)

- 3Document1 page3SM ConsultantsNo ratings yet

- Ms DD 4850 Civ DWG 0403 - Rev0Document1 pageMs DD 4850 Civ DWG 0403 - Rev0Dita Ardi NNo ratings yet

- RTPP CHP WT CVL 003 R1Document2 pagesRTPP CHP WT CVL 003 R1Sripara KrishnaNo ratings yet

- RP Wme ST TWR1 00 440 01Document1 pageRP Wme ST TWR1 00 440 01gautam kumar PODDARNo ratings yet

- Extension of Southern Expressway Project Section 1 4+000 To 6+250 SectionDocument1 pageExtension of Southern Expressway Project Section 1 4+000 To 6+250 SectionsathiyanNo ratings yet

- Plumbing and Electrical CompilationDocument8 pagesPlumbing and Electrical CompilationEDRICK ESPARRAGUERRANo ratings yet

- Mat Footing 1 - (Mf1) : Reset 1 D 0 0 1 EL STDocument1 pageMat Footing 1 - (Mf1) : Reset 1 D 0 0 1 EL STdawitgggNo ratings yet

- Customer Approval - Corrision Proof Breaker Box No. 9-10Document7 pagesCustomer Approval - Corrision Proof Breaker Box No. 9-10Sales1 mpicaNo ratings yet

- 0403bon N WM Qp02 Ci DRD 0001 b01 Battery LimitsDocument6 pages0403bon N WM Qp02 Ci DRD 0001 b01 Battery LimitsNaji RaheemNo ratings yet

- 089 - Pagar Depan SignedDocument5 pages089 - Pagar Depan Signedhansen 97No ratings yet

- Plumbing 01Document1 pagePlumbing 01Laina CabutajeNo ratings yet

- NOVA Support Staff ReidencesDocument6 pagesNOVA Support Staff ReidencesSolidr ArchitectsNo ratings yet

- Genset RM (Pit)Document1 pageGenset RM (Pit)Julius Dean DumaguingNo ratings yet

- Design Brief Report Amaravati Tourism Projects Ltd. at NidamanuruDocument111 pagesDesign Brief Report Amaravati Tourism Projects Ltd. at NidamanuruYaswanthGorantlaNo ratings yet

- Frameless BrochureDocument12 pagesFrameless BrochureLucian CiprianNo ratings yet

- IDE Lec8 Canal LiningDocument65 pagesIDE Lec8 Canal LiningFortiter FysproNo ratings yet

- Cost ComparisonDocument62 pagesCost ComparisonRhobbie NolloraNo ratings yet

- IRC and Morth Catalogue JAN 2021Document14 pagesIRC and Morth Catalogue JAN 2021rohit0% (1)

- Water Heaters - Storage TanksDocument16 pagesWater Heaters - Storage TanksRebecca TerryNo ratings yet

- CII Sohrabji Godrej Green Business CentreDocument3 pagesCII Sohrabji Godrej Green Business CentrePooja Parekh0% (1)

- Tentative Civil Work Schedule For 8760-8708 Layla FalajDocument5 pagesTentative Civil Work Schedule For 8760-8708 Layla FalajEngr Muhammad Azam ThaheemNo ratings yet

- Double Lock DL15Document2 pagesDouble Lock DL15Cathy PrikhodkoNo ratings yet

- Concrete Admixtures: For Durable & Sustainable ConstructionDocument11 pagesConcrete Admixtures: For Durable & Sustainable ConstructionShridhar VaidyaNo ratings yet

- +vernacular Terms PDFDocument3 pages+vernacular Terms PDFCyril Joy NagrampaNo ratings yet

- TOR Steel and TMT BarsDocument1 pageTOR Steel and TMT Barsramyap959862100% (1)

- Review of HVAC Systems History and Future ApplicatDocument15 pagesReview of HVAC Systems History and Future Applicatarie crespoNo ratings yet

- Chiller Plant DesignDocument48 pagesChiller Plant Designryxor-mrbl100% (1)

- System Series - 04 Ice Storage System PDFDocument121 pagesSystem Series - 04 Ice Storage System PDFpal_stephenNo ratings yet

- Selection of Roofing and Wall MaterialsDocument3 pagesSelection of Roofing and Wall MaterialsSaket Pandey100% (1)

- Sample Letter For TenderDocument3 pagesSample Letter For TenderVicwil ATLNo ratings yet

- Analisa Teknis: A. Borring Machine RT3 STDocument11 pagesAnalisa Teknis: A. Borring Machine RT3 STThor ThorNo ratings yet

- 2 Straight Line Diag.Document1 page2 Straight Line Diag.Nix GabrielNo ratings yet

- Cidco Rate ListDocument1 pageCidco Rate ListKuldeep ChakerwartiNo ratings yet

- 05-17 QCS 2014Document8 pages05-17 QCS 2014Raja Ahmed Hassan100% (2)

- 2-Storey Residential HouseDocument49 pages2-Storey Residential HouseAngel Joy NicolasNo ratings yet

- Prinston Smart Engineers InternshipDocument33 pagesPrinston Smart Engineers InternshipCalvin bNo ratings yet

- Basics of Building ConstructionDocument5 pagesBasics of Building ConstructionSirimilla Mehar100% (1)

- (KG/M) (WM °C) / (Kcal H M °C) : Pipe InsulationDocument3 pages(KG/M) (WM °C) / (Kcal H M °C) : Pipe InsulationZaid Al RayesNo ratings yet

- CATALOGO EXATECH 2021-Ok BDocument106 pagesCATALOGO EXATECH 2021-Ok BJuan David OlayaNo ratings yet

- Alsina Catalogue Alumecano EnglishDocument3 pagesAlsina Catalogue Alumecano Englishdep_vinNo ratings yet

- Manual (Aitech) : ON Accreditation of Innovative Technologies For HousingDocument48 pagesManual (Aitech) : ON Accreditation of Innovative Technologies For HousingJohn Ray Esmama CalasicasNo ratings yet