S-1 General Notes

S-1 General Notes

Uploaded by

Engr. Robnick PaduaCopyright:

Available Formats

S-1 General Notes

S-1 General Notes

Uploaded by

Engr. Robnick PaduaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

S-1 General Notes

S-1 General Notes

Uploaded by

Engr. Robnick PaduaCopyright:

Available Formats

GENERAL :

A. MATERIALS AND WORKMANSHIP SHALL CONFORM WITH THE

REQUIREMENTS OF THE FOLLOWING BUILDING CODES.

1. ACI 318 - 14

2. ASEP SEISMIC DESIGN GUIDE

CONSTRUCTION NOTES

3. NSCP - 2015 EDITION

4. UBC 1997 STRUCTURAL STEEL :

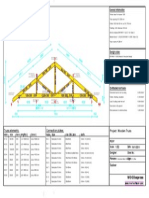

BEAM

B. ALL DRAWINGS SHALL NOT BE SCALED FOR CONSTRUCTION lb1 lb2

PURPOSES UNLESS OTHERWISE INDICATED. 1. ALL STUCTURAL STEEL SHALL CONFORM TO ASTM A-36. SEE NOTE A SEE NOTE A

5-10MMØ BARS 150MM

BAR SPACES DIA.

C. FOR ALL OTHER REQUIREMENTS , REFER TO ARCHITECTURAL , SPACED AT 200 MM O.C.

SANITARY , ELECTRICAL AND MECHANICAL WORKING DRAWINGS.

2. WELDING SHALL CONFORM TO AWS STANDARDS. 1 2

NOT LESS THAN

20MM

3. FABRICATOR SHALL SUBMIT SHOP DRAWINGS FOR APPROVAL BY LAPS SEE

100MM

50MM

FOOTINGS : CALCULATED BOND

LENGTH BUT

NOTE E

30Ø OR 600MM

1. FOOTINGS ARE DESIGNED TO REST ON FIRM SUBGRADE

WITH MINIMUM BEARING CAPACITY OF 3, 000 psf THE ENGINEER AND THE OWNER.

2. NO FOOTING SHALL REST ON FILL. 2h 2h 5-10MMØ BARS

SPACED AT 200 MM O.C.

3. MINIMUM CONCRETE PROTECTION FOR REINFORCEMENT SHALL NO LAPS ZONE

1

SEE NOTES

D,F&G 2 SEE NOTE D FOR ALL TYPICAL SLAB DEPRESSION DETAIL

BE 70 MM CLEAR FOR CONCRETE DEPOSITED AGAINST THE SEE NOTE D MINIMUM STEEL LAPS CALCULATED

SEE NOTE B LAP LENGTH

FORMWORK. BUT 300MM

40MM CLEAR

DISTANCE (MINIMUM)

END SPAN INTERNAL

CONCRETE MIXES & PLACINGS : DETAIL - 3 SUPPORT SUPPORT

1. UNLESS OTHERWISE SPECIFIED , THE MINIMUM 28-DAY CYLINDER h 500MM

40MM CLEAR DIST.

10

40MM CLEAR

00

COMPRESSIVE STRENGTH ARE AS FOLLOWS : (MINIMUM) FOR DISTANCE (MINIMUM)

FOOTINGS AND BEAMS ON GRADE 3, 000 psi

BEAMS & GIRDERS

SEE NOTE - A SEE NOTE - A 10 A. CURTAILMENT OF TOP BARS TO BE TENSION BOND LENGTH BEYOND THE POINT OF

TRIMMERS MAY BE 00

COLUMNS 3, 000 psi DETAIL - 1 OMITTED WHERE CONTRAFLEXURE BUT NOT LESS THAN lb/4 FROM SUPPORT , IF SOME BARS ARE 50MM

OPENING IS FRAMED

SLABS , BEAMS AND GIRDERS 3, 000 psi BY BEAMS CURTAILED AT SHORTER DISTANCES AT LEAST A THIRD OF TOTAL STEEL MUST

BEARING AND RETAINING WALLS 3, 000 psi EXTEND THIS DISTANCE.

C h

BEDDED SLABS , CATCH BASINS AND SIDEWALK 2,500 psi

2. ALL CONCRETE MUST BE DEPOSITED , VIBRATED AND CORED IN 2-16MMØ AT MINIMUM 1-16MMØ

B. THE AREA OF BOTTOM OF STEEL PROVIDED AT THE SUPPORTS MUST EQUAL AT

TYPICAL BEAM-COLUMN EACH CORNER

ACCORDANCE WITH ACI STANDARD 318-89. INTERCONNECTION

TOP & BOTTOM FOR LEAST HALF THE AREA OF THE TOP STEEL AT THAT SECTION.

NOTE : SLABS 125MM THK.

AND OVER

50MM

3. STRIPPING FORMS AND SHORES SHALL BE AS FOLLOWS : A. STIRRUP SPACING IN PLASTIC HINGE ZONE OF LENGTH 2h OPENING C. A MIN. OF 1/4 OF THE LARGER AMOUNT OF TOP STEEL REQUIRED AT EITHER END 500MM 10MMØ TIES AT 150MM O.C.

FOUNDATION 1 DAY SHALL BE THE LEAST OF ; 1. D/4 2. 6Ø 3. 150MM. HOOK SLAB MUST CONTINUE FOR THE WHOLE LENGTH OF THE SPAN.

EXTENDED TRIMMER BAR

COLUMNS & WALLS 3 DAYS B. Ø = DIAMETER OF MAIN LONGITUDINAL BAR FOR DISTANCE REINFORCEMENT 1000MM BEYOND SIDES

OVER TRIMMER BAR OF OPENING OR AS FAR

BEAMS & GIRDERS 21 DAYS D. NO LAPS IN TOP & BOTTOM TO OCCUR WITHIN A DISTANCE OF 2h FROM FACE OF

UNDER CONSIDERATION IN TOP OR BOTTOM WHICHEVER IS AS POSSIBLE & HOOK.

SLABS 17 DAYS SUPPORT .

SMALLER.

4. CONCRETE SHALL BE DEPOSITED IN ITS FINAL POSITION WITHOUT

SEGREGATION RE-HANDLING OR FLOWING. PLACING SHALL BE

C. THIS STIRRUP SPACING CONTINUES WITHIN THE INTERMEDIATE E. LAPS ARE TO BE KEPT TO A MINIMUM AND CRANKS IF REQUIRED TO BE AS FOR TYP. BEAM DEPRESSION DETAIL

DONE PREFERABLY WITH BUGGIES , BUCKET OR WHEELBARROWS. ZONE. COLUMNS.

NO CHUTES WILL BE ALLOWED EXCEPT TO TRANSFER CONCRETE SCHEDULE - 1 PROVIDE EXTRA BAR

(NOT SHOWN) PARALLEL 1000

FROM HOPPERS TO BUGGIES , WHEELBARROWS OR BUCKETS IN TO SIDES OF EQUAL AREA F. IF h > 750MM PROVIDE EXTRA LONGITUDINAL BARS FOR 2/3 OF THE BEAM DEPTH

OF INTERRUPTED SLAB

WHICH CASE THEY SHALL NOT EXCEED SIX (6.0) IN METER IN CONCRETE HOLLOW BLOCK REINFORCEMENT REINFORCEMENT LESS FROM THE TENSION FACE WITH SPACING > 250MM.

AGGREGATE LENGHT. NO DEPOSITING OF CONCRETE SHALL BE BLOCK REINFORCEMENT NOTES AREA TRIMMER BARS.

ALLOWED WITHOUT THE USE OF VIBRATORS. UNLESS AUTHORIZED THICK HORIZONTAL VERTICAL A. MINIMUM SPLICE AT LAP = 300MM

G. LAPS IN FRAMING BARS TO BE STAGGERED RELATIVE TO LAPS IN MAIN TOP AND

B. PROVIDE RIGHT ANGLE REINF. t

75 MM 10MM AT 600MM O.C. 10MM AT 600MM O.C. DETAIL - 4

IN WRITING BY THE DESIGNERS AND ONLY FOR USUAL CONDITIONS 100MM 10MM AT 600MM O.C. 10MM AT 600MM O.C.

AT CORNERS 1000MM LONG.

C. WHERE CHB WALLS ADJOINING COLS.

BOTTOM BARS.

WHERE VIBRATORS IS EXTREMELY DIFFICULT TO ACCOMPLISH. R.C. BEAMS. WALL DOWELS W/ SAME b b ANCHORAGE OUTSIDE

150MM 12MM AT 600MM O.C. 12MM AT 600MM O.C. PANEL ZONE PQRS

SIZE AS VERT. REINF. SHALL BE

200MM

BEAMS AND GIRDERS : 12MM AT 600MM O.C. 12MM AT 600MM O.C. PROVIDED.

P Q TYP. SLAB CONSTRUCTION JOINT

1. CAMBER ALL BEAMS AND GIRDERS AT LEAST 6.50 MM FOR EVERY

3.0 M. OF SPAN. SCHEDULE - 2

h

2. FOR TWO OR MORE LAYERS OF REINFORCING BARS USE SEPARATORS

WALL REINFORCEMENT VERTICAL

SPACED AT 1.0 M. O.C. AND IN NO CASE SHALL BE LESS THAN REMARKS

THK. HORIZONTAL VERTICAL SECTION S R

TWO (2) SEPARATORS. 10MM AT 250MM O.C. 10MM AT 300MM O.C.

HORIZONTAL & CENTER VERTICAL 1-1 2-2

100MM BARS STAGGERED OUTSIDE.

125MM 10MM AT 250MM O.C. 10MM AT 250MM O.C. - DO -

3. NO SPLICE SHALL BE PERMITTED ON BEAMS AND GIRDERS WHERE BOTH FACES HORIZONTAL BEAMS FORMING PART OF A ALTERNATIVE PREFERRED b

150MM 12MM AT 250MM O.C. 12MM AT 300MM O.C

CRITICAL BENDING STRESSES IS OCCUR. TENSION SPLICE SO PERMI-

SHALL BE INSIDE.

DUCTILE MOMENT RESISTING END SUPPORT DETAIL

175MM 12MM AT 200MM O.C. 12MM AT 250MM O.C. - DO -

TTED SHALL BE 60 DIAMETER FOR PLAIN BARS AND 40 DIAMETER 200MM 12MM AT 300MM O.C. E.F. 12MM AT 300MM O.C. BOTH FACES HORIZONTAL FRAMEWORK

SHALL BE OUTSIDE.

12Ø

FOR DEFORMED BARS. 225MM 12MM AT 200MM O.C. E.F. 12MM AT 250MM O.C. E.F. - DO -

COMPRESSION SPLICE SHALL BE 40 DIAMETERS FOR PLAIN BARS

AND 30 DIAMETERS FOR DEFORMED BARS. LAP SPLICES SHALL BE

250MM

275MM

300MM

12MM AT 300MM O.C. E.F.

12MM AT 250MM O.C. E.F.

12MM AT 200MM O.C. E.F.

12MM AT 300MM O.C. E.F.

12MM AT 300MM O.C. E.F.

12MM AT 275MM O.C. E.F.

- DO -

- DO -

- DO -

CONCRETE COLUMNS : PLAN

CONF'T

WIRED TOGETHER UNLESS OTHERWISE SPECIFIED. TOP BARS AT MID-

ZONE

L1

325MM 12MM AT 200MM O.C. E.F. 12MM AT 250MM O.C. E.F. - DO -

SPAN , BOTTOM BARS AT SUPPORT , BEND BARS AT BED POINTS IN

SUPERSTRUCTURE. WELDED SPLICES SHALL DEVELOP IN TENSION AT

350MM 16MM AT 250MM O.C. E.F. 12MM AT 300MM O.C. E.F. - DO -

A. Li = LARGEST OF :

LEAST 125% OF THE SPECIFIED YIELD STRENGTH OF THE BAR. NOT 1. h (h>b)

INTERMEDIATE ZONE

MORE THAN 50% OF THE BARS AT ANY ONE SECTION SHALL BE

PERMITTED TO BE SPLICED.

200

1

200 2. Lo/6 1000MM

Lo

LINTEL BEAM STIFFENER

4. IF BEAM REINFORCING BARS END IN A WALL THE CLEAR DISTANCE

COLUMN

1 1

3. 450 MM

FROM THE BAR TO THE FARTHER FACE OF THE WALL SHALL NOT B. FOR COLUMNS REQUIRING SPECIAL CONFINEMENT STEEL.

BE LESS THAN 50 MM EMBEDMENT LENGTH SHALL BE 40 DIAMETER Shi = SPACING OF ALL CONFINEMENT ZONE USING A

CONF'T

FOR TENSION AND 20 DIAMETER FOR COMPRESSION BARS.

ZONE

L1

MAXIMUM SPACING OS 0.20 b , 6Ø OR 200MM. h

5. MINIMUM CONCRETE PROTECTION OF REINFORCING BARS OR SHAPES

CONNECTION

THE AREA OF CONFINEMENT LINKS SHOULD BE DE-

SEE NOTE

BEAM-COL

SHALL BE AS SHOWN ON DETAIL-1.

D&E

6. UNLESS OTHERWISE NOTED IN PLANS OR SPECIFICATIONS , CAMBER

TERMINED.

Sh1/2

1 - 16MMØ

SEE NOTE

C. Sh : = SPACING FOR ALL LINKS & TIES IN INTERMEDIATE 10MMØ TIES 2-12MMØ ON

CONF'T

ALL BEAMS AND GIRDERS AT LEAST 6.5 MM FOR EVERY 3.0 M OF

ZONE

VERTICAL BAR

L1

B&C

AT 150MM O.C. BOTH SIDES

(TYPICAL)

SPAN EXCEPT CANTILEVERS FOR WHICH THE CAMBERS SHALL BE AS

NOTED IN PLANS OR AS ORDERED BY THE DESIGNER , BUT IN CASE

ZONE. SPACING TO BE THE LEAST OF :

SECTION

INTERMEDIATE ZONE

LESS THAN 7.5 MM FOR EVERY 3.0 M OF FREE SPAN. 1. 12Ø

SEE NOTE C

Lo

2. 400MM

Sh2 LAP SEE

NOTE F

CONCRETE SLABS : TYPICAL BEAM CONSTRUCTION JOINT

3. 0.40b

1. ALL REINFORCEMENT SHALL BE 20 MM CLEAR MINIMUM FROM TOP AND

0.2 Sh1

Ø = DIAMETER OF SMALLEST LONGITUDINAL BAR

CONF'T

ZONE

BOTTOM OF SLAB.

L1

2. FOR TWO-WAY SLAB BARS ALONG SHORTER SPAN SHALL BE PLACED IN COLUMN.

Sh

100-150MMØ PIPE

BELOW THOSE ALONG THE LONGER SPAN AT CENTER AND OVER THE D. SPACING AND TOTAL CROSS-SECTIONAL AREA OF HOOPS

LONGER SPAN BARS NEAR THE SUPPORT. UNLESS OTHERWISE INDICA- ELEVATION ELEVATION

b

TED OR SHOWN IN DETAILS THE SPACING OF THE BARS AT THE a

& TIES THROUGH THE BEAM COLUMN CONNECTION

COLUMN STRIPS CAN BE APPROXIMATELY 1-1/3 TIMES OF THE MIDDLE CHB WALL

STRIP BUT IN NO CASE GREATER THAN 2-1/3 TIMES THE SLAB THICK-

(OR ANY OTHER CONNECTING MEMBER). h

SUPPLEMENTARY

NESS. 300MM DOWEL(SAME DIAMETER

CROSS TIES (SEE

NOTE H)

E. ALL HOOP ARRANGEMENTS MUST ALSO BE CAPABLE

AS CHB VERTICAL REINF.)

3. UNLESS OTHERWISE DETAILED IN CONTINOUS SLABS HAVING SAME REIN- 300MM h

OF RESISTING THE APPLIED SHEARS THROUGHOUT

b

HOOPS 12MMØ ON

FORCEMENT RUNNING IN ONE DIRECTION REINFORCING SHALL BE BENDED

2-12MMØ TOP BAR b/a > 10 THE WHOLE COLUMN LENGTH INCLUDING THE BEAM BOTH SIDES

150MM

EXTENDED OR CUT AS SHOWN ON THE SCHEDULE OF SLABS 1000MM

100MM

b > 300MM

20MM

4. TEMPERATURE BARS SHALL BE GENERALLY PLACED NEAR THE TENSION

10MMØ, 1 AT 50

REST AT 250MM O.C.

1-1 COLUMN CONNECTION ZONE.

FACE AND SHALL NOT BE LESS THAN 0.0025 BT. BARS : 6-12MMØ BARS : 3-12MMØ

2-12MMØ BOTTOM BAR CRANK DETAIL F. IN MEDIUM AND HIGH RISK EARTHQUAKE ZONES NOTE :

TIES : 10Ø, 1 AT 50 TIES : 10Ø, 1 AT 50

5. UNLESS OTHERWISE NOTED ALL BEDDED SLABS SHALL REINFORCED WITH 3 AT 100, 3 AT 150

REST AT 250MM

3 AT 100, 3 AT 150

REST AT 250MM

135° (Ø) SPLICES SHOULD BE MADE OUTSIDE OF PLASTIC A. CONDUITS , PIPES & SLEEVES PASSING THROUGH

6Ø

10MMØ AT 400MMØ O.C. E.W. AT CENTER OF SLAB CONSTRUCTION

JOINTS FOR SAME SHALL NOT BE MORE THAN 3.0 M APART.

SECTION - 1 HINGE ZONES AND ARE TO BE LARGER OF : A SLAB , WALL OR BEAM SHALL NOT IMPAIR

SIGNIFICANTLY THE STRENGTH OF THE CONSTRUC-

STIFFENER COLUMN STIFFENER COLUMN 1. CALCULATED BOND LENGTH

6. PROVIDE EXTRA REINFORCEMENT AT CORNER SLABS (TWO ADJACENT FOR 6" CHB FOR 4" CHB ØM

r = 2ØM (MILD STEEL)

4ØM (HT. STEEL)

TION.

DISCONTINOUS EDGE ) AS SHOWN ON DETAIL-3. 2. 30Ø , FOR Fy = 415 MPa

B. THEY SHALL NOT BE PLACED CLOSER THAN 3 DIA-

7. PROVIDE SUPPLEMENTARY REINFORCEMENT AT SMALL UNFRAMED OPENING TYPICAL DETAIL OF LINTEL BEAM AND STIFFENER COLUMN DETAIL OF HOOP AND 3. 20Ø , FOR Fy = 275 MPa METER OR WIDTHS ON CENTER.

IN FLOOR SLABS AS SHOWN ON DETAIL-4. TIE ANCHORAGE DIMENSIONS

I. DIAMETER OF HOOPS AND CROSS - TIES :

CONCRETE HOLLOW BLOCKS : MILD STEEL REINFORCEMENT : DETAIL - 5

6MM , IF ØM < 20MM

REINFORCEMENT AS TABULATED IN SCHEDULE SHALL BE PROVIDED UNLESS 1. ALL MILD STEEL REINFORCEMENT SHALL CONFORM TO ASTM A-1562 -2T 10MM , IF 20MM <ØM<28MM TYPICAL PIPE SLEEVE DETAIL

OTHERWISE SPECIFIED IN THE PLAN . SEE SCHEDULE -1. AND DEFORMATIONS TO A-305-56 OR LATEST REVISIONS.

2. DEVELOPMENT LENGTH FOR ALL BARS SHALL BE A MINIMUM OF 40 BARS 12MM , IF ØM>28MM

CONCRETE WALLS : DIAMETERS UNLESS OTHERWISE SPECIFIED. ØM = THE DIAMETER OF LONGITUDINAL BAR.

UNLESS OTHERWISE INDICATED IN THE PLANS , WALL REINFORCEMENT SHALL SEE DETAIL - 5.

BE FOLLOWED AS TABULATED IN SCHEDULE -2. SEE SCHEDULE -2.

FOR PERMIT

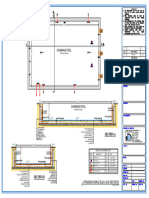

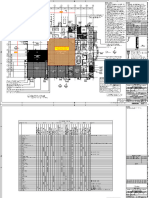

ARCHITECT: ENGINEER: PROJECT NAME: CLIENT NAME: SHEET CONTENTS: SHEET NO:

CONSTRUCTION NOTES

Proposed 3-Storey Residence w/ Deck & 2-Storey

DEBBIE ANN S. LUA JEFFERSON M. VILLARAZA

Multipurpose Bldg.

Mr. Kirk Chester Dy S-1

ARCHITECT ENGINEER

NOTE: ANY DISCREPANCIES ON ALL DRAWINGS OR

PRC: 0022594 DATE: Feb. 08, 2022 PRC: 118310 DATE: Jan. 07, 2022 Location: Dorotea St, Quezon City RA 545: THIS DRAWING AS AN INSTRUMENT OF SERVICE IS THE PROPERTY OF THE DESIGNER DRAWN BY: CHECKED BY: DATE: SPECIFICATIONS SHALL BE VERIFIED WITH THE

ARCHITECT PRIOR TO IMPLEMENTATION.

AND AS SUCH MUST NOT BE REPRODUCED IN PART OR WHOLE WITHOUT CONSENT.

PTR: 1580136 PLACE: San Juan City, Manila PTR: 9036680 PLACE: Marikina City

You might also like

- Nirmal Asangaon Plot 8-9-Dbr 260219Document7 pagesNirmal Asangaon Plot 8-9-Dbr 260219Titus PraveenNo ratings yet

- Metro Tech - Chennai: Preliminary Structural Design Brief ReportDocument26 pagesMetro Tech - Chennai: Preliminary Structural Design Brief Reportmathu100% (1)

- Batching Plant Architectural DrawingDocument1 pageBatching Plant Architectural DrawingTaposh Paul100% (1)

- KP Parts Overview Jan 2020Document94 pagesKP Parts Overview Jan 2020ANTONIO GUTIERREZ MIRANDANo ratings yet

- E-Commerce Project PDFDocument106 pagesE-Commerce Project PDFDhiraj Ahuja83% (6)

- General Construction NotesDocument1 pageGeneral Construction NoteschrisNo ratings yet

- TH-50-BLOCK 1 - STR - Drawings PDFDocument16 pagesTH-50-BLOCK 1 - STR - Drawings PDFSales ConstructionNo ratings yet

- Wood Truss DetailDocument1 pageWood Truss Detailseagull70No ratings yet

- PT Slab 240Mm Thick: First Floor Roof Framing LayoutDocument1 pagePT Slab 240Mm Thick: First Floor Roof Framing LayoutPrem saiNo ratings yet

- R1 Cheruthony Truss 4 - 4Document1 pageR1 Cheruthony Truss 4 - 4Anujith K BabuNo ratings yet

- Rev - Foundation PlanDocument1 pageRev - Foundation PlanVarun TyagiNo ratings yet

- Bar Bending Schedule For Office BuildingDocument26 pagesBar Bending Schedule For Office BuildingSurendra MaharjanNo ratings yet

- A1.24a Reflected Ceiling Plan West Level 4 Rev.4Document1 pageA1.24a Reflected Ceiling Plan West Level 4 Rev.4Miguel CasianoNo ratings yet

- Place:-Petrochemical Building Conference Hall Date Agenda: - School of Design Building Time Chair Person: - Attendees: - DesignationDocument2 pagesPlace:-Petrochemical Building Conference Hall Date Agenda: - School of Design Building Time Chair Person: - Attendees: - DesignationRushi KadgaonkarNo ratings yet

- StripDocument18 pagesStripRoshan KejariwalNo ratings yet

- Rate Book - 2011-NCP Building DPTDocument244 pagesRate Book - 2011-NCP Building DPTthak_raj84No ratings yet

- Drawing DetailsDocument1 pageDrawing DetailssuliamnNo ratings yet

- Foundation Design by Using AfesDocument31 pagesFoundation Design by Using AfesSardimalAmirNo ratings yet

- KPF P 577 SD Mep Rev05 PL 01Document1 pageKPF P 577 SD Mep Rev05 PL 01Ibrahim AliNo ratings yet

- Basement WallDocument6 pagesBasement WallNikhil KumbharNo ratings yet

- Standard DetailsDocument14 pagesStandard DetailsGayan IndunilNo ratings yet

- Client:: Structural Analysis and Design Report MontessoriDocument33 pagesClient:: Structural Analysis and Design Report MontessoriRoshan KejariwalNo ratings yet

- Sid - TG1 BW Asgc P01 PRW LG PL ST 455279Document1 pageSid - TG1 BW Asgc P01 PRW LG PL ST 455279muhammad bilalNo ratings yet

- Steel Structure Catalogue - 2Document42 pagesSteel Structure Catalogue - 2Makenson Muscadin100% (1)

- Swimming Pool Structural - Sample at AbuDhabiDocument1 pageSwimming Pool Structural - Sample at AbuDhabirajpsemacNo ratings yet

- RM Dammam Port - PDF DrawingsDocument48 pagesRM Dammam Port - PDF DrawingsKhawaja Kashif QadeerNo ratings yet

- Designs CatalogDocument77 pagesDesigns CatalogGen MendozaNo ratings yet

- OPC Mix Design (Sample)Document20 pagesOPC Mix Design (Sample)satish yadavNo ratings yet

- Midlanding: +2100 LVL 181716151413121110 R 150mm. T 300mmDocument1 pageMidlanding: +2100 LVL 181716151413121110 R 150mm. T 300mmyash ayreNo ratings yet

- Boys Toilet: W.C 1000x1600 W.C 1000x1600 W.C 1000x1600 W.C 1000x1600Document1 pageBoys Toilet: W.C 1000x1600 W.C 1000x1600 W.C 1000x1600 W.C 1000x1600yash ayreNo ratings yet

- Gate HouseDocument1 pageGate HouseJoseph Mwangi WambuguNo ratings yet

- Consultant Architect: Project: Head Office: Client:: Shahid Yousuf PartnersDocument21 pagesConsultant Architect: Project: Head Office: Client:: Shahid Yousuf Partnersrameez khanNo ratings yet

- Design of Multi-Storeyed Residential BuildingDocument72 pagesDesign of Multi-Storeyed Residential BuildingHelo100% (1)

- Ghana Building GuideDocument84 pagesGhana Building GuideDaniel ReynoldsNo ratings yet

- Session 4 - Structural Design CriteriaDocument34 pagesSession 4 - Structural Design CriteriaEdeline AnsayNo ratings yet

- StructuralDocument15 pagesStructuralMAher AbbasNo ratings yet

- An Example Problem On Wind Load Calculation According To NSCP 2010Document2 pagesAn Example Problem On Wind Load Calculation According To NSCP 2010JapoyNo ratings yet

- DeflectionDocument22 pagesDeflectionrobertantoreniNo ratings yet

- General Note SampleDocument13 pagesGeneral Note SampleShyam AwalNo ratings yet

- Shed Struc DrawingsDocument7 pagesShed Struc Drawingsfinddict0% (1)

- Torsion Irregularity Check UBC 97-1630.7 Story Load Case/Combo Label UX Drif Label UX Drif Max DrifDocument2 pagesTorsion Irregularity Check UBC 97-1630.7 Story Load Case/Combo Label UX Drif Label UX Drif Max DrifOmer HayatNo ratings yet

- Steel Design Project 2023Document18 pagesSteel Design Project 2023NUR ATIKAH BINTI ABD AZIZ / UPMNo ratings yet

- 2021 09 20 Garden Mall-A10.02-Typical Details-Sections Wall-Acoustic CeilingDocument1 page2021 09 20 Garden Mall-A10.02-Typical Details-Sections Wall-Acoustic CeilingDan SarmientoNo ratings yet

- Framing PlanDocument1 pageFraming PlanKing RickNo ratings yet

- Terrace (RCC Slab) +9150 SSL: General NotesDocument1 pageTerrace (RCC Slab) +9150 SSL: General Notescheligp1981No ratings yet

- Table For Rebars Areas & Spacings Table 1 - by CalculationDocument1 pageTable For Rebars Areas & Spacings Table 1 - by CalculationZarinaKhalidNo ratings yet

- Kns5 Axially Loaded FTNG DSNDocument23 pagesKns5 Axially Loaded FTNG DSNKanaiyalal N. ShethNo ratings yet

- 2 - Design of BeamsDocument5 pages2 - Design of BeamsheheNo ratings yet

- Metro Proj - 12 MTR Span-1Document3 pagesMetro Proj - 12 MTR Span-1kukadiya127_48673372No ratings yet

- Utsav Door Window Detail PDFDocument1 pageUtsav Door Window Detail PDFSahil AhmedNo ratings yet

- SDRE14-10 SUP 1-15 April 2024Document17 pagesSDRE14-10 SUP 1-15 April 2024SantosoNo ratings yet

- Sohar Mall Strip Footing - 01Document38 pagesSohar Mall Strip Footing - 01MIHDI PALAPUZNo ratings yet

- Footing Rebar Detail - 2Document4 pagesFooting Rebar Detail - 2Makenson MuscadinNo ratings yet

- Jain Ariditha-1Document26 pagesJain Ariditha-1preethiNo ratings yet

- AR1Document1 pageAR1erwin sarmientoNo ratings yet

- FCK Fy B H D D': Grade of Concrete (N/MM) Grade of Reinf Steel (N/MM)Document1 pageFCK Fy B H D D': Grade of Concrete (N/MM) Grade of Reinf Steel (N/MM)Manoj Kumar PalNo ratings yet

- Steel StairDocument6 pagesSteel StairFelippe Niño LusaresNo ratings yet

- Section Z-Z Section X-X: 8T12-150-T1 10T12-150-T1Document1 pageSection Z-Z Section X-X: 8T12-150-T1 10T12-150-T1inno musiimeNo ratings yet

- E0.52 ELECTRICAL SITE PLAN Rev.0Document1 pageE0.52 ELECTRICAL SITE PLAN Rev.0Abdul RahmanNo ratings yet

- T80-B001 - Central Control BuildingDocument10 pagesT80-B001 - Central Control BuildingTayyab AchakzaiNo ratings yet

- t80-R-pp-476402-001 - Rev B Floor Plan Central Control Building (Landscaping)Document1 paget80-R-pp-476402-001 - Rev B Floor Plan Central Control Building (Landscaping)Tayyab AchakzaiNo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Electronics Oct Nov LR PDFDocument207 pagesElectronics Oct Nov LR PDFYakov NoginovNo ratings yet

- Dmc-Lx2Pp Dmc-Lx2Pl Dmc-Lx2Eb Dmc-Lx2Ee Dmc-Lx2Ef Dmc-Lx2Eg Dmc-Lx2Egm Dmc-Lx2Gc Dmc-Lx2Gd Dmc-Lx2Gk Dmc-Lx2Gn Dmc-Lx2Gt Dmc-Lx2SgDocument56 pagesDmc-Lx2Pp Dmc-Lx2Pl Dmc-Lx2Eb Dmc-Lx2Ee Dmc-Lx2Ef Dmc-Lx2Eg Dmc-Lx2Egm Dmc-Lx2Gc Dmc-Lx2Gd Dmc-Lx2Gk Dmc-Lx2Gn Dmc-Lx2Gt Dmc-Lx2SgCarp CatalinNo ratings yet

- Drilling Presentation 2010Document17 pagesDrilling Presentation 2010Mah Cok JitNo ratings yet

- Micro Project Report (English)Document13 pagesMicro Project Report (English)Chaitali KumbharNo ratings yet

- Teodor ICN NetworkingDocument39 pagesTeodor ICN NetworkingMitali BiswasNo ratings yet

- CVP VVB Java Tomcat and Informix Default Versions and Upgrade ProceduresDocument4 pagesCVP VVB Java Tomcat and Informix Default Versions and Upgrade ProceduresEngin KartalNo ratings yet

- Percentage Analysis Method: Gender Wise ClassificationDocument2 pagesPercentage Analysis Method: Gender Wise ClassificationPrince AgustineNo ratings yet

- Data Sheet High Endurance Uhs I MicrosdDocument2 pagesData Sheet High Endurance Uhs I Microsdjoaquin ferNo ratings yet

- Engine Cooling System: SectionDocument85 pagesEngine Cooling System: SectionАндрей НадточийNo ratings yet

- Installation of Mode 'A''c'andmode S' Transponders. D2R-R4Document7 pagesInstallation of Mode 'A''c'andmode S' Transponders. D2R-R4james_008No ratings yet

- Linux Security Research PaperDocument5 pagesLinux Security Research Paperxvrdskrif100% (1)

- PLC DdcmisDocument63 pagesPLC DdcmisNicole LeeNo ratings yet

- Slides Ch4 Disk SchedulingDocument13 pagesSlides Ch4 Disk SchedulingAbuky Ye AmanNo ratings yet

- ECG Circuit Analysis and Design Engineers LabsDocument29 pagesECG Circuit Analysis and Design Engineers LabsDebasish HalderNo ratings yet

- Sonar IntroDocument22 pagesSonar IntroAngga HadiNo ratings yet

- 01 FIDIC Yellow Silver Books 201200613Document96 pages01 FIDIC Yellow Silver Books 201200613Sajjad Hussain100% (1)

- FlexiPacket Hub 800 Customer Release Notes R2.0EP1 PU7 R2.0 - 1.15.0Document21 pagesFlexiPacket Hub 800 Customer Release Notes R2.0EP1 PU7 R2.0 - 1.15.0Ahmed RaadNo ratings yet

- Comparison of Print Media and Electronic MediaDocument3 pagesComparison of Print Media and Electronic MediaROMAR AYUBANNo ratings yet

- Ais VB2K242 23d2acc50701401 C12 N09Document12 pagesAis VB2K242 23d2acc50701401 C12 N09Quỳnh Vy ThúyNo ratings yet

- Manual de Usuario PTZ HiLookDocument101 pagesManual de Usuario PTZ HiLookIvan Alvarado GNo ratings yet

- Brkarc 1008Document130 pagesBrkarc 1008Adilson PedroNo ratings yet

- Productivity+ Software For CNC Machine Tools: PowerfulDocument6 pagesProductivity+ Software For CNC Machine Tools: PowerfulJeffrey CastoNo ratings yet

- 6ES75262BF000AB0 - Datasheet - enDocument3 pages6ES75262BF000AB0 - Datasheet - enchochoroyNo ratings yet

- In System & Service DescriptionDocument20 pagesIn System & Service DescriptionjtobsstktjammuNo ratings yet

- Chalmlite v4Document1 pageChalmlite v4Ongkek SNo ratings yet

- Chicago Pneumatic Air CompressorDocument32 pagesChicago Pneumatic Air CompressorNeeraj gurung100% (2)

- Manual BT 3900 Caixa Portatil PhilipsDocument13 pagesManual BT 3900 Caixa Portatil PhilipsLuis DicaraNo ratings yet