HPU Manual

HPU Manual

Uploaded by

Bintang RizckyCopyright:

Available Formats

HPU Manual

HPU Manual

Uploaded by

Bintang RizckyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

HPU Manual

HPU Manual

Uploaded by

Bintang RizckyCopyright:

Available Formats

Hydraulic Power Units

D, H, V-Pak and Custom Power Units

HY28-2600-550-M1USA June 2021

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Contents D, H, V-Pak and Custom Power Units

Introduction................................................................................................................................................................................... 1

Description.................................................................................................................................................................................... 1

Preparation for Use...................................................................................................................................................................... 2

Installation..................................................................................................................................................................................... 2

Electrical Service Connections................................................................................................................................................... 3

Inverter (DCP) Wiring Information ............................................................................................................................................. 4

Component Location (Typical).................................................................................................................................................... 6

Supply and Return Connections................................................................................................................................................. 7

Reservoir Filling............................................................................................................................................................................ 7

Start-Up Procedure...................................................................................................................................................................... 8

General Maintenance................................................................................................................................................................. 10

D-Pak Parts List.......................................................................................................................................................................... 13

H-Pak Parts List.......................................................................................................................................................................... 15

V-Pak Parts List.......................................................................................................................................................................... 18

V8, Low Profile Parts List...........................................................................................................................................................

V8 Power Units are obsolete as of Oct 2017 21

Troubleshooting.......................................................................................................................................................................... 24

Power Unit Weights.................................................................................................................................................................... 25

Offer of Sale................................................................................................................................................................................ 29

WARNING - USER RESPONSIBILITY

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS

CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors provide product

or system options for further investigation by users having technical expertise. The user, through its own analysis and testing, is solely

responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance,

safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable

industry standards, and follow the information concerning the product in the current product catalog and in any other materials provided

from Parker or its subsidiaries or authorized distributors. To the extent that Parker or its subsidiaries or authorized distributors provide

component or system options based upon data or specifications provided by the user, the user is responsible for determining that such

data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.

WARNING

The products described in this catalog can expose you to chemicals, including Lead, which is known to the State of California to cause cancer and birth defects or

other reproductive harm. For more information go to www.p65warnings.ca.gov.

Offer of Sale

The items described in this document are hereby offered for sale by Parker-Hannifin Corporation, its subsidiaries or its authorized distributor.

This offer and its acceptance are governed by the provisions stated in the detailed “Offer of Sale” elsewhere in this document.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

1

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Introduction D, H, V-Pak and Custom Power Units

Introduction Description

This manual provides descriptive operation and Parker’s standard power units feature a vertical design,

maintenance instructions for standard Hydraulic Power with the pump/motor assembly vertically mounted to the

Units manufactured by the Hydraulic Pump and Power reservoir’s top plate. This minimizes the required floor

Systems Division of Parker Hannifin Corporation. Any space and keeps the pump’s inlet flooded or nearly

additional information may be obtained from Parker by flooded with oil, preventing cavitation. Make sure

referencing the unit’s model number and serial number to match the design series of your unit with the design

stamped on the Reservoir Nameplate, or by contacting series numbers in this manual. If your design series

your local authorized Parker Distributor. doesn’t match the design series numbers shown later

in this manual, consult the factory to verify form, fit and

Some of the information in this manual may not apply function of replacement parts. In the example below, the

to your power unit. Your power unit may include design series is “21”.

non-cataloged equipment or contain additional

components that were added after factory shipment D-Paks and H-Paks use fixed volume gear pumps.

from Parker, in which case this manual will not include V-Paks use variable volume piston pumps and are

information and possible required warnings regarding available with several standard pressure compensation

this additional equipment. options, load sense and horsepower limiting options.

See catalog HY28-2661-CD/US for more information

WARNING: on Parker’s standard power units. Parker also

It is imperative that personnel involved in the makes modifications to the cataloged units, and

installation, service and operation of the power these units have X numbered suffixes. Most of the

unit be familiar with how the equipment is to be information contained in this document will apply to

used. They should be aware of the limitations of those units

the system and its component parts, and have as well.

knowledge of good hydraulic practices in terms

of safety, installation and maintenance.

Model number Design series

Serial number

Pump flow (max)

LABEL Tank size (gal)

Max pressure @ rated

flow and horsepower

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

1

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Preparation for Use D, H, V-Pak and Custom Power Units

Preparation for Use Installation

Unpacking and Checking Locating Power Unit

The power unit is mounted on skids and carefully The unit should be installed indoors, and preferably in a

packed for shipment. Do not remove it from the skid clean, dry environment with an ambient temperature of 60

until it has been carefully checked for damage that to 100° F (15 to 38º C). The unit can be installed outdoors

may have occurred in transit. Report all damage if the reservoir was provided with optional weatherproof

immediately to the carrier and send a copy to the construction, and provisions were made for extreme

vendor. All open ports on the power unit are plugged temperature conditions. The reservoir can be secured to the

at the factory to prevent the entry of contamination. floor or base using the four mounting holes located on

These plugs must not be removed until just before the reservoir legs or reservoir base plate.

piping connections are made to the unit.

The power unit should be located close to the point of

Storage use. It is strongly recommended that any directional

If the power unit is not going to be installed valves controlling the actuators be located as close

immediately, it should be stored indoors, covered as possible to those actuators. This means that if the

with a waterproof sheet, and have all open ports power unit is installed away from the actuators, the

plugged. If long-term storage is expected (6 months directional valves should be remote from the power

or more), we recommend filling the reservoir unit and as close as possible to the actuators. System

completely with clean hydraulic fluid to prevent shock, response time and noise are greatly reduced by

the entry of moisture. minimizing the distance between the actuators and

the valves.

Removing from Shipping Skids

Vertical power units should be removed from the skid Condensation/Rust

by wrapping a heavy-duty nylon strap around the base Frequent temperature changes can lead to rust

of the motor mounting feet or by the lift eyes that may developing inside the reservoir. As air moves in and

be on the unit. This strap should be firmly secured out of the reservoir with fluid level changes, warm

to the lifting device when unit is lifted. The power unit humid air can condense when temperatures drop,

may have lag bolts securing it to the shipping pallet, creating rust on the underside of the top plate and

so be sure to remove these bolts before lifting. exposed tank sides. Moisture also can turn the oil

acidic, leading to varnish and pitting of components.

Do not use the lift eye in the motor. It is designed to lift Keeping the oil level as high as possible without

only the electric motor, not the entire power unit. overfilling is recommended, but remember oil will

expand when hot so do not over fill. Maintaining

Do not lift a unit that is full of oil. reservoir temperature with an auxiliary heater can

minimize these effects. Optional desiccant breathers

and/or stainless tanks are available for extreme

conditions.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

2

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Electrical Service Connections D, H, V-Pak and Custom Power Units

Electrical Service Connections the motor nameplate to match the facility power

source available. Connect the pump motor to the

Water power source following the good practices as outlined

If water cooled heat exchanger has been provided: in the National Electric Code and any local codes that

Connect the water supply to the inlet of the may apply. If solenoid valves, pressure/temperature

heat exchanger with a shut-off valve and strainer switches or oil immersion heaters have been provided

(if not supplied by Parker). If a temperature control on the power unit, refer to the component name tag or

valve (Model WTC**) has been provided, it also should other service information in this manual for operating

be installed on the inlet side. The outlet of the heat voltage and ratings.

exchanger should be connected directly to the facility

drain system. On single pass heat exchangers, the DCP, or units with inverter: Verify that the available

water connections should be installed as shown voltage is the same as the voltage rating of the

below to maximize heat transfer. On multi-pass inverter. Connect the drive to a power source following

heat exchangers, the water flow direction is not the good practices as outlined in the National Electric

important unless otherwise instructed by the heat Code and any local codes that may apply. The Parker

exchanger manufacturer. (See Figure 1) DCP units have a local disconnect to isolate the drive

from incoming power. This disconnect turns power

Electrical off to the drive and allows the motor connections to be

Non-inverter units: Verify that the available voltage is checked. Even when the motor is not running, there is

the same as the voltage identified on the motor high voltage present on the motor leads if power to the

nameplate. Most motors have dual voltage ratings drive is present unless the disconnect is in the “OFF”

(230/460), so verify that the leads in the motor conduit position.

box have been connected together as defined on

Oil in Oil out Shut-off

valve

Temperature

Water control valve Water

outlet Strainer inlet

Heat exchanger

Oil sensing bulb

Figure 1

Disconnect

WARNING:

DCPs, or units with the AC10 inverter, must have

branch circuit protection with a maximum rating

of 5KVA.

Figure 2

Factory-installed

shielded cable

from the drive to

the electric motor

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

3

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Wiring Information D, H, V-Pak and Custom Power Units

Inverter (DCP) Wiring Information

Remove the drive’s

This section covers main power wiring. Control cover by removing

wiring is application/model code specific. For more the Phillips screws

information regarding control wiring, see Catalog around the front of

HY28-2661-CD/US Mar 31, 2016 or later. the unit

The electric motor has been factory-wired to the drive

using shielded cable. The cord grips on this cable are Install an

designed to connect the cable’s shield to the drive’s appropriate cord

frame. Proper grounding of the drive is important for grip through one

user safety and the ability to minimize electrical noise. of the knock-outs

in the bottom

Connect the proper voltage 3 phase power to the steel plate for the

back of AC10’s disconnect switch (220VAC +/-15% or incoming power

480VAC +10/-15% depending on the drive selected). connection

Connect incoming power here

Ground connection: This connection

Image

must be made to a suitable ground (PE)

Ground

Terminal

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

4

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Wiring Information D, H, V-Pak and Custom Power Units

Note About Motor Wiring: Temp/Level Switch

• In general, the actual incoming voltage can be The standard temp/level switch is a discrete device

+/-10% of the motor nameplate voltage rating, as with no adjustment. The R1 is normally closed held

long as the frequency is correct. OPEN (no connection) when oil level is OK and

temperature is below 150º F (66º C).

• The ampacity of the wires feeding the electric motor

or inverter drive must be properly sized to handle the The R2 version is normally open held CLOSED

F.L.A. rating of the motor. (connection) when the oil level is OK and the temperature

is below 150º F (66º C). R2 is preferable because the logic

• Make sure the connections inside the motor’s of the monitoring device will detect a fault even if there is

terminal box are secure and cannot come loose with no connection to the temp/level switch.

vibration. Lethal shock, arc flash and or electrical

fire can result if these connections come loose. Wiring Info

Common = Black

• When a motor is connected to an across-the-line Float Level = Yellow

starter, its rotation can be changed by swapping Temperature = Red & White

any two of the three leads. If the rotation is incorrect

on a system with an inverter, two of the three leads Float Switch

between the drive and motor must be swapped. 1.5 Amps (50 va) max, 1 mv to 260 VAC or

Do not swap the power connection leads to 200 VDC max

the drive as this will have no effect on rotation.

Factory installed drives are tested to verify Temp Switch

correct rotation. 6 Amps (600 va) max @ 110 VAC, 1 mv to 240 VAC or

36 VDC max Changes state at 150ºF (66ºC)

• 60 Hz motors rated for 230/460 volts can be

operated on 50Hz at 190/380 volts, but the available

power of the motor is reduced approximately 15%.

Dual rated 50/60Hz motors are optionally available.

However, their service factor is reduced from 1.15 to

1.0 at 50Hz.* All dual rated motors have a CSA and

CE stamp. In the case of using the DCP, incoming

frequency to the drive does NOT affect motor

speed, however incoming voltage affects motor

torque. If this voltage is less than nameplate voltage,

the motor will need to be de-rated.

*The 2Hp and 3Hp motors have a 1.15SF at 60 Hz and 50Hz.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

5

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Component Location D, H, V-Pak and Custom Power Units

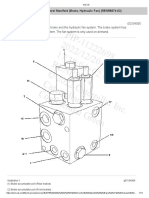

Component Location (Typical)

This shows the typical component location for a

20-gallon H-Pak. Exact configuration depends on

options selected.

Heat exchanger

Return filter

Electric motor

Pressure gage

Gage shut-off

Connection block Filler breather

3/4" NPT #12 spare Lift eye

return coupling Gasket material

Heat exchanger bypass

(65 PSI check valve)

inside reservoir Temp/level gage

Pressure filter

3/4" NPT weld coupling

(for customer use, water

valve, temperature

Image Strainer (inside reservoir)

switch,etc.) Tank drain (SAE #12)

Temp/level

switch

Solenoid

unloading valve

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

6

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Supply and Return Connections D, H, V-Pak and Custom Power Units

Supply and Return Connections 3. All openings in the reservoir such as the filler

breather or access end cover holes must remain

Complete all necessary interconnecting piping closed during installation.

between the power unit and hydraulic actuators. The

line sizes should be determined based on oil flow, 4. If Teflon tape or pipe dope is used, be sure it

operating pressure, viscosity and allowable pressure doesn’t extend beyond the first thread of the

drop between the power unit and point of use. The pipe fitting.

exact connection details will depend on how the power

unit was ordered. If the unit was ordered with a PT

block, the top plate will have a block with a “P” and a Reservoir Filling

“T” stamped on it. The “P” is the pressure connection,

and the “T” is the tank or return connection. If the The reservoir must be filled with clean fluid through

unit was ordered with a manifold option, there will be the filler cap on the reservoir. The type of fluid must be

ports labeled “A” and “B.” These are connections that compatible with the seals used on the power unit, and

normally go directly to the customer’s actuator ports. must comply with the recommendations of the

The actuator is controlled by valves mounted on the manufacturers of the component parts. Refer to

manifold. These valves could be supplied from the the component manufacturer’s catalog for fluid

factory or added by a third party or the customer. requirements. The cleanliness of the fluid going into

the reservoir is very important, and in most cases, even

WARNING: new oil out of the drum is not adequate. We recommend

Check to ensure that the proper rated hose or that any fluid being transferred into the reservoir be done

pipe is used on pressure lines. It is the customer’s with a transfer pump with a 10-micron filter installed.

responsibility to select the proper hose or tube Various Parker oil transfer pumps are available for this

style to ensure safe and reliable performance. purpose. Additionally, Parker sells pre-cleaned fluid

Improper selection of the interconnecting plumbing called DuraCleanTM. This fluid is clean from the drum

can cause serious injury or death. Make sure and has additives that resist moisture buildup, reducing

you fully understand the requirements for a safe varnish and oxidation.

installation or contact professional assistance.

Cautions About Filling

Make sure vibration and thermal expansion are Power units should be filled while they are not running,

considered. Straight tube runs should include especially if there is an accumulator in the system. If a

bends to accommodate thermal expansion and system has an accumulator and the oil level is “FULL”

contraction. If the power unit is mounted on a when running, the oil level will likely overflow when the

separate base from the rest of the installation, system is turned off.

flexible hose may be required to absorb possible

relative movement. After the initial fill, re-check the oil level after the

system has been in operation for a few cycles. In

Important: some installations, the actuators and plumbing will

One of the key ingredients for good service and long “consume” enough oil that the system will need

life from a hydraulic system is cleanliness. Since most another fill to prevent it from running low during the

dirt infiltrates a hydraulic system during installation, machine cycle.

Parker recommends the following:

1. All open ports on the power unit, cylinders,

etc. must remain plugged with tape or plastic

plugs until just before the hydraulic connections

are made.

2. All interconnecting tubing, pipe or hose should be

clean and free of rust, scale and dirt. The ends of

all connectors should be plugged until just before

they are to be installed in the system.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

7

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Start-Up Procedure D, H, V-Pak and Custom Power Units

Start-Up Procedure 3. Fixed volume systems (D and H Paks) will have a

P to T open path if it is equipped with an unloading

NOTE: option. On V Paks, the unloading option unloads

If the power unit has been provided with a variable the pump compensator, not the main pressure line,

displacement pump (V-Pak), the pump case should therefore additional work to prime the system may

be filled with clean oil prior to priming. Located on the be required.

power unit’s top plate, there is a port labeled “Pump

Case.” Remove the plug from this port, fill it with oil 4. Turn the main relief valve all the way down

and then replace the plug. See right: (counter clockwise).

5. Jog the pump motor once, and verify that the

Before proceeding to the rest of the start-up pump is rotating in the same direction as the

procedure, wear proper personal protective arrow tag on the motor fan cover. If the direction

equipment. Safety glasses and gloves are the is incorrect, reverse any two (2) of the three (3)

minimum required items to avoid exposure and motor leads, and re-check the rotation. Most units

injury from unexpected high-pressure oil leaks. are right hand rotation, or clockwise looking down

at the motor fan. If the unit has a rear mount heat

1. If the system has a standard solenoid controlled exchanger, you may need to use a small piece

unloading valve, it should be turned off to allow of thin wire or zip tie to “feel” which direction the

the system to start up at minimum pressure. A few motor’s fan is turning.

special systems have a normally closed unloading

valve, in which case it should be energized to get 6. Jog the pump/motor three (3) to six (6) times to

low pressure. prime the pump and then allow the pump to run

for several minutes at minimum pressure. Check

2. If the system has been provided with an open the piping for any leaks and correct immediately.

center directional valve, the oil during start-up will (Leaks in fittings and tubing can be the result of

flow directly back to tank when neither solenoid is vibration during shipping.)

energized. This should allow the system to prime

very quickly.

Pump prefill port

(8 to 15 GPM only) Filler breather

Remote compensator

(set lower than main relief)

Pressure filter manifold

Spare return w/ down

tube 3/4" NPT female Pressure gage w/ shutoff

Relief valve (set higher

Return filter Temp/level

than pump compensator

switch

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

8

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Start-Up Procedure D, H, V-Pak and Custom Power Units

7. If the system has not primed, the pressure line Water Control Valve (if Equipped)

may need to be bled. Do not use ports with O-ring Units that have a heat exchanger and water control

seals for bleeding, as the oil will cut the O-ring. valve may require adjustment. The valves are

One suggestion for bleeding is to close the needle adjustable between 75 to 135º F (24 to 58º C). Turning

valve at the base of the pressure gage, remove the adjustment screw clockwise decreases the valve’s

the pressure gage, then run a small hose from the opening temperature. The maximum recommended

needle valve back to the tank breather opening. oil temperature for most hydraulic systems is 120º F

With the needle valve just slightly open (1/2-1 (49º C). Running above this temperature increases the

turn), jog the pump until oil comes out of the hose. chance for causing burns and accelerates oxidation

Replace the pressure gage, close the breather and of the oil, which creates deposits and varnish in

resume startup. the system.

8. Begin adjusting the relief valve and/or pump

compensator to increase the pressure gradually. Range

adjusting

NOTE: screw

On systems with open-center directional valves,

Sensing Bulb

it will be necessary to actuate the valve in order

to build pressure.

9. Continue increasing pressure and checking

connections until normal operating pressure is

obtained. Lock adjustment screws in place. Image

NOTE:

If the system has been provided with a pressure 1/2" NPT

compensated pump and a relief valve, adjust Connector

the relief valve approximately 200 psi higher than

the compensator so that excessive heat is not

generated by the relief valve. If the relief and the

compensator are set too close to each other, 6' armored

the system pressure will oscillate or hunt. The capillary

pump compensator should be the device that

limits system pressure, while the main relief is a

redundant pressure limiter that reduces pressure

spikes the pump can’t respond to.

10. During the start-up sequence, all filters should be

monitored closely. Replace any filter elements as

soon as they begin to go into by-pass as indicated

on the visual indicator.

11. After the entire system has been wetted with fluid,

refill the reservoir to the normal operating level.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

9

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Maintenance D, H, V-Pak and Custom Power Units

General Maintenance

Electric Motors – Lubricate as recommended by the

motor vendor.

Filters – Change filter elements when indicated by the

filter’s mechanical or electrical indicator. New power

unit installs will typically have short element life until

the oil is cleaned by repeated passes through the

filter(s). When using electrical indicators, a short time

delay in the logic that reads the indicator is advisable

to prevent false alarms (0.1 – 0.25 seconds is typical).

Suction Strainers – Strainers should be cleaned

anytime it is suspected that the pump is starving

for oil. When the suction strainer is the only filter in

the system, it will clog much sooner than if there

are additional filters present. Modern systems with

proper filtration rarely have their suction strainers clog;

however heavy varnish, a failed return filter element

or other similar event could cause a rapid clogging of

the strainer.

The exact filter and strainer part numbers are model

code dependent. Contact your local distributor or

Parker’s Hydraulic Pump and Power Systems Division

0.30 – .06 TYP

Tech Support for replacement part number information.

Pump/Motor Coupling – Under normal conditions

the pump/motor coupling will last many years.

Heavy cycling, fluid compatibility or the loss of solid

attachment to the pump or motor shaft can cause the

coupling or its insert to fail. Whenever the top plate is

raised for inspection inside the tank, inspect the

pump/motor coupling for signs of wear. If the coupling

is replaced, make sure there is a small gap (approx.

1/32 – 3/32 of an inch) between the two coupling

halves to prevent axial loading when the pump and

motor get warm.

Reservoirs – Maintain proper oil level at all times.

The oil should be sampled and checked after the

first 100 hours of operation to verify that cleanliness

and moisture are in acceptable ranges. Occasional

sampling after that point is recommended. A robust

sampling program can help ensure the oil is properly

maintained and can assist in root cause analysis if

there is a component failure.

Paint – Parker’s standard paint for these units is

Sherwin Williams quick dry enamel, F77A3 Machine

Tool Grey.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

10

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Maintenance D, H, V-Pak and Custom Power Units

Maintenance Suggestions Maintaining Proper Oil Temperature

1. Set up a filter maintenance schedule and follow Hot oil in your equipment’s hydraulic system is one

it diligently. of the primary causes of poor operation, component

failure and downtime. Here are some pointers on

2. Inspect filter elements that have been removed maintaining proper oil temperature. The oil in your

from the system for signs of failure which may hydraulic system was designed for operation within

indicate that the service interval should be a specified temperature range. You may be able to

shortened, the oils viscosity is too high or too run it at hotter temperatures for short periods of time,

cold, or that the filter is undersized. intermittently, without adverse effects. If you run

continuously with oil that’s too hot, your equipment

3. Never return to the system any fluid that has

will operate poorly causing key component failure

leaked out.

and machine downtime.

4. Always keep the supply of fresh fluid

covered tightly. “Hot oil” is a relative term. In most cases, 120° F

(49º C) at the reservoir is considered an ideal operating

5. Use clean containers, hoses and funnels when temperature. Always take an oil temperature reading

filling the reservoir. Use of a filter cart when adding at the reservoir, not at a component or any of the

oil is highly recommended. piping. Some hydraulic systems are designed to

operate at 130° F (54º C) or higher. If you don’t

6. Use common sense precautions to prevent entry know the maximum operating temperature for your

of dirt into components that have been temporarily equipment, check your component manual for

removed from the circuit. temperature and viscosity limitations.

7. Make sure that all clean-out holes, filter caps

How Can You Keep Your Equipment’s Hydraulic

and breather cap filters on the reservoir are

System From Running Too Hot?

properly fastened.

8. Do not run the system unless all normally provided 1. Set up a regular schedule for checking the

filtration devices are in place. oil temperature, appearance, smell and feel.

Change oil as recommended by the equipment

9. Make certain that the fluid used in the system is of manufacturer.

a type recommended by the manufacturers of the

system or components. 2. If relief or flow-control valves are running hot,

check and adjust their settings. Follow your

10. Before changing from one type of fluid to equipment owner’s manual.

another (e.g., from petroleum base oil to a fire

resistant fluid), consult component and filter 3. Consider adding an unloading circuit to reduce

manufacturers in the selection of the fluid and system pressure between machine cycles.

filters that should be used. Also consult the

4. Consider using a VFD for motor control. Most

publication “Recommended Practice for the Use

machine cycles require maximum motor speed

of Fire Resistant Fluids for Fluid Power Systems”

for only a brief part of the cycle. Heat, noise

published by the National Fluid Power Association.

and power reductions can be substantial when

11. Parker offers an oil sampling kit, which can be using a VFD. Contact Parker or your local Parker

used to ascertain the condition of the system fluid. distributor for information regarding our Drive

Controlled Pump (DCP).

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

11

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Maintenance D, H, V-Pak and Custom Power Units

5. Keep your equipment clean. A thick layer of dirt

acts as insulation. It will prevent the hydraulic

system from getting rid of heat.

6. Proper heat exchanger selection is crucial. If a

variable system (V-Pak) runs compensated most

of the time, a return line heat exchanger won’t be

as effective as a case drain cooler. An oversized

cooler will be less efficient than a smaller cooler at

low flows. Some systems, especially ones that run

continuously above 1500 psi may require offline

(kidney loop) cooling.

7. On a variable volume system (V-Pak), make

sure the main relief is set HIGHER than the

pump compensator. If the pump compensator

is set higher than the main relief, oil will flow

continuously across the relief creating noise and

a lot of heat. Electrical power consumption will

also increase.

NOTE:

When using high water content fluids, high

temperatures are very detrimental to the entire system.

The balance of water to additives is quickly disrupted,

causing the fluid to lose its proper characteristics.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

12

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Parts List D, H, V-Pak and Custom Power Units

D-Pak Parts List

The D-Pak parts list is for standard units, design series Gear pumps, filters and valves should be purchased from

21, with directional valve information excluded. If your their respective source Parker Divisions. Parts unique to

unit is a different design series, the form, fit and function the power unit (variable piston pumps, gaskets, special

of replacement parts may not match your parts. manifolds, etc.) should be purchased from Parker’s

Hydraulic Pump and Power Systems Division.

D-Pak (D5) Parts List – Design Series 21

Universal Parts Part Number

5" level gage 875033-05

Suction strainer 875035-03

Filler breather 875034

Gasket (manifold) 875576-04

Pressure gage 875053-**** **** = Max pressure on gage

U-shaped tank edge rubber 875041-48 48" Long, trim to fit

Needle valve (gage) N400S

Unloader Options

Option Block 2-Way Valve Coil

Omit 876377 Cover plate N/A

B CAP115D

BD03-PT-A DSL101NRM

J CAP024D

D-Pak Pump Part Numbers D-Pak Motor Part Numbers

Pump Flow Pump Option (HP) Voltage/Frequency Ratings Motor Part Number

0.9 331-9110-267 U1 (1/2) 115/208-230 1Ph 60Hz 875054-02

1.3 331-9110-011 T1 (1) 115/230-230 1Ph 60Hz 875054-07

1.8 331-9110-010 T3 (1) 208-230/460 3Ph 60Hz 875054-14

2.7 331-9110-101 208-230/460 3Ph 60Hz

DG (2) 133-60021-0

190/380 50Hz

208-230/460 3Ph 60Hz

DK (3) 133-60022-0

190/380 50Hz

D-Pak Bell Housing Gasket and Coupling Part Numbers

HP Gasket Number Motor Coupling Pump Coupling Insert

Flow/HP

U1, T1, T3, DG 875577-01 L-075 5/8X3/16 L-075 1/2X1/8 L-075U

Combinations

DK 875577-02 68514411518 876975 68514411499

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

13

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Parts List D, H, V-Pak and Custom Power Units

D-Pak Accessories Parts List

Option Description Part Number Filter Element

Rear mt heat ex RM-08-2-2

B1

Bracket 875225 (2 pc)

Pressure filter

15P110QBPSKX1

(STD aluminum) 932612Q

Pressure filter (steel head) 15P110QB16690

H 876526 (aluminum)

Manifold

876526-S (steel)

Gasket 875576-16

Indicator 929081

K Check valve DT-370-MOMF-05

L Check valve C1020S65

O Return filter 12AT110CBPCS12H 921999

Switch housing w/ cover 876620

R1 Float switch

Gasket Charts

876782-01

875576-14 (2 pc required)

Switch housing w/ cover 876620

R2 Float switch 876782-02

Gasket 875576-14 (2 pc required)

The pressure filter is a standard aluminum 15P filter. For high pressure/high fatigue applications

(above 2000 psi), an optional steel manifold and special 15P with a steel head is available.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

14

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Parts List D, H, V-Pak and Custom Power Units

H-Pak Parts List

The H-Pak parts list is for standard units, design series Gear pumps, filters and valves should be purchased from

14, with directional valve information excluded. If your their respective source Parker Divisions. Parts unique to

unit is a different design series, the form, fit and function the power unit (variable piston pumps, gaskets, special

of replacement parts may not match your parts. manifolds, etc.) should be purchased from Parker’s

Hydraulic Pump and Power Systems Division.

H-Pak (H1-H4) Parts List – Design Series 14

Description Part Number Notes

5" Level gage 875033-05

10" Level gage 875033-10

Filler breather 875034

Pressure gage 875053-**** **** = Max pressure on gage

U-shaped tank edge rubber 875041-72 10 Gal tank, 72" long, trim to fit

U-shaped tank edge rubber 875041-78 20-40 Gal tank, 78" long, trim to fit

Needle valve (gage) N400S

Unloader Options

Option Block 2-Way Valve Coil

Omit 876377 Cover plate N/A 875576-13

B, J See pump/strainer/unloading valve/gasket information

H-Pak Pump/Strainer/Unloading Valve/Gasket Information

2-Way Valve & Pressure/Tank Remote Body or Unloading Valve

Pump Flow Pump Suction Strainer

Solenoid Connections Cartpak Gasket

0.9 331-9110-267

1.3 331-9110-011

875035-03

1.8 331-9110-010

DSL101NRM

O, S5, M5* => 875970 (aluminum)

2.7 331-9110-101 CAP115D (AC) 875576-13

S3,M3* => BD03-PT-A

CAP024D (DC)

3.6 334-9111-047

4.5 334-9111-068

5.1 334-9111-067

875035-10

6.3 334-9111-048

DSH161NRM

8.6 334-9116-506 CAP115D (AC) ALL => 878483 (aluminum) 875576-17

CAP024D (DC)

10.4 334-9111-347

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

15

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Parts List D, H, V-Pak and Custom Power Units

H-Pak Motor Chart

Option (HP) Voltage/Frequency Ratings Motor Part Number

U1 (1/2) 115/208-230 1Ph 60Hz 875054-02

T1 (1) 115/230-230 1Ph 60Hz 875054-07

T3 (1) 208-230/460 3Ph 60Hz 875054-14

DG (2) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60021-0

DK (3) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60022-0

L (5) 208-230/460 3Ph 60Hz 875054-21

DL (5) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60023-0

M (7.5) 208-230/460 3Ph 60Hz 875054-22

DM (7.5) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60024-0

N (10) 208-230/460 3Ph 60Hz 875054-23

DN (10) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60025-0

P (15) 208-230/460 3Ph 60Hz 875054-24

DP (15) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60026-0

S (20) 208-230/460 3Ph 60Hz 875054-25

DS (20) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60027-0

H-Pak Bell Housing Gasket & Coupling Part Numbers

HP* Flow Gasket Number Motor Coupling Pump Coupling Insert

0.9 to 2.7 L-075 5/8X3/16 L-075 1/2X1/8 L-075U

U, T, DG 875577-01

3.6 to 10.4 L-100 5/8X3/16 L-100 5/8X5/32 L-100

Flow/HP

0.9 to 2.7 68514411518 876975 68514411499

Combinations DK, L, DL

3.6 to 10.4 L-100 1-1/8X1/4 L-100 5/8X5/32 L-100

875577-02

M, DM, N, DN 3.6 to 10.4 L-100 1-3/8X5/16 L-100 5/8X5/32 L-100U

P, DP, S, DS 4.5 to 10.4 M300 1-5/8X3/8 M300 5/8X5/32 370N

*STD or dual rated motors are the same frame size

H-Pak Pressure Tank Connections

Subplate/Manufacturer

Option Relief Valve Gasket

ID Number

876305 (aluminum)

O 875576-05

876305-S (steel)

876378 (aluminum)

S3 875576-04

876378-S (steel)

876305 (aluminum) See relief valve

S5 875576-05

876305-S (steel) chart

M33 AD03P032S/C

875576-04

M35 AD03P052S/C

M53 AD05P032S/C

875576-05

M55 AD05P052S/C

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

16

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Parts List D, H, V-Pak and Custom Power Units

H-Pak Relief Valve Part Numbers

Flow HP Option* Relief Valve

U, T RAH101S20

0.9 to 3.6

DG, DK, L, M RAH101S30

U, T, DG, DK RAH101S20

4.5 to 10.4

L, M, N, P, S RAH101S30

*STD or dual rated.

H-Pak Accessories Parts List

Option Description Part Number Filter Element

Rear mt heat ex RM-08-4-2

A

Bracket 875225 (2 pc)

Rear mt heat ex RM-08-1-2

B1

Bracket 875225 (2 pc)

Rear mt heat ex RM-19-94171

B2

Bracket 875225 (2 pc)

C Water/oil heat exch BS-401-A4-O-BR

D Water/oil heat exch BS-701-B6-F-BR

E Water valve 65253

Pressure filter (aluminum head) 15P110QBPSKX1

932612Q

Pressure filter (steel head) 15P110QB16690

876526 (aluminum)

H Manifold

876526-S (steel)

Gasket 875576-16

Indicator 929081

J Weld coupling NA

K (10 GAL) Check valve C1020S

K (20 THRU 40 GAL) Check valve DT-750-MOMF-05

L Check valve C1220S65

N Return filter 40CN110QEBM2KS164 936708Q

Return filter 12AT110CBPCS12H 921999

O

Gage filter 876544

Switch housing w/cover 876620

R1 Float switch 876782-01

Gasket 875576-14 (2 pc required)

Switch housing w/cover 876620

R2 Float switch 876782-02

Gasket 875576-14 (2 pc required)

The pressure filter is a standard aluminum 15P filter. For high pressure/high fatigue applications

(above 2000 psi), an optional steel manifold and special 15P with a steel head is available.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

17

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Parts List D, H, V-Pak and Custom Power Units

V-Pak Parts List

V-Pak parts list is for standard units, design series 11, Gear pumps, filters and valves should be purchased from

with directional valve information excluded. If your unit their respective source Parker Divisions. Parts unique to

is a different design series, the form, fit and function of the power unit (variable piston pumps, gaskets, special

replacement parts may not match your parts. manifolds, etc.) should be purchased from Parker’s

Hydraulic Pump and Power Systems Division.

V-Pak (V1-V4) Parts List – Design Series 11

Description Part Number Notes

5" Level gage 875033-05 10 & 20 Gal

10" Level gage 875033-10 30 & 40 Gal

Filler breather 875034

Pressure gage 875053-**** **** = Max pressure on gage

U-shaped tank edge rubr 875041-72 10 Gal tank, 72" long, trim to fit

U-shaped tank edge rubr 875041-78 20-40 Gal tank, 78" long, trim to fit

Needle valve (gage) N400S

Compensator Options

Option Block Relief Gasket 2-Way Valve Coil P08-2

876488 (aluminum)

Omit (1 pc) 205745N-25 875576-13 N/A N/A No

876488-S (steel)

876549 (aluminum) (B) CCP115D

B, BJ (1 pc) 205745N-25 (1 pc) DSL081NRM Yes

876549-S (steel) (BJ) CCP024D

876549 (aluminum) (C) CCP115D

C, CJ (2 pc) 205745N-25 875576-15 (1 pc) DSL081NRM Yes

876549-S (steel) (CJ) CCP024D

876549 (aluminum) (D) CCP115D

D, DJ (2 pc) 205745N-25 (2 pc) DSL081NRM No

876549-S (steel) (DJ) CCP024D

F 876377 Cover plate 875576-13 N/A

V-Pak Pump And Suction Strainer Part Numbers

Pump Flow Option Pump Suction Strainer

Up to 7GPM* - PVP1630R2VM12*

Up to 7GPM* A PVP1630R2VA12* 875035-10

Up to 7GPM H See motor chart

8 to 15 GPM* - PVP3336R2VM21*

875035-30

8 to 15 GPM* A PVP3336R2VA21* (may also need adapter

1 1/2 X 1 1/4 PTR-S)

8 to 15 GPM H See motor chart

* Important: Specify flow rate to match original power unit model code. “V” compensator has no local pressure setting.

Example: Power unit V3A13Mm

Replacement pump = “PVP3336R2VA21 set at 13 GPM @ 1800 RPM”

The remote compensator on the tank top controls the pump’s pressure after it is installed in the power unit and the compensator control line is

reconnected to the remote block.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

18

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Parts List D, H, V-Pak and Custom Power Units

V-Pak Motor/Pump HP Chart

7 GPM Pump with H Option (HP Limiting) 15 GPM Pump with H Option (HP Limiting)

Option (HP) Motor Part Number

hvPump Number ^ Pressure Set (PSI) Pump Number ^ Pressure Set (PSI)

DG (2) 133-60021-0 1600

DK (3) 133-60022-0 2200

N/A

L (5) 875054-21

DL (5) 133-60023-0

M (7.5) 875054-22 2200

PVP1630R2VH12 ^

DM (7.5) 133-60024-0 2700

N (10) 875054-23 3000 PSI

DN (10) 133-60025-0

PVP3336R2VH21 ^

P (15) 875054-24

3000

DP (15) 133-60026-0

S (20) 875054-25

DS (20) 133-60027-0

^Important: specify the hp setting, rpm and pressure setting shown above to match your system. In most cases hp limited pumps are set

at max volume.

Example: Power unit: V2H7DK Replacement pump = “PVP1630R2VH12 Set for 3 HP @ 1800 RPM, minimum pressure 2200 PSI.

2200 PSI is NOT the compensator setting, the remote block on the power unit top plate will be the limiting pressure device.

The 3 HP motor is no longer available in a 56C frame. It is an 182TC frame design series 11 and beyond.

* See H-Pak motor chart for voltage ratings.

V-Pak Bell Housing Gasket & Coupling Part Numbers

HP Flow Gasket Number Motor Coupling Pump Coupling Insert

2-7 GPM 875577-01 L-075 5/8X3/16 L-075 3/4X3/16 L-075U

2 (DG)

8-15 GPM NA N/A

2-7 GPM 875577-02 L-100 1-1/8X1/4 L-100 3/4X3/16 L-100

3 (DK)

8-15 GPM C820004 L-100 1-1/8X1/4 L-100 7/8X1/4 L-100

2-7 GPM 875577-02 L-100 1-1/8X1/4 L-100 3/4X3/16 L-100

5 (L)

8-15 GPM C820004 L-100 1-1/8X1/4 L-100 7/8X1/4 L-100

Flow/HP

Combinations 2-7 GPM 875577-02 L-100 1-3/8X5/16 L-100 3/4X3/16 L-100

7.5 (M)

8-15 GPM C820004 M300 1-3/8X5/16 M300 7/8X1/4 370N

2-7 GPM 875577-02 L-100 1-3/8X5/16 L-100 3/4X3/16 L-100

10 (N)

8-15 GPM C820004 M300 1-3/8X5/16 M300 7/8X1/4 370N

2-7 GPM 875577-02 M300 1-5/8X3/8 M300 3/4X3/16 370N

15 (P)

8-15 GPM C820004 M400 1-5/8X3/8 M400 7/8X1/4 470N

2-7 GPM 875577-02 M300 1-5/8X3/8 M300 3/4X3/16 370N

20 (S)

8-15 GPM C820004 M400 1-5/8X3/8 M400 7/8X1/4 470N

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

19

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Parts List D, H, V-Pak and Custom Power Units

V-Pak Pressure Tank Connections

Subplate/Manufacturer

Option Relief Valve Gasket

ID Number

876305 (aluminum)

O 875576-05

876305-S (steel)

876378 (aluminum)

S3 875576-04

876305 (aluminum)

S5 RAH101S50 875576-05

876305-S (steel)

M33 AD03P032S/C

875576-04

M35 AD03P052S/C

M53 AD05P033S/C

875576-05

M55 AD05P053S/C

V-Pak Accessories Parts List

Option Description Part Number Filter Element

Rear mt heat exch RM-08-4-2

A

Bracket 875225 (2 pc)

Rear mt heat exch RM-08-1-2

B1

Bracket 875225 (2 pc)

Rear mt heat exch RM-19-94171

B2

Bracket 875225 (2 PCS)

C Water/oil heat exch BS-401-A4-O-BR

D Water/oil heat exch BS-701-B6-F-BR

E Water valve 65253

Pressure filter (aluminum head) 15P110QBPSKX1

932612Q

Pressure filter (steel head) 15P110QB16690

876526 (aluminum)

H Manifold

876526-S (steel)

Gasket 875576-16

Indicator 929081

J Weld coupling NA

K (10 GAL) Check valve C1020S

K (20 THRU 40 GAL) Check valve DT-750-MOMF-05

L Check valve C1220S65

N Return filter 40CN110QEBM2KS164 936708Q

Return filter 12AT110CBPCS12H 921999

O

Gage, filter 876544

Switch housing w/ cover 876620

R1 Float switch 876782-01

Gasket 875576-14 (2 pc required)

Switch housing w/ cover 876620

R2 Float switch 876782-02

Gasket 875576-14 (2 pc required)

The pressure filter is a standard aluminum 15P filter. For high pressure/high fatigue applications (above 2000 psi), an optional steel manifold and

special 15P with a steel head is available.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

20

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Parts List D, H, V-Pak and Custom Power Units

V-8 (Low Profile) Parts List

V-8 (low profile) parts list is for standard units, design Gear pumps, filters and valves should be purchased from

series 13, with directional valve information excluded. their respective source Parker Divisions. Parts unique to

If your unit is a different design series, the form, fit and the power unit (variable piston pumps, gaskets, special

function of replacement parts may not match your parts. manifolds, etc.) should be purchased from Parker’s

Hydraulic Pump and Power Systems Division.

V-8 Low Profile Parts List – Design Series 13

Universal Parts Part Number

10" level gage 875033-10

Filler breather 875034

Pressure gage 875053-**** **** - Max pressure on gage

Needle valve (gage) N400S

Clean-out cover 5087

Gasket, temp/level 875576-14

U-shaped tank edge rubber 875041-100 100" long, trim to fit

Remote comp hose F381-0606040404-35"

Compensator Options

Option Block Relief Gasket 2-Way Valve Coil

Omit 876488 (aluminum) (1 pc) 205745N-25 875576-13 N/A N/A

(B) CCP115D

B, BJ 876549 (aliminum) (1 pc) 205745N-25 (1 pc) DSL081NRM

(BJ) CCP024D

(C) CCP115D

C, CJ 876549 (aliminum) (2 pc) 205745N-25 875576-15 (1 pc) DSL081NRM

(CJ) CCP024D

(D) CCP115D

D, DJ 876549 (aliminum) (2 pc) 205745N-25 (2 pcs) DSL081NRM

(DJ) CCP024D

E 876377 Cover plate N/A 875576-13 N/A

V8 Low Profile Pump Part Number Chart

Pump (If air cooling

Pump Flow Pump Control Pump (If no air cooling or option A, B) Suction Strainer

option C)

9 to 15 GPM* - PVP33363R2M21* PVP33363R26A4M21*

9 to 15 GPM* A PVP33363R2A21* PVP33363R26A4A21* 875035-20

9 to 15 GPM H Consult factory Consult factory

16 to 23 GPM* - PVP48363R2M11* PVP48363R26A4M11*

16 to 23 GPM* A PVP48363R2A11* PVP48363R26A4A11* 875035-30

16 to 23 GPM H Consult factory Consult factory

23 to 36 GPM* - P2075RXXC5C25PA00N00S1A1U^ P2075RXXC5C25PA00N00A1A1U^

23 to 36 GPM* A P2075RXXC5C25LA10N00S1A1U^ P2075RXXC5C25LA10N00A1A1U^ 875035-50

23 to 36 GPM H Consult factory Consult factory

*Important: specify flow rate & rpm to match original power unit model code. For example: power unit = V820PM53 The replacement pump

would be PVP48363R2M11, specify the volume stop be set at 20 gpm @ 1800 rpm, pressure compensator set at 3600 PSI.

^Important: the P2’s flow rate is called out in the model code of the pump as a percentage of full flow (36 gpm).

For example: Power unit = V827RM82 27/36 = 75%, so the replacement pump model code is P2075R75C5C25PA00N00S1A1U.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

21

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Parts List D, H, V-Pak and Custom Power Units

V8 Low Profile Bell Housing Gasket and Coupling Part Numbers

HP Flow Gasket Number Motor Coupling Pump Coupling Insert

9-23 GPM C820004 M300 1-3/8X5/16 M300 7/8X1/4 370U

7.5 (M) 10(N)

24-36 GPM C820004 M400 1-3/8X5/16 M400 1-1/4X5/16 470N

9-23 GPM C820004 M400 1-5/8X3/8 M400 7/8X1/4

15 (P) 20 (S) 470N

24-36 GPM C820004 M400 1-5/8X3/8 M400 1-1/4X5/16

9-23 GPM M400 1-7/8X1/2 M400 7/8X1/4

25 (Q) 470N

24-36 GPM M400 1-7/8X1/2 M400 1-1/4X5/16

9-23 GPM M400 1-7/8X1/2 M400 7/8X1/4

30 (R) N/A 470U

24-36 GPM M400 1-7/8X1/2 M400 1-1/4X5/16

9-23 GPM M500 2-1/8X1/2 M500 7/8X1/4

40 (V) 570N

24-36 GPM M500 2-1/8X1/2 M500 1-1/4X5/16

V8 Low Profile Subplate/Manifold, Relief Valve/Gasket Numbers

Option Subplate/Manifold Number Relief Valve Gasket

877544

OMIT RAH161S50 875576-09

876305 (Al)

S5 875576-05

M53 AD05P033S/C RAH101S50

875576-05

M55 AD05P053S/C

M82 AD08P025S/C 875576-12

V-8 Low Profile Motor Part Numbers

Option (HP) Voltage/Frequency Ratings Motor Part Number

M (7.5) 208-230/460 3Ph 60Hz 875054-22

DM (7.5) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60024-0

N (10) 208-230/460 3Ph 60Hz 875054-23

DN (10) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60025-0

P (15) 208-230/460 3Ph 60Hz 875054-24

DP (15) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60026-0

S (20) 208-230/460 3Ph 60Hz 875054-25

DS (20) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60027-0

Q (25) 208-230/460 3Ph 60Hz 875054-26

DQ (25) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60028-0

R (30) 208-230/460 3Ph 60Hz 875054-27

DR (30) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60029-0

V (40) 208-230/460 3Ph 60Hz 875054-28

DV (40) 208-230/460 3Ph 60Hz | 190/380 50Hz 133-60030-0

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

22

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Parts List D, H, V-Pak and Custom Power Units

V8 Low Profile Accessories Parts List

Option Description Part Number Filter Element

Rear mt heat ex RM-08-2-2

Bracket 875225 (2 pc)

A

Suction strainer 875035-10

Gear pump 334-9111-061

Rear mt heat exch RM-19-2-2

Bracket 875225 (2 pc)

B

Suction strainer 875035-10

Gear pump 334-9111-061

Heat exchanger AOC-22-2-1PH

Gear pump 334-9111-058

C

Suction strainer 875035-10

Filter 40CN205QEBM2GS244 936711Q

E Water/oil heat exch EKS-708-T

F Water valve 65253

H Pressure filter 30P210QBM2KS161 932630Q

J Weld coupling N/A

K Check valve 493-1601-2

L Check valve C2020S65

N Return filter 40CN210QEBM2KS244 936601Q

Switch housing w/cover 876620

R1 Float switch 876782-01

Gasket 875576-14 (2 pc required)

Switch housing w/cover 876620

R2 Float switch 876782-02

Gasket 875576-14 (2 pc required)

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

23

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Troubleshooting D, H, V-Pak and Custom Power Units

Troubleshooting System Flow and/or Pressure Inadequate or Erratic

System Fails to Generate Flow/Pressure 1. Loose inlet connection or dirty inlet strainer.

1. Add oil to the unit, fill until the oil is at the top of 2. Incorrectly adjusted relief valve.Pump hasn’t

the level gage glass. Use a petroleum base fluid primed. Bleed the system and retry.

per HF-0 or HF-1. The fluid should have anti-rust, 3. If a variable pump is being used, make sure the

anti-foam properties and be designed for operating main relief and pump compensator are not set too

under high pressure. closely together. A minimum separation of 250 psi

2. Motor rotation incorrect, verify and change is recommended.

if necessary. 4. If flow and pressure are steady but weak, verify

3. Pump hasn’t primed. Bleed the system and retry. the motor is properly wired to match the incoming

voltage and that all three phases have power.

4. No resistance to flow. Pumps generate flow not Running on two phases or being wired for the

pressure. Pressure is generated by the resistance wrong voltage will cause the motor to run slow

to flow. If there is an open center directional valve and will result in motor damage.

or other path that connects the pressure line to

tank, there will be no pressure.

5. Unloading valve not activated. Verify voltage to the

solenoid, preferably with the solenoid connected.

An undersized power supply can appear to be OK

but then droop when loaded by the solenoid.

6. Failed or incorrectly adjusted relief valve.

Contamination can plug the internal pilot

pressure of a relief valve, causing it to fail in the

open position.

7. Pump/motor coupling loose or broken. Normally

the motor will stop within a second or two of losing

power. If it winds down over several seconds it is

not connected to the pump shaft.

8. Loose or disconnected inlet line.

9. Failed pump. In the case of a variable volume

pump, additionally the remote compensator

and main compensator should be inspected.

Contamination can cause the pump to de-stroke

at minimum pressure. Checking the remote

compensator should be done first because

it is mounted on the power unit top plate

(easy access).

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

24

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Troubleshooting D, H, V-Pak and Custom Power Units

DCP (Inverter) Specific Troubleshooting Items

Motor Fails to Start When Drive Is Commanded

to Do So

1. 24 VDC signal not present at required pin(s). The

exact control option determines which inputs

cause the drive to run the motor. In most cases,

at least one input (DIN1) needs to be held high

to enable the drive. As of March 2017, all drives

shipped with factory-installed software require

DIN1 and DIN2 to be held high to function. DIN1 is

a master enable; DIN2 could be tied to the temp/

level switch (if equipped) or a NC stop button that

opens when pressed. In addition to these two

discrete inputs, there are analog inputs that are

used for the “V” and “I” options.access).

2. Make sure the DC common of the remote 24 VDC

signal source is tied to the “(CM) 0VDC” terminal of

the AC10. This is necessary so both devices have

the same zero-volt reference.

Excessive Electrical Interference or EMI

1. Broken or improper shield connection of the cable

between the motor and the drive. Loose or missing

ground connection at power connection.

Motor Slows Down Unexpectedly or Stalls

1. This is a sign the drive is undersized. The AC10

can handle 150% of its rating for a few seconds.

Starting torque can often be more than this,

especially with variable volume pumps. If the

drive has trouble starting, an unloading valve or

decrease in pressure may be required until the

motor is up to speed.

2. Ampacity of the wires feeding the drive is too low.

Make sure the wires are properly sized. The longer

the run, the bigger the wire needs to be for a given

amp rating to avoid voltage droop. If the voltage to

the drive droops too much, current rise and motor

slip will lead to a complete breakdown of motor

speed.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

25

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Power Unit Weights D, H, V-Pak and Custom Power Units

Power Unit Weights Tank Size Approximate Weight Less Motor

5 Gallon 70 lbs.

Since there are so many combinations of options,

10 Gallon 106 lbs.

listing an exact weight for every model code is not

practical. The following chart will provide estimates 20 Gallon 122 lbs.

based on tank size and horsepower. Combine the 30 Gallon 126 lbs.

tank size and motor horsepower to come up with an 40 Gallon 130 lbs.

average total weight, without oil. 55 Gallon 260 lbs.

75 Gallon 313 lbs.

95 Gallon 365 lbs.

Motor HP Approximate Weight

1/4 20 lbs.

1/2 20 lbs.

3/4 40 lbs.

1 40 lbs.

2 40 lbs.

3 65 lbs.

5 75 lbs.

7-1/2 100 lbs.

10 120 lbs.

15 170 lbs.

20 200 lbs.

25 370 lbs.

30 440 lbs.

40 505 lbs.

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

26

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Notes D, H, V-Pak and Custom Power Units

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

27

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Notes D, H, V-Pak and Custom Power Units

Parker Hannifin Corporation

Hydraulic Pump and Power Systems Division

United States

28

HY28-2600-550-M1/USA Standard Hydraulic Power Units Installation and Maintenance Manual

Offer of Sale D, H, V-Pak and Custom Power Units

OFFER OF SALE

The items described in this document and other documents and descriptions provided by Parker Hannifin Corporation, its subsidiaries and its authorized distributors (“Seller”)

are hereby offered for sale at prices to be established by Seller. This offer and its acceptance by any customer (“Buyer”) shall be governed by all of the following Terms and

Conditions. Buyer’s order for any item described in its document, when communicated to Seller verbally, or in writing, shall constitute acceptance of this offer. All goods,

services or work described will be referred to as “Products”.

1. Terms and Conditions. Seller’s willingness to offer Products, or accept an attorney fees), whether for personal injury, property damage, patent, trademark or

order for Products, to or from Buyer is subject to these Terms and Conditions or copyright infringement or any other claim, brought by or incurred by Buyer,

any newer version of the terms and conditions found on-line at Buyer’s employees, or any other person, arising out of: (a) improper selection,

www.parker.com/saleterms/. Seller objects to any contrary or additional terms or improper application or other misuse of Products purchased by Buyer from Seller;

conditions of Buyer’s order or any other document issued by Buyer. (b) any act or omission, negligent or otherwise, of Buyer; (c) Seller’s use of

2. Price Adjustments; Payments. Prices stated on Seller’s quote or other patterns, plans, drawings, or specifications furnished by Buyer to manufacture

documentation offered by Seller are valid for 30 days, and do not include any Product; or (d) Buyer’s failure to comply with these terms and conditions. Seller

sales, use, or other taxes unless specifically stated. Unless otherwise specified by shall not indemnify Buyer under any circumstance except as otherwise provided.

Seller, all prices are F.C.A. Seller's facility (INCOTERMS 2010). Payment is 12. Cancellations and Changes. Orders shall not be subject to cancellation or

subject to credit approval and is due 30 days from the date of invoice or such change by Buyer for any reason, except with Seller's written consent and upon

other term as required by Seller’s Credit Department, after which Buyer shall pay terms that will indemnify, defend and hold Seller harmless against all direct,

interest on any unpaid invoices at the rate of 1.5% per month or the maximum incidental and consequential loss or damage. Seller may change product features,

allowable rate under applicable law. specifications, designs and availability with notice to Buyer.

3. Delivery Dates; Title and Risk; Shipment. All delivery dates are approximate 13. Limitation on Assignment. Buyer may not assign its rights or obligations

and Seller shall not be responsible for any damages resulting from any delay. under this agreement without the prior written consent of Seller.

Regardless of the manner of shipment, title to any products and risk of loss or 14. Force Majeure. Seller does not assume the risk and shall not be liable for

damage shall pass to Buyer upon placement of the products with the shipment delay or failure to perform any of Seller’s obligations by reason of circumstances

carrier at Seller's facility. Unless otherwise stated, Seller may exercise its beyond the reasonable control of Seller (hereinafter “Events of Force Majeure”).

judgment in choosing the carrier and means of delivery. No deferment of shipment Events of Force Majeure shall include without limitation: accidents, strikes or labor

at Buyers' request beyond the respective dates indicated will be made except on disputes, acts of any government or government agency, acts of nature, delays or

terms that will indemnify, defend and hold Seller harmless against all loss and failures in delivery from carriers or suppliers, shortages of materials, or any other

additional expense. Buyer shall be responsible for any additional shipping cause beyond Seller’s reasonable control.

charges incurred by Seller due to Buyer’s acts or omissions. 15. Waiver and Severability. Failure to enforce any provision of this agreement

4. Warranty. Seller warrants that the Products sold hereunder shall be free from will not waive that provision nor will any such failure prejudice Seller’s right to

defects in material or workmanship for a period of eighteen months from the date enforce that provision in the future. Invalidation of any provision of this agreement

of shipment from the Company. The prices charged for Seller's products are by legislation or other rule of law shall not invalidate any other provision herein.

based upon the exclusive limited warranty stated above, and upon the following The remaining provisions of this agreement will remain in full force and effect.

disclaimer: DISCLAIMER OF WARRANTY: THIS WARRANTY COMPRISES 16. Termination. Seller may terminate this agreement for any reason and at any

THE SOLE AND ENTIRE WARRANTY PERTAINING TO PRODUCTS time by giving Buyer thirty (30) days written notice of termination. Seller may

PROVIDED HEREUNDER. SELLER DISCLAIMS ALL OTHER WARRANTIES, immediately terminate this agreement, in writing, if Buyer: (a) commits a breach of

EXPRESS AND IMPLIED, INCLUDING DESIGN, MERCHANTABILITY AND any provision of this agreement (b) appointments a trustee, receiver or custodian

FITNESS FOR A PARTICULAR PURPOSE. for all or any part of Buyer’s property (c) files a petition for relief in bankruptcy on

5. Claims; Commencement of Actions. Buyer shall promptly inspect all its own behalf, or by a third party (d) makes an assignment for the benefit of

Products upon delivery. No claims for shortages will be allowed unless reported to creditors, or (e) dissolves or liquidates all or a majority of its assets.

the Seller within 10 days of delivery. No other claims against Seller will be allowed 17. Governing Law. This agreement and the sale and delivery of all Products

unless asserted in writing within 30 days after delivery. Buyer shall notify Seller of hereunder shall be deemed to have taken place in and shall be governed and

any alleged breach of warranty within 30 days after the date the defect is or construed in accordance with the laws of the State of Ohio, as applicable to

should have been discovered by Buyer. Any action based upon breach of this contracts executed and wholly performed therein and without regard to conflicts of

agreement or upon any other claim arising out of this sale (other than an action by laws principles. Buyer irrevocably agrees and consents to the exclusive

Seller for an amount due on an y invoice) must be commenced within 12 months jurisdiction and venue of the courts of Cuyahoga County, Ohio with respect to any

from the date of the breach without regard to the date breach is discovered. dispute, controversy or claim arising out of or relating to this agreement.

6. LIMITATION OF LIABILITY. UPON NOTIFICATION, SELLER WILL, AT ITS 18. Indemnity for Infringement of Intellectual Property Rights. Seller shall

OPTION, REPAIR OR REPLACE A DEFECTIVE PRODUCT, OR REFUND THE have no liability for infringement of any patents, trademarks, copyrights, trade

PURCHASE PRICE. IN NO EVENT SHALL SELLER BE LIABLE TO BUYER dress, trade secrets or similar rights except as provided in this Section. Seller will

FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL defend and indemnify Buyer against allegations of infringement of U.S. patents,

DAMAGES ARISING OUT OF, OR AS THE RESULT OF, THE SALE, U.S. trademarks, copyrights, trade dress and trade secrets (“Intellectual Property

DELIVERY, NON-DELIVERY, SERVICING, USE OR LOSS OF USE OF THE Rights”). Seller will defend at its expense and will pay the cost of any settlement or

PRODUCTS OR ANY PART THEREOF, OR FOR ANY CHARGES OR damages awarded in an action brought against Buyer based on an allegation that

EXPENSES OF ANY NATURE INCURRED WITHOUT SELLER'S WRITTEN a Product sold pursuant to this Agreement infringes the Intellectual Property

CONSENT, EVEN IF SELLER HAS BEEN NEGLIGENT, WHETHER IN Rights of a third party. Seller's obligation to defend and indemnify Buyer is

CONTRACT, TORT OR OTHER LEGAL THEORY. IN NO EVENT SHALL contingent on Buyer notifying Seller within ten (10) days after Buyer becomes

SELLER'S LIABILITY UNDER ANY CLAIM MADE BY BUYER EXCEED THE aware of such allegations of infringement, and Seller having sole control over the

PURCHASE PRICE OF THE PRODUCTS. defense of any allegations or actions including all negotiations for settlement or

7. User Responsibility. The user, through its own analysis and testing, is solely compromise. If a Product is subject to a claim that it infringes the Intellectual

responsible for making the final selection of the system and Product and assuring Property Rights of a third party, Seller may, at its sole expense and option,

that all performance, endurance, maintenance, safety and warning requirements procure for Buyer the right to continue using the Product, replace or modify the

of the application are met. The user must analyze all aspects of the application Product so as to make it noninfringing, or offer to accept return of the Product and

and follow applicable industry standards and Product information. If Seller return the purchase price less a reasonable allowance for depreciation.

provides Product or system options, the user is responsible for determining that Notwithstanding the foregoing, Seller shall have no liability for claims of

such data and specifications are suitable and sufficient for all applications and infringement based on information provided by Buyer, or directed to Products

reasonably foreseeable uses of the Products or systems. delivered hereunder for which the designs are specified in whole or part by Buyer,

8. Loss to Buyer's Property. Any designs, tools, patterns, materials, drawings, or infringements resulting from the modification, combination or use in a system of

confidential information or equipment furnished by Buyer or any other items any Product sold hereunder. The foregoing provisions of this Section shall

which become Buyer's property, will be considered obsolete and may be constitute Seller's sole and exclusive liability and Buyer's sole and exclusive

destroyed by Seller after two consecutive years have elapsed without Buyer remedy for infringement of Intellectual Property Rights.

ordering the items manufactured using such property. Seller shall not be 19. Entire Agreement. This agreement contains the entire agreement between

responsible for any loss or damage to such property while it is in Seller's the Buyer and Seller and constitutes the final, complete and exclusive expression

possession or control. of the terms of sale. All prior or contemporaneous written or oral agreements or

9. Special Tooling. A tooling charge may be imposed for any special tooling, negotiations with respect to the subject matter are herein merged.

including without limitation, dies, fixtures, molds and patterns, acquired to 20. Compliance with Law, U. K. Bribery Act and U.S. Foreign Corrupt

manufacture Products. Such special tooling shall be and remain Seller's property Practices Act. Buyer agrees to comply with all applicable laws and regulations,

notwithstanding payment of any charges by Buyer. In no event will Buyer acquire including both those of the United Kingdom and the United States of America, and

any interest in apparatus belonging to Seller which is utilized in the manufacture of of the country or countries of the Territory in which Buyer may operate, including