Test Certificate: Highway Industries Ltd. (Sahnewal)

Uploaded by

Deepak MehtaCopyright:

Available Formats

Test Certificate: Highway Industries Ltd. (Sahnewal)

Uploaded by

Deepak MehtaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Test Certificate: Highway Industries Ltd. (Sahnewal)

Uploaded by

Deepak MehtaCopyright:

Available Formats

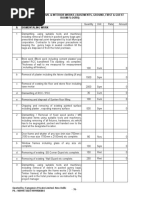

VARDHMAN SPECIAL STEELS LTD. QF R&D 4.12.

06

IATF 16949 : 2016

C-58,FOCAL POINT,PHASE V, LUDHIANA (PB.) INDIA Certificate No : 37659-2008-AQ-IND-IATF

ISO 17025 : 2005

Ph. No. : 0161-2670707-09

Certificate No : TC-7438

ISO 14001 : 2015

Certificate No : 261680-2018-AE-IND-RVA

TEST CERTIFICATE OHSAS 18001:2007

Certificate No : 261679-2018-AHSO-IND-RVA

ISO 9001 : 2015

TEST CERTIFICATE NO.: BLB530LAB2202272 Date of Issue : 08-05-2022 Certificate No : 39216-2008-AQ-IND-RVA

To: HIGHWAY INDUSTRIES LTD. (SAHNEWAL)

We certify that the material described below fully conforms to IS:7283-1992. Chemical Composition and Mechanical Properties of the product tested in accordance with

the Scheme of Testing and Inspection contained in the BIS Certification Marks licence No. CM/L-9700028216 are as indicated below against each order No. etc.

(PLEASE REFER TO IS:7283-1992 FOR DETAILS OF SPECIFICATION REQUIREMENTS)

TEST RESULTS

Order No. & Date Class & Design. Grade Heat No. Cast Section Finished Section Finish Shape Redution

(Cast No.) (mm) (Nominal Size mm) Ratio

S61-22000046/10.0 02-04-2022 20MNCR5HEH 00083912 200*200 90 Round 6.29

Supply Condition Length of Bar Color Code Invoice No. & Date No. of Bars Qty.(MT)

Hot Rolled 4.0-6.0 meter Violet

Manufacturing Route EAF-LRF-VD-CCP With EMS & AMLC

% CHEMICAL COMPOSITION - ASTM E 415

C Si Mn S P Ni Cr Mo Cu Sn Al Ti Ca B V Nb

Min. 0.200 - 1.300 0.012 - - 1.250 - - - 0.020 - - - - -

Max. 0.220 0.350 1.450 0.030 0.025 0.350 1.350 0.120 0.250 - 0.045 0.0100 0.0015 - - -

Actual 0.207 0.247 1.370 0.019 0.016 0.072 1.285 0.030 0.110 0.006 0.026 0.0023 0.0007 0.0003 0.0100 0.0016

Gases O2 N2 H2 D.I. Value Grain Size % Carbon % Manganese Decarb (mm) Micro Structure

(IS:4748/ASTM E112) Equivalent Equivalent (IS:6396)

In PPM ASTM E 1019 IS:228

Min. - 80.0 - - ASTM 5.0 or finer - - 1% of section Pearlite & Ferrite

Max. 25.0 160.0 2.7 - - -

Actual 13.0 119.0 1.3 - 6.5/7.0 - - 0.72 mm Pearlite & Ferrite

INCLUSION RATING - IS:4163 / ASTM E45A/ ISO 4967,Method A

A B C D JIS G 0555 DIN 50602 Hardness- IS:1500/1586

Thin Thick Thin Thick Thin Thick Thin Thick A B+C Total K3 K4 Min. -

Max. Req. - - - - - - - - - - - - 25 Max. 240 BHN

Actual - - - - - - - - - - - - 14.0 Actual 210-230 BHN

JOMINY HARDENABILITY IN HRC (IS 3848)

mm 1mm 1.5 mm 2 mm 3 mm 4 mm 5 mm 6 mm 6.35 mm 7 mm 8 mm 9 mm 10 mm 11 mm 12 mm 13 mm

- - - - - 43.0 - - - - - 39.0 - - -

Min.

Max. - - - - - 48.0 - - - - - 43.0 - - -

Actual - - - - - 45.50 - - - - - 41.00 - - -

MM 14 mm 15 mm 17 mm 18 mm 19 mm 20 mm 25 mm 30 mm 35 mm 40 mm 45 mm 50 mm 55 mm 60 mm

Min. - - - - - - 32.0 - - - - - - -

Max. - - - - - - 36.0 - - - - - - -

Actual - - - - - - 33.00 - - - - - - -

MECHANICAL PROPERTIES (IS:1608) IS:1499 / IS:1598

Test Condition Tensile Strength Yield Strength % Elongation % Reduction Area Impact Strength

Min - - - - -

-

Max - - - - -

Actual - - - - - -

SUPPLEMENTARY REQUIREMENTS

Internal Soundness Step Down Test Blue Fracture Test Straightness

Surface Defects

(ASTM E381 / IS11371) (IS 4075) (IS 10138) mm / meter max.

C3R2S2 max as per ASTM E381 - - Surface defects < 1% of section 6.0

Required

Actual C3R2S2 max. - - OK OK

Ultrasonic Test MFLT MPI Dimension Tolerance Ovality/Lobbing

Required Manual UST - - +1.60/-0.30 mm 75% of dimensional tolerance

Actual 100 % Bars done-OK - - OK OK

Mixup Test 100% Bars checked by Spark Test ,XRF Test

THE MATERIAL SUPPLIED TO THE STANDARD ROLLING TOLERANCES

Material is free from radioactive elements Al/N ratio= 2.18 against 2.0 minimum

Remarks

Cu+10xSn= 0.17 against 0.45% max., Sb%= 0.0012 against 0.007 max.

Reference Standard IS: 7283 -1992 Spec:- IS-HT-205, Rev. -00, Dated -09.03.2022 NPDP-220401, Rev. -00, Dated -02.04.2022

Above mentioned results relate only to the sample tested

This report shall not be reproduced except in full without the approval of laboratary / Authorised signatory

For any Technical Support / Quality related issues please contact -

Mr. Dinesh Singh Mobile no. : 081466-25586 , email : met5.vss@vardhman.com Checked by : Approved by : Dinesh Singh

For any Test Certificate related issues please contact -

Engineer - R&D Authorised Signatory

Mr. K.K. Shukla Mobile no. : 075080-02659 , email : met2.vss@vardhman.com

Website : www.vardhmansteel.com For VARDHMAN SPECIAL STEELS LTD.

You might also like

- BK91-1318-01-FSF-000-PIP-RFI-0029 Request For Inspection of Carbon Steel Pipe Material - SignedNo ratings yetBK91-1318-01-FSF-000-PIP-RFI-0029 Request For Inspection of Carbon Steel Pipe Material - Signed293 pages

- En 13602 Drawn, Round Copper Wire For The Manufacture of Electrical Conductors50% (2)En 13602 Drawn, Round Copper Wire For The Manufacture of Electrical Conductors22 pages

- 20 MIN To 90 MIN WH Fire Door Certificates - YUKINo ratings yet20 MIN To 90 MIN WH Fire Door Certificates - YUKI7 pages

- Ningbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)No ratings yetNingbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)1 page

- Baoji Marmara Metal Products Co., LTD: Material Test CertificateNo ratings yetBaoji Marmara Metal Products Co., LTD: Material Test Certificate1 page

- Mechanical Properties: Chemical CompositionNo ratings yetMechanical Properties: Chemical Composition1 page

- F.831 - Certificate of Thorough Examination of Mobile Crane Rev.03No ratings yetF.831 - Certificate of Thorough Examination of Mobile Crane Rev.032 pages

- Mill TC Passion Format EN31 Sae 52100 DIA 4.20+No ratings yetMill TC Passion Format EN31 Sae 52100 DIA 4.20+1 page

- IGQ0811.100379 - Dye Penetrant Inspection According To API 6D - Rev2100% (1)IGQ0811.100379 - Dye Penetrant Inspection According To API 6D - Rev28 pages

- Western India Forgings Pvt. LTD.: Test CertificateNo ratings yetWestern India Forgings Pvt. LTD.: Test Certificate1 page

- Quality Certificate / Material Test Certificate (Certificate Acc To Bs en 10204/3.1)No ratings yetQuality Certificate / Material Test Certificate (Certificate Acc To Bs en 10204/3.1)1 page

- TRI000001381 - Advice Note of Devlivery To K&S From London Fittings and Flanges With Test CertificatesNo ratings yetTRI000001381 - Advice Note of Devlivery To K&S From London Fittings and Flanges With Test Certificates16 pages

- CQI-9 Special Process: Heat Treat System AssessmentNo ratings yetCQI-9 Special Process: Heat Treat System Assessment35 pages

- Liberty Galati S.A. - Romania: Inspection Certificate 20614009 ACCORDING TO: EN 10204/2004/3.1 DATE: 20.01.2020No ratings yetLiberty Galati S.A. - Romania: Inspection Certificate 20614009 ACCORDING TO: EN 10204/2004/3.1 DATE: 20.01.20201 page

- Guide For Internal Audit and Management Review For Conformity Assessment Bodies (Laboratories / PTP / RMP)100% (1)Guide For Internal Audit and Management Review For Conformity Assessment Bodies (Laboratories / PTP / RMP)26 pages

- Laboratories Accredited by Cnas For Testing of MaksNo ratings yetLaboratories Accredited by Cnas For Testing of Maks34 pages

- Tayade Aaryan Hiralal FeeReceipt ExportToPDFNo ratings yetTayade Aaryan Hiralal FeeReceipt ExportToPDF1 page

- RR Plast Extrusions Pvt. LTD - Internal Audit Report September 2021 (MY)No ratings yetRR Plast Extrusions Pvt. LTD - Internal Audit Report September 2021 (MY)16 pages

- A World Class Carbon and Stainless Steel Flange ManufacturerNo ratings yetA World Class Carbon and Stainless Steel Flange Manufacturer5 pages

- A Tut$&ii:': Zhejiang Tsingshan Steel CO,,LTD, Mill EN'10204/3 2014l68/EUNo ratings yetA Tut$&ii:': Zhejiang Tsingshan Steel CO,,LTD, Mill EN'10204/3 2014l68/EU73 pages

- Character Verification Certificate: Office of Superintendent of Police, BhiwaniNo ratings yetCharacter Verification Certificate: Office of Superintendent of Police, Bhiwani1 page

- Declaration of Performance: Construction Product: System 2+No ratings yetDeclaration of Performance: Construction Product: System 2+1 page

- Contact Persons & Nos:: Grasim Industries LimitedNo ratings yetContact Persons & Nos:: Grasim Industries Limited5 pages

- Test Certificate: Flash Electronics India Pvt. LTDNo ratings yetTest Certificate: Flash Electronics India Pvt. LTD1 page

- 6-2660 - MTC Reliable - A420 Wpl6 - 6 Inch X SCH 80 - Fittings-2No ratings yet6-2660 - MTC Reliable - A420 Wpl6 - 6 Inch X SCH 80 - Fittings-21 page

- Arcelormittal Nippon Steel India Limited: Heat Analysis (%) of 24400486No ratings yetArcelormittal Nippon Steel India Limited: Heat Analysis (%) of 244004861 page

- Quantitative Evaluation of Structural Alloy Steel Banded StructureNo ratings yetQuantitative Evaluation of Structural Alloy Steel Banded Structure8 pages

- Heat Treatment Analysis Report: Observation Less Bluish More BluishNo ratings yetHeat Treatment Analysis Report: Observation Less Bluish More Bluish1 page

- Supply Specification Coating / Painting For Parts With High Corrosive Stress DBL 7391100% (1)Supply Specification Coating / Painting For Parts With High Corrosive Stress DBL 739121 pages

- Ncert Solution For Class 8 Science Chapter - 3 Synthetic FibresNo ratings yetNcert Solution For Class 8 Science Chapter - 3 Synthetic Fibres4 pages

- Schema Elettrico Esquema Electrico Electric Diagram SchaltplanNo ratings yetSchema Elettrico Esquema Electrico Electric Diagram Schaltplan71 pages

- Experimental Works For The Beter Understanding Failure Activity Aspects and ResultsNo ratings yetExperimental Works For The Beter Understanding Failure Activity Aspects and Results16 pages

- GATE 1991 - Question Paper TF: Textile Engineering and Fiber ScienceNo ratings yetGATE 1991 - Question Paper TF: Textile Engineering and Fiber Science4 pages

- Stop Motion Puppet Construction 1st Edition: The Mummy (C) Mauricio Paragua All Rights ReservedNo ratings yetStop Motion Puppet Construction 1st Edition: The Mummy (C) Mauricio Paragua All Rights Reserved8 pages

- CN101407428A - Concrete Superficial Hardener Patent SummaryNo ratings yetCN101407428A - Concrete Superficial Hardener Patent Summary13 pages

- Effect of Water Flow Rate On The Yield Strength ofNo ratings yetEffect of Water Flow Rate On The Yield Strength of6 pages

- Nano Particles in Waste Water TreatmentNo ratings yetNano Particles in Waste Water Treatment13 pages

- Heucophos Zcp-Plus / Heucorin RZ: Solvent BasedNo ratings yetHeucophos Zcp-Plus / Heucorin RZ: Solvent Based2 pages

- Quote - R1, 20012021, Boq For BOH Area Interiors & Civil WorkNo ratings yetQuote - R1, 20012021, Boq For BOH Area Interiors & Civil Work19 pages

- Tycoons - Specs of Carbon Steel Wire - 10B21, 10B38, 1010, 4140No ratings yetTycoons - Specs of Carbon Steel Wire - 10B21, 10B38, 1010, 41401 page