Nonlinear Numerical Simulation of Bolted Ring Flanges in Wind Turbine Towers

Nonlinear Numerical Simulation of Bolted Ring Flanges in Wind Turbine Towers

Uploaded by

Tiago CunhaCopyright:

Available Formats

Nonlinear Numerical Simulation of Bolted Ring Flanges in Wind Turbine Towers

Nonlinear Numerical Simulation of Bolted Ring Flanges in Wind Turbine Towers

Uploaded by

Tiago CunhaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Nonlinear Numerical Simulation of Bolted Ring Flanges in Wind Turbine Towers

Nonlinear Numerical Simulation of Bolted Ring Flanges in Wind Turbine Towers

Uploaded by

Tiago CunhaCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/303862943

Nonlinear Numerical Simulation of Bolted Ring Flanges in Wind Turbine

Towers

Conference Paper · September 2014

CITATIONS READS

4 249

3 authors, including:

Ilias D. Thanasoulas Charis Gantes

National Technical University of Athens National Technical University of Athens

7 PUBLICATIONS 17 CITATIONS 167 PUBLICATIONS 1,817 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

structural control View project

ADDitively Manufactured OPTimized Structures by means of Machine Learning-ADDOPTML View project

All content following this page was uploaded by Ilias D. Thanasoulas on 09 June 2016.

The user has requested enhancement of the downloaded file.

Proceedings of the IASS-SLTE 2014 Symposium

“Shells, Membranes and Spatial Structures: Footprints”

15 to 19 September 2014, Brasilia, Brazil

Reyolando M.L.R.F. BRASIL and Ruy M.O. PAULETTI (eds.)

NONLINEAR NUMERICAL SIMULATION OF BOLTED RING

FLANGES IN WIND TURBINE TOWERS

Ilias D. Thanasoulas*, Konstantina G. Koulatsoua, Charis J. Gantesb

* Institute of Steel Structures, National Technical University of Athens

9 Heroon Polytechniou Street, GR-15780 Zografou, Greece

ithana@central.ntua.gr

a

Institute of Steel Structures, National Technical University of Athens

b

Institute of Steel Structures, National Technical University of Athens

Abstract

The efficiency against fatigue of connections between adjacent parts of tubular wind turbine towers is

investigated, taking realistically into account the dynamic nature of applied wind loads. Such connections are

realized by means of double ring flanges that are pre-welded on the adjacent shell parts and are bolted together

with fully preloaded bolts. In order to achieve that goal, two numerical models are created with the finite element

program ADINA. The first is a detailed model of a single bolt using solid elements for bolt and flanges, while in

the second the entire bolted ring flange connection is modeled employing shell elements for the flanges and

beam elements for the bolts. Contact elements are appropriately used in both models to introduce the

connection’s nonlinear behavior due to the interaction between flanges and bolts and between nuts and flanges.

Nonlinear dynamic analysis results from the second model are used for fatigue checks according to Eurocode 3.

The imposed wind load results from artificial wind pressure time histories obtained via an appropriate

aerodynamic approach and producing wind forces acting on the wind turbine blades and transmitted to the hub.

Keywords: Wind Turbine Towers, Bolted Ring Flanges, Contact, Nonlinearity, Finite Element Modeling.

1. Introduction

As wind energy is gaining great attention nowadays as a mature type of cost-effective renewable energy,

investigation of several aspects of the design, construction and operation of wind turbines becomes progressively

more interesting and demanding. A very commonly used type of wind turbine tower is the tubular steel tower,

which is composed of a number of cylindrical and/or conical shells. Its construction is achieved by (i) cold-

curving flat steel plates into the desired conical shape, (ii) welding the two edges, to obtain a closed conical

shell, usually 2.5m to 3.0m long, as imposed by the industrially available steel plates, (iii) welding consecutive

shell parts together, to obtain 15m to 30m long shells, as imposed by transportability constraints, (iv)

transporting these parts to the wind park site by tracks, lifting them by means of cranes or helicopters and bolting

them together with fully preloaded bolts, using pre-welded double ring flanges.

The prevailing structural action on such towers is bending due to lateral wind pressures on the tower itself and,

mostly, on the rotating blades. In-line with the objective of growing energy production from renewable sources,

wind turbine dimensions increase in order to take better advantage of the available wind potential. Namely, taller

towers introduce higher wind velocities, while longer blades provide larger incident area. As a result, the wind

load acting on the wind turbine towers increases also, inducing larger forces and, particularly, bending moments

upon the wind turbine tower and its connections. Wind related actions are the cause of the two most common

types of structural failures, either buckling failure of the tower itself, or fatigue failure at its connections.

In the present article the efficiency of the preloaded connections against fatigue for a 3-bladed 1.5 MW wind

turbine of tower height 82.39m is investigated, taking into account the dynamic nature of applied wind loads [4].

Such connections have been investigated in the literature by means of approximate analytical models [2] as well

as numerical analyses and experimental tests [9, 10]. In the proposed approach, three public domain software

tools produced by the National Renewable Energy Laboratory (NREL) and the National Wind Technology

Center (NTWC) are first used in order to obtain realistic wind actions. Then, two numerical models are created

with the finite element program ADINA [1]. The first is a detailed model of a single bolt using solid elements

Copyright © 2014 by the authors.

Published by the International Association for Shell and Spatial Structures (IASS) with permission. 1

Proceedings of the IASS-SLTE 2014 Symposium

“Shells, Membranes and Spatial Structures: Footprints”

for bolt and flanges, and is mostly used in order to gain qualitative insight into the connection’s behavior. In the

second model the entire bolted ring flange connection is simulated employing shell elements for the flanges and

beam elements for the bolts. Contact elements are appropriately used in both models to introduce the

connection’s nonlinear behavior due to the interaction between flanges and bolts and between nuts and flanges.

The results of the second model are used for subsequent fatigue checks of the connection’s bolts and welds.

2. Artificial wind load time histories generation

The first part of the paper focuses on the generation of artificial wind load time histories in order to obtain

reliable and realistic actions for the subsequent finite element analyses. For this purpose three public domain

computational engineering tools, namely FAST [7], AeroDyn [6] and TurbSim [8], are used. With TurbSim a

realistic wind profile is created, with AeroDyn the aerodynamic behavior of the rotating blades is properly taken

into account and finally with FAST the dynamic action on the wind turbine tower and hub is determined. Each

software can use IEC 61400-1 [5] standard for its computations.

2.1. Normal wind speed distribution

The wind speed distribution is significant for wind turbine design because it determines the frequency of

occurrence of individual load conditions for the normal design situations. The mean value of the wind speed over

a time period of 10 min shall be assumed to follow a Rayleigh distribution at hub height given by

PR (Vhub ) 1 exp[ π(Vhub / 2Vave )2 ] (1)

where in our case Vave=0.2∙Vref,, Vref = 42.5 m/s.

0.1 1

Probability density function

0.08 0.8

Cumulative Distribution

0.06 0.6

0.04 0.4

0.02 0.2

0 0

0 5 10 15 20 25 0 5 10 15 20 25

V (m/s) V (m/s)

hub hub

Figure 1: Rayleigh probability density function Figure 2: Rayleigh cumulative distribution function

2.2. Normal wind speed turbulence

For the normal turbulence model, the representative value of the turbulence standard deviation, σ1, is given by

σ1 I ref 0.75Vhub b (2)

where b=5.6m/s, Iref=0.14 for turbulence B category. The component power spectral densities were assumed via

“Kaimal (1972) spectrum and exponential coherence model”

f Sk ( f ) 4 f Lk / Vhub (3)

σk 2 5

( 1 6 f Lk / Vhub ) 3

2.3. Longitudinal wind velocity time histories

In Fig. 3, the produced wind load time histories for mean wind velocities 5 m/s, 10 m/s and 15 m/s at hub height

employed for this paper are illustrated. X axis is pointing in the nominal (0°) downwind direction, while Y axis

is pointing to the left when looking in the nominal downwind direction.

30 30 30

Velocity m/s

Velocity m/s

Velocity m/s

20 20 20

10 10 10

0 0 0

0 200 400 600 0 200 400 600 0 200 400 600

Time sec Time sec Time sec

Figure 3: Wind velocity time histories at hub height with standard deviations σ1=1.3093, σ2=1.8341, σ3= 2.3617

Copyright © 2014 by the author(s).

Published by the International Association for Shell and Spatial Structures (IASS) with permission.

Proceedings of the IASS-SLTE 2014 Symposium

“Shells, Membranes and Spatial Structures: Footprints”

2.4. Design force time histories

The dynamic tower loads obtained from Fast software due to the wind velocity time histories shown in Fig. 3,

represent the intensity field developed at the steel tower for normal design situations, which are critical for

fatigue failure. Indicative results are illustrated in Fig. 4.

150 300 300

100

Fx at top (kN)

Fx at top (kN)

Fx at top (kN)

200 200

50

100 100

0

-50 0 0

0 200 400 600 0 200 400 600 0 200 400 600

Time sec Time sec Time sec

0 500 1000

Myy at top (kNm)

Myy at top (kNm)

Myy at top (kNm)

0

-500 0

-500

-1000 -1000

-1000

-1500 -1500 -2000

0 200 400 600 0 200 400 600 0 200 400 600

Time sec Time sec Time sec

4 4

10000 x 10 x 10

3 3

Myy at base (kNm)

Myy at base (kNm)

Myy at base (kNm)

5000

2 2

0 1 1

-5000 0 0

0 200 400 600 0 200 400 600 0 200 400 600

Time sec Time sec Time sec

Figure 4: Shear and bending moment time histories at base and top of the tower

3. Numerical simulation of interaction between single bolt and flange

In order to investigate the flange and bolt interaction, four models of a single bolt and the surrounding flange

part were analyzed in Adina [1] using 3d-solid elements and appropriate contact surfaces. Advantage was taken

of symmetry conditions in order to reduce the model’s size. Successive mesh refinement was employed to ensure

the convergence of the results (Fig. 5).

Figure 5: Finite element simulation models for bolt and flange interaction

The model consists of a quarter of a bolt M20 10.9, half bolt head according to DIN 6914 and a slice of half

flange ring, taking into account symmetry boundary conditions. Contact elements between bolt head and upper

flange surface, bolt and flange hole rim surfaces, as well as upper and lower flange interface were considered.

Analyses for eccentric loading parallel and transverse to the bolt axis were performed and results started to

converge for the 3rd model. Results presented below concern this 3rd model.

3.1. Eccentric loading parallel to the bolt axis

An upward force up to 120kN was imposed gradually to the model at the outer surface of the ring flange, as

shown in Fig. 5, for different bolt pretension forces 10kN, 50kN, 100kN and 150kN. Initially, this force is

received via redistribution of the vertical reaction from the bottom flange to the upper one and when the force is

increased sufficiently, so that no more redistribution is possible, the bolt starts to stretch.

Copyright © 2014 by the author(s).

Published by the International Association for Shell and Spatial Structures (IASS) with permission.

Proceedings of the IASS-SLTE 2014 Symposium

“Shells, Membranes and Spatial Structures: Footprints”

250 250

150 kN

200

Contact Force z (kN)

200 100 kN

Bolt Force (kN)

50 kN

150 150 10 kN

100 150 kN 100

100 kN

50 50 kN 50

10 kN

0 0

0 20 40 60 80 100 120 0 20 40 60 80 100 120

Imposed Force (kN) Imposed Force (kN)

Figure 6: Bolt axial tensioning due to imposed force Figure 7: Transverse reaction between flanges

Figure 8: Redistribution of vertical contact reaction between flanges

3.2. Eccentric loading transverse to the bolt axis

A shear force up to 40kN was imposed gradually at the model assuming bolt pretension force equal to 50kN and

Coulomb friction coefficient μ=0.5. Shear is initially received entirely by friction at the interface between the

two flanges till they slip and then the rest is received through bolt shear and contact of the bolt head.

0

Flange surface

-5

Bolt surface

Friction y (kN)

-10

-15

-20

-25

-30

0 1 2 3 4 5 6 7 8

Displacement y -4

x 10

Figure 9: Shear received from flange and bolt due to friction Figure 10: Upper and lower flange surface

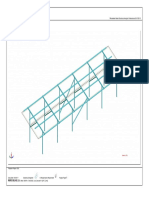

4. Numerical simulation of entire connection

An actual wind turbine flange connection has then been simulated, as shown in Fig. 11. The outer and inner

diameters of the ring are 3.30m and 3.04m, respectively, the flange’s thickness is 60mm and the tower shell

thickness is 15mm. The two flange rings are bolted together with 90 pretensioned bolts M36-10.9 spaced at four

degrees angles. Bolt pretension force is calculated equal to 571.9kN (70% of bolt tensile strength according to

EC3). Only half of the problem was simulated due to symmetry. The tower truncated conical shell, flange, and

bolt heads were simulated with shell elements while the bolt shafts with beam elements. Contact elements

between the two flanges and between bolt head and upper flange were also considered. The model was first

calibrated for two loading cases, one causing bending and the other shear of the connection. Then, the model was

used to perform dynamic analysis and check against fatigue.

Copyright © 2014 by the author(s).

Published by the International Association for Shell and Spatial Structures (IASS) with permission.

Proceedings of the IASS-SLTE 2014 Symposium

“Shells, Membranes and Spatial Structures: Footprints”

Figure 11: Perspective view with details of tower, flange and bolts connection

4.1. Bending loading

In the first phase self-weight was applied to the tower and pretension to the bolts. Then bending moment was

imposed at the top of the tower increasing gradually up to 10000kNm. The resulting contact surfaces are

illustrated in Fig. 12, while bolt forces and shell normal stresses are shown in Figs. 13 and 14, respectively.

Figure 12: Contact status at the interface of the two ring flanges at imposed moments 5000kNm and 10000kNm

5

610 x 10

2

Bolt Forces (kN)

600

Stress zz (kPa)

1

590

0

580

570 -1

0 2000 4000 6000 8000 10000 0 2000 4000 6000 8000 10000

Imposed Moment at the top (kNm) Imposed Moment at the top (kNm)

Figure 13: Bolt force response curves Figure 14: Stress σzz at the tensioned bottom side of tower

4.2. Shear loading

For normal design conditions shear is undertaken entirely through flange friction and not from bolts. As far as

tower-flange weld’s shear, it is not critical, as it takes negligible values whereas normal stress dominates.

5. Connection fatigue analysis

The 10 minute load time histories for the entire range of wind velocities for normal external conditions, obtained

from aeroelastic analysis as mentioned in section 2, were imposed at the top of the tower. Then, knowing the

annual probability, f, of the wind speed being in the interval Vp<Vo<Vp+1, the actual number of annual 10 minute

periods for which the wind velocity is in this interval is 6·8760·f. To count the number of cycles from an actual

time series the well-known technique of ‘rainflow counting’ was used (Fig. 15). The fatigue check was

performed according to EC3 part 1.9 [3] S-N curves (Fig. 16). The reference value of the fatigue strength at

NC=2 million cycles is 40MPa for this detail category. The cut-off limit below which stress ranges of the design

spectrum do not contribute to the calculated cumulative damage is 12.0MPa and the constant amplitude fatigue

limit is 21.8MPa. To estimate the total number of cycles for failure, the Palmgren-Miner rule gives the

cumulative damage during cyclic loading. This rule assumes that the ratio between the number of applied stress

cycles, nEi, with a given mean stress level σmEi and range γFf Δσi , and the number of cycles, NRi, which would lead

to failure with the same mean stress and range, constitutes the expended part of the useful fatigue life and that

the sum of these ratios is thus the damage D. Hence, the criterion for not failing is that D is less than 1.

Copyright © 2014 by the author(s).

Published by the International Association for Shell and Spatial Structures (IASS) with permission.

Proceedings of the IASS-SLTE 2014 Symposium

“Shells, Membranes and Spatial Structures: Footprints”

n

nEi

Dd (4)

i N Ri

3

600 10

Stress range σR (MPa)

Nr of cycles

400

2

10

200

1

0 10

4 6 8

0 0.5 1 1.5 2 2.5 10 10 10

Stress amplitudes (kPa) x 10

4 Endurance, number of cycles N

Figure 15: Histogram of stress σzz amplitude at the tensioned Figure 16: Fatigue strength curve

side of weld, for 10 m/s mean 10-minute wind speed

For normal external conditions, bolts maintain constant tension equal to their pretension force, as redistribution

takes place. In contrary the weld between the flange and the tower is subjected to cyclic tension, which from the

above analysis leads to annual ratio damage Dd= 0.0253, meaning failure after 39.5 years.

5. Conclusions

A first attempt to investigate fatigue of wind turbine tower ring connections with preloaded bolts taking into

account the dynamic nature of wind load has been presented. The wind load was obtained from artificial wind

pressure time histories produced by public domain software tools produced by the National Renewable Energy

Laboratory (NREL) and the National Wind Technology Center (NTWC). First, the flange and bolt interaction

was investigated via a detailed model of one bolt created with solid and contact finite elements. Then, a full

model of the connection was created in order to check bolts and welds against fatigue. In the presented numerical

example welds were more influenced from fatigue than bolts, which remained fully tight.

Acknowledgement

This research has been co-financed by the European Union (European Social Fund - ESF) and Hellenic national

funds through the Operational Program "Competitiveness and Entrepreneurship" of the National Strategic

Reference Framework (NSRF 2007-2013) - Research Funding Program: Bilateral R&D Cooperation between

Greece and China 2012-2014.

References

[1] ADINA System 8.3, Release Notes ADINA R&D Inc, 71 Elton Avenue, Watertown, USA, 2005.

[2] C. Petersen, Stahlbau: Grundlagen der Berechnung und baulichen Ausbildung von Stahlbauten, Vieweg,

1993.

[3] Eurocode 3 – Design of steel structures, Part 1-9: Fatigue, European Committee for Standardization, 2003.

[4] H. Schmidt and A. Jakubowski, Ermüdungssicherheit imperfekter vorgespannter Ringflanschstösse in

windbeanspruchten turmartigen Stahlbauten, U. of Essen, 2001.

[5] IEC 61400-1, “Wind turbines, Part I – Design requirements”, International standard, 3rd edition, 2005.

[6] NWTC Computer-Aided Engineering Tools (AeroDyn by David J. Laino, Ph.D.).

http://wind.nrel.gov/designcodes/simulators/aerodyn/, last modified 23-Feb.-2013; accessed 1-Nov.-2013.

[7] NWTC Computer-Aided Engineering Tools (FAST by Jason Jonkman, Ph.D.),

http://wind.nrel.gov/designcodes/simulators/fast/ , last modified 28-Oct.-2013; accessed 1-Nov.-2013.

[8] NWTC Computer-Aided Engineering Tools (TurbSim by Neil Kelley, Bonnie Jonkman),

http://wind.nrel.gov/designcodes/preprocessors/turbsim/, last modified 30-May-2013; accessed 1-Nov.-

2013.

[9] V.-L. Hoang, J.-P. Jaspart and J.-F. Demonceau, Behaviour of bolted flange joints in tubular structures

under monotonic, repeated and fatigue loadings I: Experimental tests, Journal of Constructional Steel

Research, 2013, 85, 1-11.

[10] Y.Q. Wang, L. Zong and Y.J. Shi, Bending behavior and design model of bolted flange-plate connection,

Journal of Constructional Steel Research, 2013, 84, 1-16.

Copyright © 2014 by the author(s).

Published by the International Association for Shell and Spatial Structures (IASS) with permission.

View publication stats

You might also like

- Flagro Fvo 400 Heater Operations and TroubleshootingDocument30 pagesFlagro Fvo 400 Heater Operations and TroubleshootingJocelyn DuteauNo ratings yet

- Good Wrench ManualDocument146 pagesGood Wrench ManualPM83% (12)

- United Motors V2S650R 650R Hyosung United MotorsDocument135 pagesUnited Motors V2S650R 650R Hyosung United MotorsFabian Sanchez100% (1)

- ACI Moment Coefficient Design AID PDFDocument13 pagesACI Moment Coefficient Design AID PDFSufian Ahmad50% (4)

- Nextracker White Paper Mitigating Extreme Weather Risk Part 1Document15 pagesNextracker White Paper Mitigating Extreme Weather Risk Part 1Tiago CunhaNo ratings yet

- ESCO Roundtable Borderless Prospectus v7Document21 pagesESCO Roundtable Borderless Prospectus v7Tiago CunhaNo ratings yet

- Multiparameter Equations of State An Accurate Source of Thermodynamic Property Data Span 2000Document46 pagesMultiparameter Equations of State An Accurate Source of Thermodynamic Property Data Span 2000Fátima ReyesNo ratings yet

- Beam Design StepsDocument14 pagesBeam Design StepsAnonymous Of0C4d100% (2)

- Reuss BeamDocument19 pagesReuss BeamJunaid AliNo ratings yet

- Haddard Proof JMES 2021Document14 pagesHaddard Proof JMES 2021Nikolay TokmantsevNo ratings yet

- 716 Composite ArticleDocument2 pages716 Composite ArticlesidzmailsterNo ratings yet

- Tensile Structures of Cables Net Guidelines To DesDocument33 pagesTensile Structures of Cables Net Guidelines To DesSamuellgerard SamuellgerardNo ratings yet

- 2012 - Friction Connection in Tubular Towers For A Wind Turbine - Veljkovic-Simoesdasilva - STAHLBAU - 290Document15 pages2012 - Friction Connection in Tubular Towers For A Wind Turbine - Veljkovic-Simoesdasilva - STAHLBAU - 290Tiago LopesNo ratings yet

- Design of Aluminium Bicycle Frames PDFDocument7 pagesDesign of Aluminium Bicycle Frames PDFPablo FadulNo ratings yet

- paper_balance_saeDocument12 pagespaper_balance_sae2255200084No ratings yet

- Simulation of Viscous Fingers Developed in Lifting Plate Hele-Shaw Cell in Volume of Fluid ModelDocument8 pagesSimulation of Viscous Fingers Developed in Lifting Plate Hele-Shaw Cell in Volume of Fluid ModelChetna SharmaNo ratings yet

- Online Wind Tunnel Laboratory: June 2008Document20 pagesOnline Wind Tunnel Laboratory: June 2008Ro RohadiNo ratings yet

- Arch 1Document21 pagesArch 1Rishi RamakrishnanNo ratings yet

- Full Text 01Document86 pagesFull Text 01baluNo ratings yet

- 1 s2.0 S0307904X11006986 MainDocument14 pages1 s2.0 S0307904X11006986 MainRUSxALI 77No ratings yet

- Modeling and Manual Design Comparision of Streeses in Castellated Beam Using AnsysDocument5 pagesModeling and Manual Design Comparision of Streeses in Castellated Beam Using AnsysAdnan NajemNo ratings yet

- Frequency Response Analysis of Steel Beams With Web OpeningsDocument11 pagesFrequency Response Analysis of Steel Beams With Web Openingssourabh mahanaNo ratings yet

- The Spacedrive Project - First Results On Emdrive and Mach-Effect ThrustersDocument11 pagesThe Spacedrive Project - First Results On Emdrive and Mach-Effect ThrustersSandra BartkiNo ratings yet

- Modeling Verification of An Advanced Torsional SPRDocument8 pagesModeling Verification of An Advanced Torsional SPRAnisha KoatNo ratings yet

- Numerical Study of Mono-Strand Anchorage Mechanism Under Service LoadDocument18 pagesNumerical Study of Mono-Strand Anchorage Mechanism Under Service LoadKarin Soldatelli BorsatoNo ratings yet

- Selamawit DegeDocument95 pagesSelamawit DegeSultan MohammedNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument6 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologyFrankie KOWANo ratings yet

- Numerical Simulation of Nozzle Flow Based On Euler Equation: Journal of Physics: Conference SeriesDocument17 pagesNumerical Simulation of Nozzle Flow Based On Euler Equation: Journal of Physics: Conference SerieszhaozhaomonsterNo ratings yet

- Numerical Analysis of Labyrinth Seal Performance FDocument20 pagesNumerical Analysis of Labyrinth Seal Performance FYan ManurungNo ratings yet

- Han 2020Document8 pagesHan 2020enterlogNo ratings yet

- Kareem 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012077Document14 pagesKareem 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012077khashehchi1356No ratings yet

- Cotter Joint CoferenceDocument5 pagesCotter Joint CoferenceMuhammad AliNo ratings yet

- An Iterative Calculation Method For Suspension Bridge's Cable SystemDocument10 pagesAn Iterative Calculation Method For Suspension Bridge's Cable SystemSaroj BhattaraiNo ratings yet

- Applsci 12 08037 With CoverDocument15 pagesApplsci 12 08037 With Coverlokakshasridhar2006No ratings yet

- Finite Element Analysis of Composite Aircraft Fuselage FrameDocument8 pagesFinite Element Analysis of Composite Aircraft Fuselage FrameIRJMETS JOURNALNo ratings yet

- Application of Numerical Methods To Truss Bridge Using Finite Element AnalysisDocument12 pagesApplication of Numerical Methods To Truss Bridge Using Finite Element AnalysisBenmark JabayNo ratings yet

- Analysis of a Reinforced Concrete DomeDocument11 pagesAnalysis of a Reinforced Concrete DomekaushalmainakyaNo ratings yet

- Analysis of Tunnel For Different Subsoil Plaxis PDFDocument7 pagesAnalysis of Tunnel For Different Subsoil Plaxis PDFGuillermo MansillaNo ratings yet

- Three-Dimensional Numerical Flutter Simulation: Gergely Szabo, Gergely KristofDocument8 pagesThree-Dimensional Numerical Flutter Simulation: Gergely Szabo, Gergely KristofVinh NguyenNo ratings yet

- Adaptables 2006 - NetherlandsDocument308 pagesAdaptables 2006 - NetherlandsLUIS ALBERTO MARROQUIN RIVERANo ratings yet

- 117 EOW2009presentationDocument9 pages117 EOW2009presentationJACKNo ratings yet

- Crusado InterpolationDocument13 pagesCrusado InterpolationgiovannidiazduranNo ratings yet

- IRJET-V7I607Document6 pagesIRJET-V7I607Cheran pandian SNo ratings yet

- CFD Simulation of Time Dependent OxygenDocument9 pagesCFD Simulation of Time Dependent OxygenBắc Phạm LêNo ratings yet

- Reconfigurable Four-Bar Linkages For Mechanism Design LaboratoryDocument12 pagesReconfigurable Four-Bar Linkages For Mechanism Design LaboratoryMahmood AbuZaidNo ratings yet

- Nonlinear Interval Analysis of the Rotor Response with Joints Under UncertaintiesDocument14 pagesNonlinear Interval Analysis of the Rotor Response with Joints Under Uncertaintieswangyongfeng1992No ratings yet

- Numerical Simulations of A Rocket Engine Internal Flow: Conference PaperDocument12 pagesNumerical Simulations of A Rocket Engine Internal Flow: Conference PaperVidushee GeetamNo ratings yet

- Belt Conveyor Network Design Using Simulation: Delft University of Technology, Delft, The NetherlandsDocument9 pagesBelt Conveyor Network Design Using Simulation: Delft University of Technology, Delft, The NetherlandsclebimsfNo ratings yet

- A Vortex Lattice MATLAB Implementation For Linear Aerodynamic Wing ApplicationsDocument46 pagesA Vortex Lattice MATLAB Implementation For Linear Aerodynamic Wing ApplicationsAlvin AnthonyNo ratings yet

- AL03Document17 pagesAL03Miguel MartínezNo ratings yet

- !!est Practice Guidelines For Computational Fluid Dynamics of Dispersed Multiphase FlowsDocument131 pages!!est Practice Guidelines For Computational Fluid Dynamics of Dispersed Multiphase FlowsjymmyneutronnNo ratings yet

- Aero-Structural Blade Design of A High-Power Wind Turbine: Bruno M. Tojo and Andr e C. MartaDocument14 pagesAero-Structural Blade Design of A High-Power Wind Turbine: Bruno M. Tojo and Andr e C. MartaMIGUEL ANGEL DURON SAAVEDRANo ratings yet

- Evaluating The Evolution and Analysis of Axle Fatigue and Crack Propagation On RailwayDocument7 pagesEvaluating The Evolution and Analysis of Axle Fatigue and Crack Propagation On Railwaybethel lemmaNo ratings yet

- 11 MIC2017 BUy-SHicks-WHKang HERAstreamDocument64 pages11 MIC2017 BUy-SHicks-WHKang HERAstreamvodugu123No ratings yet

- Ri Ha Definitivo InglesDocument16 pagesRi Ha Definitivo InglesPopoola Olalekan MansoorNo ratings yet

- 581 A Coupled CFD Multibody Dynamics Analysis Tool For Offshore Wind Turbines With Aeroelastic Mbdyn Software Blades LiuDocument10 pages581 A Coupled CFD Multibody Dynamics Analysis Tool For Offshore Wind Turbines With Aeroelastic Mbdyn Software Blades LiuMariela TisseraNo ratings yet

- Performance of Integrated Ground-Air-Space FSO Links Over Various Turbulent Environments - IEEE Journals & Magazine - IEEE XploreDocument33 pagesPerformance of Integrated Ground-Air-Space FSO Links Over Various Turbulent Environments - IEEE Journals & Magazine - IEEE XploreHANZ V2No ratings yet

- Tesis Maestria Nejad Modelo Simscape ImportanteDocument114 pagesTesis Maestria Nejad Modelo Simscape Importantexgboost1991No ratings yet

- Design and Development of Low-Cost Wind Tunnel For Educational PurposeDocument13 pagesDesign and Development of Low-Cost Wind Tunnel For Educational Purposeirfan aNo ratings yet

- A Fast and Precise Tool For Multi-Layer Planar CoilDocument18 pagesA Fast and Precise Tool For Multi-Layer Planar CoilAhmed Farahat 202-000-228No ratings yet

- 3-D Finite Element Modeling of Nanostructure Enhanced SAW SensorDocument6 pages3-D Finite Element Modeling of Nanostructure Enhanced SAW SensornitinsriniwasNo ratings yet

- A New Variable Stiffness Spring Using A Prestressed MechanismDocument8 pagesA New Variable Stiffness Spring Using A Prestressed MechanismDhanyata KancharlaNo ratings yet

- FSI PaperDocument10 pagesFSI PaperHasan AdelNo ratings yet

- Design of A Savonius Wind TurbineDocument25 pagesDesign of A Savonius Wind TurbinePeri Pitriadi CaralozNo ratings yet

- Modelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyFrom EverandModelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyGiorgio DianaNo ratings yet

- Embedded Systems: Analysis and Modeling with SysML, UML and AADLFrom EverandEmbedded Systems: Analysis and Modeling with SysML, UML and AADLFabrice KordonNo ratings yet

- Resonanace Investigation and Its Effects On Weight Optimization of Tubular Wind Turbine TowerDocument9 pagesResonanace Investigation and Its Effects On Weight Optimization of Tubular Wind Turbine TowerTiago CunhaNo ratings yet

- Guyed Wind Turbine Tower Concept Low ResDocument2 pagesGuyed Wind Turbine Tower Concept Low ResTiago CunhaNo ratings yet

- The Economic Contribution of The European Tower SectorDocument36 pagesThe Economic Contribution of The European Tower SectorTiago CunhaNo ratings yet

- TX CALA2020 Prospectus-1Document16 pagesTX CALA2020 Prospectus-1Tiago CunhaNo ratings yet

- E-Sourcing Quick GuideDocument41 pagesE-Sourcing Quick GuideTiago CunhaNo ratings yet

- Edotco Structure CatalogueDocument17 pagesEdotco Structure CatalogueTiago CunhaNo ratings yet

- PD/ Subcon Nonconformance Sheet: Non-Conformance DetailsDocument1 pagePD/ Subcon Nonconformance Sheet: Non-Conformance DetailsTiago CunhaNo ratings yet

- Design Report EC1 / EC3: Project #Edition Date: SheetDocument7 pagesDesign Report EC1 / EC3: Project #Edition Date: SheetTiago CunhaNo ratings yet

- ASMTower Verification 40m TowerDocument47 pagesASMTower Verification 40m TowerTiago Cunha100% (1)

- ES01MM00 4H22 ManmoelDocument1 pageES01MM00 4H22 ManmoelTiago CunhaNo ratings yet

- ©autodesk Robot Structural Analysis Professional 2015 2015: View - Cases: 1 (PP)Document3 pages©autodesk Robot Structural Analysis Professional 2015 2015: View - Cases: 1 (PP)Tiago CunhaNo ratings yet

- 17108-131-01 Status Meeting MoM #01Document2 pages17108-131-01 Status Meeting MoM #01Tiago CunhaNo ratings yet

- Autodesk Robot Structural Analysis Professional 2015 - (View - Cases - 1 (PERM1) )Document2 pagesAutodesk Robot Structural Analysis Professional 2015 - (View - Cases - 1 (PERM1) )Tiago CunhaNo ratings yet

- Steel Design EC3Document45 pagesSteel Design EC3Tiago CunhaNo ratings yet

- Design Ex 22010Document13 pagesDesign Ex 22010Tiago CunhaNo ratings yet

- Design Note Tower 30mDocument5 pagesDesign Note Tower 30mTiago CunhaNo ratings yet

- HLFT Cargoes GuidlinesDocument76 pagesHLFT Cargoes GuidlinesСтепан БандераNo ratings yet

- Lateral Response Analysis of GRS Bridge Abutments Under Passive PushDocument6 pagesLateral Response Analysis of GRS Bridge Abutments Under Passive PushRamalakshmi MNo ratings yet

- GBT 50087-2013Document29 pagesGBT 50087-2013BUĞRANo ratings yet

- How Corrosion Happens in Oil and Gas IndustryDocument6 pagesHow Corrosion Happens in Oil and Gas Industrysurekha surekha100% (1)

- Quantum 110vDocument32 pagesQuantum 110vFernando DavilaNo ratings yet

- Previews HI 9-6-4 PreDocument9 pagesPreviews HI 9-6-4 PreZoebairNo ratings yet

- Filter List AapDocument47 pagesFilter List AapFren KitaNo ratings yet

- Vibration Analysis - An Introduction To BasicsDocument23 pagesVibration Analysis - An Introduction To Basicswaj1100% (1)

- Ncert Solutions Mar3 For Cbse Class 7 Science Chapter 13Document8 pagesNcert Solutions Mar3 For Cbse Class 7 Science Chapter 13guruvisnu sureshNo ratings yet

- Wheel Bearing Hub Knuckle Upper Arm and Lower Arm 8212 Front Removal and Installation PDFDocument5 pagesWheel Bearing Hub Knuckle Upper Arm and Lower Arm 8212 Front Removal and Installation PDFMichael HernandezNo ratings yet

- Cert-Vb172 - (1-2199) FF-1002-1Document23 pagesCert-Vb172 - (1-2199) FF-1002-1TarasNo ratings yet

- Rigging Calc. Kato NK550Document9 pagesRigging Calc. Kato NK550ashadiamirNo ratings yet

- Plano Eléctrico Camión 793DDocument4 pagesPlano Eléctrico Camión 793DCarlos Florencio UrbanoNo ratings yet

- PV YK Vibrating Screen - Sal PDFDocument7 pagesPV YK Vibrating Screen - Sal PDFAaNo ratings yet

- Air Compressor Parts PDFDocument51 pagesAir Compressor Parts PDFRudi Arianto Rismod0% (1)

- CIVE1171 Lecture 1Document33 pagesCIVE1171 Lecture 1Josh100% (1)

- Halliday/Resnick/Walker Fundamentals of Physics: Classroom Response System QuestionsDocument51 pagesHalliday/Resnick/Walker Fundamentals of Physics: Classroom Response System QuestionsOlimpiade InfoNo ratings yet

- Manual de Operacion de Compresor Ingersoll RandDocument102 pagesManual de Operacion de Compresor Ingersoll RandAnonymous Jd6v1D6r50% (2)

- KM 2810Document28 pagesKM 2810Yec TiliaNo ratings yet

- Terzaghi Theory 1-D ConsolidationDocument6 pagesTerzaghi Theory 1-D ConsolidationSuman Narsingh RajbhandariNo ratings yet

- 20191119-3 - JGS 620 Technical Description and Calculation - enDocument8 pages20191119-3 - JGS 620 Technical Description and Calculation - enjonathan arboledaNo ratings yet

- AquaMist Machinery Space US 1017 LoResDocument8 pagesAquaMist Machinery Space US 1017 LoResSI Comércio e ServiçosNo ratings yet

- Chapter Two Yield Line: Prof. Dr. Mustafa B. Dawood Dr. Bilal Ismaeel Al-ShraifyDocument32 pagesChapter Two Yield Line: Prof. Dr. Mustafa B. Dawood Dr. Bilal Ismaeel Al-ShraifyToys 3ANo ratings yet

- FCR51 Control Flujo PDFDocument5 pagesFCR51 Control Flujo PDFAnonymous bTIzUkNo ratings yet