Section 30 - Relief Valves

Section 30 - Relief Valves

Uploaded by

hammamiCopyright:

Available Formats

Section 30 - Relief Valves

Section 30 - Relief Valves

Uploaded by

hammamiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Section 30 - Relief Valves

Section 30 - Relief Valves

Uploaded by

hammamiCopyright:

Available Formats

STE

Well Test Manual 3

Section 30

Instrumentation – Pilot Relief

Valves

Table of Contents

Introduction and Objectives…………………………………………… 30-2

Introduction to Relief Valves…...……………………………………… 30-3

Series 400 Modulating Valve……………………………………….…. 30-6

Installation and Startup Instruction………………………………… 30-12

Important Note regarding Operations………………………………… 30-16

Issued May 2007 1 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

Introduction

The section contains information on Pilot Relief Valves

Objectives

After completing this section, you should be able to

• Understand the Specification of the Pilot Relief Valve.

• Understand the workings of Pilot Relief Valve.

• Know how to install Pilot Relief Valve.

Issued May 2007 2 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

Pilot Relief Valves

Introduction

A pressure relief valve is a safety device designed to protect a pressurized

vessel or system during an overpressure event. An overpressure event refers

to any condition which would cause pressure in a vessel or system to

increase beyond the specified design pressure or maximum allowable working

pressure (MAWP).

Since pressure relief valves are safety devices, there are many Codes and

Standards written to control their design and application. The purpose of this

discussion is to familiarize you with the various parameters involved in the

design of a pressure relief valve and provide a brief introduction to some of

the Codes and Standards which govern the design and use of pressure relief

valves. Excerpts of various applicable Codes and Standards are included in

other sections of this handbook.

Many electronic, pneumatic and hydraulic systems exist today to control fluid

system variables, such as pressure, temperature and flow. Each of these

systems requires a power source of some type, such as electricity or

compressed air in order to operate. A pressure relief valve must be capable of

operating at all times, especially during a period of power failure when system

controls are nonfunctional. The sole source of power for the pressure relief

valve, therefore, is the process fluid.

Issued May 2007 3 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

Once a condition occurs that causes the pressure in a system or vessel to

increase to a dangerous level, the pressure relief valve may be the only

device remaining to prevent a catastrophic failure. Since reliability is directly

related to the complexity of the device, it is important that the design of the

pressure relief valve be as simple as possible.

The pressure relief valve must open at a predetermined set pressure, flow a

rated capacity at a specified overpressure, and close when the system

pressure has returned to a safe level. Pressure relief valves must be designed

with materials compatible with many process fluids from simple air and water

to the most corrosive media. They must also be designed to operate in a

consistently smooth and stable manner on a variety of fluids and fluid phases.

These design parameters lead to the wide array of Crosby products available

in the market today and provide the challenge for future product development.

Spring Loaded Design

The basic spring loaded pressure relief valve has been developed to meet the

need for a simple, reliable, system actuated device to provide overpressure

protection. Figure F2-1 shows the construction of a spring loaded pressure

relief valve. The valve consists of a valve inlet or nozzle mounted on the

pressurized system, a disc held against the nozzle to prevent flow under

normal system operating conditions, a spring to hold the disc closed, and a

body/bonnet to contain the operating elements. The spring load is adjustable

to vary the pressure at which the valve will open.

Spring Loaded Pressure Relief Valve

Figure F2-1

Figure F2-2 is a simple sketch showing the disc held in the closed position by

the spring. When system pressure reaches the desired opening pressure, the

force of pressure acting over Area A1 equals the force of the spring, and the

disc will lift and allow fluid to flow out through the valve.

Issued May 2007 4 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

When pressure in the system returns to a safe level, the valve will return to

the closed position. When a pressure relief valve begins to lift, the spring force

increases. Thus system pressure must increase if lift is to continue. For this

reason pressure relief valves are allowed an overpressure allowance to reach

full lift. This allowable overpressure is generally 10% for valves on unfired

systems. This margin is relatively small and some means must be provided to

assist in the lift effort.

Trim Areas Diagram

Figure F2-2

Most pressure relief valves, therefore, have a secondary control chamber or

huddling chamber to enhance lift. A typical configuration is shown in Figure

F2-3. As the disc begins to lift, fluid enters the control chamber exposing a

larger area A2 of the disc (Figure F2-2) to system pressure. This causes an

incremental change in force which overcompensates for the increase in spring

force and causes the valve to open at a rapid rate. At the same time, the

direction of the fluid flow is reversed and the momentum effect resulting from

the change in flow direction further enhances lift. These effects combine to

allow the valve to achieve maximum lift and maximum flow within the

allowable overpressure limits. Because of the larger disc area A2 (Figure F2-

2) exposed to system pressure after the valve achieves lift, the valve will not

close until system pressure has been reduced to some level below the set

pressure. The design of the control chamber determines where the closing

point will occur.

The difference between the set pressure and the closing point pressure is

called blowdown and is usually expressed as a percentage of set pressure.

Issued May 2007 5 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

Pressure Relief Valve Trim

Figure F2-3

The design of the control or huddling chamber involves a series of design

tradeoffs. If the design maximizes lift effort then blow down will be long. If the

design objective is to minimize blow down, then the lift effort will be

diminished. Many pressure relief valves are, therefore, equipped with a nozzle

ring which can be adjusted to vary the geometry of the control chamber to

meet a particular system operating requirement (Figures F2-2 and F2-3).

Series 400* Modulating Valve

The Series 400 modulating valve, with non-flowing pilot, incorporates an

advanced design in pilot operated valves. Under process conditions, both

pilot and main valve can be tight as high as 98 percent of set pressure. The

main valve lifts proportionally, according to demand, restricting product loss to

only that which must be relieved to prevent process pressure from exceeding

the code allowance.

Issued May 2007 6 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

The Series 400 valve is well suited for gas and/or liquid services, including

dirty and/or wet services. The modulating action is strongly preferred for liquid

relief because it eliminates the destructive effects of ‘liquid hammer.’ The

Series 400 valve is available with the following: effective orifice areas of 0.110

through 38.96 inch2 [0.710 through 251.3 cm2] valve inlet sizes 1-inch

through 8-inch [25 mm through 200 mm], set pressure between 15 and 1480

psig [1.03 and 102.0 barg], and continuous service temperatures from -65°F

to +500°F [-54°C to +260°C].

Features and Benefits

• Unique Field Test Capability. Allows accurate set pressure verification with

valve in service. No system isolation valve or rupture disc required.

• Reduced Product Loss and Pollution. Soft seats for premium tightness

before and after relief cycles. Modulating action relieves minimum product to

prevent overpressure.

• ASME Section VIII Code Stamp. Certified National Board capacities for

both gas and liquid service assures user of independent third party flow rate

verification.

• Suited for Dirty or Wet Service. Non-flowing pilot minimizes entrance

of dirt and formation of hydrates in pilot. Due to low velocities within the pilot

and supply tubing, most particles will drop out upstream of pilot inlet screen.

Optional cartridge type pilot filter is available for extremely dirty services.

• Rugged Bracket Pilot Mounting.

Extremely rigid mounting protecting against vibration and careless handling.

Shake table proven.

• Reduced Noise. Modulating action minimizes flow and resultant noise

during normal system upset, reducing noise abatement costs.

• Increased System Output. Because of valve tightness to 98 percent of set

pressure, the system can be operated nearer set pressure without valve

leakage, resulting in greater system throughput.

• Reduced Maintenance Costs. Soft seats greatly extend service life, making

costly and time-consuming metal seat lapping unnecessary.

• Ease of Adjustment. Single adjustment for set pressure allows accurate

and dependable setting.

• Balanced Design. Proper valve operation and lift are unaffected by

back pressure. Costly and fragile metal bellows are not required.

• Patent Protected

Operation

With no system pressure, the pilot inlet seat is open and the outlet seat is

closed.

As pressure is admitted to the main valve inlet, it enters the pilot through a

filter screen. Pressure is then transmitted through passages in the feedback

piston, past the inlet seat, into the main valve dome, which causes the main

valve piston to remain closed.

Issued May 2007 7 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

As system pressure increases and approaches valve set pressure, it acts

upward on the sense diaphragm, with the feedback piston also moving

upward to close the inlet seat. This seals in the main valve dome pressure,

since the outlet seat is also closed. A small, further increase in system

pressure opens the outlet seat, partially venting the main valve dome

pressure. This reduced dome pressure acts on the unbalanced feedback

piston to reduce feedback piston lift, tending to ‘lock in’ the dome pressure.

Thus, at any stable inlet pressure, there will be no pilot flow (i.e., zero

leakage).

As inlet pressure rises above set pressure, dome pressure reduction will

provide modulating action of the main valve piston proportional to the process

upset. The spool/feedback piston combination will move, responding to

system pressure, to alternately allow pressure in the main valve dome to

increase or decrease. This moves the main valve piston to the exact lift that

will keep system pressure constant at the required flow. Full main valve lift,

and therefore full capacity, is achieved with relatively little overpressure. As

system pressure decreases below set pressure, the feedback piston moves

downward and opens the inlet seat to admit system pressure to the dome.

This closes the main valve. Due to the extremely small pilot flow, the pilot on

gas/vapor valves normally discharges to atmosphere through a weather and

bug proof fitting. Pilots for liquid service valves have their discharge piped to

the main valve outlet.

Specifications

• Non-flowing pilot.

• Single point set pressure adjustment.

• Replaceable main valve seat, located on piston to take wear.

• Feedback mechanism in pilot, independent of primary pressure sensing

mechanism, to ensure smooth modulation of main valve.

• Indicator button for field test capability.

• Field replaceable main valve nozzle.

Issued May 2007 8 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

Issued May 2007 9 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

Issued May 2007 10 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

Iso-Dome* Series 400 Valve

The Iso-Dome accessory for the 400 pilot provides protection of the critical

pilot internals from the process media. The pilot is actuated by the process

fluid and is ASME Section VIII Code stamped for gas and liquid service. The

Iso-Dome 400 pilot is available with the following: effective orifices areas of

0.110 through 38.96 inch2 [0.710 through 251.3 cm2 ], valve inlet sizes 1-inch

through 8-inch [25 mm through 200 mm], set pressure between 15 and 1480

psig [1.03 and 102.1 barg], and continuous service temperature from -65°F to

+500°F [-54°C to +260°C].

Features and Benefits

• Critical Pilot Internals and Main Valve Dome Protected from Process

Media. Expands the application of pilot operated valve technology.

• Valve is Fail-safe. Meets ASME code requirements.

• Allows System Operating Pressure to be Near Set Pressure. SRV

tightness is maintained, resulting in greater system throughput.

• All Adjustments are Factory Sealed. Just add the clean gas supply for

simple and inexpensive field installation.

• Modulating Action. Minimizes fugitive emissions, product release, product

loss, and noise.

• Valve Operation Insensitive to Back Pressure. Costly and fragile metal

bellows not required.

• Unique Field Test Capability. Set pressure may be verified while valve

remains in service protecting the system. No system isolation valve or rupture

disc required.

Issued May 2007 11 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

INSTALLATION & START-UP INSTRUCTIONS

TYPE 423,433,473 NO-FLOW MODULATING ACTION PlLOT

1. PRINCIPLE OF OPERATION

The Anderson-Greenwood Pilot Operated Pressure Relief Valves use the

principle of back-loading the top, large area, of a differential area piston with

line pressure to hold it closed below set pressure. At set the pilot valve

actuates, partially evacuating the dome (volume above piston) and the piston

lifts permitting discharge from the main valve. When process pressure

decreases the pilot repressurizes the main valve dome, closing the main

valve.

2. CONNECTIONS

Piping to the inlet of the safety valve should meet the general requirements

set forth in the AMERICAN PETROLEUM INSTITUTE RECOMMENDED

PRACTICE 520, PART 11. This document recommends inlet piping pressure

losses not exceed 3% o f the set pressure, discharge piping be properly

braced t o withstand reactive thrust forces when the safety valve relieves and

the safety valve be properly supported t o withstand system vibration. main

valve.

Issued May 2007 12 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

3. PREINSTALLATION HANDLING

Dirt can be damaging and cause a safety relief valve t o become inoperative.

Valves which are not installed immediately should have the inlet and outlet

connections closed off. All safety valves should be handled with care and not

subject t o heavy shocks.

Procedure

A. Remove cap from field test fitting and connect flex hose from test gas

bottle.

B. Close vent valve "C" on gas bottle, open block valve "A" t o slowly

pressurize pilot and observe test pressure gage.

C. Set pressure i s where the pressure gage stops increasing and test gas

rapidly vents from field test indicator port . Caution: Stand clear of indicator

port during test to avoid contact with high pressure gas

D. To remove set up, close block valve "A", open vent valve "C" and install

cap on field test fitting .

Issued May 2007 13 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

4. MAINTENANCE

Maintenance should be performed on a regular basis. Depending on the

service conditions, an inspection/maintenance on an annual basis is the

recommended maximum time interval.

5. INSTALLATION

The installation of the safety valve should be in accordance with the

recommendations set forth in the American Society of Mechanical

Engineers, Section VIII, Appendix M Pressure Vessel Code. This document

recommends the safety valve be installed in the upright position, as

shown in Figure 1.

6. PRESSURIZING THE VALVE

There must be pressure at the valve inlet to establish a differential in force

across the piston and "load" it in the closed position. Pressure must pass

through the pilot supply tube and pilot and exert force on the top of the piston.

On normal plant start-up the valve loads itself as plant pressure increases. It

is not uncommon that slight leakage past the main seat occurs until system

pressure reaches two or three pounds.

7. USE OF BLOCK VALVES UNDER THE SAFETY VALVE

Block valves are often used under safety valves in order to isolate them when

maintenance is required. When putting the safety valve in service be sure the

block valve is fully opened. If the block valve is opened after start-up, the

safety valve may briefly vent past the main valve seat before the dome gets

pressurized; it will then close.

Issued May 2007 14 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

8. USE OF REMOTE PRESSURE PICK-UP

When remote pressure pick-up is used the pilot supply tube is connected to a

remote location rather than to the inlet neck of the valve. A block valve for

shut off in the remote pilot sense line is not recommended. If one is used, it

must be opened before pressurizing the system.

NOTE : Remove pressure pick-up piping must have the equivalent flow

area of 318" tubing for lengths up to 100 feet. For lengths greater than

100 feet, larger tubing or pipe should be used.

9. OTHER USES OF A SAFETY REZIEF VALVE

A safety relief valve should be used only to protect a system from

overpressure during a pressure upset. It should not be used as a control valve

that is required to operate continuously. It should not be used as a pipe fitting

or transition piece in a piping system.

10. FIELD TEST INSTRUCTIONS

The set pressure of valves equipped with a field test accessory can be

checked with the valve installed, in operation, using a test set up similar to

that shown in Figure 2. This procedure accurately checks the set pressure; it

will not be an accurate check of the reseat pressure.

The main valve will not open using the procedure described here. If the main

valve must be opened, slowly increase the test gas pressure beyond set point

until the valve opens. To close the valve, close block valve "A" on the test gas

bottle and open vent valve "C".

NOTE:

Field Service

The pilot assembly is not intended to be field serviceable; doing so will void

the set point certification.

Field service is limited to the main valve, filter, and accessories. Many

potential problems may be prevented by frequent draining and cleaning of the

filter and dipper tube.

If not present, add the heavy dome spring(s) which assist in the initial low

pressure seal.

Nitrogen charge system

If a valve starts to leak during pressure testing or while in service a Nitrogen

charge can be applied to the dome to energize the main valve piston. To

preserve full functionality, the rig up of the nitrogen to the relief valve must be

done as per the attached drawing. Deviation or omissions from the complete

system as shown may impede the relief valve function.

Each component of the nitrogen charge system performs a specific task. The

small orifice needle valve limits the N2 flow rate from overrunning the pilot

vent capability. The rupture disc guards in case of regulator failure. The back

flow preventer ensures that the pilot senses the greater pressure of the

nitrogen supply or process fluid.

Issued May 2007 15 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

Nitrogen pressure must not exceed 1/2 relief valve set pressure. Rupture disc

setting must not exceed 70% of relief set point.

Prior to applying the nitrogen dome charge check the following:-

1. Check relief valve filters for debris.

2. Check the SS tubing and dipper tube for leaks, damage, or plugging.

3. Check main valve seat and piston. Replace as necessary.

If any valve continues to leak, remove leaking valve from service and send it

to an approved AGCO service shop for further inspection and testing.

Issued May 2007 16 Pilot Relief Valves

Revision 1

STE

Well Test Manual 3

Issued May 2007 17 Pilot Relief Valves

Revision 1

You might also like

- Kioti NX4510, NX5010, NX5510, NX6010 Tractor Operator's ManualDocument15 pagesKioti NX4510, NX5010, NX5510, NX6010 Tractor Operator's ManualLisakolyNo ratings yet

- E Hyd PDocument112 pagesE Hyd PVlad AndronacheNo ratings yet

- Basic Hydraulics: Pressure Control Circuits Pressure Control CircuitsDocument50 pagesBasic Hydraulics: Pressure Control Circuits Pressure Control CircuitsJose Manuel Barroso Pantoja100% (1)

- 9hp48TE Introduction PDFDocument63 pages9hp48TE Introduction PDFТетяна Ліч100% (7)

- System x3550 M2 Problem Determination and Service GuideDocument244 pagesSystem x3550 M2 Problem Determination and Service GuideLukas Beeler100% (1)

- Control ValvesDocument43 pagesControl Valvesanaho8687No ratings yet

- Manual Partes Martillos GBDocument72 pagesManual Partes Martillos GBfredyNo ratings yet

- Hydraulic Machinery: Force and Torque MultiplicationDocument10 pagesHydraulic Machinery: Force and Torque MultiplicationNezar Amin Ali ElfadilNo ratings yet

- Honeywell Sensing HP He Me MH LP Le Datasheet 50094081 5 en FINALDocument15 pagesHoneywell Sensing HP He Me MH LP Le Datasheet 50094081 5 en FINALDanielNo ratings yet

- Sps Mk2 Bhs ManualDocument78 pagesSps Mk2 Bhs ManualKerryjames Campbell StenhouseNo ratings yet

- MODULE 9 - Pilot-Operated ValvesDocument12 pagesMODULE 9 - Pilot-Operated ValvesKEERAKYRYL MAGAWAYNo ratings yet

- Section 26 - Oilgear PV Liquid MeterDocument18 pagesSection 26 - Oilgear PV Liquid MeterhammamiNo ratings yet

- Advanced HydraulicsDocument41 pagesAdvanced HydraulicsAlex TacuriNo ratings yet

- Maintenance Instructions For Power SystemDocument3 pagesMaintenance Instructions For Power Systemsanach100% (1)

- Sun Logic Valves ExampleDocument13 pagesSun Logic Valves Examplerammysi100% (1)

- Fault Finding HydraulicSystemsDocument7 pagesFault Finding HydraulicSystemsahmedNo ratings yet

- Pilot Operated Pressure Relief Valve - Series Vr4VDocument10 pagesPilot Operated Pressure Relief Valve - Series Vr4VajaydevbNo ratings yet

- Section 1.4 - Processing Control EquipmentDocument35 pagesSection 1.4 - Processing Control EquipmentLakshman Kumar JulapalliNo ratings yet

- Testers Ma Mul 1812 PDFDocument68 pagesTesters Ma Mul 1812 PDFJesus N RodriguezNo ratings yet

- Aircraft Hydraulic SystemDocument3 pagesAircraft Hydraulic SystemDesiree Cena CapunoNo ratings yet

- Unit 24: Applications of Pneumatics and HydraulicsDocument15 pagesUnit 24: Applications of Pneumatics and HydraulicsEmad ElsaidNo ratings yet

- Hydraulics Online Ebook Hydraulic Symbols 1Document20 pagesHydraulics Online Ebook Hydraulic Symbols 1CakwinNo ratings yet

- Basics of Directional-Control ValvesDocument11 pagesBasics of Directional-Control ValvesJosh LeBlancNo ratings yet

- Snubbing Equipment 1664467576Document96 pagesSnubbing Equipment 1664467576fumar26No ratings yet

- 4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMDocument8 pages4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMAhmed Abd Elhakeem100% (1)

- Leak-Free Load-Control Valve, Size 6Document9 pagesLeak-Free Load-Control Valve, Size 6Yazad DoctorrNo ratings yet

- CRT 350 Interlock Panel User ManualDocument74 pagesCRT 350 Interlock Panel User ManualAliHabesNo ratings yet

- 9886A Circuit RecommendataionsDocument34 pages9886A Circuit Recommendataionsbee140676No ratings yet

- Directional Control ValveDocument27 pagesDirectional Control ValveRajib ChhataitNo ratings yet

- Fluid Power ControlDocument25 pagesFluid Power Controlshantanuchoudhary007No ratings yet

- European Accumulator Catalogue 050613 Final VersionDocument60 pagesEuropean Accumulator Catalogue 050613 Final Versionscibduser001100% (2)

- Pos.14 - Hydrokraft Piston Pump - PVW - 2016Document73 pagesPos.14 - Hydrokraft Piston Pump - PVW - 2016Дмитрий МазуренкоNo ratings yet

- Basic Hydraulic SystemDocument72 pagesBasic Hydraulic SystemFahmy MohazNo ratings yet

- Batch Mixer ManualDocument40 pagesBatch Mixer ManualAndrew ArNo ratings yet

- Part Number TW600: Installation, Operation, and MaintenanceDocument20 pagesPart Number TW600: Installation, Operation, and MaintenanceLuis AlbarracinNo ratings yet

- Manual Jereh CTDocument133 pagesManual Jereh CTYngrid BritoNo ratings yet

- CETOP EduBook GeneralDocument33 pagesCETOP EduBook GeneralManuel VizcarraNo ratings yet

- Rapport PDFDocument135 pagesRapport PDFbrunosamaeian100% (1)

- Chapter 6 HYDRAULICDocument93 pagesChapter 6 HYDRAULICShishir Gyawali100% (1)

- Model Code. Series 02. Medium Pressure. Valid From January 1, 2014Document16 pagesModel Code. Series 02. Medium Pressure. Valid From January 1, 2014Ali100% (1)

- 010 - Denison Control Valve 3-EN2400-ADocument15 pages010 - Denison Control Valve 3-EN2400-Agustavo aguilarNo ratings yet

- CD 500 CentrifugeDocument2 pagesCD 500 Centrifugesaa6383No ratings yet

- Basic Hydraulics A IlyasDocument64 pagesBasic Hydraulics A IlyasshafiqNo ratings yet

- Lecture 17Document16 pagesLecture 17Sourabh Makham100% (1)

- Eaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UKDocument63 pagesEaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UKbatuhan kılıç100% (1)

- STEM-I: CPF Cement Pump Float: HRDH-1856 / Site-26 22-Nov-2019 Night Shift CPF-377Document1 pageSTEM-I: CPF Cement Pump Float: HRDH-1856 / Site-26 22-Nov-2019 Night Shift CPF-377Mohamed El-SawahNo ratings yet

- 29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingDocument6 pages29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingWaode GabriellaNo ratings yet

- M60es44 NX449L Man 001Document24 pagesM60es44 NX449L Man 001Riski KurniawanNo ratings yet

- Gold Cup Centering With Hydraulic ControllerDocument2 pagesGold Cup Centering With Hydraulic ControllerRami DalNo ratings yet

- Hyd Drive MtceDocument52 pagesHyd Drive Mtceramanujam59No ratings yet

- Re92060 2014-04Document28 pagesRe92060 2014-04Ibrahim GökmenNo ratings yet

- Section 22 - MCII Flow AnalyserDocument19 pagesSection 22 - MCII Flow AnalyserhammamiNo ratings yet

- Fluid Kenetics PDS BrochureDocument2 pagesFluid Kenetics PDS BrochureempswookNo ratings yet

- JP - Chapter 02Document11 pagesJP - Chapter 02dewidar1234No ratings yet

- VSD Pump Solution Catalog E-PUIO-CC002-E LRDocument63 pagesVSD Pump Solution Catalog E-PUIO-CC002-E LRharisNo ratings yet

- Proportional Pressure Relief Valve R4V DENISONDocument15 pagesProportional Pressure Relief Valve R4V DENISONBerenice Bautista BelmontesNo ratings yet

- PRD Design FundamentalsDocument6 pagesPRD Design Fundamentalsnarayanan_anoobNo ratings yet

- 고려특수금속 (PSV-FLANGED TYPE) PDFDocument56 pages고려특수금속 (PSV-FLANGED TYPE) PDFStanley PeterNo ratings yet

- Relief Valves: Gases and Gas EquipmentDocument22 pagesRelief Valves: Gases and Gas EquipmentInspection EngineerNo ratings yet

- 5 Pressure Relief ValvesDocument11 pages5 Pressure Relief ValvesNyoman RakaNo ratings yet

- Control Valve - Surge Relief Valve Selection GuideDocument20 pagesControl Valve - Surge Relief Valve Selection GuideSriya PetikiriarachchigeNo ratings yet

- Types of Valves in Piping: Types of Valves - Tables to estimate man hours of assemblyFrom EverandTypes of Valves in Piping: Types of Valves - Tables to estimate man hours of assemblyNo ratings yet

- Section 33 - Fisher 2100 and 2100EDocument14 pagesSection 33 - Fisher 2100 and 2100EhammamiNo ratings yet

- Section 32 - Hi-Lo Press PilotDocument46 pagesSection 32 - Hi-Lo Press PilothammamiNo ratings yet

- Section 26 - Oilgear PV Liquid MeterDocument18 pagesSection 26 - Oilgear PV Liquid MeterhammamiNo ratings yet

- Section 23 - Floco 382 and 383 MetersDocument24 pagesSection 23 - Floco 382 and 383 MetershammamiNo ratings yet

- Section 27 - Ranarex GravitometerDocument20 pagesSection 27 - Ranarex GravitometerhammamiNo ratings yet

- Section 9, Rigging Up and DownDocument24 pagesSection 9, Rigging Up and Downhammami100% (1)

- Section 24 - Floco F2500 MeterDocument28 pagesSection 24 - Floco F2500 Meterhammami100% (1)

- Section 25 - GFC 332 Gas Flow ComputerDocument30 pagesSection 25 - GFC 332 Gas Flow ComputerhammamiNo ratings yet

- Section 10, Conducting The Well TestDocument24 pagesSection 10, Conducting The Well TesthammamiNo ratings yet

- Section 6, Well Test PlanningDocument10 pagesSection 6, Well Test PlanninghammamiNo ratings yet

- Section 8 - Control Valve Flow CharacteristicsDocument6 pagesSection 8 - Control Valve Flow CharacteristicshammamiNo ratings yet

- Section 22 - MCII Flow AnalyserDocument19 pagesSection 22 - MCII Flow AnalyserhammamiNo ratings yet

- Section 3, Drilling and Well CompletionDocument17 pagesSection 3, Drilling and Well CompletionhammamiNo ratings yet

- Section 7, Introduction To Well Testing EquipmentDocument54 pagesSection 7, Introduction To Well Testing Equipmenthammami100% (1)

- Section 21 - Liquid Turbine MeterDocument9 pagesSection 21 - Liquid Turbine MeterhammamiNo ratings yet

- CH 4Document20 pagesCH 4api-19663123No ratings yet

- Air Conditioning Service: ACS 511, ACS 611 and ACS 810Document2 pagesAir Conditioning Service: ACS 511, ACS 611 and ACS 810Gicauto Formia AutopartsNo ratings yet

- Manual RoboticsDocument4 pagesManual RoboticsSiri CherukuriNo ratings yet

- CPX-SF34 35 2010-07 570541g1 PDFDocument111 pagesCPX-SF34 35 2010-07 570541g1 PDFwiruNo ratings yet

- General Specifications For 3500 TCD PlantDocument185 pagesGeneral Specifications For 3500 TCD PlantArun MauryaNo ratings yet

- Cleaning and Inspection of LP Heater NewDocument6 pagesCleaning and Inspection of LP Heater NewMuhammad Hasbi AsidiqiNo ratings yet

- Procdure For ACB and VCBDocument4 pagesProcdure For ACB and VCBMelkin NPNo ratings yet

- Fdocuments - in - PLC Programming A Ladder L N Switch Motor Ladder Diagram Power Supply L NDocument21 pagesFdocuments - in - PLC Programming A Ladder L N Switch Motor Ladder Diagram Power Supply L NHoang Nam NguyenNo ratings yet

- Jy992d77801s PDFDocument292 pagesJy992d77801s PDFOsvaldino JuniorNo ratings yet

- AQV12VBCN - AQV12VBCN Service Manual PDFDocument100 pagesAQV12VBCN - AQV12VBCN Service Manual PDFnovyNo ratings yet

- Summer Internship Project Report in L&T PDFDocument18 pagesSummer Internship Project Report in L&T PDFVishal Biswakarma100% (1)

- Kawasaki ZX 6r 05 Service ManualDocument20 pagesKawasaki ZX 6r 05 Service ManualMaritza100% (68)

- EEE 315 Lecture PlanDocument4 pagesEEE 315 Lecture PlanSowmitraDasNo ratings yet

- Inverter - English 2022Document17 pagesInverter - English 2022Dudes and ToolsNo ratings yet

- Replacement Parts For RyobiDocument13 pagesReplacement Parts For RyobiSorin80% (5)

- 6.cool Level Circuit TestDocument4 pages6.cool Level Circuit TestbejoythomasNo ratings yet

- SET A 8-25-2022 Answer KeyDocument5 pagesSET A 8-25-2022 Answer KeyAndrew Perez EstoqueNo ratings yet

- Cat 16MDocument28 pagesCat 16MBelra Impex inc Belra Impex incNo ratings yet

- Main VFD - ACS800 User Manual - Cooling UnitDocument164 pagesMain VFD - ACS800 User Manual - Cooling Unitcingizcingiz53No ratings yet

- Gen Av Change Order No.1 7-24-22 EngineeringDocument4 pagesGen Av Change Order No.1 7-24-22 EngineeringmrdnnmnNo ratings yet

- Electronic Fuel Injection AssignmentDocument11 pagesElectronic Fuel Injection AssignmentyogapostNo ratings yet

- Power Sonic - PSH-12180FR - DatasheetDocument2 pagesPower Sonic - PSH-12180FR - DatasheetNaitsirch VillegasNo ratings yet

- Luv Petrol PDFDocument442 pagesLuv Petrol PDFjaimeNo ratings yet

- One: Introduction and FeaturesDocument59 pagesOne: Introduction and Featurestharun100% (2)

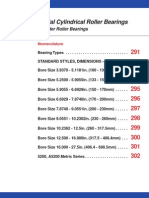

- Radial Cylindrical Roller BearingsDocument14 pagesRadial Cylindrical Roller BearingsbbdrreNo ratings yet

- MD6240 2 PDFDocument28 pagesMD6240 2 PDFWill WeinsoffNo ratings yet

- Learning Home: C6327 InstructionsDocument12 pagesLearning Home: C6327 Instructionssro1990No ratings yet

- Diagramas Electrico Unifilar Chiller Pycca-ModelDocument1 pageDiagramas Electrico Unifilar Chiller Pycca-ModelFernando Garnica DelgadoNo ratings yet