0 ratings0% found this document useful (0 votes)

109 viewsBoom Concrete Pump Checklist

Boom Concrete Pump Checklist

Uploaded by

Vilky VargheseThis inspection checklist is used to ensure concrete placing boom pumps are safe for operation. It contains three sections to check: 1) Required documentation such as manuals, inspection reports, and operator training, 2) A visual inspection of equipment components and safety features, and 3) Verification that proper work area requirements are met such as traffic control plans and exclusion zones. A thorough inspection is conducted to approve equipment use on projects.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Boom Concrete Pump Checklist

Boom Concrete Pump Checklist

Uploaded by

Vilky Varghese0 ratings0% found this document useful (0 votes)

109 views2 pagesThis inspection checklist is used to ensure concrete placing boom pumps are safe for operation. It contains three sections to check: 1) Required documentation such as manuals, inspection reports, and operator training, 2) A visual inspection of equipment components and safety features, and 3) Verification that proper work area requirements are met such as traffic control plans and exclusion zones. A thorough inspection is conducted to approve equipment use on projects.

Original Description:

CHECKLIST

Original Title

BOOM CONCRETE PUMP CHECKLIST

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This inspection checklist is used to ensure concrete placing boom pumps are safe for operation. It contains three sections to check: 1) Required documentation such as manuals, inspection reports, and operator training, 2) A visual inspection of equipment components and safety features, and 3) Verification that proper work area requirements are met such as traffic control plans and exclusion zones. A thorough inspection is conducted to approve equipment use on projects.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

109 views2 pagesBoom Concrete Pump Checklist

Boom Concrete Pump Checklist

Uploaded by

Vilky VargheseThis inspection checklist is used to ensure concrete placing boom pumps are safe for operation. It contains three sections to check: 1) Required documentation such as manuals, inspection reports, and operator training, 2) A visual inspection of equipment components and safety features, and 3) Verification that proper work area requirements are met such as traffic control plans and exclusion zones. A thorough inspection is conducted to approve equipment use on projects.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

NAEL READY MIX

PO BOX – 18381, ALAIN, UAE, PH: 03-7625444, FAX: 03-7629282

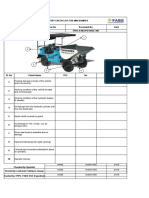

INSPECTION CHECKLIST – CONCRETE PLACING BOOM PUMP

PROJECT/FACTORY NAME: DATE & TIME:

EQP. SERIAL NUMBER: EQP. REGISTRATION:

1. DOCUMENTATION DESCRIPTION Y/N

1.Operators manual available in cab

2 Logbook available and up to date

3 Maintenance and servicing are available.

4 Maintenance and Inspection Reports on all pipes (Monthly)

5 Plant Risk assessment

6 Current road registration

7 Plant Registration Certificate available in cab

8 Magnetic particle test records (12 monthly intervals)

9 Operator training / competency - Work License.

10 Pump mounting base is good.

11 Inspect pipe fixing points.

2. VISUAL INSPECTION DESCRIPTION Y/N

1 Compliance ID plates fitted to machine.

2 Reverse beeper working.

3 Flashing lights working.

4 Fire extinguisher fitted to machine & Proper date.

5 Tyres properly inflated and in roadworthy condition.

6 All controls clearly labelled, marked and operating correctly, including lights,

horn, emergency stop, brakes, gauges etc.

7 No obvious signs of oil leaks to any components.

8 Inspect pipe sections for obvious damage, obvious wear and identification

markings & ensure hose cuff is placed.

9 All hot surfaces guarded (engine, exhaust).

10 Check for warning signs (crushing and entanglement hazard).

11 Check ground conditions, underground services and overhead. power lines

NR/OSH/BP/00 Rev.00 30/12/2021

NAEL READY MIX

PO BOX – 18381, ALAIN, UAE, PH: 03-7625444, FAX: 03-7629282

3. WORK AREA REQUIREMENTS Y/N

1 Was a pre start meeting conducted prior to commencing

2 Has a task specific SWMS been developed, reviewed and updated specific to

this site

3 Is traffic management required, in place and a current TMP available on site

4 Is there an established exclusion zone in place and warning signage displayed

5 Are spotters required and in place

6 Are radio communications required and provided

5 Is adequate lighting in place

6 Is worker fatigue being managed

Inspected By Approved by

NR/OSH/BP/00 Rev.00 30/12/2021

You might also like

- Nato Stanag 6001 Reading Sample Test With Answer KeyDocument11 pagesNato Stanag 6001 Reading Sample Test With Answer KeyLaurentiu Ciobanu78% (9)

- Sop For Set Up & Operation of Concrete PumpDocument3 pagesSop For Set Up & Operation of Concrete Pumplelu ojhaNo ratings yet

- Shukrani Yangu-1Document4 pagesShukrani Yangu-1CharleskagayoNo ratings yet

- SAMPLE Water-Vehicle PowerPoint RIIMPO326EDocument20 pagesSAMPLE Water-Vehicle PowerPoint RIIMPO326EKenan mira Mohammed Nasher0% (1)

- VIBRO HAMMER ChecklistDocument1 pageVIBRO HAMMER ChecklistMuhammad Rifqi0% (1)

- Martin N. Muller, Richard W. Wrangham, David R. Pilbeam - Chimpanzees and Human Evolution-Belknap Press (2017)Document848 pagesMartin N. Muller, Richard W. Wrangham, David R. Pilbeam - Chimpanzees and Human Evolution-Belknap Press (2017)Fernanda BuckeridgeNo ratings yet

- Walter Russell's Home Study Course - Unit 2 - Lessons 5,6,7,8Document70 pagesWalter Russell's Home Study Course - Unit 2 - Lessons 5,6,7,8Jason Verbelli100% (17)

- Service Manual: Innova LV Tower 6K (S) / 10K (S)Document35 pagesService Manual: Innova LV Tower 6K (S) / 10K (S)Valentin HernandezNo ratings yet

- Concrete Boom Pump Truck Pre-Acceptance Checklist: Plant DetailsDocument2 pagesConcrete Boom Pump Truck Pre-Acceptance Checklist: Plant DetailsBassam HSENo ratings yet

- SMOOTH OR PAD FOOT ROLLER Daily Inspection ChecklistDocument1 pageSMOOTH OR PAD FOOT ROLLER Daily Inspection ChecklistBorislav Vulić100% (1)

- Daily Checklist Bulldozerpdf PDF FreeDocument1 pageDaily Checklist Bulldozerpdf PDF FreeRama Asmara TariganNo ratings yet

- Weekly Lift Truck Pre-Use Check Sheet: Operator Signature: Supervisor SignatureDocument2 pagesWeekly Lift Truck Pre-Use Check Sheet: Operator Signature: Supervisor Signaturetemter gandaNo ratings yet

- Form-067-Weekly Crane Inspection ChecklistDocument2 pagesForm-067-Weekly Crane Inspection Checklistshamroz khanNo ratings yet

- Towed Scraper Checklist V0810.1 PDFDocument1 pageTowed Scraper Checklist V0810.1 PDFcherifNo ratings yet

- MSDS York C Oil (En)Document9 pagesMSDS York C Oil (En)Jakeer hussain ShaikNo ratings yet

- MMDA DigestDocument2 pagesMMDA DigestMickey Celles100% (3)

- Sop Installing PumpDocument4 pagesSop Installing Pumpilham100% (1)

- Concrete Pump TPIDocument1 pageConcrete Pump TPIWakil AhmadNo ratings yet

- Boomlift ChecklistDocument1 pageBoomlift ChecklistakimiNo ratings yet

- Concrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistDocument2 pagesConcrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistTFattah100% (1)

- Concrete SafetyDocument2 pagesConcrete SafetyStar StreamNo ratings yet

- Tower Crane Daily Inspection Form PDFDocument1 pageTower Crane Daily Inspection Form PDFMd Imteyaz AnsariNo ratings yet

- Safe Work Method - ConcretingDocument11 pagesSafe Work Method - ConcretingJustin Ranjit100% (1)

- 286 Concrete Pump SafetyDocument1 page286 Concrete Pump Safetyamolmanave6049No ratings yet

- Inspection Checklist For Concrete Pump: Name of Site: Id NoDocument2 pagesInspection Checklist For Concrete Pump: Name of Site: Id NoJithin M Krishna EzhuthachanNo ratings yet

- Checklist For Equipment Inspection CONCRETE PUMPDocument1 pageChecklist For Equipment Inspection CONCRETE PUMPbagas prakosoNo ratings yet

- Weekly Monthly Inspection-Pdf-En PDFDocument1 pageWeekly Monthly Inspection-Pdf-En PDFMohamed Moustafa ElashwahNo ratings yet

- Equipment Maintenance LogDocument5 pagesEquipment Maintenance LogAgus Putra AdnyanaNo ratings yet

- JAPL-F-HE-007-Concrete Pump ChecklistDocument1 pageJAPL-F-HE-007-Concrete Pump ChecklistFarrukh IjazNo ratings yet

- Catalogue For Self Loading Concrete MixerDocument11 pagesCatalogue For Self Loading Concrete Mixereduardofarfan30123265No ratings yet

- Grinding Machine Check Sheet: Machine Set No.: Department: Contractor Name: Last Inspection Date: Inspection DateDocument1 pageGrinding Machine Check Sheet: Machine Set No.: Department: Contractor Name: Last Inspection Date: Inspection Datepartha100% (1)

- Daily Plant Inspection ChecklistDocument2 pagesDaily Plant Inspection ChecklistMuthu KumarNo ratings yet

- 35 (V) - Concrete PumpDocument9 pages35 (V) - Concrete PumpPrasanta ParidaNo ratings yet

- E2 - Equipment Operators Daily ChecklistDocument1 pageE2 - Equipment Operators Daily ChecklistRob WillestoneNo ratings yet

- Crane Inspection Checklist RevDocument1 pageCrane Inspection Checklist RevMuhammadHaziqHaiqalNo ratings yet

- Concrete Vibrator ChecklistDocument2 pagesConcrete Vibrator ChecklistIdada EzekielNo ratings yet

- Movable Tower Light-Monthly Inspection Checklist: Acceptable Not Acceptable N/ADocument1 pageMovable Tower Light-Monthly Inspection Checklist: Acceptable Not Acceptable N/Amunna yadav100% (1)

- Form Inspection Premob - Quarterly (1) - 2Document26 pagesForm Inspection Premob - Quarterly (1) - 2Ryan Rhamdhani100% (1)

- Checklist For Concrete Pumping PDFDocument1 pageChecklist For Concrete Pumping PDFBenson LimNo ratings yet

- D4. Dozer WEEKLY Checklist BULLDocument1 pageD4. Dozer WEEKLY Checklist BULLcortananoahNo ratings yet

- Excavator Daily Inspection ChecklistDocument2 pagesExcavator Daily Inspection ChecklistFira KurniatyNo ratings yet

- Wheel Loader Updated Daily Inspection ChecklistDocument1 pageWheel Loader Updated Daily Inspection ChecklistAmir ahmadNo ratings yet

- GRC Overhead Crane Daily Checklist - NasaDocument2 pagesGRC Overhead Crane Daily Checklist - NasaFlorfloresta Alfa OneNo ratings yet

- Scheduled MaintenanceDocument1 pageScheduled MaintenanceTan Minh Tam TruongNo ratings yet

- JAPL-F-HE-004-Weekly Water Tanker Inspection LogDocument1 pageJAPL-F-HE-004-Weekly Water Tanker Inspection LogAli Hassan100% (1)

- Road RollerDocument1 pageRoad RollerSafety ManagerNo ratings yet

- Piling Rig Plant Pre-Acceptance ChecklisDocument3 pagesPiling Rig Plant Pre-Acceptance Checklisosama F. MohamedNo ratings yet

- Name Signature Date Name Signature Date Name Signature DateDocument1 pageName Signature Date Name Signature Date Name Signature DateMithlesh SinghNo ratings yet

- Checklist For Concrete Vibrator.Document1 pageChecklist For Concrete Vibrator.Gyanendra SrivastavaNo ratings yet

- Concrete Mixer PDFDocument1 pageConcrete Mixer PDFcityofdarwingis100% (1)

- Concrete Work - Truck PumpingDocument1 pageConcrete Work - Truck PumpingPrakash PavuralaNo ratings yet

- 09-02-01 Aerial Lift Daily Inspection LogDocument1 page09-02-01 Aerial Lift Daily Inspection LogJorgeNo ratings yet

- 05 Water PumpDocument2 pages05 Water PumpIvan ShiuNo ratings yet

- Operator'S Pre-Operation Checklist Electric Pallet Jack: Have A Qualified Mechanic Correct All ProblemsDocument1 pageOperator'S Pre-Operation Checklist Electric Pallet Jack: Have A Qualified Mechanic Correct All ProblemsPradeep ShindeNo ratings yet

- Scissor Lift Pre-Use Inspection ChecklistDocument1 pageScissor Lift Pre-Use Inspection ChecklistHarun SaniNo ratings yet

- Sumant Kumar Singh: Concrete Pipe Line Rigger & Labour SupplyDocument2 pagesSumant Kumar Singh: Concrete Pipe Line Rigger & Labour SupplySanu RajNo ratings yet

- Borang Pemeriksaan Air KompressorDocument1 pageBorang Pemeriksaan Air KompressorAndara Asifa YudianaNo ratings yet

- Heavy Equipment Inspection Checklists - MRBDocument5 pagesHeavy Equipment Inspection Checklists - MRBMyla AguadoNo ratings yet

- Vibro Roller Inspection ChecklistDocument3 pagesVibro Roller Inspection ChecklistjohainaNo ratings yet

- Mobile Plant Checklist - Drum RollerDocument1 pageMobile Plant Checklist - Drum Rollerosama F. MohamedNo ratings yet

- TLB ChecklistDocument2 pagesTLB Checklistdeonstuurman777100% (1)

- ATTACH 3 LOG SHEET UpdatedDocument12 pagesATTACH 3 LOG SHEET UpdatedHedi Ben MohamedNo ratings yet

- Section 03 Site Clearance N Demolition PDFDocument11 pagesSection 03 Site Clearance N Demolition PDFlakmalperera1986100% (1)

- Compressed Gas Cylinder ChecklistDocument2 pagesCompressed Gas Cylinder ChecklistJAVIERNo ratings yet

- JZC JZR Series Concrete Mixer QuotationDocument11 pagesJZC JZR Series Concrete Mixer QuotationhectorNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Materials Characterisation NotesDocument69 pagesMaterials Characterisation NotesoliverparkudjaNo ratings yet

- AP Chem Test - Chapter 10,11,13 - Gases, Solutions, Solids, Liquids, Inter Forces (2010-2011)Document12 pagesAP Chem Test - Chapter 10,11,13 - Gases, Solutions, Solids, Liquids, Inter Forces (2010-2011)dlloyd63050% (2)

- Magnaflyer 08 - 01Document4 pagesMagnaflyer 08 - 01mark_59No ratings yet

- Chapter 16 Environmental CostDocument34 pagesChapter 16 Environmental CostAngga100% (1)

- 22 August 2020 Schedule Eac Psych 3Document3 pages22 August 2020 Schedule Eac Psych 3Dhruva PatelNo ratings yet

- Ajol File Journals - 86 - Articles - 222335 - Submission - Proof - 222335 1021 544002 1 10 20220303Document8 pagesAjol File Journals - 86 - Articles - 222335 - Submission - Proof - 222335 1021 544002 1 10 20220303EMMANUEL JUNIOR EMMANUELNo ratings yet

- Namakaran - Samagri PDFDocument3 pagesNamakaran - Samagri PDFDhondiram KakreNo ratings yet

- OA1 - Grammar - Worksheets - Final (1) - Convertido 17 PREGUNTASDocument17 pagesOA1 - Grammar - Worksheets - Final (1) - Convertido 17 PREGUNTASBlanca Zoraida Mahecha BenitoNo ratings yet

- Casr 135Document224 pagesCasr 135arifsyaifudinahmadylightworkNo ratings yet

- BDCDocument2 pagesBDCmichael ricafort100% (1)

- Physical Development of Infants and ToddlersDocument39 pagesPhysical Development of Infants and ToddlersMylene Mahinay80% (5)

- Philippine Magazine April, 1940 Vol. XXXVIIDocument40 pagesPhilippine Magazine April, 1940 Vol. XXXVIIKathleen J. Burkhalter100% (1)

- Lack of Acceleration and or Unusual Brake Pedal Feeling "SKYACTIV-D 2.2"Document15 pagesLack of Acceleration and or Unusual Brake Pedal Feeling "SKYACTIV-D 2.2"abu humairaNo ratings yet

- 1TXH000115C0201 Technical+Sales+Guide+Overvoltage+Protection BRDocument43 pages1TXH000115C0201 Technical+Sales+Guide+Overvoltage+Protection BRSergio Aldo Enriquez LoriaNo ratings yet

- Working With Feelings & Strong Emotions - MasterDocument7 pagesWorking With Feelings & Strong Emotions - MasterB100% (1)

- Nato Quality Assurance Requirements For Inspection and Test: AQAP 2130 (Edition 1)Document18 pagesNato Quality Assurance Requirements For Inspection and Test: AQAP 2130 (Edition 1)Bahadır HarmancıNo ratings yet

- 0-4748 Ultra-Cut 100 Operator's ManualDocument164 pages0-4748 Ultra-Cut 100 Operator's ManualTolga KökalpNo ratings yet

- MP 1Document3 pagesMP 1Fake Account 1No ratings yet

- MOD GPD Rev 1V1Document5 pagesMOD GPD Rev 1V1Sebastian JimenezNo ratings yet

- Dynamic Simulation of Insulin-Glucose Interaction in Type 1 Diabetes With MATLAB Simulink®Document11 pagesDynamic Simulation of Insulin-Glucose Interaction in Type 1 Diabetes With MATLAB Simulink®Jonas KristantoNo ratings yet

- Case Study-Risk Mitigation in Remedial H PDFDocument18 pagesCase Study-Risk Mitigation in Remedial H PDFjcNo ratings yet

- Retinal DetachmentDocument40 pagesRetinal DetachmenthometechonoNo ratings yet

- Physics Sample PaperDocument6 pagesPhysics Sample PaperfalconalphaworkspaceNo ratings yet

- PH of Common FoodsDocument2 pagesPH of Common Foodsfisayobabs11No ratings yet