3048421

3048421

Uploaded by

Philippe VelhaCopyright:

Available Formats

3048421

3048421

Uploaded by

Philippe VelhaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

3048421

3048421

Uploaded by

Philippe VelhaCopyright:

Available Formats

SMD291SNL

Datasheet revision 1.2 www.chipquik.com

Solder Paste No-Clean SAC305 in 5cc Syringe 15g T3 Mesh

Product Highlights

Printing speeds up to 100mm/sec Excellent wetting compatibility on most board finishes

Long stencil life Dispense grade

Wide process window Compatible with enclosed print heads

Clear residue Passes BONO test @1.56%

Low voiding RoHS II and REACH compliant

Specifications

Alloy: Sn96.5/Ag3.0/Cu0.5

Mesh Size: T3

Micron (µm) Range: 25-45

Flux Type: Synthetic No-Clean

Flux Classification: REL0

Metal Load: 87% Metal by Weight

Melting Point: 217-220°C (423-428°F)

Packaging: 5cc/15g Syringe

Shelf Life: Refrigerated >6 months, Unrefrigerated >2 months *See notes below:

*Shelf Life Notes: Chip Quik® solder paste is good past its quoted shelf life, regardless of refrigeration. Before use, visually

inspect the solder paste to ensure it is not dried out or clumpy, or check stencil release. If stored in a jar, stir the product

thoroughly for 2-3 minutes before inspection and use.

Chip Quik® solder paste is manufactured using Made in USA high quality synthetic flux and precision atomized metal

powder. Chip Quik® solder paste is guaranteed for 12 months from date of manufacture, regardless of refrigeration. If you

have any issues with our solder paste, please contact Chip Quik® directly for no charge warranty replacement. Please retain

original bill of sale, and solder paste in original container as we may request its return for internal R&D testing purposes.

Printer Operation

Print Speed: 25-100mm/sec

Squeegee Pressure: 70-250g/cm of blade

Under Stencil Wipe: Once every 10-25 prints, or as necessary

Stencil Life

>8 hours @ 20-50% RH 22-28°C (72-82°F)

>4 hours @ 50-70% RH 22-28°C (72-82°F)

Stencil Cleaning

Automated stencil cleaning systems for both stencil and misprinted boards. Manual cleaning using isopropyl alcohol (IPA).

Storage and Handling

Refrigerate at 3-8°C (37-46°F). Do not freeze. Allow 4 hours for solder paste to reach an operating temperature of 20-25°C

(68-77°F) before use.

Transportation

This product has no shipping restrictions. Shipping below 0°C (32°F) or above 25°C (77°F) for normal transit times by ground

or air will not impact this product’s stated shelf life.

1 © 1994-2017 Chip Quik® Inc.

Recommended Profile

Reflow profile for Sn96.5/Ag3.0/Cu0.5 solder assembly, designed as a starting point for process optimization.

249°C (480°F)

217°C (423°F)

175°C (347°F)

Temperature

150°C (302°F)

25°C (77°F)

0sec 90sec 180sec 210sec 240sec 270sec

Time

Test Results

Test J-STD-004 or other Test Requirement Result

requirements as stated

Copper Mirror IPC-TM-650: 2.3.32 L: No breakthrough

Corrosion IPC-TM-650: 2.6.15 L: No corrosion

Quantitative Halides IPC-TM-650: 2.3.28.1 L: <0.5%

Electrochemical Migration IPC-TM-650: 2.6.14.1 L: <1 decade drop (No-clean)

Surface Insulation Resistance 85°C, IPC-TM-650: 2.6.3.7 L: ≥100MΩ (No-clean)

85% RH @ 168 Hours

Tack Value IPC-TM-650: 2.4.44 64g

Viscosity – Malcom @ 10 RPM/25°C IPC-TM-650: 2.4.34.4 Print: 155-215, Dispense: 125-170

3

(x10 mPa/s)

Visual IPC-TM-650: 3.4.2.5 Clear and free from precipitation

Conflict Minerals Compliance Electronic Industry Citizenship Compliant

Coalition (EICC)

REACH Compliance Articles 33 and 67 of Regulation (EC) Contains no substance >0.1% w/w that

No 1907/2006 is listed as a SVHC or restricted for

use in solder materials

Conforms to the following Industry Standards:

J-STD-004B, Amendment 1 (Solder Fluxes): Yes

J-STD-005A (Solder Pastes): Yes

J-STD-006C, Amendments 1 & 2 (Solder Alloys and Fluxed/Non-Fluxed Solders): Yes

RoHS 2 Directive 2011/65/EU: Yes

2 © 1994-2017 Chip Quik® Inc.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5891)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1103)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (870)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (597)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (912)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (543)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (352)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (830)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (414)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (272)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (99)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2270)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (269)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (235)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (232)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Thomsen, Wallace - 1995 - Displacement Based Design of Reinforced Concrete Structural Walls An Experimental Investigation of Walls With - YazıDocument375 pagesThomsen, Wallace - 1995 - Displacement Based Design of Reinforced Concrete Structural Walls An Experimental Investigation of Walls With - YazıÖzlem Temel YalçınNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Flame Straightening ProcedureDocument7 pagesFlame Straightening ProcedureRomi Abdul RahmanNo ratings yet

- OYSTAR Benhil Multipack 8600 EnglishDocument6 pagesOYSTAR Benhil Multipack 8600 EnglishÁgost VitaNo ratings yet

- ATX and P4 Power Supplies PDFDocument6 pagesATX and P4 Power Supplies PDFvladareanucatalindanNo ratings yet

- Philips DCC 900 Service Manual Searchable PDFDocument92 pagesPhilips DCC 900 Service Manual Searchable PDFUgo Rampazzo100% (1)

- شيت مختبر الاسس PDFDocument23 pagesشيت مختبر الاسس PDFMohamad AlhadithyNo ratings yet

- Installation, Starup and Performance of A Static Var Compensator For An Electric Arc Furnace UpgradeDocument9 pagesInstallation, Starup and Performance of A Static Var Compensator For An Electric Arc Furnace UpgradeWilver SánchezNo ratings yet

- Boq - Pani BhabanDocument116 pagesBoq - Pani Bhabanapi-26147616No ratings yet

- Waterstops TestingDocument1 pageWaterstops Testingvinay rodeNo ratings yet

- YMCA Documentation PPT G-1Document8 pagesYMCA Documentation PPT G-1shaik irshath ainNo ratings yet

- Deleting Oracle SIDDocument2 pagesDeleting Oracle SIDlagogo100% (2)

- BizChannel Maintenance FormDocument3 pagesBizChannel Maintenance FormaliffalniNo ratings yet

- Pyrolytic Carbon Growth On Tap Changer of TransformerDocument4 pagesPyrolytic Carbon Growth On Tap Changer of TransformerVikash Singh SachanNo ratings yet

- Concurrent ModelDocument5 pagesConcurrent ModelMNaveedsdk100% (2)

- TLE-Carpentry7 Q4M4Week4 PASSED NoAKDocument12 pagesTLE-Carpentry7 Q4M4Week4 PASSED NoAKAmelita Benignos OsorioNo ratings yet

- Soft Robotics - Control Strategies For Robots Interacting With HumansDocument31 pagesSoft Robotics - Control Strategies For Robots Interacting With Humansharikiran3285No ratings yet

- 962 Chemistry (PPU) Semester 2 Topics-SyllabusDocument9 pages962 Chemistry (PPU) Semester 2 Topics-SyllabusJosh, LRT100% (1)

- Buick V 6 Casting Numbers and Internal SpecsDocument5 pagesBuick V 6 Casting Numbers and Internal SpecsAnonymous vyUisZImrNo ratings yet

- Creating A Split Tunnel VPN Connection in LinuxDocument11 pagesCreating A Split Tunnel VPN Connection in LinuxLORENA BOTERO BETANCURNo ratings yet

- AUMUND Chain Conveyors 2Document12 pagesAUMUND Chain Conveyors 2NavidJalalianNo ratings yet

- Tutorial of Adobe Dreamweaver CS3 Part 01Document5 pagesTutorial of Adobe Dreamweaver CS3 Part 01Bang SatryaNo ratings yet

- Enzyme ImmobilizationDocument27 pagesEnzyme Immobilizationsabuz pataNo ratings yet

- Bab 4 Kertas 2-Jawapan SUBDocument4 pagesBab 4 Kertas 2-Jawapan SUBayukhirNo ratings yet

- Tugas Bhs Inggris Dan LaguDocument21 pagesTugas Bhs Inggris Dan LaguEiGe TasaebNo ratings yet

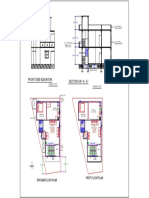

- Section On ' A - A ' Front Side Elevation: First Floor Plan Ground Floor PlanDocument1 pageSection On ' A - A ' Front Side Elevation: First Floor Plan Ground Floor PlanHusen GhoriNo ratings yet

- PMMI Mechatronics SheetDocument4 pagesPMMI Mechatronics SheetBarlarlar JuckNo ratings yet

- 3.1 L-830 TransformersDocument2 pages3.1 L-830 TransformersEduardoTopitoFerrerNo ratings yet

- Explain The Differences Between The Following: A) RISC and CISC Processors B) Harvard and Von-Neumann ArchitecturesDocument45 pagesExplain The Differences Between The Following: A) RISC and CISC Processors B) Harvard and Von-Neumann ArchitecturesShashank M ChanmalNo ratings yet

- LCD Power SupplyDocument4 pagesLCD Power Supplyhamed razaNo ratings yet

- Subaru Outback Brochure PDFDocument44 pagesSubaru Outback Brochure PDFKundan PatelNo ratings yet