HSE Management Plan Rev. 08

HSE Management Plan Rev. 08

Uploaded by

rajaCopyright:

Available Formats

HSE Management Plan Rev. 08

HSE Management Plan Rev. 08

Uploaded by

rajaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

HSE Management Plan Rev. 08

HSE Management Plan Rev. 08

Uploaded by

rajaCopyright:

Available Formats

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Contract Name: Catchment Zone Framework

Project Code: AA DOM 2018 M 1867 G

HSE MANAGEMENT PLAN

Contractors Name : MIC Construct – WABAG/Roots – APPLUS VELOSI Consortium

Clients Name: ASHGHAL PUBLIC WORKS AUTHORITY

Document Ref. No.: AA DOM 2018 M 1867 G-HSP-CONTRACTOR-Rev.08

Name &

Position Signature

Signature

Prepared By: Raja Krishnasamy Deputy HSE Manager

Approved By: David Henderson Framework Manager

Revision History

Rev. Date Change Description

08 08 Sept 2022 Revision

07 10 March 2021 Approved

06 02 March 2021 For Approval

05 20 Jan 2021 For Approval

04 14 Nov 2020 For Approval

03 27 oct 2020 For Approval

02 07 July 2020 For Approval

01 05 July 2020 For Approval

00 20 January 2020 Initial Issue

Date: 08/09/2022 Page 1 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

TABLE OF CONTENTS

CHAPTER DESCRIPTION PAGE

NO. NO.

1 HSE ACKNOWLEDGEMENT SLIP 8

2 DEFINITION AND ACRONYMS 8

2.1 ZERO ACCIDENT TOLERANCE POLICY 10

3 DISTRIBUTION OF COPIES 10

4 GENERAL 10

4.1 INTRODUCTION 10

4.2 PURPOSE 11

4.3 PROJECT HSE OBJECTIVES 11

4.4 MANAGEMENT ACCOUNTABILITY 12

4.5 PROJECT SCOPE OF WORKS 12

5 LEGISLATIONS AND STANDARDS 14

6 LEADERSHIP AND COMMITMENT 14

6.1 DRUG AND ALCOHOL POLICY 15

6.2 PPE POLICY 15

6.3 NON-SMOKING POLICY 16

6.4 SECURITY & EMPLOYEE RESPONSIBILITY 16

7 HSE PROMOTION & EMPLOYEE MOTIVATION 16

7.1 INCENTIVE SCHEME 16

8 HSE MANAGEMENT AND IMPLEMENTATION 18

8.1 TRAINING 18

8.1.1 HSE INDUCTION 18

Date: 08/09/2022 Page 2 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

8.1.2 TOOLBOX TALK 19

8.1.3 IN-HOUSE TRAINING 19

8.1.4 THIRD PARTY/ COMPETENCY TRAINING 19

8.2 COMMUNICATION, PARTICIPATION AND CONSULTATION 20

8.2.1 PURPOSE 20

8.2.2 VISITOR COMMUNICATION PROCEDURE 21

8.2.3 PARTICIPATION AND CONSULTATION PROCEDURE 22

8.2.4 MEETINGS 22

9 WORKERS WELFARE MANAGEMENT 22

9.1 WELFARE FACILITY 22

9.2 MEDICAL AND FIRST AID 23

9.3 EMPLOYEE MEDICAL SCREENING 24

10 24

10.1 FRAMEWORK MANAGER 25

10.2 HSE MANAGER 25

10.3 QA/QC MANAGER 26

10.4 HSE OFFICERS 27

10.5 SITE ENGINEER 27

10.6 FOREMAN 28

10.7 WORKERS 28

10.8 NURSE 28

10.9 FIRST AIDERS 28

11 HAZARD IDENTIFICATION AND RISK MANAGEMENT 29

Date: 08/09/2022 Page 3 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

11.1 PURPOSE 29

11.2 RESPONSIBILITIES 29

11.3 REFERENCES 29

11.4 TERMS AND DEFINITION 29

11.5 PROCEDURE FOR HAZARD/ASPECT IDENTIFICATION 30

11.6 RISK ASSESSMENT 31

11.7 METHOD STATEMENT 34

12 ENVIRONMENTAL MANAGEMENT PROCEDURE 35

12.1 PURPOSE 35

12.2 GENERAL PROJECT RISK TO THE ENVIRONMENT 35

12.3 IDENTIFYING ENVIRONMENTAL ASPECTS 36

12.4 ASSESSING ENVIRONMENTAL IMPACTS 37

12.5 CONTROL MEASURES FOR ENVIRONMENTAL ASPECTS 37

13 EMERGENCY PROCEDURES 37

13.1 CONFINED SPACE EMERGENCY RESCUE PROCEDURES 37

13.2 EVACUATION PROCEDURE 39

13.3 AWARENESS AND TRAINING 39

14 COMMUNICATION 40

14.1 WEEKLY PROGRESS MEETING 41

14.2 HSE SPECIFIC MEETINGS 41

14.3 DAILY PRE-START MEETINGS 41

14.4 SAFETY SIGNS 41

15 MANAGEMENT OF SUBCONTRACTORS 42

Date: 08/09/2022 Page 4 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

15.1 PRE – QUALIFICATION OF SUB-CONTRACTORS AND 42

SUPPLIERS

15.2 HSE EVALUATION OF SUB-CONTRACTORS AND SUPPLIERS 43

15.3 SUB-CONTRACTORS ADMINISTRATION 43

15.4 SUB-CONTRACTOR CONTROL 43

15.5 ROLES AND RESPONSIBILITIES 44

15.6 WORK PLANNING AND CONTROL 45

16 HSE INCIDENT REPORTING AND INVESTIGATION 45

16.1 EVENTS (NEAR MISSES) 45

16.2 REPORTING OF UNSAFE ACTS, CONDITIONS, OBSERVATIONS 46

AND UNSAFE OBSERVATIONS

16.3 DANGEROUS OCCURRENCES 46

16.4 INCIDENT REPORTING PROCEDURE 46

16.5 INCIDENT INVESTIGATION PROCEDURE 47

17 HSE PERFORMANCE MONITORING 48

17.1 HSE INSPECTIONS 49

17.2 HSE STATISTICS REPORT 49

17.3 PRO ACTIVE AND REACTIVE MONITORING 49

17.4 INTERNAL AUIDIT 50

17.5 EXTERNAL AUDITS 54

17.6 PROJECT HSE TASKS AND KPI’S 54

17.7 NON- CONFORMANCE AND CORRECTIVE ACTION 55

17.7.1 TERMS AND DEFINITION 55

17.7.2 PROCEDURE 55

17.7.3 IDENTIFYING ROOT CAUSE AND IMPLEMENTING 56

CORRECTIVE ACTION

Date: 08/09/2022 Page 5 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

17.7.4 VERIFICATION AND VALIDATION OF ACTION TAKEN 56

18 MANAGEMENT REVIEW 57

18.1 PURPOSE 57

18.2 SCOPE 57

18.3 RESPONSIBILITIES 57

18.4 REFERENCES/ PROCEDURE REFERENCE 58

18.5 TERMS AND DEFINITIONS 58

18.6 PROCEDURE 58

18.6.1 preparation for Review Agenda 58

18.6.2 Review Input 58

18.6.3 Review Output 59

18.6.4 Management Review Team 59

18.6.5 Conduct of Meeting 59

19 CONTINUAL IMPROVEMENT 59

20 PLAN REVIEW 60

21 APPENDICES (Attached separately) 60

APPENDIX A: HSE POLICY

APPENDIX B: ISO 45001:2018 CERTIFICATE

APPENDIX C: ISO 14001:2015 CERTIFICATE

APPENDIX D: SAFE WORK PRACTICES AND PROCEDURES

APPENDIX E: COMPLIANCE REGISTER

APPENDIX F: HSE ORGANIZATIONAL CHART

APPENDIX G: TRAINING PROCEDURE

Date: 08/09/2022 Page 6 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

APPENDIX H: HSE TRAINING MATRIX

APPENDIX I: HAZARD AND RISK MANAGEMENT PROCEDURE

APPENDIX J: ENVIRONMENTAL MANAGEMENT PROCEDURE

APPENDIX K: RISK REGISTER

APPENDIX L: ENVIRONMENTAL ASPECT and IMPACT REGISTER

APPENDIX M: INCIDENT RESPONSE & REPORTING

APPENDIX N: NON-CONFORMING SERVICE AND CORRECTIVE

ACTION PROCEDURE

APPENDIX O: INTERNAL AUDIT & MANAGEMENT REVIEW

PROCEDURE

APPENDIX P: HSE MONITORING PROGRAM

APPENDIX Q: HSE ADMINISTRATION PROCEDURE

APPENDIX R: ENV. RISK & OPPORTUNITIES REGISTER

APPENDIX S: LEGISLATIVE, REGULATORY AND OTHER

REQUIREMENTS PROCEDURE

1 HSEM PLAN ACKNOWLEDGEMENT SLIP

To: (Refer to 4. Distribution of Copies)

Catchment Zone Framework

From: All controlled copyholders. I have received and read the HES Plan, policy and procedures

related to my scope of the works. I take full responsibility to ensure that compliance with all HSE

requirements will be met.

Date received: ………………………………..

Project Name: ………………………………..

Company: …………………………………….

Date: 08/09/2022 Page 7 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Title: …………………………………………..

Name: …………………………………………

Signature: …………………………………….

(Please return this signed original copy to the HSE Manager)

2 DEFINITION AND ACRONYMS

Contractor (MWRV) – MIC Construct – WABAG/ROOTS-APPLUS VELOSI Consortium

ANSI – American National Standard Institute

Accident – Unwanted, unexpected event, which has result in actual injuries, illness, damage or

loss. All accidents are therefore incidents but not all incidents are accidents.

ALARP – “As Low as Reasonable and Practicable”. It refers to reduction of risk to a level where the

cost of risk reduction is grossly disproportionate when compare to actual risk deduction that would

be achieved.

Approval – Means prior written assent of the client ASHGHAL. The term approval shall in no way

to construed as relieving the Contractor of any of its obligations, responsibilities and liability's.

Approve or Approved shall be construed accordingly.

CAP – Corrective Action Plan

CSI – Collective Sewer Infrastructure

Competent – Displaying practical & theoretical knowledge and actual experience of the work

activity is that they are required, a person competence will some cases be tangibly demonstrated by

the award of a qualifications and skills.

DBA – Decibels abbreviation. An expression of the relative loudness of sounds in air as perceived

by the human ear.

EMT – Emergency Medical Technician

Employer – ASHGHAL-Public Works Authority

FS – Foul Sewer

GIS - Geographical Information System

HSE – Health, Safety & Environment

HSMP– Heath, Safety Management Plan

IDLH – Immediately Dangerous to Life or Health

JHA – Job Hazard Analysis

LEL – Lower Explosive Limit

LOLER – Lifting Operations Lifting Equipment Regulations.

LTI – Lost Time Injury a work-related Injury which renders the injured person unable to perform his

regular job.

MTC – Medical Treatment Case a work-related injury, which results in neither lost time nor

restricted work, but which requires treatment by under the supervision of medical doctor.

Date: 08/09/2022 Page 8 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Method Statement – A work method statement is a document that details the way a work task to

be carried out. It gives step by step guides how to do a work safely, outlines the hazards involved

and the control measures that have to be introduced to ensure the safety.

ISO 45001 – Occupational Health and Safety Management System

ISO 14001 – International Standard for Environmental Management System

SDS – Safety Data Sheet

Near Miss – A Near Miss is an incident which could have, but did not result in injury, illness,

damage, product loss or harm to the company reputation.

NCR – Non-Compliances Report

PLC – Programmable Logic Controller

PPE – Personal Protective Equipment

PTW – Permit to Work.

QCS 2014 – Qatar Construction Specification 2014

QWZTMS – Qatar Work Zone Traffic management system

RPE – Respiratory Protective Equipment

Risk – Risk is the combination of the likelihood or probability of an event occurring and the severity

of the outcome.

Reasonable & Practicable – where a legal requirement is qualified by term "reasonable &

practicable" the cost in term of money & time and inconvenience of taking precautions may be

balanced against the risk being considered.

RIDDOR – Reporting of injuries disease & dangerous occurrence regulations 1995.

Risk Assessment – Is the process of identifying hazards and determining the risks they pose, to

qualify and decide if a task or activity can proceed safely or if control measures are required to

deliver the risk as acceptable.

RRRU – Repair, Replacement, Rehabilitation and Upgrading

RTU – Remote Telemetry Control Panel

SCADA – Supervisory Control and Data Acquisition

SGW – Surface and Ground Water

TW – Treated Water

TWN – Treated Water Network

WEL – Workplace Exposure Limit.

PMV – Plant Machineries and Vehicles

2.1 Zero Accident Tolerance Policy

a. All endeavor to adopt a zero-accident tolerance attitude to any occurrence threaten the

Health and Safety & Environment of our workforce and the general Public. The management

is committed to achieving and sustaining

b. "ZERO ACCIDENT TOLERANCE" through continuous improvement practices.

c. Objectives

d. No workplace injuries and occupational Diseases.

Date: 08/09/2022 Page 9 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

e. No accidents

f. Promote HSE as an integral part of our day –to- day activities.

g. Spread Health & Safety Management Plan throughout the organization.

h. Enhance employee awareness & involvement in Health and safety & Environment program

implementation.

i. Optimize the use of continuous improvement practices as the basis.

j. "Zero Accident Tolerance" initiative.

k. Eliminate all Environmental Impacts aspects.

3 DISTRIBUTION OF COPIES

1 Client Representative Head office

2 HSE Manager Head office

3 Framework Manager Site office

4 HSE Engineer / HSE Officer Site office

5 Project Engineer Site office

6 Planning Engineer Site office

7 QA/QC Engineer Site office

8 Contractor Head office

HSE Officer will maintain additional copies at Site Office.

4 GENERAL

4.1 Introduction

The Primary objective is to ensure that the Contractor HSE policy is adhered to, on all Works

order that are undertaken and that it is continuously reviewed in relation to current legislation

requirements.

Contractor performs Catchment Zone Framework and therefore, this plan is intended to

convey our policy for maintaining HSE procedures for Contractor personnel as well as

subcontractors employed.

The site HSEM Plan is to be managed and administrated by the Framework manager and

HSE Manager.

HSE Plan has been prepared to guide the Framework Manager in supervising and

maintaining the Contractors safety aspects in this project. The objective is to perform and

carry out work in a safe and healthy manner. Therefore, the expectation is to manage the

project activities and supervise personnel in an efficient manner consistent with these

objectives and in particular to eliminate accidents/incidents.

The requirement given in this document is in addition to the requirement of any other Local

Statutory Regulations and the safety rules and regulations of ASHGHAL.

Date: 08/09/2022 Page 10 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

The basic responsibility of enforcing this HSE Plan rests with the Framework manager of

every site. The HSE Manager / HSE Officer for the project will assist them in implementing

this HSE Plan. Contractor believes firmly that managing safety is a line management

responsibility and it is seen as a good business practice to provide a safe working

environment to the workmen at site.

The role and responsibilities of the site personnel in accident prevention is dealt with in the

chapter 11: Organization and Responsibilities.

The HSE Manager/HSE Officer for the project will act as a catalyst in motivating the frontline

engineers and foremen to fulfill their obligations on safety. He will monitor the safety activities

on a day-to-day basis and will report to the Framework manager if there is any deviation and

or violation from the regulations contained in this document.

4.2 PURPOSE

The purpose of this document is to provide guidance and supporting information to enable the

Contractor to meet client requirements. It is an organizational document that describes different

processes to manage HSE risks and meet its HSE Objectives.

4.3 PROJECT HSE OBJECTIVES

The following are the specific HSE objectives for the Project.

Prevention of work-related injuries and illness in line with our client’s HSE Philosophy

Minimize/avoid the employee’s exposure to risk associated with the high-risk activities.

Create and establish a good health and safety culture among its workers including good

organizational climate during the whole course of the project.

Strict adherence and implementation of client other related HSE rules, standards and policies

To be equipped with competent personnel in their chosen field of expertise leading to quality

works delivered on time.

Reporting of any untoward incidents, analyzed its causes, conveyed the lessons learned to all

project personnel and means of tracking its corrective action implementation.

Establish the consultation and coordination among all project personnel, including clear

accountabilities and responsibilities in HSE.

Provide proper guidance to implement environmental waste management plans, programs,

compliance obligations and initiatives to protect the environment.

Proper monitoring and evaluation of Sub-Contractors performance on HSE

Implementation of Project specific KPI’s

Improving performance levels

MWRV Commit To reduce environmental aspects & impacts within and outside the

organization’s

Contractor Vision to Achieve the objectives and target Please refer the HSE monitoring program

Appendix P

4.4 Management Accountability

Contractors management is responsible and will be held accountable for the Safety and Health of

all employees on the project. Management’s objective is an efficient, productive effort that

incorporates all elements of Health, Safety & Environment through the participation of

management, work team, employees, subcontractors and suppliers.

Date: 08/09/2022 Page 11 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

All subcontractors, vendors, suppliers, visitors and Contractors employees shall comply with this

plan.

Each subcontractor’s senior person on the project shall acknowledge to Contractors Management

that the Project Health and Safety Management Plan, policy, guidelines and procedures will be

adhered to with no exemptions prior to work commencing.

4.5 Project Scope of Works

Repair, replacement, rehabilitation and upgrading (RRRU) works for any of the Authority operated

sewer assets across FS, SGW and TWN system in the state of Qatar.

4.5.1 The Scope of Work consists of, but is not limited to the following:

Upgrading of existing network pipelines via open trench and no-dig construction

methodology.

Construction of new sewer network capacity within allocated corridors

Refurbishment of existing sewer manholes, manhole covers and frames.

Construction of new sewer manholes and house connection chambers and related

pipework

Construction of sewer rising mains, discharge and washout chambers and

related pipework

Removal of existing sewer T-Connections

Construction of new TW customers’ and associated valve chambers

Relocations of existing TW valve chambers and associated assets Construction of

flow diversion schemes between catchments to facilitate sewer infrastructure

operational flexibility.

Stopper placement and removal works.

Construction of Ventilation networks

SCADA and telemetry equipment.

Attenuation tanks

Flow measurement instrumentation.

New connections and connection points.

Electrical power supply and control panels.

Installation of sampling points.

Any associated assets, included but not limited to gullies, catch pits, inspection

chambers, foul gravity sewers, lagoons, soakaways, towers and reservoirs, hydrants,

ventilations pipes, bollards and boundaries.

Any associated fittings and accessories including all, chambers, valves, pressure

sensors, actuators, covers and frames, grates, signage and access chamber, access

shafts, asset tags, marker plates, ladders and signage.

Site decommissioning including removal of facilities.

Demolition, breaking out of surfaces, manholes, chambers, pipe runs including

excavation to sufficient depth and width;

Repair any internal lining which has been disturbed’;

Rehabilitation of walls by plugging, patching, removing and replacing;

Providing or replacing mortar, coatings, sealants, lining and liners to improve

structural condition.

4.5.2 The scope of work methods may include, but not limited to:

open excavation;

Date: 08/09/2022 Page 12 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

micro-tunneling.

horizontal directional drilling.

pipe jacking;

horizontal auger boring;

pneumatic pipe bursting;

static pull bursting;

hydraulic expansion; and

pipelining.

4.5.3 The scope of works shall include but not limited to the following activities:

excavation to sufficient depth;

re-construction;

over pumping;

dewatering;

construction; and

reinstatement.

4.5.4 Work Zones

4.5.4.1 SGW Catchment Zones

For visualization purposes, the SGW Catchment Zones shall be split as indicated

below. Secondary Catchment Zone awarded to for Contractors.

Date: 08/09/2022 Page 13 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

5 LEGISLATIONS AND STANDARDS

The following is a list of the minimum applicable Qatar Laws, Standards and Specifications:

Qatar Labor Law 14 Year 2004

Qatar Construction Specification 2014

Qatar Environmental Protection Law 30 Year 2002

Qatar Civil Defense Fire & Safety Handbook

Qatar Civil Defense Fire and Life Safety Guidelines (Volume 1 of 2015)

Qatar Civil Defense Law No.13 to 1997

Qatar Civil Defense Law No.9 to 2012

OHS-P2/G1-Kahramaa Safety Guidelines for Contractors (Oct 2017)

NFPA 70E-2015 Standard for Electrical Safety in the Workplace

ISO 45001:2018

ISO 14001:2015

ISO 9001:2015

Work Zone Traffic Management Guide (Rev. 1.2, November 2015)

NEBOSH Manuals

Ministerial Decree No. 16 of 2007 (Heat Stress Prevention)

CFW – Consortium procedures

Workplace Guidelines for Covid-19 (MoPH-March 2020)

Contractor Welfare Adherence Plan -AA DOM 2018 M 1867 G-WAP- CONTRACTOR -

Rev.03

Incident, Accident & Emergency Response plan (AA DOM 2018 M 1867 G- EPRP-

CONTRACTOR-Rev.00)

Worker Rights Booklet 2009 – Qatar Human Rights Committee

PWA Guidelines and Requirements

Legal Compliance register (Appendix E)

6 LEADERSHIP AND COMMITMENT

Date: 08/09/2022 Page 14 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Contractors are committed to developing and implementing the HSE objectives and is committed to

providing a safe and healthy work environment throughout the duration of the project.

Communicating to all employees of the importance of Health, Safety and environment approach to

improve the effectiveness and achieving the project HSE Objectives.

Meeting and fulfilling statutory and regulatory requirements by ensuring that those performing the

activities are made aware of these requirements and the compliance is ensured through adequate

supervision. This is carried out through reviewing the requirements thoroughly by the designated

persons.

Each employee must receive HSE training on a regular basis.

Each employee must implement the health, safety and environmental practices in order to anticipate

risks and make the right decisions.

All Project key personnel shall demonstrate their commitment to the development and improvement

of safety and healthy work environment through their involvement in the internal audit process, and

through their proactive involvement in the continual improvement activities where emphasis is placed

on improving both effectiveness and efficiency of key HSE processes.

Company Management shall provide strong and visible leadership throughout locations and Project

sites, and amongst their Contractors, to promote a culture of shared commitment to HSE by:

Providing strong, visible leadership through being a good role model for all employees and sub-

contractors.

Actively participating in site HSE visits.

Attending HSE meetings and forums.

Reviewing HSE Performance of sub-contractors.

Reviewing findings from high potential incidents and near misses.

Showing visible, timely and involved response to significant incidents, or any other upset to

normal business.

Implementing the IMS and monitoring progress against specific milestones within the HSE Plan.

Communicating HSE expectations to the employees and subcontractors, through the IMS Policy.

Demonstrating active personal participation in HSE activities such as training, reward, risk

assessment, environmental aspects and impacts, control measures, identifying risk and

opportunities, incident investigation, HSE objectives and targets, and others.

6.1 Drug and Alcohol Policy

Abuse of legally permitted prescribed drugs and alcohol or the use, possession, distribution or

sale of illegal or non-prescribed drugs and alcohol during working hours is not permitted in

accordance with QCS 2014, any person found under the influence of drugs or alcohol will be

removed from the project and reported to the Framework manager. Appropriate disciplinary

action will be taken to the offending person as per our disciplinary scheme. Alcohol testing will be

periodically conducted if deemed necessary.

6.2 PPE Policy

It is the policy of Contractors to provide Personal Protective Equipment (PPE) to protect the

employees from exposure to workplace hazards and the risk of injury in accordance with QCS

2014, section 11 part 1.6.1.8 and section 1-part 10.9.2. PPE is not a substitute for more effective

control methods and its use shall be considered only when other controls unless no other means

of hazard control exist.

Date: 08/09/2022 Page 15 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Personal protective equipment shall be provided, used, and maintained when it has been

determined that its use is required to ensure the safety and health of our employees and that

such use shall lessen the likelihood of occupational injury and/ or illness. The following shall be

provided to Contractors staff as and when identified by the risk assessment process.

Checklist for safety appliance will be maintain at all time and Site works / operations will be

periodically reviewed to determine the requirement of any additional safety equipment.

6.3 Non-Smoking Policy

Non-smoking policy will be applied in certain working areas (defendant on which phase and

location of works) including the office. In accordance with QCS 2014 Smoking is only permitted

in assigned locations; non-combustible ashtrays must be provided wherever smoking is

permitted.

All smoking areas will be designated in safe areas and clearly defined as “Smoking Areas” with

appropriate signage. “No Smoking” signs will be deployed in strategic locations around the site

in order that smoking is controlled.

6.4 Security

The Contractor project Security will control the security gate and make sure contractor premises

including store, main yard well secured. To ensure that only authorized persons work at or visit

the site, the Contractor security will stop the newcomers at the security gate and guide them to

attend Contractor mandatory induction program. In accordance with QCS 2014 section 1, part

10.8.1, clause 8, Contractor shall provide Client with photocopies of passports or Qatar ID and

any similar personal documentations like driving license etc. to obtain Client temporary

identification cards and passes for Contractor Personnel to enter limit of work premises.

Contractor shall ensure that Contractor Personnel display such identification at all times when

they are on the premises.

Contractor shall ensure safe and secure storage of materials, equipment/plant to protect against

theft.

6.4.1 Employee Responsibility

All staff and employees have a responsibility to actively participate in the implementation

of the Security Procedure to ensure an adequate level of protection is achieved.

It should be recognized that the action of any individual could have a negative impact on

the security of others. Do not put yourself in any situation that could jeopardize your own

safety.

7 HSE PROMOTION & EMPLOYEE MOTIVATION

7.1 Incentive Scheme

An incentive scheme will be introduced in this project in order to motivate the workforce to follow

site HSE rules and regulations. Two Employees will be chosen among the entire workforce every

month and they will be provided with cash prize or gift items.

7.1.1 Criteria for selecting the safety man of the week will be as follows:

HSE awareness of the employee

Safety attitude of the employee

Date: 08/09/2022 Page 16 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Risk Assessment for the job performed

Participation in housekeeping

Toolbox meeting attendance

Safety violations made during the month (if any)

Not involved in any first aid cases/accident

Usage of PPE

Reporting of near misses

Worksite supervisor and HSE Manager/HSE Officer’s recommendation will be

obtained through an endorsement.

Framework manager and HSE Manager/HSE Officer will select the safety man of the

week certificates or cash prize will be awarded to the winner.

7.1.2 Employee Motivation:

a. Contractor employees and subcontractors will be highly motivated to follow the site

HSE rules and regulations in order to prevent any accidents/incidents.

b. Provision of a healthy, environmentally sound and safe work environment for all

employees.

c. Supervisors will support and lead the Health & Safety process and empower the

employees to participate and execute the process.

d. Site project management will enhance the Zero Accidents Performance through

accident prevention and behavior-based safety management.

e. Everyone goes home every day the same way came to work.

f. Zero Accidents Performance from everyone.

g. Optimum performance in safety and health work activities.

h. Promoting Safety as a value not priority.

i. Promote Safety Culture throughout our Organization.

j. Spreading ownership for Safety & Health program in our Organization.

k. Enhancing Employee/Subcontractor involvement in Health & Safety program

implementation.

l. Share responsibilities for day-to-day implementation.

7.1.3 Disciplinary Procedures:

All employees are expected to comply with jobsite rules and regulations, and to follow

established operating procedures set forth by this company. Violations will not be

tolerated, and superintendent/foreman will be held accountable for the conduct of their

employees.

Engineers and foremen are required to act when a violation is observed. Immediate

action to control or eliminate a hazard is required.

Examples include:

a. Knowingly putting yourself or other at risk of injury.

Date: 08/09/2022 Page 17 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

b. Smoking where it is prohibited.

c. Interfering with safety equipment (fire alarms, extinguishers, handrails, scaffolding and

barricades etc.)

d. Horseplay or malicious behavior that could lead to injury.

e. Consuming or bringing on site alcohol, illegal drugs or substances.

f. Being under the influence of alcohol, illegal drugs or substances.

g. Urinating or defecating other than in the facilities provided.

In the event a violation is observed, the following procedures have been established to

place an employee on notice Depending on the severity, Scenario of the offense.

NOTIC ACTION

E

A written warning addressed to the employee and a copy placed in

First

the employee's file referencing the violation and warning, including

Offense

date and time.

A written warning addressed to the employee with reference to the

Second violation including date and time of the occurrence. A copy of this

Offense: warning will be given to the employee and another copy will be

placed in the employee's file.

A written warning similar to the second notice will be prepared and

distributed in the same manner. This warning will be followed by a

Third meeting with the employee, foreman and/or framework manager and

Offense senior management to determine whether the employee will be

suspended without pay or terminated depending upon the nature of

the violation.

Fourth

Termination

Offense

8 HSE MANAGEMENT AND IMPLEMENTATION

8.1 TRAINING

8.1.1 HSE INDUCTION

HSE induction is one part of the communications procedure between the QHSE Dept

and new or transferee employees/sub-contractors, visitors. Reference (Appendix G)

The induction program for all employees includes all new employees regardless of the

number of years worked in the industry. It covers every person new to the company,

new to a particular project site or only new to a work crew.

The company takes into account language skills and literacy of attendees. A translator

shall always be present at all times.

HSE induction shall cover the HSE responsibilities and accountabilities to the new

employee to be familiar with the roles and his subordinates, and aggressively ensure

compliance with these requirements.

HSE induction program shall consist of; types of potential hazards, significant

environmental aspects, state and local laws, site requirements and client's request.

Date: 08/09/2022 Page 18 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Specific HSE Induction will be conducted once Team member’s/visitors transfers from

one site to another

A refresher HSE Induction shall be conducted every six months which will cover all

Team Members.

Contractors have to provide all necessary training as per the Appendix H (Training

matrix) and need to update and add trainings as per the requirements.

8.1.2 TOOLBOX TALK

Toolbox talk is one part of the communications procedure to communicate hazards,

risks, task execution and significant environmental aspects to those undertaking work.

It shall be conducted by all Team members at the worksite daily

Site Engineers/Supervisors and HSE Officers train their employees to work safely on

the projects during toolbox meetings and as otherwise needed.

Guidelines to follow when planning a Toolbox Meeting are:

All members of the workforce must attend.

It is held daily and before starting the activities.

The topics for discussion must pertain the specific task at hand, and in addition,

to incident prevention, hazards and risks associated with the activity

Point out unsafe acts, practices or conditions that have been observed in the

project area and delegate corrective measures, if applicable.

Review recent incidents in the project area, why they happened and what is to

be done to prevent recurrence.

Encourage employee by suggestions and discussion.

Brief the employees on new types of equipment in the area, with specific

reference to their capabilities and safeguards.

Request that the respective HSE Officer assist in providing topics for

discussion and further assist in the presentation of the Toolbox periodically.

Information on technical matters such as procedures for confined space entry,

hazards of toxic chemicals in use, lift capabilities of specific lifting devices, etc.,

must be requested from the HSE Officer.

Site Engineers/Foreman, Technician and HSE Officer has to take signatures from the

attendees.

8.1.3 IN- HOUSE TRAINING

In-house training is one part of the communications procedure between the Project

Team and other employees/sub-contractors to present one subject of HSE in detail to

them.

The Project Team draws up in-house training program associated with its

Environmental risks, significant environmental aspects, and IMS Management System

to all employees and sub-contractor to ensure that Contractors Management,

Engineers, Employees and Sub-contractors are motivated to act in a safe manner, and

to increase a HSE awareness of them, and the following is In-house training program:

Safety Officer will present to all site employees and sub-contractors, and some

employee’s attendees shall be selected to explain to others in their mother languages

because the company takes into account language skills.

Different Training identified shall be itemized using Training Plan

All in-house trainings shall be documented using Training Attendance Record

Date: 08/09/2022 Page 19 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

To evaluate the effectiveness of the in-house training Reference (Appendix G), HSE

Officer has to take signatures from the attendees using training feedback form

8.1.4 THIRD- PARTY/ COMPETENCY TRAINING

HSE third party training is one part of the communications procedure between third

party and site employees.

Framework/Project Manager and HSE Officer identifies the required third party and

competency training as per the following requirements:

Client’s Policy and Procedures

Site and activity requirements

Results of Training Analysis

Compliance Obligations

Scope of Works

Only ASHGHAL approved training centers from client shall be selected

All training cards shall be distributed to the concerned employees to use it in all work

activities and shall be valid.

Third party training certificates are maintained and recorded

All trainings undertaken shall be evaluated it is effective or not by conducting Training

Effectiveness Assessment.

The following list of competency training are identified for the said project (not

exhaustive)

First Aider

Fire Warden

Safety/Hole Watch

Fire Watch

Confined Space Entrants

Confined Space Supervisors

H2s

Rigger

Lorry Loader Operator/Crane Operator

Scaffolders

Authorized Gas Testers

Contractors have to provide all necessary training as per Appendix H (Training matrix)

and need to update and add trainings as per the requirements.

8.2 COMMUNICATION, PARTICIPATION AND CONSULTATION

8.2.1 PURPOSE

To document the process of receiving, documenting and responding to relevant

communications from external interested parties (Example: sub-contractors, suppliers

and visitors) to worksite.

To document the process for internal communication among company’s different

activities and departments regarding HSE Objectives and IMS.

To document communication with the sub-contractors and visitors to the workplace.

To encourage workers participation and consult with external parties about pertinent

HSE matters.

Date: 08/09/2022 Page 20 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Contractor will ensure that the right message is clearly and comprehensively conveyed to

all Project Personnel with respect to HSE. Matters to be communicated to all composes

of but not limited to;

IMS Policy

Risks Assessments/Job Safety Analysis

QHSE Risks and Opportunity registers

List of Interested Parties, needs and expectations

Compliance Obligations

Site HSE Rules

Site Security Rules

Different processes and activities for Project, (including other sites)

based on the scope of the Project

Hazardous Substances safe use, storage and handling, including

MSDS

Emergency Procedures and Emergency contact details

Incident Reports

Lessons Learned from Incidents

Emerging HSE Issues

Control of Substances Hazardous to Health (COSHH) Assessments

The above matters will be communicated to all employees, sub-contractors and other

interested parties through one or more of the following means:

Site HSE Induction

Pre-start Safety Briefings

Toolbox Talks

Posting information on Site HSE Notice Boards

E-mail messages

Formal and informal meetings

Relevant HSE matters necessary to be communicated to ASHGHAL (but not limited to)

Incidents and near misses

Captured non-conformances

Closeout reports and completion of corrective actions

Any non-conformities noticed issued by regulatory agencies

Any dangerous occurrences

8.2.2 VISITOR COMMUNICATION PROCEDURE

In order to gain entry to the site upon arrival, visitors are required to sign a Visitor

Control Register containing such information as name, company name, purpose of

visit, time in, time out, and person to be seen. At the end of their visit, visitors are

required to sign out, using the Visitors Control Register.

Safety Induction shall be conducted by the Site HSE Officer to the visitors to

announce the hazards and environmental significant aspects in operations and the

precautionary measures to be taken before entering the worksite.

Visitors shall be escorted to and from their destination by a staff member.

Date: 08/09/2022 Page 21 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

All visitors are required to ensure that any hazard/aspect observed or created is

reported to Contractor staff member.

Any incident suffered or observed by a visitor shall be reported to a Contractor staff

member.

In the event of a fire emergency, the Fire Warden for each worksite is required to take

Visitor Control Register with them when they evacuate the area.

8.2.3 PARTICIPATION AND CONSULTATION PROCEDURE

In order to ensure that all HSE procedures and actions are understood and carried

out by the workforce it is necessary to have regular communication and consultation

with them. This will be carried out as part of the morning briefing and toolbox talk

sessions.

Copies of the toolbox talk/site briefing/communication form will be made available to

the ASHGHAL HSE Representatives during inspections.

Similarly, the Project Team will appoint Worker’s Representative who will

communicate and raise concerns on HSE issues between his co-workers and HSE

Team

Workers shall be informed about their participation arrangements, including their

representative(s) on HSE matters in each site, as well as consultation with the

external parties such as contractors, where there are any changes that affects them.

8.2.4 MEETING

Meetings are the one part of communications procedure and it consists of:

a. HSE induction for the new arrival, transferee employees and subcontractors, visitors,

suppliers and other interested parties of the organization

b. Toolbox talks at sites

c. HSE meetings

Meetings between the site HSE and operations teams to discuss about the following

(but not limited to):

Client’s comments on Health, Safety and Environment.

Non-conformance and corrective actions

Site HSE requirements

Near misses’ incidents

Other HSE issues.

Minutes of the Meeting shall be accomplished by the participants and to provide a

timetable on the action items that needs to be acted by responsible Department or

person.

A report of each meeting is documented and recorded such as;

HSE meeting internally

Third party training meetings

External meetings with the external interested parties like clients,

subcontractors, suppliers and others (if needed)

Information is disseminated to the external interested parties and consulted with them by

means of regular or irregular meetings

Date: 08/09/2022 Page 22 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

9 WORKERS WELFARE MANAGEMENT

9.1 Welfare Facility

The availability of welfare facilities, their location on site and regular maintenance must be

considered at the planning and preparation stages of the project, before construction work starts

in accordance with QCS 2014, section 1 part 10.10.

When planning welfare provision, consider:

The nature of the work to be carried out and the health risks associated with it. For

example, rest shelter especially when the workers operating directly under the sunlight.

The distance workers will have to travel to the welfare facilities; the duration of the work

and number of different locations;

The numbers of people who will use them;

The cleaning and maintenance of the welfare facilities;

Whether they need to be relocated during the construction phase.

Minimum Requirements for Welfare Facilities

The following are the minimum requirements for welfare facilities in CONTRACTOR project site

will be provided:

Portable Toilets

Drinking Water Station

Rest Facilities

Designated Smoking Area

Washing Facilities

Clinic Facilities

Site mess hall (if required as per project manpower)

Prayer Room

Contractor are committed to establishing and maintaining high worker welfare standards for all

employees and individuals working on our project. In addition, we shared the policy (attached in

welfare plan) with our clients and strive to influence other firms in our industry to adhere to the

practices outlined in the policy. The procedure for the management of all contractors and

subcontractor’s personnel health and welfare shall be in accordance with: -

Qatar construction specifications 2014

Ministry of labor and Social Affairs including No.18 of 2014

Ministry of Municipality and Environment (MME) Workers Accommodation Planning

Regulation

The Construction Workers Accommodation and Welfare Standard.

Supreme Committee For Delivery & Legacy (Workers Welfare Standards (Edition 2)

Date: 08/09/2022 Page 23 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Contractor will follow comply the all requirements in Contractor Welfare Adherence Plan -

AA DOM 2018 M 1867 G-WAP- CONTRACTOR - Rev.03

For more details of worker welfare Please refer Contractor Welfare Adherence Plan -AA

DOM 2018 M 1867 G-WAP- CONTRACTOR - Rev.03

9.2 Medical and First Aid

First aid or medical assistance will be rendered to any person in genuine need of assistance,

irrespective of whether they work on the project or a member of the public.

CONTRACTOR will provide and maintain a comprehensive First Aid Kit in the project site office

which will be inspected through on weekly basis by competent responsible personnel.

The First aid box furnished with medicines tools and equipment shall be kept in a conspicuous

place in the establishment of buildings and others. The first aid box shall be available to the

workers. The use of the box shall be entrusted to a worker trained in providing first aid service

[First Aider].

Trained first-aiders or other medical services will; be available on the worksite as minimum

requirement of the Qatar worker law 14, Part 10, Article (104). First-aiders and medical personnel

are as per project requirements.

All Accidents, Incidents, Near Miss, Major Injury, Property Damage, Dangerous Occurrences,

etc. the contractor shall immediately notify the ASHGHAL by telephone where it impacts on the

operation of the project and electronically (Initial report) in all cases never more than 24 hours

and minor first aid cases will be informed to ASHGHAL through weekly statistical report. Incident

Investigation final reports to be submitted for all lost time major reportable Incidents within 7-10

days of the incident. QCS 2014 Section 01 General Part 10: Occupational Health and Safety.

9.3 Employee Medical Screening

CONTRACTOR providing Health insurance for every labor in the project. For workers annual

medical screening CONTRACTOR have a contract with a local hospital. Throughout the project

life campaigns on health monitoring will be carried out such as blood test, urine test etc.

Contractor shall commit to Worker’s Compensation and Employer’s Liability (including

Occupational Diseases) insurances shall be provided for all employees employed by the

Contractor and its sub-contractors and suppliers.

For more details of worker welfare Please refer Contractor Welfare Adherence Plan -AA DOM

2018 M 1867 G-WAP- CONTRACTOR - Rev.04

10 ORGANIZATION AND RESPONSIBILITIES

All managers, supervisor and workers on the project are responsible for safety within their defined

scope of activities.

This includes:

Ensuring compliance with all HSE acceptance criteria, design premises and strategies.

Implementing all relevant regulatory and project requirements within area of responsibility.

Initiation and follow up of relevant safety related studies/analysis.

The managers and their subordinates are responsible for contacting the Project HSE

Manager when assistance is needed. The HSE Manager shall act as advisor, but this does

not reduce or replace the responsibility of the other departments for their activities

Date: 08/09/2022 Page 24 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

The individual discipline responsibility is neither reduced nor replaced by the HSE Manager’s

scope of work.

The CONTRACTOR will provide qualified and competent persons whose sole responsibility is

dedicated to administering the safety and health program and manage the safety and health

for the project. The CONTRACTOR will provide at least one safety officer per 50 site workers

as per QCS 2014

CONTRACTOR will provide the following key safety personnel on site. To ensure that all

project personnel understand their group and individual responsibilities, the units of

responsibility with regard to the implementation of the project are set below.

10.1 Framework Manager

The Framework manager is responsible for implementations and directly reports to the

Project Director. Duties and responsibilities on safety are as follows: Ensuring in

implementing safety procedures;

Be fully conversant with state of Qatar labor law, QCS 2014 Section 1 Part 10 and section

11, part 1.2 to part 2.4.01 and CONTRACTOR Safe Operating Procedures.

Using the principles of the Hierarchy of Controls, guide in [7. Hazard Identification and Risk

Assessment] in all construction activities to minimize the risk to all personnel in the

workplace;

Participating in the planning and design stages of activities; stimulating a high level of safety

awareness at all times;

Identifying safety training needs;

Leading by example and promoting management accountabilities; Ensuring safe equipment

and plant is provided and maintained; enforcing the use of safe working procedures at all

times;

Ensuring that the responsibility for electrical safety of the permanent works under

construction shall remain with the operational line management.

Assisting in the identification and preparation for safe working procedures.

Reviewing safety reports and inspections and initiating corrective action where necessary;

Participating in accident/incident investigations; Monitoring safety meetings and programs;

Monitoring compliance with safe working procedures (controls);

10.2 HSE Manager

The HSE Manager will be having relevant experience, in infrastructure & Building works. as

per QCS 2014 Section 1-part 10.1.3

Implementing the company QHSE policy together with upholding standards required by

Client.

Represents the company in all safety matters pertaining to internal and external activities.

Liaising with subcontractors and in drafting daily, weekly, and monthly reports.

Updating Health, Safety and Environmental Management Plan/ Procedures/ Forms not less

than yearly or earlier if required.

Date: 08/09/2022 Page 25 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Assisting in preparing and reviewing documents (e.g. Risk Assessments, Method

Statements). Monitoring safety performance and conducting daily safety inspections.

Compiling daily reports from sub-contractors.

Leading and managing labor force camp Health and Safety minimum requirements

inspection.

Preparing statistical reports to maintain the records.

Ensuring suitable number of competent full-time fire tender crew and drivers.

Assisting in emergency drills.

Communicating with subcontractors.

Leading weekly sub-contractor safety officer meetings.

Leading and managing incident/accident investigations.

Leading and managing the Health, Safety and Environmental training

Lead Health, Safety & Environmental monthly rewards program.

Attending weekly Managers meetings. Attending weekly progress meetings.

Liaise with the construction group to ensure that all necessary safety and health precautions

are being adhere to and that any information or instruction on safety, health and

environmental issued by Client.

Understand the management framework, moral & economic requirements & implications for

good standards in health & safety

Stimulating a high level of safety awareness at all times. Doing safety & health inspections

Be familiar with all requirements stipulated in QCS 2014 Section 1 Part 10 and section 11,

part 1.2 to 2.4.01 and CONTRACTOR SOP; Implements the company safety policy by

establishing and managing a safety program that meets or exceeds all current standards.

Rectifies complaints from main contractor and consultants.

Receives assignments in terms of broad objectives from the Manager of Construction.

Reviews, interprets and provides assistance on safety regulations and standards.

Monitors company HSE performance and conducts project HSE inspections.

Ensuring adequacy of emergency arrangements and conduct periodic drills.

Implementing all HSE awareness & employee participation campaigns.

Investigating all actual and potential accidents/ incidents and report them efficiently.

Conducting toolbox talks & HSE training for employees and subcontractors.

Analyzing risks and identify. Environmental aspects & impacts; and prioritize corrective

actions; and advise site management accordingly.

Monitoring & ensuring safe area, equipment & work activities at site, through inspections,

walk through, permit to work follow ups and audits.

10.3 QA/QC Manager

The Overview of Quality Management system functioning, enhance & implement Quality

criteria across the assigned contract packages to ensure adherence & to compliance with

established standards, process/procedures.

Date: 08/09/2022 Page 26 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Facilitate concerned for preparation of Work Method Statements, and ensure Method

statements, Inspection and Test Plans, Pre-qualification Documents, Plans, Procedures and

checklists relevant to the activities are in compliance with the approved design drawings,

relevant specifications and Contract agreements.

Prepare, review & evaluate Project Quality Plans, QA Procedures, ITPs, Checklists, as

necessary for the projects and ensure all the approved documents are in place and

communicated across the Project teams for implementation.

Monitor construction quality at Project sites by periodical surveillance inspections and ensure

all the project quality requirements are fulfilled.

Communicate and liaise with Project Team, regarding the Project specific standards/system,

ensure efficient document management system to ensure close-out of Project documentation

& appropriate handover as per client requirements.

Liaise with the Work Managers with regards to the effective implementation of the Quality

management system.

Prepare audit schedules, perform audits & monitor audit closeouts.

Provide inductions and trainings on management systems.

Ensure all the complaints from customers and interested parties are effectively addressed in

line with appropriate Non-conformance procedure, as applicable, and ensure maintenance of

closeout records.

Performs other responsibilities associated with this position as may be appropriate

10.4 HSE Officers

The HSE Officer is responsible for safety accordance with QCS 2014 Section 1 Part 10 and

section 11, part 1.2 to part 2.4.01 and Contractor SOP; on the project and duties include:

Ensure the implementation of the HSE Plan at site level.

Active involvement in the implementation of the Project HSE Plan; Observing all Safety

requirements and Statutory rules and regulations;

Ensuring that all works are conducted in a safe manner and without risk to employee’s health

and safety;

Conducting workplace inspections;

Participating in safety meetings and safety programs; Participation in the preparation of Start

cards;

Participating in safety inductions, toolbox talks and daily team briefings; Participation in

accident / incident investigations as required;

Leading by example and integrate safety into standard operating procedures; Supervising

and ensuring compliance with safe work procedures on the site;

Reporting safety performance to the HSE Manager (including performance of

subcontractors). Has the authority to instruct unsafe working practices and cease

immediately on site. Participating company’s monthly safety walks.

Participating the joint weekly safety walks with Consultant safety and health team.

Coordinates at all times with project team in all safety related matters of the project. Issue

permits and update permit track register.

10.5 Site Engineer

Date: 08/09/2022 Page 27 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

The Site Engineer is responsible for the implementation of the safety regulation explained in

this HSE plan in his particular job and area, reports to the Construction Manager and Project

Director. The duties of the Project Engineer are:

Follow up the implementation of HSE regulations in reference to in QCS 2014 Section 1 Part

10 and section 11, part 1.2 to part 2.4.01 and CONTRACTOR SOP; in his particular area and

job;

Makes sure that his crew are working under safe conditions;

Makes sure that his crew aware about the HSE regulations;

Closely coordinates with HSE Manager on site for the implementation of the safety

regulations;

Reports accidents and incidents to the HSE Manager and Framework manager immediately;

Reports training needs of his crew to the Site engineer and Framework manager;

Attends to the monthly safety walks for his particular area and job; Participates to the

accident incident investigations.

10.6 Foreman

The Foreman is responsible for effectiveness of the company’s accident prevention effort and

the duties it includes;

Understand and comply with requirements stipulated in QCS 2014 Section 1 Part 10 and

section 11, part 1.2 to part 2.4.01 and CONTRACTOR SOP; and the Work Permit System;

Organize work area so that men can perform their duties with maximum efficiency and

minimum risk to themselves or to equipment; maintain good housekeeping;

Inspect equipment and tools before use and ensure correct storage facilities are available

and properly utilized;

Enforce the use of applicable personal protective equipment (PPE); Correct unsafe

conditions immediately as they arise, Attend supervisor’s meetings;

Cooperate with the HSE team to create and maintain safe working conditions in all

operations being performed; Set a personal example.

10.7 Workers

The Workers has responsibilities for accident prevention, for not even the best of supervisors

can watch over each person every minute of the workday.

Using the correct tools and personal protective equipment provided;

Being alert to hazards effecting all workers and equipment;

Obeying safety rules and not damaging or removing any safety materials.

10.8 Nurse

The Nurse shall have Ministry of health approval, the nurse(s) have the role of immediately

intervening for handling any casualty(s) injured in the area(s). The nurse(s) have the

following basics responsibilities:

Understand and comply with requirements stipulated in QCS 2014 Section1, part 10.6 &

section 11, part 1.2.4.3,

Date: 08/09/2022 Page 28 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Conduct periodical inspections of their first aid, emergency and medical evacuation

equipment.

Keep employees aware about basic first aid practices through toolbox meetings or other

trainings.

10.9 First Aiders

The first aider(s) have the role of immediately acting rapidly in case of an accident and provide

first aid in case of emergency while waiting for outside emergency aid.

Understand and comply with requirements stipulated in QCS 2014 Section11, part1.2.4.3.

Be familiar with the worksite.

Conduct periodical inspections of their first aid, emergency and medical evacuation

equipment.

Assist HSE personnel in site practice drills such as fire drill.

Be familiar with the emergency response plan.

11 HAZARD AND RISK MANAGEMENT

11.1 Purpose

This procedure describes a method for identifying the occupational health and safety hazards

associated with this project and assessing the risk level of those hazards. The results of risk

assessments will be used to establish a means of risk reduction such as control measures or

health and safety objectives, targets, and programs to better manage the risks to achieve an

overall continual improvement in occupational health and safety performance.

For more details please (Appendix - I )

11.2 RESPONSIBILITIES

Works Manager/Framework Manager

The Contractor framework manager / Engineers shall consider whether a job needs a RA, based

on the assessment results done by job initiator. If RA is deemed necessary, then assigns a RA

team and validates the RA.

Discipline Engineers/Foreman/Technicians/Site HSE Officer:

Participate to RA (with other members), assess the criticality of risk and make proposals for

control measures.

Employees

Employees also have responsibilities under health and safety law to; take care of the health and

safety of themselves and others, co-operate with the Management to help you comply with health

and safety legislation, follow any instructions and training given regarding the measures you

have in place to control health and safety risks, report of work situations that present a serious

and imminent risk, and inform any other failings they identify in your health and safety

arrangements.

Date: 08/09/2022 Page 29 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

11.3 REFERENCES

ISO 14001:2015

ISO 45001:2018 clause 6.1.2

ISO 9001:2015

QCS 2014, Section 11, Part 1.1.7, and Part 2.4.01

11.4 TERMS AND DEFINITIONS

RA Risk Assessment

ALARP As Low As Reasonably Practicable (This means balancing the level of risk

against the measures needed to control the real risk in terms of money, time or trouble.

However, you do not need to take action if it would be grossly disproportionate to the level of risk).

JSA Job Safety Analysis

Critical-Qualifies an item of equipment, a product, a situation or an operation having the

potential to give rise directly or indirectly to risk of ill, health or injury, damage to property,

plant or the environment.

Hazard-Potential source of physical injury or damage to the health of people, or damage to

property or the environment.

Risk Assessment (RA)-A method to review a job aiming:

o To determine any potential hazard

o To assess the level of risks

o To define precautions that will reduce the residual risk to an acceptable level.

Task-A defined part of job carried out by one or more persons.

Job-A specific work assignment, consisting of a set of tasks required to achieving the

objective.

Probability-The likelihood of specific event occurring within a specific time frame.

Risk- effect of uncertainty.

Safety criticality-A ranking indicating the potential to cause ill health or injury, damage to

property, the environment or assets, or production losses.

Severity-It is a measure of the consequences of an incident (human injury and/or

environment damage and/or material or production loss)

Residual risk (revised risk rating)-Risk remaining after the risk reduction measures has

been taken.

Tolerable Risk (initial risk rating)-Risk, which is accepted in a given context, based on the

current values of society.

11.5 PROCEDURE FOR HAZARD/ASPECT IDENTIFICATION

Discipline Engineers, Worker Representatives and HSE Officer, shall identify and evaluate all

associated hazard or aspects present from their activities and/or processes or modified

activities, products and services that it can control and those that it can influence including

those activities with interested parties.

Actual and potential risk or impact resulting from these hazards or aspects shall be rated in

accordance with Hazard / Aspect Evaluation below:

For Hazards:

Physical (fire, explosion, slips, fall, trips, pinch by, struck by, crush, etc.)

Chemical (inhalation, absorption, ingestion, injection)

Ergonomics (manual handling repeated actions and sustained postures)

For Aspects:

Date: 08/09/2022 Page 30 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Emission to air

Discharge to water

Discharge to land

Use of natural resources

Regulatory issues / requirements

Waste Management

Utilities Consumption

The computation to follow for the computation for the Significance of Risk / Impact:

Significant Risk / Impact = Probability of Occurrence x Consequence of Severity

The evaluation and review shall include the identification and compliance to applicable legal

requirements which primarily be the basis for establishing objectives. Programs are also

established to support in achieving the objectives.

The hazard / aspect identification and risk / impact evaluation shall be reviewed periodically

by Project Team by: (a) changes or proposed changes, (b) Addition or reduction, (c)

Routine or non-routine of the following:

Process related

Facility / equipment

Manpower and other resources (machine, methods or materials)

11.6 RISK ASSESSMENT

Based on the project progress planning schedules such as monthly/weekly and day-to-day

planning, all critical activities will be analyzed to identify the hazards likely to be encountered

prior to execution and to decide the precautions to be taken.

Each applicable hazard identified for a specific process or operation shall be entered into the risk

register kindly refer (Appendix K - Risk Register)

Activity specific risk assessments with safety requirements for new activities will be prepared and

submitted to ASHGHAL by the project team along with method statements.

All HSE Critical issues shall be identified based on the project scope and job safety analysis for

all such activities will be submitted later.

Risk Management provides a systematic approach to the control and elimination of accidents at

work. It simply means:

Thinking about what can go wrong

Deciding if enough has been done to prevent it.

The purpose and function of risk management is:

To identify hazards — operations, tasks and processes that may foreseeably cause harm

to employees or others, including members of the public.

To identify risk — the likelihood of the realization of the hazard, and the potential

consequences

The ultimate purpose is to provide a "safe" place of work.

At the heart of the risk, management process is risk assessment. The risk management

process can be summed up by the following stages.

Date: 08/09/2022 Page 31 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Consider all tasks and situations.

Identify the hazards that are, or may be, involved.

Identify those persons who may be exposed to the hazards.

Analyze the risks of injury or loss from hazards (risk assessment).

Determine whether the risk is adequately controlled (risk assessment).

Consider measures that may eliminate or reduce risk further in line with the basic

principles of hazard control.

Implement the risk control measures.

Monitor those measures.

Review and feedback any corrective action.

The key words used in HSE risk assessment are defined below:

HAZARD - Source, situation, or act with a potential for harm in terms of human injury or ill health

or combination of these.

HARM - Includes death, injury, physical or mental ill health, damage to property or the

environment, loss of production or any combination of these.

ACCIDENT - An accident is an incident, which has given rise to injury, ill health or fatality.

INCIDENT - An incident adhere no injury, ill health, or fatality occurs may also be referred to a

"near-miss”, "near-hit", "close call" or "dangerous occurrence”.

RISK - Combination of the likelihood of an occurrence of a hazardous event or exposure(s) and

the severity of injury or ill health that can be caused by the event or exposure.

DANGER - A state in which there is exposure to a hazard; the opposite of safety (often used in

terms such as dangerous condition, danger area, danger zone, etc.).

SAFE: - A state in which exposure to hazards has been adequately controlled; the opposite of

dangerous (safe plant, safe system of work, etc.).

RISK MANAGEMENT - The process of analyzing the level of risk, considering those in danger,

and evaluating whether hazards are adequately controlled, considering any measures already in

place.

The methodology of risk assessment study is described and is briefly illustrated in the following

figure:

Project HSE Plan

Date: 08/09/2022 Page 32 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Risk assessment methods are used to decide on priorities and to set objectives for eliminating

hazards and reducing risks. Wherever possible, risk is eliminated through selection and design of

facilities, equipment and processes. If risk can’t be eliminated, then it is minimized by the use of

physical controls such as implementation of Work instructions, distribution of personal protective

equipment and training of employees. This methodology is illustrated in the following figure;

Diagram of Risk Reduction Methodology

Risk assessment is revised, in the following cases:

Changes in working activities/methods.

Results of internal HSE Audits

Occurrence of accidents or emergencies

Changes to the legislative requirements

HSE Manager/HSE Officer revises risk assessment in collaboration with authorized

personnel and the results are communicated to all employees

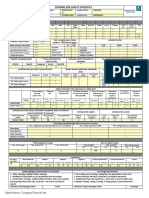

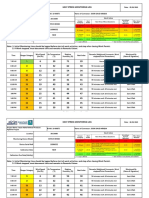

RISK RATING CALCULATOR

Date: 08/09/2022 Page 33 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

Note: PPE should be the last barrier to protect people when all other control options are

exhausted.

High-risk activities risk mitigation register/plan will be revised in Three month.

11.7 METHOD STATEMENT

The accident prevention approach is based on these general prevention principles such as

avoiding risks, assessing risk, which cannot be avoided, combating the risk at source, adapting

the work to the individual, adapting to technical progress, replacing the dangerous by no

Date: 08/09/2022 Page 34 of 61 AA DOM 2018 M 1867 G-HSP-Contractor-

Rev.08

MIC Construct

MIC Construct – WABAG/Roots –

APPLUS VELOSI Consortium

dangerous or less dangerous, developing a coherent overall prevention policy which covers

technology, work conditions etc. The work procedure is essential for accident prevention through

the analysis of risk through each phase of operation. Contractor will submit method statement in

accordance with the QCS 2014 requirements and contractual requirements for review and

approval of the Engineer. Prior to that, the MS will be reviewed and approved by Contractor

Quality Manager. As a general rule a method statement and shall be required for all work

packages. Method statement shall include a risk assessment, which identifies hazards

associated with the work and includes the mitigation measures, which will be followed to control

the hazards.

Method Statements should be prepared via the collaboration and feedback from all those

personnel directly undertaking the activity on Site. The Site Engineer / Project Engineer should

review and include additional information outside the scope of the workers - e.g. such as the

number of concrete mixers / pump trucks / delivery intervals - and then the QA/QC Department

and Safety Team should also review and comment prior to the document being submitted.

This is to ensure that MS meet the requirements of the task, is relevant and comprehensive and

ensure safe system of work implementation.

The primary purpose of a Method of Statements (MOS) is to help Engineers, Supervisors,

Workers and any other persons at the workplace to understand the requirements that have been

established to carry out the high risks work in a safe and healthy manner.

It shall address as a minimum the following:

Introduction/Scope

Location and identification of the work covered by the method statement

Permits and Licenses Required

Specific Occupational Health and Safety Issues including Risk Assessments and Job

Safety Analysis

Environmental Issues

Quality Issues

Responsibilities

Sequence of Work

Resources

Drawings and Sketches

Reference documentation

Method Statements are required for all operations including temporary works.

Note1: No work covered by the Method Statement shall begin until it has been approved by the

Respective Engineer and client representative

Note 2: Approved MOS shall be one of the basis for conducting Risk Assessments/JSA

12 ENVIRONMENTAL MANAGEMENT PROCEDURE

12.1 PURPOSE

The purpose of this procedure is to define the process for identifying environmental aspects,