21-300-310-500XP-610XP CV Spec Sheet Rev 7-30-08

21-300-310-500XP-610XP CV Spec Sheet Rev 7-30-08

Uploaded by

Francisco SantanaCopyright:

Available Formats

21-300-310-500XP-610XP CV Spec Sheet Rev 7-30-08

21-300-310-500XP-610XP CV Spec Sheet Rev 7-30-08

Uploaded by

Francisco SantanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

21-300-310-500XP-610XP CV Spec Sheet Rev 7-30-08

21-300-310-500XP-610XP CV Spec Sheet Rev 7-30-08

Uploaded by

Francisco SantanaCopyright:

Available Formats

TECHNICAL SPECIFICATIONS

Ball Check Valves Sizes 1”- 6”

Nil-Cor

Series 300 / 310 / 500XP / 610XP

1. SCOPE 4. DESIGN

Ball Check Valves made from fiber-reinforced Thermoset • Valves shall be flanged and conform to the face-to-

Resins for corrosive chemical service used in construction face dimensions of ANSI/ASME B16.10.

of pressurized piping systems. • Flanges shall be flat-faced with serrated finish to

allow installation in metallic, lined metal, FRP, and

2. SERVICE RATING thermoplastic piping systems.

• Flange bolt sizes and spacing shall conform to ANSI

Temperature rating from -50 to 275o F as shown on B16.5 Class 150. DIN, JIS and BS shall be available.

pressure/temperature chart on the reverse side. See Catalog • Vertical pressure drop to unseat shall be less than 1

1000 for temperature limits for specific materials of psi.

construction and specific chemicals. • Horizontal reseat velocity in liquid flow shall not

exceed 2 feet/sec.

3. MATERIALS

5. QUALITY ASSURANCE

• 300: Vinyl ester resin, graphite fiber reinf.

• 310: Vinyl ester resin, glass fiber reinf. • The Manufacturer’s facility shall be certified to ISO

• 500XP: Novolac Epoxy resin, graphite fiber reinf. 9001 or equivalent. The Manufactuer shall be certified

• 610XP: Novolac Epoxy resin, glass fiber reinf. to the European Pressure Equipment Directive (PED)

and the “CE” mark shall be affixed to each valve

4. CONSTRUCTION label.

• Each valve shall be hydrostatically shell tested at no

(1) Body: Compression molded fiber-reinforced less than 1.43x its rated cold working pressure for 3

Thermoset Resins with integrally molded ball guides. minutes.

(2) Ball: Solid Virgin PTFE. Other materals available. • Each valve shall be seat tested with water at 20 and

165 psig. No visible leakage shall be permitted for

(3) Seat: PTFE-coated Viton the duration of the tests.

(4) Body O-Ring: PTFE-coated Viton.

(5) Body Insert: Compression molded fiber-reinforced 6. PACKING AND SHIPPING

Thermoset Resin.

• Valves shall be shipped with both ends capped to

exclude dirt and properly boxed to avoid damage.

• Each valve shall be marked with the manufacturer,

valve size, model, serial number, and valve

component designations.

7. AVAILABILITY

Valves meeting this specification are available from:

Nil-Cor®, LLC

4855 Broadmoor Ave.

Kentwood, MI 49512

P: 616-554-3100

F: 616-554-5623

www.nilcor.com

7-30-08 300-310-610XP CV Spec Sheet Rev 7-30-08 Catalog 425

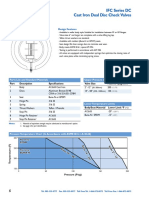

Flanged Ball Check Valve Dimensions And

Technical Specifications

Pressure/Temperature Rating

300

1", 1.5"

Pressure (psig) 250 2"- 3"

200

150 4", 6"

100

50

0

-50 0 50 100 150 200 250 275

O

Temperature ( F)

Installation Dimensions (Inches)

C - Bolt Circle

D - Number of Holes

E - Hole Size

A B

Size A B C D E Weight: lbs (kg) Cv

1 5.00 4.25 3.13 4 5/8” 3 (1.4) 32

1-1/2 6.50 5.00 3.88 4 5/8” 6 (2.7) 45

2 7.00 6.00 4.75 4 3/4” 8 (3.6) 50

3 8.00 7.50 6.00 4 3/4” 14 (6.4) 155

4 9.00 9.00 7.50 8 3/4” 23 (10.5) 275

6 10.50 11.00 9.50 8 7/8” 40 (18.2) 550

7-30-08 300-310-610XP CV Spec Sheet Rev 7-30-08 Catalog 425

You might also like

- Butterfly ValveDocument1 pageButterfly ValveDnyaneshwar0% (1)

- Pure 50Document9 pagesPure 50Carlos LagosNo ratings yet

- Kompact Series: Flanged / Wafer Full Bore Ball ValveDocument4 pagesKompact Series: Flanged / Wafer Full Bore Ball ValveJuan CisnerosNo ratings yet

- PDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"Document11 pagesPDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"pablopasqualini18No ratings yet

- Clarkson - Knife Gate Valves - KS3 - Install Manual - 2022-11 - r00Document18 pagesClarkson - Knife Gate Valves - KS3 - Install Manual - 2022-11 - r00Vitor BandeiraNo ratings yet

- Cat AXCATDocument80 pagesCat AXCATgazwang478No ratings yet

- Check Valve Parker Serie CDocument4 pagesCheck Valve Parker Serie CRamiro EspinozaNo ratings yet

- Intervalve-Butterfly ValvesDocument4 pagesIntervalve-Butterfly ValvesMurli Ramchandran100% (1)

- Wafer Style Twin Disc Ductile Iron Check ValveDocument1 pageWafer Style Twin Disc Ductile Iron Check ValveAlbeiro LeivaNo ratings yet

- 2852 - OMB Orientation To Valves - Part 2Document20 pages2852 - OMB Orientation To Valves - Part 2Thang Hung PhamNo ratings yet

- Series 850 Specification SheetDocument2 pagesSeries 850 Specification SheetFEBCONo ratings yet

- TS 6p-200Document2 pagesTS 6p-200Arnold Abalos VersozaNo ratings yet

- KGV Bi MDocument3 pagesKGV Bi MArmando Palacios EscuderoNo ratings yet

- Storagetech 100 Pressure Vacuum Relief Valve SMDocument4 pagesStoragetech 100 Pressure Vacuum Relief Valve SMkhaled SAYEDNo ratings yet

- Apollo Valves Marine Valvescat - MACA9000Document12 pagesApollo Valves Marine Valvescat - MACA9000Michael MangadaNo ratings yet

- AloycoDocument32 pagesAloycoSidney RiveraNo ratings yet

- Catalog Series 223 Asco en 3674094Document2 pagesCatalog Series 223 Asco en 3674094Galih KusumaNo ratings yet

- Type Series Booklet ECOLINE BLT150-300Document7 pagesType Series Booklet ECOLINE BLT150-300Amornsak W.No ratings yet

- Ball ValveDocument7 pagesBall ValveaerudzikriNo ratings yet

- Henry - 022 Safety ValvesDocument3 pagesHenry - 022 Safety ValvesPaweł HejmowskiNo ratings yet

- Aloyco Stainess Steel ValvesDocument26 pagesAloyco Stainess Steel Valvescristi_molins100% (1)

- Technical Information Series BVMM General Description: Ball ValvesDocument6 pagesTechnical Information Series BVMM General Description: Ball ValvesAliArababadiNo ratings yet

- FNW Fig.340Document4 pagesFNW Fig.340Imtinan MohsinNo ratings yet

- CatalogueDocument79 pagesCatalogueRhouzlane AbdelfattahNo ratings yet

- F80 Manual RevE PDFDocument17 pagesF80 Manual RevE PDFNaseer HydenNo ratings yet

- Swi D80004Document4 pagesSwi D80004Wu MonaNo ratings yet

- Spectacle Line Blinds Product SpecsDocument2 pagesSpectacle Line Blinds Product Specsvinoj chandranNo ratings yet

- ECOLINE GL - 7247.11-10 - Type Series BookletDocument8 pagesECOLINE GL - 7247.11-10 - Type Series BookletpauloNo ratings yet

- Kat A 1331 Lug Cerex300 L Wasser en 03 12Document6 pagesKat A 1331 Lug Cerex300 L Wasser en 03 12Sathishkumar DhamodaranNo ratings yet

- Descote 2100BDocument4 pagesDescote 2100BarrikanNo ratings yet

- KAT-A 5022 Klamflex VARIplus-DC Dedicated Coupling 16-01-2014 ENDocument3 pagesKAT-A 5022 Klamflex VARIplus-DC Dedicated Coupling 16-01-2014 ENSonny LuuNo ratings yet

- Actuator SpecificationDocument12 pagesActuator SpecificationFactory FactoryNo ratings yet

- Roller SupportsDocument14 pagesRoller SupportsArun KumarNo ratings yet

- Vintrol Ball ValveDocument8 pagesVintrol Ball ValvechadNo ratings yet

- Catalogo WfiDocument36 pagesCatalogo WfiJack DominikNo ratings yet

- DemblaDocument12 pagesDemblaISHAN VERMANo ratings yet

- 702G Quick Pressure Relief Control VavleDocument8 pages702G Quick Pressure Relief Control VavleThinh Chu100% (1)

- Procedure Manual: Forged Valve ProductionDocument12 pagesProcedure Manual: Forged Valve ProductionJaison JoseNo ratings yet

- Copper Pipe - unifLOWDocument8 pagesCopper Pipe - unifLOWdesignNo ratings yet

- GD486548NFPDocument1 pageGD486548NFPNoe ANo ratings yet

- Series dc125Document2 pagesSeries dc125Daniel FigueroaNo ratings yet

- American ValveDocument12 pagesAmerican Valveviller_lpNo ratings yet

- BallValues PDFDocument12 pagesBallValues PDFDevdatt WaghuleNo ratings yet

- Data Sheet 7.04 Issue C: Test & Drain Valve Fig. 801Document2 pagesData Sheet 7.04 Issue C: Test & Drain Valve Fig. 801Le DucNo ratings yet

- 3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsDocument4 pages3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsrodrurenNo ratings yet

- Brass Ball Valve (BBV) V0816Document1 pageBrass Ball Valve (BBV) V0816Saiful Islam SagorNo ratings yet

- Belimo G350B-N SVX24-SR Assembly En-UsDocument6 pagesBelimo G350B-N SVX24-SR Assembly En-UsWilber MartínezNo ratings yet

- Ball Valves: For SteamDocument8 pagesBall Valves: For SteamcontorrresjulianNo ratings yet

- Isv B492RDocument4 pagesIsv B492RdeborazoletNo ratings yet

- Drip Pan Elbow-Technical Information PDFDocument1 pageDrip Pan Elbow-Technical Information PDFAnonymous B1AOOsmRMiNo ratings yet

- Vaas Knife Gate ValveDocument2 pagesVaas Knife Gate ValveParmeshwar Nath TripathiNo ratings yet

- tl15 (3) - 231207 - 141952Document2 pagestl15 (3) - 231207 - 141952Sam JohnNo ratings yet

- Flange 1 Catalogue PDFDocument55 pagesFlange 1 Catalogue PDFYaakoubi FethiNo ratings yet

- Catalogo GROFE IngDocument50 pagesCatalogo GROFE IngAlvaro Antonio Cristobal AtencioNo ratings yet

- leaf-ABO Series 3e-Eng - 2014 - 11 - 07Document6 pagesleaf-ABO Series 3e-Eng - 2014 - 11 - 07BHARGAVNo ratings yet

- General Purpose Butterfly ValvesDocument2 pagesGeneral Purpose Butterfly Valvesphe zenNo ratings yet

- High-Performance Butterfly Valve CatalogDocument2 pagesHigh-Performance Butterfly Valve CatalogAndrea Tapia FuentesNo ratings yet

- Microfilters Separators: API / IP 1581 5th Ed. Type S, Cat. MDocument4 pagesMicrofilters Separators: API / IP 1581 5th Ed. Type S, Cat. MMurli RamchandranNo ratings yet

- Eaton FNQ-R-1: Product SpecificationsDocument2 pagesEaton FNQ-R-1: Product SpecificationsFrancisco SantanaNo ratings yet

- Product Data SheetDocument2 pagesProduct Data SheetFrancisco SantanaNo ratings yet

- ECOPACK Section 10.0 - Rev.1Document9 pagesECOPACK Section 10.0 - Rev.1Francisco SantanaNo ratings yet

- OB35Document6 pagesOB35Francisco SantanaNo ratings yet

- IwakiEHNA0045 09ENDocument12 pagesIwakiEHNA0045 09ENFrancisco SantanaNo ratings yet

- MFE600E Electromagnetic FlowmeterDocument39 pagesMFE600E Electromagnetic FlowmeterFrancisco SantanaNo ratings yet

- 1290 - Polyglass TanksDocument2 pages1290 - Polyglass TanksFrancisco SantanaNo ratings yet

- Solidworks 2010Document197 pagesSolidworks 2010Jie RongNo ratings yet

- STR5A464x Series Data Sheet: For Non-Isolated Off-Line PWM Controllers With Integrated Power MOSFETDocument23 pagesSTR5A464x Series Data Sheet: For Non-Isolated Off-Line PWM Controllers With Integrated Power MOSFETHeru susantoNo ratings yet

- PG Diploma in Arbitration and MediationDocument5 pagesPG Diploma in Arbitration and MediationArvind YadavNo ratings yet

- Delta VFD E User Manual PDFDocument403 pagesDelta VFD E User Manual PDFInfoprime CharqueadasNo ratings yet

- Applications of Additive Manufacturing in The Marine IndustryDocument6 pagesApplications of Additive Manufacturing in The Marine IndustryJeeva RathnamNo ratings yet

- Lijia BlogDocument12 pagesLijia Bloglijia ann joseNo ratings yet

- Bullying at Boarding SchoolDocument3 pagesBullying at Boarding SchoolDaryl MabutoNo ratings yet

- TA500 Ignition System Analyser Operation ManualDocument9 pagesTA500 Ignition System Analyser Operation ManualKarlitosmanNo ratings yet

- Analyse Signal EMGDocument12 pagesAnalyse Signal EMGAlfonso Molina RamirezNo ratings yet

- Cambridge International AS & A Level: Biology October/November 2023 2 HoursDocument24 pagesCambridge International AS & A Level: Biology October/November 2023 2 HoursZhemaiah OzeNo ratings yet

- Heavyduty Kits Catalog 2017Document8 pagesHeavyduty Kits Catalog 2017panamapuro100% (1)

- Fact Sheet - Electrician (General)Document4 pagesFact Sheet - Electrician (General)Saravanan Rasaya100% (1)

- NA To Sls en 1993-1-10Document12 pagesNA To Sls en 1993-1-10Shan Sandaruwan AbeywardeneNo ratings yet

- Lecture 15 Ergonomics in Product Design PDFDocument19 pagesLecture 15 Ergonomics in Product Design PDFKarandeep SinghNo ratings yet

- If Steam Drum Under Vacuum Then What Will HappenDocument2 pagesIf Steam Drum Under Vacuum Then What Will HappenyogacruiseNo ratings yet

- SDS Product SF 05 English VersionDocument11 pagesSDS Product SF 05 English VersionfaisalchemNo ratings yet

- Previn Double Concerto PDFDocument172 pagesPrevin Double Concerto PDFJacob DziubekNo ratings yet

- Syllabus Spring 2016 CIS 4296Document6 pagesSyllabus Spring 2016 CIS 4296troll4500No ratings yet

- Board 3 - E108630 - 1661944617556Document34 pagesBoard 3 - E108630 - 1661944617556Lenin RamirezNo ratings yet

- Passat B5 - Brakes. Technical DataDocument13 pagesPassat B5 - Brakes. Technical DataPedrojzbNo ratings yet

- Usr Local SRC Education - Com Files Static Lesson-Plans Superhero-Citizens Superhero-CitizensDocument8 pagesUsr Local SRC Education - Com Files Static Lesson-Plans Superhero-Citizens Superhero-Citizenshannah songNo ratings yet

- Proposal BinodDocument16 pagesProposal BinodbinuNo ratings yet

- Ashish Joshi ResumeDocument2 pagesAshish Joshi Resumeashish joshiNo ratings yet

- Malefic Planet As Per LagnaDocument6 pagesMalefic Planet As Per Lagnajaiswal.utkarshNo ratings yet

- Technical Note Hoymiles Export Management Using 3rd Gen DTU Pro V1.4 1Document29 pagesTechnical Note Hoymiles Export Management Using 3rd Gen DTU Pro V1.4 1Luiz Otávio PachecoNo ratings yet

- Ipaml FinalsDocument3 pagesIpaml FinalsQuenneeNo ratings yet

- Kodak Verichrome PanDocument4 pagesKodak Verichrome Panfoster747No ratings yet

- GOLDEN DAWN 3 8 Energy Influences On The PathsDocument4 pagesGOLDEN DAWN 3 8 Energy Influences On The PathsF_RCNo ratings yet

- LV Lead Sheathed CablesDocument60 pagesLV Lead Sheathed Cablesmegamaster2010No ratings yet