MTC Elbow 6in

MTC Elbow 6in

Uploaded by

henryCopyright:

Available Formats

MTC Elbow 6in

MTC Elbow 6in

Uploaded by

henryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

MTC Elbow 6in

MTC Elbow 6in

Uploaded by

henryCopyright:

Available Formats

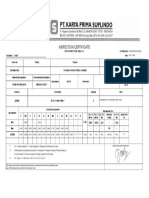

INSPECTION CERTIFICATE

ACCORDING TO EN 10204 / 3.1 Certificate No: 01269/KPS/PF/XI/2022

Purchaser : CASH Date : 04-11-2022

Order No. Project Product OEM Manufacturer

051/BMJ/XI/22 CARBON STEEL BUTT WELDING FITTINGS CZHX

Material Specifications Dimensional Specifications HEAT TREATMENT (*2)

Appearance GOOD Dimension GOOD

ASTM/ASME A/SA234 WPB-2018 ASTM/ASME B16.9-2018 N x HF

Heat No. Description Quantity Note.

2759 ELBOW 90D LR A234 WPB 6" SCH.STD/40 7 CONFIRMS WITH NACE MR0175/ISO 15156

Chemical Composition

Mechanical Test

Specification

Y.S. (*1) T.S. (*1) E.L (*1) Hardness R.A.(*1) Impact Test

C Mn P S Si Cr Mo V Cu Nb AL TI N

(MPA) (MPA) (%) (HBW) (%) (J)

Min. - 0.290 - - 0.100 - - - - - - - - - C.Eq 240 415 30 - - -

Max. 0.300 1.060 0.050 0.058 - 0.400 0.400 0.150 0.080 0.400 - - - - - - - 197 - -

2759 0.160 0.720 0.014 0.003 0.180 - - - - - - - - - 0.280 325 501 58 151 - -

*1 T.S = Tensile Strength,Y.S = Yield Strength,E.L=Elongation,R.A=Reduction of Area. Quality Assurance Department

*2 HF = Hot formed with final temperature ( 620 - 980ºC ) and cooled in still air.

N = Cold formed and normalized ( 850ºC x 0.5 HR ) and cooled in stiil air.

*3 C.E. Value = C + (Mn /6)+(Cr + Mo + V) /5 + (Ni + Cu) / 15

We hereby certify that the material has been tested in accordance with the above specification and

also with the requirements called for by the above order

You might also like

- Askeland Chap 4 SolutionDocument10 pagesAskeland Chap 4 SolutionDamita de Peña50% (2)

- CSWIP 3.1 Exam Prep NotesDocument12 pagesCSWIP 3.1 Exam Prep NotesMeritorious Khan100% (3)

- Cert ACERO INOX 316L PDFDocument1 pageCert ACERO INOX 316L PDFCarlos RomeroNo ratings yet

- 1.20mm T.C - Mehta SteelsDocument1 page1.20mm T.C - Mehta SteelsRonak FireNo ratings yet

- 577 API ExercisesDocument41 pages577 API Exercisesadel100% (2)

- Internet BIS ReportDocument64 pagesInternet BIS Reporthaathinath010% (1)

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- 1in 300 19 73716Document1 page1in 300 19 73716Mygame 1402No ratings yet

- Inspection Certificate 3.1: According To en 10204Document2 pagesInspection Certificate 3.1: According To en 10204JuanNo ratings yet

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- Snervamento 0,2% Snervamento 1,0% Yield Strength 0,2% Yield Strength 1,0% Sez/Sect mm2 Gauge L.MMDocument1 pageSnervamento 0,2% Snervamento 1,0% Yield Strength 0,2% Yield Strength 1,0% Sez/Sect mm2 Gauge L.MMMygame 1402No ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- Manufacturer'S Test Certificate: National Builtech Trading and Contracting CoDocument3 pagesManufacturer'S Test Certificate: National Builtech Trading and Contracting CoQc QatarNo ratings yet

- MTC Jfe Eh500Document2 pagesMTC Jfe Eh500Immalatulhusna100% (1)

- Quality Test Certificate Flange 4Document1 pageQuality Test Certificate Flange 4Charles OnyechereNo ratings yet

- (WWW - Dillinger.de/certificate) : DNV GL Cert. No. 33-11582 IDHHDocument4 pages(WWW - Dillinger.de/certificate) : DNV GL Cert. No. 33-11582 IDHHDhanush NairNo ratings yet

- Crne Besavne CeviDocument10 pagesCrne Besavne CeviDragan MarkovicNo ratings yet

- D72307 TC2 PDFDocument2 pagesD72307 TC2 PDFshivdas bichukaleNo ratings yet

- 1.5 SCH 40 (B2101104)Document1 page1.5 SCH 40 (B2101104)Mahmoud MetwallyNo ratings yet

- MTC 410Document1 pageMTC 410Vaseem AhmedNo ratings yet

- Material Test Report: (Established 1918)Document1 pageMaterial Test Report: (Established 1918)Adrian GalvisNo ratings yet

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- 622888Document1 page622888DeepakNo ratings yet

- Outokumpu: Si MN P S CR NiDocument3 pagesOutokumpu: Si MN P S CR NiDarkedgeNo ratings yet

- Check Valve 6in HT 6YF4Document1 pageCheck Valve 6in HT 6YF4Juan Pablo Perdomo OrtizNo ratings yet

- Material Test Report: ISO EN 10204 2004-3.1Document4 pagesMaterial Test Report: ISO EN 10204 2004-3.1Johan Sebastian C. SNo ratings yet

- TRILAD Flanges and Fittings, Inc.: 1652 Q"'4HRSDocument111 pagesTRILAD Flanges and Fittings, Inc.: 1652 Q"'4HRSMohamed RaafatNo ratings yet

- Offshore A312A358 R2Document1 pageOffshore A312A358 R2Prathamesh OmtechNo ratings yet

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument1 pageCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed RaafatNo ratings yet

- Certificado 3.1 y Calibracion Termopares - TecamDocument11 pagesCertificado 3.1 y Calibracion Termopares - TecamigorNo ratings yet

- Jyoti Steel Industries: Test Certificate As Per en 10204-3.1Document1 pageJyoti Steel Industries: Test Certificate As Per en 10204-3.1Gagat GongatNo ratings yet

- TC No-1451Document1 pageTC No-1451Structures ProductionNo ratings yet

- LF' JLRDocument1 pageLF' JLRIslam SahafayatNo ratings yet

- Hollow Bar 304L Φ80ΧΦ50Document6 pagesHollow Bar 304L Φ80ΧΦ50Agoritsa100% (1)

- Mittal Corp Limited Test Certificate FinalDocument1 pageMittal Corp Limited Test Certificate FinalMehmet SoysalNo ratings yet

- 1jsl Ltd. TPI 3 (31803) MMDocument2 pages1jsl Ltd. TPI 3 (31803) MMPratik KarekarNo ratings yet

- Mill Certificate: 2 2 2 3 3 3 4 N/mm2 N/mm2 % x10 x10 x10 x10 x10 x10 x10Document1 pageMill Certificate: 2 2 2 3 3 3 4 N/mm2 N/mm2 % x10 x10 x10 x10 x10 x10 x10Binh Hung OngNo ratings yet

- MFF Spect. Blind 6 CL 150Document1 pageMFF Spect. Blind 6 CL 150Mohamed RaafatNo ratings yet

- GR 70 32MMDocument1 pageGR 70 32MMquality nakodaNo ratings yet

- FRA20-034-3 - Filttro YDocument1 pageFRA20-034-3 - Filttro YHuber Pucuhuayla RojasNo ratings yet

- MTC 2Document3 pagesMTC 2azam RazzaqNo ratings yet

- MTC - Rel-01 (Rev.00)Document16 pagesMTC - Rel-01 (Rev.00)Alam MD SazidNo ratings yet

- Test Certificate (EN 10204 3.1)Document1 pageTest Certificate (EN 10204 3.1)gobinath ramachandranNo ratings yet

- Derval SRL: Material Test CertificateDocument1 pageDerval SRL: Material Test CertificateMohamed RaafatNo ratings yet

- PSP TCDocument7 pagesPSP TCPSP kanpurdehatNo ratings yet

- GK 223370 SRTDocument1 pageGK 223370 SRTömer cılızNo ratings yet

- Po31510 Fres30x24 SF48410Document1 pagePo31510 Fres30x24 SF48410Keshia Murillo PinnockNo ratings yet

- Eil FormatDocument1 pageEil Formatsales.aquavalvesNo ratings yet

- Mgoha : ' "Xsjjl8Document1 pageMgoha : ' "Xsjjl8PetroPower OilandgasNo ratings yet

- Material Test Certificate: For: Priminox OverseasDocument2 pagesMaterial Test Certificate: For: Priminox OverseasDSAFNo ratings yet

- JCOUSER03Document1 pageJCOUSER03Neem LalNo ratings yet

- AcerinoxDocument1 pageAcerinoxOmkar PrindavankarNo ratings yet

- DVC6200Document2 pagesDVC6200Abid Hossain Rupam100% (1)

- MTC Sample Dia 36 Inch Heat 639914 4130Document2 pagesMTC Sample Dia 36 Inch Heat 639914 4130emadabdelsattarNo ratings yet

- LVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateDocument1 pageLVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateEMTC EMTCNo ratings yet

- PSV 430066 PDFDocument41 pagesPSV 430066 PDFErikikoNo ratings yet

- Universal 1-2 Clase 6000 Tipo 316Document2 pagesUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- MTC 410-317-304 - FastenerDocument2 pagesMTC 410-317-304 - Fastenermiguel contrerasNo ratings yet

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- MTC FormatDocument1 pageMTC FormatNirmit GandhiNo ratings yet

- Alleima 140MM Rod F53 S32750 MTCDocument2 pagesAlleima 140MM Rod F53 S32750 MTCmetalexinNo ratings yet

- MTC SO FLG 4inDocument1 pageMTC SO FLG 4inhenryNo ratings yet

- Swage NippleDocument1 pageSwage Nipplemaul093930No ratings yet

- Certs-Viernes PasadoDocument15 pagesCerts-Viernes PasadoPedro Lapizco FuerteNo ratings yet

- Lampiran PaintingDocument18 pagesLampiran PaintinghenryNo ratings yet

- ArticleText 36362 1 10 20210727Document9 pagesArticleText 36362 1 10 20210727henryNo ratings yet

- Tahapan SURFACE PREPARATIONDocument3 pagesTahapan SURFACE PREPARATIONhenryNo ratings yet

- Dup Instrument Gudang BufferDocument4 pagesDup Instrument Gudang BufferhenryNo ratings yet

- Yosemite Sport ClimbingDocument29 pagesYosemite Sport ClimbinghenryNo ratings yet

- Dokumen - Tips - Piping Hydrotest ProcedureDocument5 pagesDokumen - Tips - Piping Hydrotest ProcedurehenryNo ratings yet

- Expedition Proposal TemplateDocument2 pagesExpedition Proposal TemplatehenryNo ratings yet

- AMG001-S1-DS-SF-001 - Datasheet For Safety and Fire Fighting Equipment Kerendan Facility - Rev. 0Document25 pagesAMG001-S1-DS-SF-001 - Datasheet For Safety and Fire Fighting Equipment Kerendan Facility - Rev. 0henryNo ratings yet

- Standard Time UPHDocument7 pagesStandard Time UPHhenryNo ratings yet

- 2013 - AMGA - SPI - Manual Silabus Untuk KursusDocument63 pages2013 - AMGA - SPI - Manual Silabus Untuk KursushenryNo ratings yet

- Standard Time ClampDocument48 pagesStandard Time ClamphenryNo ratings yet

- MTC SO FLG 4inDocument1 pageMTC SO FLG 4inhenryNo ratings yet

- TDS 48342 Jotatemp 1000 Euk GBDocument5 pagesTDS 48342 Jotatemp 1000 Euk GBhenryNo ratings yet

- MTC Pipe 4in S40Document1 pageMTC Pipe 4in S40henryNo ratings yet

- MTC Item 4, 5, 6, 7, 8, 10Document6 pagesMTC Item 4, 5, 6, 7, 8, 10henryNo ratings yet

- MSDS Bioduco Chalk PaintDocument5 pagesMSDS Bioduco Chalk PainthenryNo ratings yet

- ASTM & SAE Grade Markings For Steel Bolts and ScrewsDocument2 pagesASTM & SAE Grade Markings For Steel Bolts and ScrewsAsnawi Al KhoiriNo ratings yet

- 1F Flat PositionDocument14 pages1F Flat PositionAlejandro Jr. TagacayNo ratings yet

- Brazil Rail Map - Ferrovias BRDocument1 pageBrazil Rail Map - Ferrovias BRcriscavasottoNo ratings yet

- Presentation On Power Plant Layout and Flow ChartDocument45 pagesPresentation On Power Plant Layout and Flow ChartSrinivasa Rao Pallela100% (1)

- PIA - Ciencia de Los MaterialesDocument9 pagesPIA - Ciencia de Los MaterialesLesly YañezNo ratings yet

- BMI Catalogue NEWDocument40 pagesBMI Catalogue NEWيوسف ابراهيم حاج عمرNo ratings yet

- Gaskets App 2Document6 pagesGaskets App 2Darshan PanchalNo ratings yet

- Nasm315 An315Document1 pageNasm315 An315GFS ConsultoriaNo ratings yet

- Materials of Pharmaceutical Plant ConstructionDocument2 pagesMaterials of Pharmaceutical Plant Constructionrhittum1802No ratings yet

- Steel Decking InfographicsDocument11 pagesSteel Decking InfographicsAnne Jean ValenzuelaNo ratings yet

- Taptite 2000 Brochure 1Document12 pagesTaptite 2000 Brochure 1ANIKET ZAWARNo ratings yet

- SpecificationsDocument7 pagesSpecificationsMarine SleimanNo ratings yet

- TiwagoxDocument3 pagesTiwagoxprabhuNo ratings yet

- Aluminum-And Magnesium-Alloy Products: Standard Terminology Relating ToDocument7 pagesAluminum-And Magnesium-Alloy Products: Standard Terminology Relating Toanurag yadavNo ratings yet

- Hot Dip Galvanized Steel Strip Voestalpine en 20181002 TwosideDocument5 pagesHot Dip Galvanized Steel Strip Voestalpine en 20181002 TwosideAndy HuffNo ratings yet

- Lecture 8 - Selective LeachingDocument16 pagesLecture 8 - Selective Leachingprakush01975225403No ratings yet

- Coating Maintenance of BridgesDocument51 pagesCoating Maintenance of BridgesMalmbergetNo ratings yet

- Chizzy 400level It ReportDocument46 pagesChizzy 400level It ReportChizzy56No ratings yet

- Speeds & Feeds WorksheetDocument46 pagesSpeeds & Feeds WorksheetEnmanuel Roa BeltreNo ratings yet

- HILTI Anchor SelectorDocument1 pageHILTI Anchor SelectorRajed MaglinteNo ratings yet

- Hemkunt Home AppliancesDocument20 pagesHemkunt Home AppliancesManish KumarNo ratings yet

- MSC - 614 Va MWF 112011Document4 pagesMSC - 614 Va MWF 112011sunilbauchkarNo ratings yet

- Morgan-Stelmor Controlled Cooling Conveyor SystemDocument5 pagesMorgan-Stelmor Controlled Cooling Conveyor SystemJanak LalNo ratings yet

- WasteDocument8 pagesWasteBubinns BeansNo ratings yet

- Wise - P252Document6 pagesWise - P252Vũ PhươngNo ratings yet

- Asm Handbook Volume 17Document3 pagesAsm Handbook Volume 17Mahesh Nvsr BNo ratings yet