Line Data: Piping Isometric Drawings

Line Data: Piping Isometric Drawings

Uploaded by

ksat85Copyright:

Available Formats

Line Data: Piping Isometric Drawings

Line Data: Piping Isometric Drawings

Uploaded by

ksat85Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Line Data: Piping Isometric Drawings

Line Data: Piping Isometric Drawings

Uploaded by

ksat85Copyright:

Available Formats

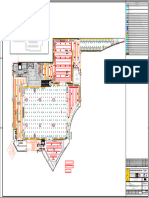

LINE DATA PIPING ISOMETRIC DRAWINGS Job E C T

IDENTIFICATION CODE

AREA NO. SHEET ISSUE

FLUID CODE P FLUID P, GENERAL PROCESS 4240 XHDL 4802A P0483121 1 A

ISOMETRIC LIST

REFERENCES

P0483121 B2A2 NI 0 4240-XZ-DM- ERR 4240-XH-LD-04802011001

PIPE SUPPORT SUMARY 4240-XH-LP-04802011001

A 14.10.2022 ISSUED FOR INTERNAL REVIEW R. Sawant S. Singh M. Pai

LINE ID PIPING CLASS THK.MM P&ID WELDING HEAT PAINTING

REV DATE REVISION DESCRIPTION DRAWN CHECKED APPROVED MATERIAL CLASS INSULATION CLASS TREAT. SYSTEM SPECIAL SUPPORT SUMMARY 4240-XH-LP-04802012001

N

ALL DIMENSION AND PROPER CONFIGURATION FOR LINES NPS 1.1/2" AND SMALLER SHALL BE CHECKED IN FIELD BEFORE CONSTRUCTION.

WITH THE AIM TO OPTIMIZE NUMBER OF SHOP WELDS THE SPOOLING ACTIVITY SHALL BE PREFERABLY AS COMPLETE LINES WITHIN A DEFINED CONSTRUCTION AREA.

PT N.S. HOLD

NO COMPONENT DESCRIPTION (INCH) ITEM CODE QTY STATUS

PIPE

N - CONVENTIONAL NORTH 1 PIPE - A106-B BE SMLS T01AC03V02 S-STD 10 I117798 2.1 M

VALVE HANDWHEELS OR LEVERS ORIENATIONS MUST BE VERIFIED WITH 3D MODEL BEFORE INSTALLATION BY ERECTION CONTRACTOR.

2 PIPE - A106-B BE SMLS T01AC03V02 S-XS 2 I117863 0.3 M

FITTINGS

ACTUAL CUT LENGTH OF PIPE AND FIELD WELDS SHALL BE DEFINED BY ERECTION CONTRACTOR. GUSSETING TO BE IMPLEMENTED BY MECHANICAL SUBCONTRACTOR AS PER 4240-XH-SG-00000000002.

3 REDUCING SOCKOLET MSS-SP-97 6000# A105 BE SWE - 10X3/4 I939563 1

R13DOC01V101 NREQD

4 90 LR ELBOW ASME B16.9 A234-WPB BE SMLS C01DC04V01 S-STD 10 I128461 4

FLANGES

5 WN FLANGE-JACK SCREW ASME B16.5 300# A105 RFFE BE 125 - 250 10 I973202 1

AARH JACK SCREWS PROVIDED F30CFC01BV01 S-STD

6 WN FLANGE ASME B16.5 300# A105 RFFE BE 125 - 250 AARH 2 I118188 1

F01CFC01BV05 S-XS

INSTRUMENTS

7 INSTRUMENT COMPONENT 2 Component-45733 1

MISCELLANEOUS COMPONENTS

527 8 SPACER RING ASME B16.48 300# A515-70 FFTBE 125 - 250 AARH 10 I3964339 1

498 ASME B16.5 D0501FC32O03

F5 G11 B13 PT N.S. HOLD

4 NO COMPONENT DESCRIPTION (INCH) ITEM CODE QTY STATUS

2

116 10/8 FITTINGS

CONN TO 9 REINFORCED BRANCH 90 DEGREES A1Y90 S-STD 10X2 A1Y90 1

048-F-002A/N6

1 E- 413.985M

10"NPD 10 BLIND DISC ASME B16.48 300# A515-70 FFTBE 125 - 250 AARH 10 I46930088 1

G11 N- 1757.237M

ASME B16.5 D0401FC32O03 NREQD

EL +116.030M

4 Component GASKETS

7 E- 415.147M

45733 11 SPIRAL WOUND GASKET ASME B16.20 300# RFTBE 304/GRAP CARBON 10 I60875183 2

N- 1757.287M

EL +116.521M STEEL SS 304 High integrity sealing materials ASME B16.5

G03GFP1IE1G

F6 G12 B14 12 SPIRAL WOUND GASKET ASME B16.20 300# RFTBE 304/GRAP CARBON 2 I60875188 1

STEEL SS 304 High integrity sealing materials ASME B16.5

488

Rev. Cause ID

G03GFP1IE1G

N- 1757.287M

2

BOLTS

This document is Tecnimont's property, and cannot be used by others for any purpose, without prior written consent.

CONT. ON

580 LINE P0483121-2 13 STUD BOLTS&NUTS ASME B18.2.1/2 A193-B7/A194-2H INCH SIZE 1 I401682 16

SPEC B2A2 I01NB0301 - 2 NUTS PER BOLT - 190 mm Length

9 AREA 4802A

10"X2"NPD 14 STUD BOLTS&NUTS ASME B18.2.1/2 A193-B7/A194-2H INCH SIZE 5/8 I401429 8

E- 415.147M I01NB0301 - 2 NUTS PER BOLT - 90 mm Length

N- 1757.687M

EL +116.189M

N- 1757.687M

400 3

STREAM VER NO.-

216

1 10X3/4"NPD

PIPE SUPPORT SHALL BE WELDED BEFORE THERMAL TREATMENT, WHERE APPLICABLE.

1

LINES 1"1/2 AND SMALLER SHALL BE SUPPORTED IN FIELD IF NOT OTHERWISE INDICATED.

118

1

4

CROSSING BETWEEN WELDS ON PIPELINE SHALL NOT BE ADMITTED. .

STREAM NO.-

1

10"NPD

4 2

106

CONT. ON

LINE P0483102-2

SPEC B2A2

REFER LATEST LINE LIST FOR PROCESS PARAMETERS .

AREA 4802A

E- 416.209M

N- 1759.249M

381 EL +116.030M

Extr. Date 27-12-2022 17:14:17

PAINT:

ERR

PAINT:

CS2

:- INDIAN OIL CORPORATION LIMITED

OWNER

ISOMETRIC NUMBER

AUTHORIZED FOR CONSTRUCTION

EXT.NO. 6

PMC :- TOYO ENGINEERING INDIA PRIVATE LIMITED

LineNo. :- 10"-P-048-3121-B2A2-NI Signature for construction is shown on Iso list of relevant piping area CONTRACTOR :- TECNIMONT PVT LTD 4802A-P0483121-1-IS00

1) PIPING FABRICATION AND ERECTION SPECIFICATION. IPPX-6394-8710-PR-000-0011-T1. 5) PMI SPECIFICATION. IPPX-6394-8710-PR-000-0018_T1. :- 1.2 MMTPA PX-PTA PROJECT IPPP-4240-8230-52--

Notes:

PROJECT

1 DENOTES PARTS PIPE A = RESTING SUPPORT G = GUIDE F = AXIAL STOP B = ANCHOR M = SPRING S = TEFLON PAD

SUPPORT 2) PIPING INSULATION SPECIFICATION. 4240-XL-SG-00000000003. 6) SUPPORT SPECIFICATION. 4240-XH-SG-00000000002.

LIST NO WHERE A WITHOUT NUMBERING IS INDICATED, THIS MEANS THAT THERE IS A PLANT :- PARAXYLENE (PX)

3) TYPICAL INSTALLATIONS ENGINEERING SPECIFICATIONS. 4240-XH-SL-00000000011. 7) PAINTING SPECIFICATION. 4240-VW-SG-00000000003.

REST DIRECTLY ON STEEL STRUCTURE. 4) PIPING SPECIFICATION - PIPING PRESSURE TEST 4240-XH-SG-00000000004. 8) LINE LIST. 4240-XH-LL-00000000002. LOCATION :- PARADIP, ODISHA STATE, INDIA.

SIZE A3 SHEET 1 OF 1 REV. A

You might also like

- Utilizing The Usage of Hibiscus Rosa Sinensis As Dishwashing LiquidDocument17 pagesUtilizing The Usage of Hibiscus Rosa Sinensis As Dishwashing LiquidRodessa CacayuranNo ratings yet

- Mineral Wool CharacteristicsDocument14 pagesMineral Wool Characteristicsminsara madtNo ratings yet

- Supervisor Job DescriptionDocument4 pagesSupervisor Job DescriptionshareyyyyyNo ratings yet

- Line Data: Piping Isometric DrawingsDocument1 pageLine Data: Piping Isometric Drawingsksat85No ratings yet

- Line Data: Piping Isometric DrawingsDocument1 pageLine Data: Piping Isometric Drawingsksat85No ratings yet

- Line Data: Piping Isometric DrawingsDocument1 pageLine Data: Piping Isometric Drawingsksat85No ratings yet

- Line Data: Piping Isometric DrawingsDocument1 pageLine Data: Piping Isometric Drawingsksat85No ratings yet

- Line Data: Piping Isometric DrawingsDocument1 pageLine Data: Piping Isometric Drawingsksat85No ratings yet

- Line Data: Piping Isometric DrawingsDocument1 pageLine Data: Piping Isometric Drawingsksat85No ratings yet

- TK03 SP XH DL 4540 VZ4501612 21 Is0 SH.01Document1 pageTK03 SP XH DL 4540 VZ4501612 21 Is0 SH.01Rashad AlasgarovNo ratings yet

- 3520 So3503232 1 Is1Document1 page3520 So3503232 1 Is1GökhanNo ratings yet

- Gas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTDocument54 pagesGas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTTĩnh Hồ TrungNo ratings yet

- Terrace Floor Frabrication Section DetailDocument1 pageTerrace Floor Frabrication Section DetailVishek BisenNo ratings yet

- Yard Pipe - Sludge Drying Bed - Rev DDocument4 pagesYard Pipe - Sludge Drying Bed - Rev DgawtomNo ratings yet

- Yard Pipe - Sludge Drying BedDocument4 pagesYard Pipe - Sludge Drying Bedgawtom100% (1)

- 4124 Fy VD SD17517L10100002 Is02Document2 pages4124 Fy VD SD17517L10100002 Is02titir bagchiNo ratings yet

- Rani Durgawati DWG 2Document1 pageRani Durgawati DWG 2Bharat SharmaNo ratings yet

- 5th Floor Marked Up Steel LocationsDocument1 page5th Floor Marked Up Steel LocationsCos CostyNo ratings yet

- HOUSEDocument1 pageHOUSEksaoji1No ratings yet

- Incendio Nuevo P01 132235 I23 16550 Z Caracas Ccsambil Pci 1.8Document1 pageIncendio Nuevo P01 132235 I23 16550 Z Caracas Ccsambil Pci 1.8Danis MachadoNo ratings yet

- 1 MergedDocument21 pages1 MergedamostafacandpegNo ratings yet

- Earth Filling of Roads-Ghassu FillingDocument1 pageEarth Filling of Roads-Ghassu Fillingkashifsaeed52No ratings yet

- A-UAE-7717-956 - Global RemortDocument1 pageA-UAE-7717-956 - Global RemortAlbinNo ratings yet

- J9101er011 R4Document1 pageJ9101er011 R4Sinaga93No ratings yet

- GR An Ite As /ap PR Ov Al: DC - 4 DC - 5 DC - 6Document1 pageGR An Ite As /ap PR Ov Al: DC - 4 DC - 5 DC - 6AVINASHNo ratings yet

- TELEPHONE SETTING LAYOUT-CAMEL FARM-ModelDocument1 pageTELEPHONE SETTING LAYOUT-CAMEL FARM-Modelmohib.dlinkcssNo ratings yet

- Ac DrawingsDocument3 pagesAc DrawingsAsad KhanNo ratings yet

- TC 5000 (FS) - TC 5100 (FS)Document1 pageTC 5000 (FS) - TC 5100 (FS)Alfarizqi WijayaNo ratings yet

- Wind Substation-ModelDocument1 pageWind Substation-ModeldesignNo ratings yet

- Kanstin Plant BDocument1 pageKanstin Plant Bviero widyantoNo ratings yet

- CGT Pk18 Sho RMC SD Elec 0011 02Document14 pagesCGT Pk18 Sho RMC SD Elec 0011 02Mohamed AbdelshafyNo ratings yet

- Windrose Green Section 2 PlansDocument36 pagesWindrose Green Section 2 PlansJR ZunigaNo ratings yet

- FT II Sector QRS TDocument1 pageFT II Sector QRS Tengrbilal2112No ratings yet

- Notes: Notes: SR - No. Drawing No. Description: D47 A 1A-PI0009 001 CDocument1 pageNotes: Notes: SR - No. Drawing No. Description: D47 A 1A-PI0009 001 Cmohamed esmailNo ratings yet

- 107IrisSt 31102024Document5 pages107IrisSt 31102024Rohan DuttNo ratings yet

- DN#1200 TB1 - 3Document1 pageDN#1200 TB1 - 3Arbaz KhanNo ratings yet

- LEM-EMO-EDO-SD-EL-100A (GROUND FLOOR LIGHTING - KNX DEVICES) .Rev 0Document1 pageLEM-EMO-EDO-SD-EL-100A (GROUND FLOOR LIGHTING - KNX DEVICES) .Rev 0PatrickNo ratings yet

- B38-RC-B-321099 (Rev-B)Document1 pageB38-RC-B-321099 (Rev-B)con.sup.amchfcNo ratings yet

- Phase 3Document1 pagePhase 3Himmanshu SabharwalNo ratings yet

- Bathroom B-17-Elev.2: Master Bathroom Plans & ElevationsDocument1 pageBathroom B-17-Elev.2: Master Bathroom Plans & ElevationsWinmentolMalisaNo ratings yet

- Saudi Arabian Oil Company: Key PlanDocument1 pageSaudi Arabian Oil Company: Key Plancon.sup.amchfcNo ratings yet

- KH24-60419-FEED-01: Key PlanDocument8 pagesKH24-60419-FEED-01: Key PlanNafis TyagiNo ratings yet

- mcc2 PDFDocument1 pagemcc2 PDFSravyaSree100% (2)

- First Floor Fabrication DetailDocument1 pageFirst Floor Fabrication DetailVishek BisenNo ratings yet

- Latest Drawing A2.11C ASI4 DRAFTDocument1 pageLatest Drawing A2.11C ASI4 DRAFTJose FerrerNo ratings yet

- LEM-EMO-EDO-SD-EL-100A (GROUND FLOOR LIGHTING - KNX DEVICES) .Rev 0... NEW TINSDocument1 pageLEM-EMO-EDO-SD-EL-100A (GROUND FLOOR LIGHTING - KNX DEVICES) .Rev 0... NEW TINSPatrickNo ratings yet

- Section Break LineDocument1 pageSection Break Line김대환No ratings yet

- Section: Key PlanDocument1 pageSection: Key Plan김대환No ratings yet

- North ElevationDocument1 pageNorth Elevation김대환No ratings yet

- UNDP - SZ - Environment - Doors-Windows Schedule PDFDocument1 pageUNDP - SZ - Environment - Doors-Windows Schedule PDFA MNo ratings yet

- DrgsDocument1 pageDrgsntfsrttsx7No ratings yet

- 8.water Supply Final ContourDocument1 page8.water Supply Final Contourdanaokasho11No ratings yet

- 3002402-E - Page 1Document1 page3002402-E - Page 1Daniel OjedaNo ratings yet

- Lighting System First Floor Tower A Layout - Part 2Document1 pageLighting System First Floor Tower A Layout - Part 2Ibrahim Haggag 8No ratings yet

- Sheet 1 KKVDocument1 pageSheet 1 KKVdfNo ratings yet

- Wards CurrentDocument1 pageWards CurrentbruinonfireNo ratings yet

- Docking PlanDocument1 pageDocking PlanRoland GrardNo ratings yet

- Towards CST: Titwala Railway Vehicular Circulation PlanDocument1 pageTowards CST: Titwala Railway Vehicular Circulation PlanshubhamkhedekartaNo ratings yet

- P2 Submission Working DrawingDocument5 pagesP2 Submission Working DrawingajNo ratings yet

- ACT ScantronDocument2 pagesACT ScantronnonsenseNo ratings yet

- ACT ScantronDocument2 pagesACT ScantronnonsenseNo ratings yet

- Line Data: Piping Isometric DrawingsDocument1 pageLine Data: Piping Isometric Drawingsksat85No ratings yet

- ThadupoosiDocument50 pagesThadupoosiksat85No ratings yet

- Appollo Tyre AnalysisDocument7 pagesAppollo Tyre Analysisksat85No ratings yet

- IME Time TableDocument1 pageIME Time Tableksat85No ratings yet

- Gold OutlookDocument5 pagesGold Outlookksat85No ratings yet

- SOP, Lab 5 - Coulometric Determination of Vitamin C, v2Document3 pagesSOP, Lab 5 - Coulometric Determination of Vitamin C, v2thinkofparis7No ratings yet

- Best Practices For UFAD System PDFDocument6 pagesBest Practices For UFAD System PDFL LNo ratings yet

- Air Receivers Volume CalculationDocument19 pagesAir Receivers Volume CalculationKenny Ruiz100% (4)

- Fluttershy and The Furry Friends FairDocument42 pagesFluttershy and The Furry Friends FairNiharika NishchalNo ratings yet

- A Case Study On The Endocrine System: Part I: As A Teenager..Document4 pagesA Case Study On The Endocrine System: Part I: As A Teenager..Josue Santiago LopezNo ratings yet

- Autodata Training Course GuideDocument25 pagesAutodata Training Course GuideWaqar AliNo ratings yet

- 08 BQ - PADSB - Elect - P2 - R2 (Subcon Empty BQ)Document89 pages08 BQ - PADSB - Elect - P2 - R2 (Subcon Empty BQ)Middle EastNo ratings yet

- People Vs Tito Zuela 323 SCRA 589Document3 pagesPeople Vs Tito Zuela 323 SCRA 589Ian MarcoNo ratings yet

- Aleem CV Mechanic EXPDocument3 pagesAleem CV Mechanic EXPmohd nadeem ahmedNo ratings yet

- Clark, Aramouni - 2018 - Evaluation of Quality Parameters in Gluten-Free Bread Formulated With Breadfruit (Artocarpus Altilis) FlourDocument13 pagesClark, Aramouni - 2018 - Evaluation of Quality Parameters in Gluten-Free Bread Formulated With Breadfruit (Artocarpus Altilis) FlourArinamelia PsNo ratings yet

- Ha05 - Bus CouplerDocument5 pagesHa05 - Bus CouplerAsgher khkattakNo ratings yet

- Separation and Analysis of Some Sugars by Using Thin Layer ChromatographyDocument2 pagesSeparation and Analysis of Some Sugars by Using Thin Layer ChromatographyTapasNo ratings yet

- BCH Range of Motor Starters Eng 57216Document6 pagesBCH Range of Motor Starters Eng 57216rikumohan0% (1)

- 1 FDF&FGF 15-3ta5Document612 pages1 FDF&FGF 15-3ta5onesimo100% (2)

- Makanan Tabu Di Jeneponto Sulawesi SelatanDocument1 pageMakanan Tabu Di Jeneponto Sulawesi Selatan'Jessica Noviana'No ratings yet

- Daily Stock RecordDocument27 pagesDaily Stock Recordnasir ahmedNo ratings yet

- RCRA WATCHDOG - NCDEQ Secretary Biser: Wakeup! Part 6Document60 pagesRCRA WATCHDOG - NCDEQ Secretary Biser: Wakeup! Part 6Don GordonNo ratings yet

- Naturopathy: A Range of Non-Invasive TreatmentsDocument1 pageNaturopathy: A Range of Non-Invasive Treatmentsrentpe propertyNo ratings yet

- Hirarc Sep HK 2015Document9 pagesHirarc Sep HK 2015moganNo ratings yet

- This Study Resource WasDocument4 pagesThis Study Resource WasglezamaeNo ratings yet

- Growing PainsDocument7 pagesGrowing PainsIan Gumapac100% (1)

- ROGI PARIKSHA AND ROGA PARIKSHA Ijariie11126Document14 pagesROGI PARIKSHA AND ROGA PARIKSHA Ijariie11126MSKCNo ratings yet

- Bearez 1998 - FishingPoisonSeaEnvironmentSalango PDFDocument6 pagesBearez 1998 - FishingPoisonSeaEnvironmentSalango PDFNayelitzin J. CanoNo ratings yet

- Assessment of IntelligenceDocument12 pagesAssessment of IntelligencekennethNo ratings yet

- 7 Day Mental DietDocument6 pages7 Day Mental DietMunteanu Ionut100% (11)

- Annexure-1 - Micro Action Plan Fro Anganwadi Children ScreeningDocument5 pagesAnnexure-1 - Micro Action Plan Fro Anganwadi Children ScreeningZEETECH COMPUTERSNo ratings yet

- Specification: NC 12: Shenzhen Comen Medical Instruments Co.,LtdDocument6 pagesSpecification: NC 12: Shenzhen Comen Medical Instruments Co.,LtdXinwen ChenNo ratings yet