Is 1828-1 (Iso 7500-1) - 6

Is 1828-1 (Iso 7500-1) - 6

Uploaded by

Svapnesh ParikhCopyright:

Available Formats

Is 1828-1 (Iso 7500-1) - 6

Is 1828-1 (Iso 7500-1) - 6

Uploaded by

Svapnesh ParikhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Is 1828-1 (Iso 7500-1) - 6

Is 1828-1 (Iso 7500-1) - 6

Uploaded by

Svapnesh ParikhCopyright:

Available Formats

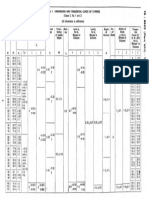

IS 1828 (Part 1) :2005

1s07’500-1:1999

6.2 Determination of the resolution

6.2.1 Analogue scale

The thickness of the graduation marks on the scale shall be uniform and the width of the pointer shall be

approximately equal to the width of a graduation mark.

The resolution, r, of the indicator shall be obtained from the ratio between the width of the pointer and the centre-to-

centre distance between two adjacent scale graduation marks (scale interval). The recommended ratios are 1:2, 1:5

or 1:10, a spacing of 2,5 mm or greater being required for the determination of one-tenth of a scale division.

6.2.2 Digital scale

The resolution is taken to be one increment of the count of the numerical indicator, provided that when the

instrument is unloaded and the motors and controls system are operating, the indication does not fluctuate by more

than one increment.

6.2.3 Variation of readings

If the readings vary by more than the value previously calculated for the resolution (with the calibration of the force-

indicating instrument unloaded and with the motor and/or drive mechanism and control on for determining the sum

of all electrical noise), this resolution, r, shall be deemed to be equal to half the range of fluctuation plus one

increment.

NOTE 1 This only determines the resolution due to system noise and does not account for control errors, i.e. hydraulic

machines.

NOTE 2 For auto-ranging machines, the resolutionof the indicatorchanges as the resolutionor gain of the system changes.

6.2.4 Unit

The resolution, r, shall be expressed in units of force.

6.3 Prior determination of the relative resolution of the force indicator

The relative resolution, a, of the force indicator is defined by the relationship :

a=~xloo” (4)

where

r is the resolution defined in 6.2;

F is the force at the point under consideration.

The relative resolution shall be determined at each calibration point and shall not exceed the values given in Table 2

for the class of machine being verified.

6.4 Calibration procedure

6.4.1 Alignment of the force-proving instrument

Mount tension force-proving instruments in the machine in such a way as to minimize any effects of bending

(see ISO 376). For the alignment of a force-proving instrument in the compression mode, mount a platen with a

spherical seat on the instrument if the machine does not have an incorporated spherical seat.

6.4.2 Temperature compensation

The calibration shall be carried out at an ambient temperature between 10 “C and 35 “C. The temperature at which

the calibration is carried out shall be noted in the verification report.

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- PAUT Model Procedure PDFDocument12 pagesPAUT Model Procedure PDFநந்த குமார் சம்பத் நாகராஜன்81% (16)

- BS 7882Document23 pagesBS 7882Curtis Keller100% (2)

- Ahri 551-591 (Si) 2011Document82 pagesAhri 551-591 (Si) 2011Nidas SameeraNo ratings yet

- Procedure Pa-DraftDocument20 pagesProcedure Pa-Draftmahmoud naviddoustNo ratings yet

- Technical Note How To Calculate Pressure Transmitter Calibration Intervals en 7432098Document6 pagesTechnical Note How To Calculate Pressure Transmitter Calibration Intervals en 7432098Murphy's LawNo ratings yet

- Synchronous Generator Load Angle Measurement and EstimationDocument8 pagesSynchronous Generator Load Angle Measurement and EstimationKaruppannasamy Shanmugam100% (1)

- Expt. 1 Experimental Verification of Dynamic Balancing of Rotating MassesDocument7 pagesExpt. 1 Experimental Verification of Dynamic Balancing of Rotating MassesPranjalNo ratings yet

- Iso 67892003Document5 pagesIso 67892003Sebar48No ratings yet

- SMC006Document6 pagesSMC006Sreejith KumarNo ratings yet

- Standard Calibration Procedure of Analogue or Digital Pressure GaugesDocument26 pagesStandard Calibration Procedure of Analogue or Digital Pressure Gaugeskimjt5538No ratings yet

- BS 7882 - 2008 PaperDocument25 pagesBS 7882 - 2008 PaperMohamed Naser0% (1)

- Is 1828-1 (Iso 7500-1) - 7Document1 pageIs 1828-1 (Iso 7500-1) - 7Svapnesh ParikhNo ratings yet

- CP-001 - Calibration of Dial Gages.Document13 pagesCP-001 - Calibration of Dial Gages.SUNIL100% (1)

- Tegam Inc. Model Dsrs-5Da Decade Synco/Resolver Standard: Instruction ManualDocument25 pagesTegam Inc. Model Dsrs-5Da Decade Synco/Resolver Standard: Instruction ManuallauguicoNo ratings yet

- Pitch Error BacklachDocument12 pagesPitch Error BacklachmcspvNo ratings yet

- Ari575 94Document17 pagesAri575 94hongquan.ntcNo ratings yet

- Principles of CalibrationDocument10 pagesPrinciples of CalibrationClark Joshua Fernandez100% (1)

- SAEJ602 V 001Document8 pagesSAEJ602 V 001Marcelo ColomboNo ratings yet

- Proceq DY-2 Additional Information Calibration Software Guide - EnglishDocument12 pagesProceq DY-2 Additional Information Calibration Software Guide - EnglishMauricio PiresNo ratings yet

- ASTM E74-and-Uncertainty-Calculation-ExampleDocument48 pagesASTM E74-and-Uncertainty-Calculation-ExampleLuân Nguyễn QuỳnhNo ratings yet

- Guide On MEPS For AC (UPDATED)Document12 pagesGuide On MEPS For AC (UPDATED)moukarjunnNo ratings yet

- Leica HDS Check Adjust Manual 2Document13 pagesLeica HDS Check Adjust Manual 2ddpdltNo ratings yet

- Force Verification of Testing Machines: Standard Practices ForDocument10 pagesForce Verification of Testing Machines: Standard Practices Forruben carcamoNo ratings yet

- CON 700 ManualDocument24 pagesCON 700 ManualVijay YadavNo ratings yet

- Instrument Calibration ExplanationDocument10 pagesInstrument Calibration ExplanationCris RonaldNo ratings yet

- Guide To Set Up RheometerDocument7 pagesGuide To Set Up RheometerMattia RosaNo ratings yet

- Application Note Using Veo For AWS Inspection PDFDocument10 pagesApplication Note Using Veo For AWS Inspection PDFwiNo ratings yet

- PowerSwingDetection TestingMethodologyDocument6 pagesPowerSwingDetection TestingMethodologybaskaranjay5502No ratings yet

- ISO 376 Explained PDFDocument67 pagesISO 376 Explained PDFrobertNo ratings yet

- Basic Principles of Instrument Calibration PDFDocument6 pagesBasic Principles of Instrument Calibration PDFchdiNo ratings yet

- Procedura Za Proveru VagaDocument4 pagesProcedura Za Proveru VagaDragan LazicNo ratings yet

- SOP10 - 20141022 - ReglasDocument9 pagesSOP10 - 20141022 - ReglasDiego LincangoNo ratings yet

- What Does Class A Mean To Me?: Application NoteDocument2 pagesWhat Does Class A Mean To Me?: Application NoteNestor AlbarranNo ratings yet

- Iso 2372Document10 pagesIso 2372WulaNda Rika75% (4)

- E4 16 PDFDocument11 pagesE4 16 PDFcaveroglassaNo ratings yet

- SOP-Torque WrenchDocument2 pagesSOP-Torque Wrenchniranjankumar.090399No ratings yet

- Monitoring Performance Ratio CalculationDocument7 pagesMonitoring Performance Ratio CalculationrogimarsolaricNo ratings yet

- Pruebas de Vibración en RodamientosDocument5 pagesPruebas de Vibración en Rodamientospatos81No ratings yet

- Vibration Specifications Standards Setup CriteriaDocument43 pagesVibration Specifications Standards Setup CriteriamaspanuciNo ratings yet

- Soft Servo Glossary: For Servoworks CNC Products and SMP Series General Motion Control ProductsDocument32 pagesSoft Servo Glossary: For Servoworks CNC Products and SMP Series General Motion Control Productsعبد الكريم ملوحNo ratings yet

- 3 Test and Calibration StandardsDocument48 pages3 Test and Calibration StandardsumarsaboNo ratings yet

- Vibration Specifications Standards Gearboxes With Alarm LimitsDocument40 pagesVibration Specifications Standards Gearboxes With Alarm LimitsHemanth Kumar83% (6)

- Saep 150Document13 pagesSaep 150Abdullah100% (1)

- Kohtect Avv-701 Laser Shaft Alignment System: Operating Instructions ManualDocument23 pagesKohtect Avv-701 Laser Shaft Alignment System: Operating Instructions Manualpardocarr4091No ratings yet

- Stewart-Warner Electronic Speedometer System With Transmission-Mounted Magnetic SensorDocument2 pagesStewart-Warner Electronic Speedometer System With Transmission-Mounted Magnetic SensorSgly ZemogNo ratings yet

- E002 For Instrument Acceptance StandardsDocument14 pagesE002 For Instrument Acceptance StandardsSuresh Kumar RanaNo ratings yet

- Surge Warning SystemDocument19 pagesSurge Warning SystemKajal PrajapatiNo ratings yet

- EG 15-14-1.2 Instrument Calibration: ScopeDocument21 pagesEG 15-14-1.2 Instrument Calibration: ScopeaminNo ratings yet

- Calibration Method of Medical CentrifugeDocument3 pagesCalibration Method of Medical Centrifugelorena091186No ratings yet

- System Alignment: Service Periodic Maintenance Schematics Illustrated Parts InstallationDocument26 pagesSystem Alignment: Service Periodic Maintenance Schematics Illustrated Parts InstallationQasim SyedNo ratings yet

- Ad7714 15 Faqs CalibrationDocument4 pagesAd7714 15 Faqs CalibrationYudha PrastyaNo ratings yet

- Methods For The Calibration of Electrostatic Measuring InstrumentsDocument24 pagesMethods For The Calibration of Electrostatic Measuring InstrumentsMatthew Sibanda100% (1)

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Experimentation, Validation, and Uncertainty Analysis for EngineersFrom EverandExperimentation, Validation, and Uncertainty Analysis for EngineersNo ratings yet

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachFrom EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNo ratings yet

- HALT, HASS, and HASA Explained: Accelerated Reliability Techniques, Revised EditionFrom EverandHALT, HASS, and HASA Explained: Accelerated Reliability Techniques, Revised EditionNo ratings yet

- Is 12308-8 - 1997 - 5Document1 pageIs 12308-8 - 1997 - 5Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 4Document1 pageIs 10719 (Iso 1302) - 4Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 1Document1 pageIs 10719 (Iso 1302) - 1Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 3Document1 pageIs 12308-7 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 5Document1 pageIs 12308-6 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 5Document1 pageIs 10719 (Iso 1302) - 5Svapnesh ParikhNo ratings yet

- Is 12308-8 - 1997 - 3Document1 pageIs 12308-8 - 1997 - 3Svapnesh ParikhNo ratings yet

- Is 11166 - 1993 - 10Document1 pageIs 11166 - 1993 - 10Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 14Document1 pageIs 10719 (Iso 1302) - 14Svapnesh ParikhNo ratings yet

- Is 12308-3 - 1987 - 1Document1 pageIs 12308-3 - 1987 - 1Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 8Document1 pageIs 10719 (Iso 1302) - 8Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 3Document1 pageIs 12308-5 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 12Document1 pageIs 10719 (Iso 1302) - 12Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 3Document1 pageIs 8422-3 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 8422-8 - 1977 - 2Document1 pageIs 8422-8 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 2102-2 (Iso 2768-2) - 8Document1 pageIs 2102-2 (Iso 2768-2) - 8Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 3Document1 pageIs 8422-2 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 8422-6 - 1977 - 4Document1 pageIs 8422-6 - 1977 - 4Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 1Document1 pageIs 8422-3 - 1977 - 1Svapnesh ParikhNo ratings yet

- Is 2102-2 (Iso 2768-2) - 2Document1 pageIs 2102-2 (Iso 2768-2) - 2Svapnesh ParikhNo ratings yet

- Is 2102-2 (Iso 2768-2) - 5Document1 pageIs 2102-2 (Iso 2768-2) - 5Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 6Document1 pageIs 8422-2 - 1977 - 6Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 2Document1 pageIs 8422-3 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 5519 - 4Document1 pageIs 5519 - 4Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 5Document1 pageIs 8422-1 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 2Document1 pageIs 8422-1 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 2102-2 (Iso 2768-2) - 4Document1 pageIs 2102-2 (Iso 2768-2) - 4Svapnesh ParikhNo ratings yet

- Is 2102-2 (Iso 2768-2) - 3Document1 pageIs 2102-2 (Iso 2768-2) - 3Svapnesh ParikhNo ratings yet

- Is 5519 - 2Document1 pageIs 5519 - 2Svapnesh ParikhNo ratings yet

- Is 5519 - 9Document1 pageIs 5519 - 9Svapnesh ParikhNo ratings yet

- Elatech - Drive Calculation D E 0316Document24 pagesElatech - Drive Calculation D E 0316akshayNo ratings yet

- Corrected - Gear - 9 Teeth - ContactAnalysisDocument10 pagesCorrected - Gear - 9 Teeth - ContactAnalysiskarthikeyan NNo ratings yet

- Chapter 12Document37 pagesChapter 12Ngan Nguyen Ho KimNo ratings yet

- Ab Design-Grid PDDocument16 pagesAb Design-Grid PDSaurabh GuptaNo ratings yet

- PALM Flat Scanner: For General Weld InspectionDocument4 pagesPALM Flat Scanner: For General Weld InspectionYoucef ChorfaNo ratings yet

- Electrostatic PressureDocument4 pagesElectrostatic PressureAmrit Kamal LenkaNo ratings yet

- A Micromechanical Muscle Model For Determining TheDocument14 pagesA Micromechanical Muscle Model For Determining TheMazinNo ratings yet

- Work Energy and Power : DPP 05 (of Lec 06)Document3 pagesWork Energy and Power : DPP 05 (of Lec 06)ronitsharma2182008No ratings yet

- ECAT Past Paper 2016Document11 pagesECAT Past Paper 2016Moiz ShaikhNo ratings yet

- Chapter 3Document28 pagesChapter 3Anonymous lOMOpX3No ratings yet

- GR 6 - Ans-FUN WITH MAGNETS Term End Revision WKSHT - ANSWER KEYDocument3 pagesGR 6 - Ans-FUN WITH MAGNETS Term End Revision WKSHT - ANSWER KEYJoseph JayakanthanNo ratings yet

- P2.5 Student Bump Up Your Grade: Thermal ConductivityDocument3 pagesP2.5 Student Bump Up Your Grade: Thermal Conductivityjryjh8s2s5No ratings yet

- M.E (Microelectronics and MEMS) - SyllabusDocument69 pagesM.E (Microelectronics and MEMS) - SyllabusDare LeyyNo ratings yet

- Fundamental of Electrical Engineering Msbte Manual Msbte StoreDocument183 pagesFundamental of Electrical Engineering Msbte Manual Msbte Storemontuneshram358No ratings yet

- Latihan Soal STRUCTUREDocument4 pagesLatihan Soal STRUCTURELusi PadmaNo ratings yet

- Heat SettingDocument6 pagesHeat SettingHaco Chinedu ObasiNo ratings yet

- A LESSON PLAN For Pythagorean TheoremDocument9 pagesA LESSON PLAN For Pythagorean TheoremColeen SchrimeathNo ratings yet

- Scopus Indexed Journals ListDocument1,358 pagesScopus Indexed Journals ListDr. Gaurav SinhaNo ratings yet

- 09 Samss 099 PDFDocument7 pages09 Samss 099 PDFFlorante Nobleza0% (1)

- Phase Transformations in Metals and Alloys, Porter y Easterling (2ed.) BC-305-331Document13 pagesPhase Transformations in Metals and Alloys, Porter y Easterling (2ed.) BC-305-331NIKOLEE LIZETH TORRES ZUÑIGANo ratings yet

- Spectrometer I I Curve XXDocument5 pagesSpectrometer I I Curve XXArunnarenNo ratings yet

- Determination of DensitiesDocument4 pagesDetermination of DensitiesJulian CarantoNo ratings yet

- BS 5268 - 4.1 Structural Use of TimberDocument14 pagesBS 5268 - 4.1 Structural Use of TimberTom YeeNo ratings yet

- PM 2.5 Final - Report - RC - 121753 - Ermcz110Document68 pagesPM 2.5 Final - Report - RC - 121753 - Ermcz110Thanachai TengjirathanapaNo ratings yet

- 04 NSF Design and Ec7 Prof Harry Tan PDFDocument66 pages04 NSF Design and Ec7 Prof Harry Tan PDFEmily ShumNo ratings yet

- Zhang 1998Document14 pagesZhang 1998WAHYU DWI LESTARINo ratings yet

- Insulation Thermobreak Tube - TDSDocument2 pagesInsulation Thermobreak Tube - TDSDuy ChuNo ratings yet

- Introduction To Measurements & Error Analysis: The Uncertainty of MeasurementsDocument18 pagesIntroduction To Measurements & Error Analysis: The Uncertainty of MeasurementsMuhammad RafayNo ratings yet

- Activity 6Document2 pagesActivity 6Charm Banlaoi100% (1)

- Iec 61019-2-2005Document58 pagesIec 61019-2-2005Matej FridayNo ratings yet