0 ratings0% found this document useful (0 votes)

24 viewsPage 2 of 3

Page 2 of 3

Uploaded by

Danang Tri PermadiThis document provides specifications for a cooling tower, including:

1. Process design data such as water temperatures, flow rates, and heat load.

2. Fan data like manufacturer, number of blades, diameter, and air flow.

3. Dimensional information and electrical requirements.

4. Liquid specifications for parameters like ions, conductivity, pH, and temperature for water entering and exiting the cooling tower.

5. Site data including location (outdoor), noise levels, and ambient temperature ranges.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Page 2 of 3

Page 2 of 3

Uploaded by

Danang Tri Permadi0 ratings0% found this document useful (0 votes)

24 views1 pageThis document provides specifications for a cooling tower, including:

1. Process design data such as water temperatures, flow rates, and heat load.

2. Fan data like manufacturer, number of blades, diameter, and air flow.

3. Dimensional information and electrical requirements.

4. Liquid specifications for parameters like ions, conductivity, pH, and temperature for water entering and exiting the cooling tower.

5. Site data including location (outdoor), noise levels, and ambient temperature ranges.

Original Title

MDS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides specifications for a cooling tower, including:

1. Process design data such as water temperatures, flow rates, and heat load.

2. Fan data like manufacturer, number of blades, diameter, and air flow.

3. Dimensional information and electrical requirements.

4. Liquid specifications for parameters like ions, conductivity, pH, and temperature for water entering and exiting the cooling tower.

5. Site data including location (outdoor), noise levels, and ambient temperature ranges.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

24 views1 pagePage 2 of 3

Page 2 of 3

Uploaded by

Danang Tri PermadiThis document provides specifications for a cooling tower, including:

1. Process design data such as water temperatures, flow rates, and heat load.

2. Fan data like manufacturer, number of blades, diameter, and air flow.

3. Dimensional information and electrical requirements.

4. Liquid specifications for parameters like ions, conductivity, pH, and temperature for water entering and exiting the cooling tower.

5. Site data including location (outdoor), noise levels, and ambient temperature ranges.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

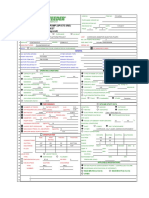

DOC NO:

Datasheet for Cooling Tower

NO DATE PREP'D REV. SLON-GATHMGNO000-MEC-DAS-PHR-2005-00

1 30-Mar-2023 IWI A1

2

PO. NO : SPHR00130A

3

DED INSTALASI COOLING TOWER -

4 ORIG CHK APP'D

MENGGALA NORTH

5 IWI AF/TM AND

1 Client : PERTAMINA HULU ROKAN Unit : *

2 Destination : MENGGALA NORTH Manufacturer : *

3 Service : PRODUCED WATER Serial No. : *

4

5 PROCESS DESIGN DATA (NOTE 4 & 7) LIQUID SPECIFICATION (NOTE 7)

6 Air Relative Humidity (%) : 74.8 COOLING POND SAMPLIING POINT 3

7 Water Temperature Barium mg/L : PROCESS TO INPUT

8 Hot (Inlet) (0F) : 149 Calcium mg/L : PROCESS TO INPUT

9 Cold (Outlet) (0F) : 109.4 Iron mg/L : PROCESS TO INPUT

10 Cooling Range (0F) : 71 Magnesium mg/L : PROCESS TO INPUT

11 Design Wet Bulb Temperature (0F) : 91.4 Strontium mg/L : PROCESS TO INPUT

12 Design Dry Bulb Temperature (0F) : 99.14 Sodium mg/L : PROCESS TO INPUT

13 Water Flowrate (BWPD) : 52834 Potassium mg/L : PROCESS TO INPUT

14 Atmospheric Pressure (Psia) : 14.69 Sulphate mg/L : PROCESS TO INPUT

15 Heat Load (MW) : 8.94 Chloride mg/L : PROCESS TO INPUT

16 Service: l Continuous Intermitten Total Hardness as CaCO3 mg/L : PROCESS TO INPUT

17 Conductivity at 77 0F umhos/cm : PROCESS TO INPUT

18 Operating Conditions (Note 3) Resistivity at 77 0F Ohm.m : PROCESS TO INPUT

19 Air Flow (m3/hr) : VTA Salinity mg/L : PROCESS TO INPUT

20 Drift Loss (gpm) : VTA Carbonate CO3 mg/L : PROCESS TO INPUT

21 Drift Rate (% of Circulating Flow) (%) : VTA Bicarbonate HCO3 mg/L : PROCESS TO INPUT

22 Evaporation Rate (At Design) (%) : VTA Hydroxide mg/L : PROCESS TO INPUT

23 Evaporation Loss (gpm) : VTA P-Alkalinity mg/L : PROCESS TO INPUT

24 Blowdown Loss (gpm) : Not Applicable M-Alkalinity mg/L : PROCESS TO INPUT

25 Sum of Anionic mg/L : PROCESS TO INPUT

26 FAN DATA (NOTE 4 & 7) Sum of Cationic mg/L : PROCESS TO INPUT

27 Fan Manufacturer : VTA Cation Anion Balance %: PROCESS TO INPUT

28 Fan Type : VTA Scale Index - Stiff Davis : PROCESS TO INPUT

29 Quantity of Fan : VTA Total Dissolved Solids (TDS) mg/L : PROCESS TO INPUT

30 No. of Blades : VTA pH : PROCESS TO INPUT

31 Fan Diameter (mm) : VTA Density g/cm3: PROCESS TO INPUT

32 Quantity of Air per Fan (m3/hr) : VTA Total Suspended Solid (TSS) mg/L : PROCESS TO INPUT

33 Fan Speed (Note 5) (RPM) : VTA Chemical Oxygen Demand (COD) mg/L : PROCESS TO INPUT

34 Tip Speed (Note 5) (ft/min) : 10,000 Ammonia as NH3-N mg/L : PROCESS TO INPUT

35 Pitch Adjustment : VTA Sulfida mg/L : PROCESS TO INPUT

36 Air Flow (m3/hr) : VTA Fenol mg/L : PROCESS TO INPUT

37 Sound Power Level (dB) : VTA Temperature On-site 0

F: PROCESS TO INPUT

38 Sound Pressure Level (at Rated) (dB) : ELECTRICAL TO INPUT Oil & Grease mg/L : PROCESS TO INPUT

39 Vibration Switch : VTA

40 Driver / Motor Manufacturer (Note 13) : VTA SITE & UTILITY DATA (NOTE 7)

41 Model No. of Motor / Driver (Note 13) : VTA Location:

42 Enclosure : ELECTRICAL TO INPUT o Indoor

43 Power Req. (For Each CT) (kW) : VTA n Outdoor

44 Power Speed (RPM) : VTA Noise Level dBA : ELECTRICAL TO INPUT

45 Voltage (V) : 460 Electric Area Class:

46 Frequency (Hz) : 60 Zone : ELE/PRO TO INPUT Gr : ELE/PRO TO INPUT Class : ELE/PRO TO INPUT

Phase : 3 Range of Ambient Temperature : PROCESS TO INPUT

48 Dry Bulb Wet Bulb

49 DIMENSION (NOTE 6) PROCESS TO INPUT PROCESS TO INPUT

50 Number of Units : 1* Site Rated ( F) : PROCESS TO INPUT

o PROCESS TO INPUT

51 Number of Cells : 1* Normal (oF) : PROCESS TO INPUT PROCESS TO INPUT

52 Nominal Cell Dimension Maximum ( F) : PROCESS TO INPUT

o PROCESS TO INPUT

53 Length (mm) : VTA Minimum (oF) : PROCESS TO INPUT PROCESS TO INPUT

54 Width (mm) : VTA Design Wind Load (psi) : CIVIL/PRO TO INPUT

55 Height of Basin Curb Aboveground (mm) : VTA Seismic Load : CIVIL/PRO TO INPUT

56 Height Air Inlet Above Basin Curb (mm) : VTA

57 Height Water Inlet Axis Above Basin Curb (mm) : VTA TOWER MATERIAL (NOTE 10, 11 & 12)

58 Nominal Tower Dimension Framework Members VTA

59 Length (mm) : VTA Casing VTA

60 Width (mm) : VTA Louvers VTA

61 Depth (mm) : VTA Fill Media VTA

62 Nominal Basin Dimension Drift Eliminators VTA

63 Length (mm) : VTA Fan Cylinder VTA

64 Width (mm) : VTA Water Distribution System VTA

65 Depth (mm) : VTA Internal Ladder VTA

66 Water Inlet Fasteners (Bolts, Nuts & Washers) VTA

67 Header per Cell (mm) : VTA Water Basin VTA

68 Diameter Header (mm) : VTA Stairway VTA

69 Fan Blade VTA

70 Walkway VTA

71 NOZZLE CONNECTIONS (NOTE 7) Platform VTA

72 Size Rating Facing

73 Water Inlet BY PRO BY PRO RF ACCESSORIES (NOTE 10, 11 & 12)

74 Water Outlet 1 (Basin Cell 1) BY PRO BY PRO RF Internal Ladder YES, REQUIRED (Note 11)

75 Water Outlet 2 (Basin Cell 2) BY PRO BY PRO RF Safety Railing YES, REQUIRED (Note 11)

76 Walkway YES, REQUIRED (Note 11)

77 Lifting Lug YES, REQUIRED (Note 11)

78 WEIGHT INFORMATION (NOTE 6) Earthing Lug / Bosses YES, REQUIRED (Note 11)

79 Platform YES, REQUIRED (Note 11)

80 Empty (lb) : VTA Maintenance Access YES, REQUIRED (Note 11)

81 Testing (lb) : VTA Handrail YES, REQUIRED (Note 11)

82 Operating (lb) : VTA Stairway YES, REQUIRED (Note 11)

83

Page 2 of 3

You might also like

- API 610 10th Edition (Iso 13709) Pump DatasheetDocument3 pagesAPI 610 10th Edition (Iso 13709) Pump DatasheetMuhammad Azka50% (4)

- ChE CalculationsDocument12 pagesChE CalculationsFrances Gem ZaraspeNo ratings yet

- API 675 Pump DatasheetDocument2 pagesAPI 675 Pump DatasheetArun CP100% (1)

- Heater DatasheetDocument3 pagesHeater DatasheetReza Muhammad100% (4)

- MWP - Miln DS M 0008Document6 pagesMWP - Miln DS M 0008nguyenmainamNo ratings yet

- API 610 Vertical Centrifugal PumpDocument7 pagesAPI 610 Vertical Centrifugal PumpNAHASALI11100% (2)

- CWC Mec DTS P001abcdDocument8 pagesCWC Mec DTS P001abcdAlonso1593No ratings yet

- CWC Mec DTS P002abDocument8 pagesCWC Mec DTS P002abAlonso1593No ratings yet

- Centrifugal Compressor Specification Sheet: Operating ConditionsDocument6 pagesCentrifugal Compressor Specification Sheet: Operating ConditionsIsmail SayyedNo ratings yet

- Data Sheet TEG-Gas Exchanger (E-5050)Document2 pagesData Sheet TEG-Gas Exchanger (E-5050)Elias EliasNo ratings yet

- KE3-DST-MEQ-0908-3509 Rev 0 Floating Oil Colletion SystemDocument4 pagesKE3-DST-MEQ-0908-3509 Rev 0 Floating Oil Colletion SystemSUBAS CHANDRA BEHERANo ratings yet

- KNT-001-TS-ME6-DS-002 - 3 - Mechanical DataSheet For Seawater Lift PumpsDocument10 pagesKNT-001-TS-ME6-DS-002 - 3 - Mechanical DataSheet For Seawater Lift PumpsAnh ChiếnNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar Perdawood100% (1)

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- 001.17056.000028-AK007-01 Cartridge FilterDocument5 pages001.17056.000028-AK007-01 Cartridge FilterQuy RomNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Document7 pagesData Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Panisa BanimaNo ratings yet

- Compaq Prover - Rev - ABDocument1 pageCompaq Prover - Rev - ABPsa Metering RU II DumaiNo ratings yet

- Gerencia de Proyectos de Refinacion Y Petroquimica Departamento de Ingeniería - PinDocument4 pagesGerencia de Proyectos de Refinacion Y Petroquimica Departamento de Ingeniería - PinGerencia Rigar Colombia SASNo ratings yet

- Data Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Document7 pagesData Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Panisa BanimaNo ratings yet

- Data Sheet For Colombia Project 300# LPTDocument1 pageData Sheet For Colombia Project 300# LPTarmando.lopezperez9No ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- KNT-001-TS-ME6-DS-003 - 2 - Mechanical Data Sheet For Fire Water PumpDocument14 pagesKNT-001-TS-ME6-DS-003 - 2 - Mechanical Data Sheet For Fire Water PumpAnh ChiếnNo ratings yet

- AQ10T-BFM, 363PL 2335kWDocument2 pagesAQ10T-BFM, 363PL 2335kWLiviu ConstantinNo ratings yet

- Greater Nile Petroleum Company Limited OGP Technical Services SDN BHDDocument2 pagesGreater Nile Petroleum Company Limited OGP Technical Services SDN BHDwado11No ratings yet

- Plate Heat Exchanger Data SheetDocument2 pagesPlate Heat Exchanger Data SheetZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- Orifice Plate DatasheetDocument29 pagesOrifice Plate DatasheetshayabajNo ratings yet

- Rich Gas Pre Cooler - E101 A-BDocument4 pagesRich Gas Pre Cooler - E101 A-B29031978No ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Data Shiel de EquiposDocument6 pagesData Shiel de EquiposRodrigo Andres CeledonNo ratings yet

- MAVSP-P19002-W01-M-DS-0002 Rev. 0 Data Sheet For Fire Pumps (Elctrical, Diesel and Jockey)Document16 pagesMAVSP-P19002-W01-M-DS-0002 Rev. 0 Data Sheet For Fire Pumps (Elctrical, Diesel and Jockey)fendi zulfiantoNo ratings yet

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpDocument5 pagesObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381No ratings yet

- 001.17056.000028-AK008-01 1st Stage PreheaterDocument5 pages001.17056.000028-AK008-01 1st Stage PreheaterQuy RomNo ratings yet

- Process Design Conditions: 842-PA-K17-3"-ES32EKFR-NIDocument2 pagesProcess Design Conditions: 842-PA-K17-3"-ES32EKFR-NITHOMASNo ratings yet

- MGP1-TPS-AOS-MS-2105-0001 DATA SHEET FOR DIESEL STORAGE TANK with comments code BDocument4 pagesMGP1-TPS-AOS-MS-2105-0001 DATA SHEET FOR DIESEL STORAGE TANK with comments code B胡子No ratings yet

- Datasheet Rev 1Document7 pagesDatasheet Rev 1Tauasi TauasisNo ratings yet

- Anexo 3.2 Hoja de Datos Del Reactor 3401 DA - DBDocument16 pagesAnexo 3.2 Hoja de Datos Del Reactor 3401 DA - DBLuis ColinaNo ratings yet

- Es 22 002406 Ing Aci CH 001 00Document16 pagesEs 22 002406 Ing Aci CH 001 00Eduardo Serrano AtiroNo ratings yet

- TC 2212921 - Washtech Industries - 20.02 PDFDocument1 pageTC 2212921 - Washtech Industries - 20.02 PDFDevesh PathakNo ratings yet

- NHT Heater API DatasheetDocument9 pagesNHT Heater API DatasheetAravind AravindNo ratings yet

- 5923G-GL-M-DS-3044 Rev0B - Propane Accumulator Data SheetDocument5 pages5923G-GL-M-DS-3044 Rev0B - Propane Accumulator Data Sheetgecep58342No ratings yet

- Data Motor & Pump-1Document29 pagesData Motor & Pump-1naspauzanNo ratings yet

- Data Sheet No. Ds-P-5983 Rev. 1: Centrifugal Pump Data Sheet U.S. Customary UnitsDocument10 pagesData Sheet No. Ds-P-5983 Rev. 1: Centrifugal Pump Data Sheet U.S. Customary Unitsrajindo1No ratings yet

- Hoja API Vs4 001Document9 pagesHoja API Vs4 001brujula24No ratings yet

- Process Data Sheet For Fired HeaterDocument8 pagesProcess Data Sheet For Fired HeaterKarla SánchezNo ratings yet

- 35-TCV-005 & 35-TCV-006 Control Valve Sizing Project - Pembangunan 2 Tangki Black Product Control Valve - Gas, Steam or Vapor FlowDocument1 page35-TCV-005 & 35-TCV-006 Control Valve Sizing Project - Pembangunan 2 Tangki Black Product Control Valve - Gas, Steam or Vapor FlowFIRMANSYAHNo ratings yet

- Section 1.9 - PTH-1-JEL-GAF-N262-00 O&M RWBPDocument122 pagesSection 1.9 - PTH-1-JEL-GAF-N262-00 O&M RWBPDedika MulyanaNo ratings yet

- Chiller Data SheetDocument3 pagesChiller Data SheetMoriyasuNguyen100% (2)

- CS - MVAC Package (Commercial+Technical)Document14 pagesCS - MVAC Package (Commercial+Technical)Newaz KabirNo ratings yet

- 417 2016052-Di041-509 - 1Document1 page417 2016052-Di041-509 - 1lamisma09No ratings yet

- Gas Compressor Package DatasheetDocument69 pagesGas Compressor Package Datasheetjohn100% (2)

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- MKI-DS-J-001-A4 - Rev A Data Sheet PCVDocument60 pagesMKI-DS-J-001-A4 - Rev A Data Sheet PCVFIRMANSYAHNo ratings yet

- Data Sheet No. Ds-P-5107 Rev. 2: 6590-10 6590-10D1-J310-03 J-RE-PUMP-610-P 2 12-Jul-00 1 6 KMG / BeyDocument8 pagesData Sheet No. Ds-P-5107 Rev. 2: 6590-10 6590-10D1-J310-03 J-RE-PUMP-610-P 2 12-Jul-00 1 6 KMG / Beyrajindo1No ratings yet

- 077154C - 1813 PDS 1543 001 A Technip India LTD.: Client MRPL Location Mangalore, Karnata Unit New LPG AtuDocument1 page077154C - 1813 PDS 1543 001 A Technip India LTD.: Client MRPL Location Mangalore, Karnata Unit New LPG AtuChakravarthy BharathNo ratings yet

- 2 Phase Separator Sizing: Vertical Horizontal OrientationDocument2 pages2 Phase Separator Sizing: Vertical Horizontal Orientationmohideenaliyarjafeer.shanawazNo ratings yet

- Specification Datasheet For Instrument Air Compressor PackageDocument5 pagesSpecification Datasheet For Instrument Air Compressor PackageBarata RendengNo ratings yet

- PT201Document1 pagePT201srini1308No ratings yet

- Data Sheet-Bandar - Dayyer - MACDocument1 pageData Sheet-Bandar - Dayyer - MACmeisamNo ratings yet

- DATASHEET MOTOR INDUCTION - UnofficialDocument3 pagesDATASHEET MOTOR INDUCTION - UnofficialDanang Tri Permadi100% (2)

- Report LEDDocument9 pagesReport LEDDanang Tri PermadiNo ratings yet

- LightingDocument13 pagesLightingDanang Tri PermadiNo ratings yet

- Project: Cgk-064 Electrical Power Discrimination Study by Using Etap SoftwareDocument2,948 pagesProject: Cgk-064 Electrical Power Discrimination Study by Using Etap SoftwareDanang Tri PermadiNo ratings yet

- Pt. Wilmar Nabati Indonesia Area PanDocument12 pagesPt. Wilmar Nabati Indonesia Area PanDanang Tri PermadiNo ratings yet

- MV MCC AbbDocument14 pagesMV MCC AbbDanang Tri PermadiNo ratings yet

- A PPT Presentation On Rankine Based Heat Recovery System in Heavy Vehicles by Er. Moien Muzaffar BhatDocument14 pagesA PPT Presentation On Rankine Based Heat Recovery System in Heavy Vehicles by Er. Moien Muzaffar BhatMoienNo ratings yet

- Chapter-7 PDFDocument71 pagesChapter-7 PDFAdrienne Chelsea GabayNo ratings yet

- Thermodynamics SK MondalDocument265 pagesThermodynamics SK MondalSãröj ShâhNo ratings yet

- ARI STD 540 - EvapTempRangeDocument16 pagesARI STD 540 - EvapTempRangeVasti Diaz AguilarNo ratings yet

- Analysis and Performance Evaluation of Gas Turbine by Incorporating A Wetted Evaporative Media CoolerDocument7 pagesAnalysis and Performance Evaluation of Gas Turbine by Incorporating A Wetted Evaporative Media Coolerdu dx100% (1)

- Electrochemistry: WWW - Crackjee.xyzDocument8 pagesElectrochemistry: WWW - Crackjee.xyzRashmi Ranjan DasNo ratings yet

- Science 6 # 11 - Separating Mixtures Through Filtering, Sieving, EvaporationDocument46 pagesScience 6 # 11 - Separating Mixtures Through Filtering, Sieving, EvaporationarminaNo ratings yet

- Unit 1 (Organic Chemistry) NotesDocument5 pagesUnit 1 (Organic Chemistry) Notesmisfits.dakshNo ratings yet

- The Electrolysis of Acidified Water Using A Hofmann VoltameterDocument1 pageThe Electrolysis of Acidified Water Using A Hofmann VoltameterSadhanshyhan ShyhanNo ratings yet

- Saturator Design and CalsDocument11 pagesSaturator Design and Calschuanpham08No ratings yet

- Salicylic Acid 1 KG 17e09-H11-00066 enDocument1 pageSalicylic Acid 1 KG 17e09-H11-00066 enCV HEXACINDO CHEMICALNo ratings yet

- MassTransfer MCQSDocument44 pagesMassTransfer MCQSyaseenNo ratings yet

- Fluid MechanicsDocument25 pagesFluid MechanicsforzamaNo ratings yet

- MSE101 Final Examination 2018 AnswerDocument14 pagesMSE101 Final Examination 2018 Answerعبدالملك جمالNo ratings yet

- Material Science LEC TermsDocument5 pagesMaterial Science LEC TermsrheahabyennNo ratings yet

- Lattice Energy: The Born-Haber CycleDocument4 pagesLattice Energy: The Born-Haber CycleAllalannNo ratings yet

- Heat TransferDocument382 pagesHeat TransferManish Chouhan100% (1)

- 2016-17 Ap Chemistry SyllabusDocument24 pages2016-17 Ap Chemistry Syllabusapi-258761667No ratings yet

- Chapter 11 Spectrophotometry: Beer-Lambert LawDocument12 pagesChapter 11 Spectrophotometry: Beer-Lambert LawImad AghilaNo ratings yet

- Gr10 Physical Sciences P2 (ENG) NOV Possible AnswersDocument6 pagesGr10 Physical Sciences P2 (ENG) NOV Possible Answersbic bibNo ratings yet

- (3X800 MW) Patratu: 11Kv HT Feedr List - (1ua) Package Code PXXDocument23 pages(3X800 MW) Patratu: 11Kv HT Feedr List - (1ua) Package Code PXXrahul.srivastavaNo ratings yet

- 9701 w04 QP 1 PDFDocument20 pages9701 w04 QP 1 PDFSanthi RamanNo ratings yet

- Lesson WK 1 - Matter and Its PropertiesDocument5 pagesLesson WK 1 - Matter and Its PropertiesChristine Gabuya CagasNo ratings yet

- Tds e DF610Document1 pageTds e DF610尹燕祥No ratings yet

- Fundamentals of Lubrication Gear Oil For Wind TurbinesDocument35 pagesFundamentals of Lubrication Gear Oil For Wind TurbinesMohd Khairi Asyraf Ab HamidNo ratings yet

- QUIZ 1 Semicon TheoryDocument33 pagesQUIZ 1 Semicon TheoryAnand JavierNo ratings yet

- Chapter 2 C Envirn Charact SolarDocument46 pagesChapter 2 C Envirn Charact Solarmqdesat66No ratings yet

- 20-05-13 JR - Coipl (Coming) Jee-Advanced (2012 p1) Wta-1 Final Q'paperDocument14 pages20-05-13 JR - Coipl (Coming) Jee-Advanced (2012 p1) Wta-1 Final Q'paperGopal PenjarlaNo ratings yet

- Macsi The Initiation of GuinnessDocument41 pagesMacsi The Initiation of GuinnessSophia RoseNo ratings yet