Miele 6243

Miele 6243

Uploaded by

Med KerroumCopyright:

Available Formats

Miele 6243

Miele 6243

Uploaded by

Med KerroumCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Miele 6243

Miele 6243

Uploaded by

Med KerroumCopyright:

Available Formats

Operating instructions

Washer-Extractor

PW 6163

PW 6243

PW 6323

To avoid the risk of accidents or damage to the machine it is en - GB

essential to read these instructions before installing,

commissioning and using it for the first time. M.-Nr. 07 511 244

2 M.-Nr. 07 511 244

Contents

Contents

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Description of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Control elements on the unclean side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Control elements on the clean side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Brief instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

How to wash correctly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Sort the laundry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Max. load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Add detergent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Detergent dispensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Select a programme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Opening the door on the unclean side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Opening the door on the clean side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Card operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Card access operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Additional options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Language selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Start date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Programme stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Programme cancellation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Changing the programme order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Optional modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Liquid dispensers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Peak load cut-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Communication module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Operating data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Weighing sytem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Suds tap connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Problem solving guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Power cut during a wash programme

Emergency door release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

After sales service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Explanation of symbols on the data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Noise emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Notes for the installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Installing and securing the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Transit fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Transit fittings on the weighing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Dispenser system connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Connecting the dispenser pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Steam connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

M.-Nr. 07 511 244 3

Warning and Safety instructions

~ For disinfection programmes, use

Explanation of the Warning and appropriate temperatures, temperature

Safety symbols on the machine holding times, suds ratios and disinfecting

agents where necessary to achieve the

It is essential to read these required infection prophylaxis in accordance

operating instructions. with current microbiological and health and

safety regulations.

Please refer to specific ~ If items being processed have to meet

instructions, e.g. Installation particular quality standards, e.g. particulate

instructions free rinse results, the procedure must be

validated and the user must make regular

Caution, hot surfaces. quality checks to ensure appropriate

standards are being maintained.

~ Chemical dry cleaning agents must not

Caution, voltage up to 1000 volts. be used in this machine. Most dry cleaning

agents, e.g. benzine, pose a fire and

explosion hazard.

Earthing ~ Petrol, paraffin, or any easily flammable

liquid must not be stored or used near the

machine. Do not use the machine lid as a

storage shelf. Fire and explosion risk!

~ When used in a commercial environment

To avoid the risk of accidents and ensure that all operators are trained to use

damage to the machine read the the machine correctly.

operating instructions carefully before ~ This machine is not intended for outdoor

using it for the first time. They contain use.

important information about the

installation, safety, use and maintenance Technical and electrical safety

of the machine. Keep these operating

instructions in a safe place and ensure ~ This machine must be installed by an

that new users are familiar with the authorised technician only.

content. Pass them on to any future owner ~ The electrical safety of this machine can

of the machine. only be guaranteed if connected to a

correctly installed earthing system on site. It

Correct usage is most important that this basic safety

requirement is present and tested regularly,

~ This machine is not designed for washing and where there is any doubt, the on-site

items which have been treated with

electrical wiring should be inspected by a

dangerous or flammable substances.

qualified electrician. The manufacturer

~ Only use the machine to wash items cannot be held liable for the consequences

which are specified by the manufacturer to of an inadequate earthing system (e.g.

be machine-washable on the wash-care electric shock).

label.

Any other applications may be dangerous. ~ Do not damage, remove or bypass the

safety features, fixtures and control elements

The manufacturer is not liable for damage

of this machine.

resulting from improper use or operation.

~ Do not use a machine with damaged

controls or cables. These must be repaired

before it is used again.

4 M.-Nr. 07 511 244

Warning and Safety instructions

~ Any removable outer panels must be ~ Always close the door after use. This way

back in place, and all moving or electrical you will avoid the danger of:

parts shielded before the machine is – children climbing onto or into the machine

switched on.

or hiding things in it.

~ The machine is only completely isolated – pets or other small animals climbing into it.

from the electricity supply either when it is

switched off at the isolator switch or the ~ Take care in the area of the hinges of the

mains fuse has been withdrawn. drum door. Danger of injury.

~ Repairs to electrical or steam operated ~ The drum door must be able to be

machines may only be carried out by a opened to its fullest extent. This area must

suitably qualified person in accordance with not be restricted by doors or structural

national and local safety regulations. Repairs features.

and other work by unqualified persons could

be dangerous. The manufacturer cannot be ~ Always make sure that the drum is

held liable for unauthorised work. stationary before reaching into the machine

to remove laundry. Reaching into a moving

~ Faulty components must only be replaced drum is extremely dangerous.

by genuine Miele original spare parts. Only

when these parts are fitted can the safety ~ This manual does not cover procedures

standards of the machine be guaranteed. for medical devices. Please see the

Programme Overview booklet for details

~ The best materials are used in the about programmes and when to use them.

manufacture of this machine, and every care

is taken to check all parts. However, with ~ It is the operator's responsiblity to ensure

time, deterioration of parts can occur, that the standard of disinfection in thermal

especially with such components as hoses, as well as chemo thermal procedures is

giving rise to leaks. Check the inlet hoses maintained (in accordance with § 18 IFSG

regularly for signs of wear and tear. Change and national health and safety regulations)

in good time to avoid the risk of leaks and by carrying out suitable validation tests.

subsequent damage. These procedures should be checked on a

regular basis, either thermo-electrically

~ Local regulations regarding regular using loggers, or bacteriologically with bio

inspection and maintenance of this machine indicators. The operator must pay particular

must be observed. A log book should be attention to maintaining the correct

kept with the machine. parameters in the procedure, including

temperature and with chemo thermal

Using the machine programmes, the chemical concentration

used. Disinfection programmes must not be

~ This machine is not intended for use by interrupted, as this can have a limiting effect

people with reduced physical, sensory or

mental capabilities, or lack of experience on the disinfection result.

and knowldege, unless they are supervised ~ Disinfection only takes place in those

whilst using it or have been shown how to programmes that include a disinfection

use it correctly by a person responsible for stage. Other programmes do not include

their safety. disinfection (see Programme overview,

Hygiene).

~ This machine is not a toy! To avoid the If disinfected laundry is processed in these

risk of injury never allow children to play on

or near the machine, or to operate it programmes and unloaded from the Clean

themselves. side there is a risk of bacterial infection and

contamination occuring.

~ Remember that the door glass will be hot Unloading laundry that has not been

when washing at very high temperatures. Do disinfected on the Clean side is the

not let children touch it. responsibility of the operator.

M.-Nr. 07 511 244 5

Warning and Safety instructions

~ The water used for washing is a suds ~ Do not use a pressure washer or hose to

solution and is not drinking water. clean the machine.

It must be drained away via an appropriate

drainage system. Using accessories

~ The washer-extractor may only be ~ Accessory parts may only be fitted when

operated without supervision if there is a expressly approved by Miele. If spare parts

floor drain (gully) in the immediate vacinity. or accessories from other manufacturers are

~ Cleaning and disinfecting agents often used, this will invalidate the guarantee, and

contain chlorine-based substances. Do not Miele cannot accept liability.

let such agents come into contact with the

stainless steel surfaces, as the chlorine can

have a corrosive effect. Use chlorine-free

agents for washing and disinfecting and also

for cleaning stainless steel surfaces to

protect them from corrosion.

If in doubt about a particular agent contact

the manufacturer for advice.

If any agent containing chlorine comes into

contact with the stainless steel surfaces,

wipe it away immediately with clean water.

Then dry with a soft cloth.

~ Confirm with the detergent manufacturer

that their product can be used in

combination with another type of product.

This is particularly important when using a

combination of cleaning agents and special

application products. Only use the product

for the application described by the

manufacturer, to avoid any material damage

or the occurrence of strong chemical

reactions.

~ The manufacturer cannot be held liable

for the effect of a chemical cleaning agent

on laundry or the machine, even when the

use of such agents is recommended.

Please note that changes to the product

which have not been made known by the

manufacturer can affect the quality of the

wash result.

~ Only use dyes, colour run and dye

removers specified as being suitable for use

in washing machines. Always observe the

manufacturer's instructions carefully.

~ Laundry that was soiled with biological

oils or fat should be washed using a suitable

detergent and /or wash programme. It must

also be inspected after washing. If oils or fat

are not sufficiently removed they could

cause the laundry to self ignite during the

drying process.

6 M.-Nr. 07 511 244

Warning and Safety instructions

Chlorine and component damage Disposing of your old machine

Notes on using chlorine bleach and ~ Before disposing of an old machine, first

make the door lock unusable. This way you

perchlorethylene

will prevent children from accidentally

~ Frequent use of chlorine increases the locking themselves in and endangering their

risk of component damage. lives.

The use of agents containing chlorine, such

Keep these instructions in a safe and

as sodium hypochlorite and chlorine bleach

accessible place.

in powder form, can damage the protective

upper surface of stainless steel and cause

corrosion to components. Factors affecting

this are chlorine concentration levels,

contact time and temperature. It is therefore

advisable to avoid the use of such agents.

Oxygen based bleaching agents should be

used instead.

If, however, chlorine based bleaching

agents have to be used for particular types

of soiling, then anti-chlorine measures must

also be carried out. If this is not done

irreparable damage can occur to

components in the machine and to laundry.

Anti-chlorine treatment

Anti-chlorine treatment has to be carried out

immediately after chlorine bleach has been

used. The use of hydrogen peroxide or an

oxygen based cleaning or bleaching agent

is recommended and the laundry should not

be drained in between.

With thiosulfate, especially when used with

hard water, gypsum can form, which can

lead to incrustations on laundry or deposits

in the machine. The use of hydrogen

peroxide is preferable as it aids the chorline

neutralising process.

The exact quantity of additives and the

treatment temperatures required must be set

and tested on site in accordance with the

dosage recommendations of the detergent

and additive manufacturers. The laundry

must also be tested to check whether it

contains any active chlorine residues.

M.-Nr. 07 511 244 7

Caring for the environment

Disposing of the packing material Tips on saving energy

The packaging is designed to protect the To save energy and water, try to load the

machine during transportation. The materials maximum for the programme selected.

used are environmentally friendly for Underloading is uneconomical. Overloading

disposal. gives a poorer quality of wash result and

Rather than just throwing these materials may cause unnecessary creasing.

away, please ensure that they are recycled.

Make sure that your laundry is thoroughly

,Packaging materials such as plastic spun before drying. This saves time and

film and bags must be kept out of the energy.

reach of babies and children. Danger of Carrying out the final rinse with hot water

suffocation. helps to reduce the residual moisture level,

and the residual heat in the laundry will help

Disposing of your old machine keep processing time down in the dryer,

thus saving energy.

Electrical and electronic machines often

contain materials which, if handled or Follow detergent manufacturer's advice

disposed of incorrectly could be potentially regarding the right amount of detergent to

hazardous to human health and to the use.

environment. They are, however, essential This will depend on the size of the load, the

for the correct functioning of your machine. water hardness level and the amount of

Please do not dispose of your old it with your soiling in the laundry.

general waste.

Chose the correct programme (with

pre-wash or intensive options selected) and

the correct temperature.

Please dispose of it at your local community

waste collection/recycling centre.

Please contact your dealer, your local waste

collection centre or scrap merchant about

recycling schemes.

Please store it out of the reach of children

whilst awaiting disposal.

8 M.-Nr. 07 511 244

Description of the machine

Unclean side (loading side) Clean side (unloading side)

c f b a a b

d

e

a Emergency stop switch

Press the red button to switch the machine f Heating switch

off. (special version only)

b Control panel This enables you to choose between steam

c Detergent dispenser drawer or electric heating.

Pull the handle to open the compartment.

d Door

The door is opened by the handle. To open

pull the handle upwards and push it

downwards to close the door. Do not use

force to open it.

e Door handle

The door handle is fitted with a safety device

to ensure that the door lock functions Steam heating Electric heating

correctly. If you try and open the door when

it is locked the handle will go up but the door

will stay shut. Push the handle back down

and wait for the programme to finish before

trying to open the door again.

M.-Nr. 07 511 244 9

Description of the machine

a b c d e f g h i

Control elements on the unclean d PC / Optical interface

side This interface is used for transferring data to

the control unit from a PC and vice versa.

a Display

Connection is from the front via the optical

1 Thermal disinfection 90 °C interface on the control panel.

2 Thermal disinfection RKI 90 °C e Rotary selector

3 Chemo-thermal disin. 60 °C

Turning the selector brings up options and

i FC A

menus in the display.

Pressing the selector confirms your

After switching on the "Welcome" display will selection.

appear for a short time followed by the

programme list. The most recently used f Chip card reader

programme is highlighted. When a chip card is inserted, the

b Function buttons programmes on the chip card can be used.

Insert the card in the direction of the arrow

These buttons have specific functions (on the card).

depending on the status of the machine.

These functions will be listed in the display g I Mains on switch

above the buttons and will be highlighted Switches the machine on.

once selected.

h 0 Mains off switch

If the machine is reprogrammed to "Direct

Switches the machine off.

button allocation" the first 6 programmes

listed in the display can be selected directly i Emergency stop switch

via these buttons. Only for use in an emergency.

c START button Press the red button to switch the machine

off. After the problem has been resolved,

The lightring will flash when a selected

turn the red dial clockwise to release it.

programme can be started. Pressing the

Start button will start the programme. After a Then press the START button to continue the

programme has started, pressing this button interrupted programme.

will show the display as it was before the

start of the programme.

10 M.-Nr. 07 511 244

Description of the machine

Control elements on the clean side

Full version

a b

a Emergency stop switch

b Display

Basic version

c d e

c Emergency stop switch

d Red "Programme stop" indicator light

This lights up when a programme has

stopped and when a fault has caused the

programme to stop. It also comes on if

peak-load is active.

e Green "Programme finished" indicator

light

This lights up after a programme has

started, and flashes when the programme

has finished to indicate that the door can be

opened.

M.-Nr. 07 511 244 11

Description of the machine

Function buttons $ Programme locked

Once a locked programme has been

Pressing the button activates the function started, the End button can only be used to

and pressing the button again deactivates it. stop and cancel it during the first 1 minute.

f Stop/End The programme finishes on the "clean side".

The function button on the right-hand side is ) Programme unlocked

used as the End button after the start of a This unlocks a locked programme.

programme.

Once it has been pressed the selected ß Dispensing

programme is stopped or a programme

ä Dispensing switched off

which has been stopped is finished.

\ Operating data

+i Block plus

The relevant programme block (e.g. If when the drum is empty the load display is

Pre-wash) is added to the programme. not showing "00,0", you will need to press

the -> I <- button to reset it to 0.

m Starch stop

Press this button if you wish to laundry to be

starched. D Data transfer

k Without spin

Press this button if you do not want the

laundry to be spun after being rinsed.

Supervisor Chip card

FC Settings

Press this button to switch to another The chip card is supplied without any

language temporarily. programmes.

See the Programming Manual for information

m Start time on transferring data from the control unit to

Pressing this button before the start of a the chip card and vice versa.

programme displays the message that a

start time can be selected.

K Information

Press this button to call up programme

information in the display.

q Water drainage

i Manual control

See the programming instruction booklet.

ü Change order

The order of the programme in progress can

be changed or programme blocks can be

repeated. The chip card can store a maximum of 30

A Back programmes, each with 6 blocks.

Takes you back to the previous display. The back of the chip card can be labelled.

e/- Indicates that there is more

information on next or previous line

S Save

See the programming instruction booklet.

12 M.-Nr. 07 511 244

Brief instructions

Sort the laundry

1 Thermal disinfection 90 °C

Only use the machine to wash items 2 Thermal disinfection RKI 90 °C

which are specified by the manufacturer 3 Chemo-thermal disin. 60 °C

to be machine-washable on the i FC A

wash-care label.

Any other applications may be ^ Use the rotary selector to highlight the

dangerous. The manufacturer is not liable programme you want to use.

for damage resulting from improper use or

operation. Press the START button

^ Empty any pockets. The programme will begin.

Switch the machine on and load the drum The following message will appear in the

display when the programme has finished

^ Press the "On" l button in.

2 Thermal disinfection RKI

^ Open the door and load the drum.

Programme finished

^ Close the drum and then the door. Unload drum - CLEAN SIDE

m FC A

Add detergent

The green "Programme finished"

indicator light will then start flashing on

the clean side.

Locked programmes finish on the clean

side, unlocked ones on the unclean side.

^ To open the door at the end of the

programme pull on the handle, open the

drum and then unload the laundry.

If no more laundry is to be processed:

^ Close the drum and then close the door on

the clean side.

^ Dispense agents as follows:

Detergent for the main wash into Once it has been closed the drum will

compartment j, automatically relocate to the unclean side.

Detergent for the pre-wash into

^ Switch the machine off by pressing the

compartment i,

"Off" 0 button.

Fabric conditioner into compartment p,

Any additional liquid agents into the

compartment behind the fabric conditioner

p compartment

(if this facility has been programmed into

the machine).

M.-Nr. 07 511 244 13

How to wash correctly

Sort the laundry

The machine must be commissioned by

an authorised Miele service technician or

dealer before it is used for the first time.

^ Open the on-site stopcocks for water and

depending on the type of heating, for

steam.

^ Switch on the on-site mains switch.

^ Press the "On" I button to switch the

machine on.

Miele

PROFESSIONAL

PW 6xx3

Welcome ^ Empty any pockets.

Foreign objects (e.g. nails, coins, paper

A "Welcome" message will appear in the

clips, etc.) can cause damage to textiles

display.

and to components in the machine.

1 Thermal disinfection 90 °C

2 Thermal disinfection RKI 90 °C

3 Chemo-thermal disin. 60 °C

i FC A Max. load

(Dry weight of laundry)

This is followed by the programme list (with

the most recently used programme PW 6163 PW 6243 PW 6323

highlighted). max. 16 kg max. 24 kg max. 32 kg

Turn the rotary dial to highlight the

programme you want. The programme can

be then started by simply pressing the

START button.

14 M.-Nr. 07 511 244

How to wash correctly

Close the drum:

^ Unlock and open the door.

Gas compression stays raise the door

^ Release the upper drum section from its

upwards.

retainers.

Open the drum: ^ First bring down the section with the

locking device, then close the other

section making sure the locking device

engages and is secure.

When closing the drum door make sure

laundry does not get trapped.

^ To open the drum, press against the

locking device and at the same time press

both sides of the drum opening inwards to

release them.

^ To ensure that the drum door is correctly

closed make sure that the arrow on the

locking device is clearly visible.

,If these procedures are not followed

there is a danger of the drum door

opening and causing considerable

damage.

^ Then secure the upper section into its

retainers.

^ Load the laundry

M.-Nr. 07 511 244 15

How to wash correctly

^ To prevent the risk of trapping your ^ Place other liquid washing additives, e.g.

fingers, hold the door handle with both liquid starch, in the rear section of the

hands to lower and close the door. compartment p (only if the machine has

been programmed for this function).

The drum door should be checked

regularly to make sure it is working

properly. Any fluff that has built up around

the drum door must be removed.

Add detergent

^ Do not exceed the level marker in

compartment p. Otherwise the agent will

run through the suction tube into the suds

container.

^ With the standard programmes, place

detergent for the main wash in

compartment j and if wished, detergent

for the Pre-wash in compartment i.

Place fabric conditioner in the front section

of compartment p.

16 M.-Nr. 07 511 244

How to wash correctly

Bleaching agents Detergent dispensing

Only use bleaching agents on textiles with It is important to avoid adding too much

the x symbol on the wash care label. detergent as this causes excessive foam.

– Do not use detergents which create a lot

of foam.

– Follow the detergent manufacturer's

instructions for use.

The right amount to dispense will depend on

the following:

– The size of the load

– The water hardness level

– The soiling level of the load

Liquid bleaching agent may only be placed The amount to dispense

in the compartment designated for it. This is Take the water hardness into account and

to ensure that the agent is added follow the detergent manufacturer's

automatically at the second rinse. Liquid instructions on the packaging.

bleaching agents should only be used with

coloureds if the textile manufacturer's wash The water hardness level

care label states that the textile is colour fast

and suitable for bleaching. Hard- Water Hardness German

ness properties level in scale

A 3rd rinse cycle must be programmed in range mmol/l °d

if bleach is to be used (see Profitronic I Soft 0 - 1.3 0-7

programming manual). II Medium 1.3 - 2.5 7 - 14

III Hard 2.5 - 3.8 14 - 21

IV Very hard Above 3.8 Above 21

,Frequent use of chlorine increases the

risk of component damage. Check with your local water supplier if you

do not know the hardness level in your area.

Only use dyes, colour run, dye removers

and limescale removers which are

specified as being suitable for use in

washing machines. Always observe the

manufacturer's instructions carefully.

M.-Nr. 07 511 244 17

How to wash correctly

Select a programme If you do not wish to make any further

alterations to the programme:

(see Programme overview, Hygiene)

^ Press the START button. The programme

^ Turn the rotary dial to select a programme

will start.

from the list (e.g. Programme 7 Cottons).

The following (example) will appear in the

display:

If you wish to make alterations before the

23 Separate drain start of the programme, e.g. to the load

7 Cottons 90 °C size, temperature or spin speed:

8 Cottons 60 °C Load weight

i ä FC A You can enter the weight of the load

manually before the start of the programme.

7 Cottons 10.0 16.0 kg

Select the Pre-wash, Starch stop or 40 °C Pre-wash

Without spin additional option 90 °C Main wash e

+i m k m A

^ Confirm the selection of the programme by

pressing the rotary dial.

^ Turn the rotary dial until "Load" (10.0 /

The following (example) will appear in the 16.00 kg) is highlighted. Press the dial to

display: confirm your selection. Turn the dial to

alter the weight and confirm your selection

7 Cottons 16.0 / 16.0 kg by pressing it.

90 °C Main wash

Rinses 975 rpm

+i m k m A Temperature in 1 °C increments from cold,

15 to max. 95 °C .

^ If wished you can now select the Pre-wash

programme block, by pressing the +i ^ Turn the rotary dial to select the

function button. "Temperature" field (40°C for pre-wash)

and press it to confirm your selection.

When the +i function button is pressed,

the following will appear in the display: 7 Cottons 10.0 / 16.0 kg

40 °C Pre-wash

7 Cottons 16.0 / 16.0 kg 90 °C Main wash e

40 °C Pre-wash +i m k m A

90 °C Main wash 975 rpm

+i m k m A ^ Turn the rotary dial to alter the temperature

value and then press it to confirm your

"+i" is highlighted. selection.

Press the function button again to deselect

the function.

Press the m Starch stop button if the

laundry is to be starched.

Press the k Without spin button if you do not

want the laundry to be spun after being

rinsed.

18 M.-Nr. 07 511 244

How to wash correctly

Spin speed in 25 rpm increments from 300

to max. 7 Cottons

90 °C Main wash 60 °C

^ Turn the rotary dial to select the "Spin Rinse 1 Cold Ready at 12:35

speed" field (for the final spin) and press it

+i m k m K f

to confirm your selection.

7 Cottons 10.0 / 10.0 kg Pressing the K "Information" button will call

90 °C Main wash up further information about the programme

Rinses 975 rpm e.g.:

+i m k m A

7 Cottons

Start date and time: 10.7.2008

^ Turn the rotary dial to alter the spin speed Start time: 9:47 e

and then press it to confirm your selection.

A

Maximum spin speeds

Time after start: 0h 23 min

PW 6163 PW 6243 PW 6323 Time left: 0h 11min

1025 rpm 975 rpm 975 rpm Time after start: 0h 23 min e

Time left: 0h 11min

^ Press the START button. The programme Repeat: No

will start. Area 3: rinse e

Once a programme has started the Block 2: Rinse 2

programme sequence will appear in the

Programme step: Wash time 1

display.

Actual level: 22 mm e

7 Cottons

Rqrd. level: 60 mm

40 °C Pre-wash 20 °C

Actual temperature: 35 °C

Main wash Ready at 12:35

+i m k m K f Rqrd. temperature: 60 °C e

7 Cottons

In the 2nd line of the display, pre-wash in

Spin speed: 40 rpm

this example, the actual suds temperature

will also be shown. Rhythm: 12 / 3 -

A

7 Cottons

90 °C Main wash 60 °C ^ Press the A "Back" button to return to the

Rinse 1 Cold Ready at 12:35 programme sequence display.

+i m k m K f

Once the pre-wash programme block has

finished the programme block for the main

wash will appear in the 2nd line of the

display together with the actual suds

temperature. Under that the following

programme block will be listed. Rinse 1 in

this example.

The time that the programme will finish is

shown on the right hand side of the display.

M.-Nr. 07 511 244 19

How to wash correctly

Opening the door on the unclean Opening the door on the clean side

side Locked programmes always finish on the

The following message will appear in the "clean side".

display at the end of the programme as long The following message will appear in the

as there is no water in the machine and the display at the end of the programme as long

drum is stationary: as there is no water in the machine and the

7 Cottons

drum is stationary:

Programme finished

1 Thermal disinfection

Unload drum - UNCLEAN SIDE

Programme finished

m FC A Unload drum - CLEAN SIDE

m FC A

At the same time an acoustic buzzer will

sound for 5 seconds to let you know that the With the Basic version of the machine:

programme has finished. The green "Programme finished" indicator

^ Pull the door handle to open the drum light will start flashing to let you know the

door. Do not use force to open it. programme has finished.

^ Press against the locking device and at At the same time an acoustic buzzer will

the same time press both sides of the sound for 5 seconds to let you know that the

drum opening inwards to release the programme has finished.

locking device. ^ Pull the door handle to open the drum

Carefully open out both sides. door. Do not use force to open it.

^ Then secure the upper section into its ^ Press against the locking device and at

retainers. the same time press both sides of the

^ Unload the drum. drum opening inwards to release the

locking device.

Carefully open out both sides.

^ Then secure the upper section into its

retainers.

^ Unload the drum.

^ Close the drum and then the door.

The door on the clean side must be

closed after the drum has been unloaded.

Once it has been closed the drum will

automatically relocate to the unclean side.

20 M.-Nr. 07 511 244

How to wash correctly

If the programme has been interrupted with To position the drum door on the

water in the drum or during a spin, for clean side

example, the following message will appear

in the display: The "Drum locating" programme is used to

rotate the drum opening to the clean side.

7 Cottons This programme can be used to direct a

Programme finished. Water in the drum. load in the drum to the clean side. It is the

operator's responsibility to make sure that

q m FC A the load is hygienically clean.

or

7 Cottons

Programme finished. Drum still rotating.

m FC A

^ Press the q "Water drainage" function

button or select the Separate spin

programme and press the START button.

The programme finishes on the "unclean

side".

^ Open the door at the end of the

programme.

If no more laundry is to be processed:

^ Switch the machine off by pressing the

"Off" 0 button and then switch off at the

on-site mains switch.

^ Close all stopcocks for water and steam as

applicable.

M.-Nr. 07 511 244 21

Card operation

Cards on which a programme has been If the card is inserted the wrong way round

saved can only be used on the machine the following message will appear in the

type for which they have been written. display:

Unwritten cards can be used universally.

Card fault

^ Press the "On" I button to switch the

machine on. § Card incorrectly inserted in card reader.

The Welcome screen will appear.

A

^ Insert the card the right way round in the

card reader.

If the card is not the right one for the

machine it is being used in the following

message will appear in the display:

Card contents

Programmes on the card are

only suitable for machine type PW 6161.

^ Insert the correct card for the machine in

the card reader.

Card access operation

^ Insert the card in the reader. Programmes requiring special procedures

The programmes listed on the card will are written on to a card which is then used to

appear in the display. run the programme.

"Card access" has to be activated via the

Card operation supervisor level in the machine.

17 Masks 45 °C The machine will then only run programmes

18 Minimum iron 60 °C by using a card (on which one programme

i ß FC A has been saved). Programmes in the

machine's control unit cannot then be

accessed.

^ Use the rotary dial to highlight the

programme you want to use. Press the

rotary dial to select the programme you

have highlighted.

^ Press the START button. The programme

will start.

After pressing the START button you can

remove the card from the reader. The

programme is deleted from the machine's

memory once it has finished.

,Never insert any other type of card or

object into the card reader!

22 M.-Nr. 07 511 244

Additional options

Language selection Start date and time

The language shown in the display can be If you want a programme to start at a later

changed briefly before starting a time use the m button for "Start date and

programme if you wish. To do so use the time".

button underneath the flag symbol.

The language will revert back to the default To set a date and time

setting 5 minutes after the end of a

After selecting your programme, e.g.

programme with the door open.

Cottons in the example here, the following

7 Cottons 90 °C will appear in the display:

8 Cottons 60 °C

7 Cottons 10.0 / 16.0 kg

9 Cottons intensive 60 °C

90 °C Main wash

i FC A

Rinses 975 rpm

+i m k m A

If you press the FC button the following will

appear in the display:

^ Press the m "Start date and time" button.

Settings Back <-

Main menu Language

The following (example) will appear in the

Supervisor level

display:

FC A

7 Cottons 10.0 /16.0 kg

^ Press the rotary dial to confirm your Start time: 16 : 10 Start date: 2.4.2008

selection of the "Language" menu. After selection press the start button.

A

Settings deutsch

Language F english (GB)

The actual time and date will then appear.

español

The input field for hours will be highlighted.

FC A

^ Press the rotary dial to select the hour.

^ Turn the rotary dial to highlight the Turn the rotary dial to alter the hour and

language you want and then press the dial then press it to confirm your selection.

to confirm your selection. ^ Then turn the rotary dial to select the

"Minutes" field and press it to confirm your

selection.

Turn the dial to alter the minutes and then

press it to confirm your selection.

^ Then turn the rotary dial to select the "Start

date" field and press it to confirm your

selection.

Turn the dial to alter the date and then

press it to confirm your selection.

^ Do the same for the month and the year.

M.-Nr. 07 511 244 23

Additional options

After setting the required start date and time: Starch

^ Press the START button and the Starching via the dispenser drawer

programme selected will commence at the

time specified. Starch can be selected with all the standard

programmes (except for Separate spin and

The display will now contain the following Separate drain) before starting a programme

information: by selecting the m "Starch stop" option.

7 Cottons 10.0 / 16.0 kg The m field will be highlighted in the

90 °C Main wash

display.

16:15 -2.4.2003 Start 6:00 -3.4.2008 Pressing the button again deselects the

+i m k m A option.

7 Cottons

The current time and date as well as the

start time will be displayed. Prog. stopped. Starch stop pressed. m

The door can be opened.

^ If the door is opened again you will have to i ü f

press the START button again.

Once the "Starch stop" programme stage is

To cancel the start time and date function reached the words "Starch stop" will start

Press the m "Start date and time" button flashing in the display.

again or press the A"Back", and any Make up the starch solution following the

changes will be rejected. manufacturer's instructions on the

packaging and then add it to the front

section of compartment p. If necessary

dilute the starch with water. The wash time is

With pre-wash automatically increased by 4 minutes.

For heavily soiled laundry a pre-wash can be Press the START button to continue the

added by pressing the "Block+" button i programme.

before starting a programme.

Pressing the button again deselects the Dispensing directly into the drum (suds

option. container)

When the "Blockplus" + i button is Make the starch up following the

pressed, the following will appear in the manufacturer's instructions on the

display: packaging. Once the "Starch stop"

programme stage has been reached open

7 Cottons 14.0 / 16.0 kg the door and add the starch. Close the drum

40 °C Pre-wash door.

Main wash e

The following message will appear in the

+i m k m A

display again:

The "+i" field will be highlighted in the 7 Cottons

display. Prog. stopped. Starch stop pressed. m

The door can be opened.

i ü f

Press the START button and the programme

selected will commence.

24 M.-Nr. 07 511 244

Additional options

Without spin Programme stop

"Without spin" can be selected with all the To halt the programme press the f button.

standard programmes (except for Separate The programme remains stationary.

spin and Separate drain) before starting a

7 Cottons

programme by selecting the k "Without

Programme stop

spin" option.

The k field will be highlighted in the display.

i ü f

Pressing the button again deselects the

option. To continue the programme press the

START button.

7 Cottons

Prog. stopped. Without spin pressed. k The programme will finish on the Unclean

side.

i ü f

Programme cancellation

Once the "Without spin" programme stage is

Press the f button twice in succession to

reached the words "Without spin" will start

cancel a programme. The programme will

flashing in the display.

finish on the Unclean side.

To finish the programme without spinning If there is still water in the machine or if it

and with water left in the drum press the f was cancelled during spinning the following

button. (example) will appear in the display:

To continue with a spin press the START 7 Cottons

button. Programme finished. Water in the drum.

i ü f

or:

7 Cottons

Programme stopped. Drum rotating.

i ü f

To open the door press the q "Water

drainage" button or select the Separate spin

programme and press the START button.

M.-Nr. 07 511 244 25

Additional options

Programme cancelled with a locked Changing the programme order

programme The order of the programme in progress can

be changed or programme blocks can be

It is not possible to stop or cancel a

repeated.

programme if the programme is locked.

^ Press the f button and the programme

7 Cottons

will stop.

90 °C Main wash

Locked Ready at 12:35 7 Cottons

) A Programme stop

The display will show that the machine is i ü f

locked if you try to cancel the programme

with the f button. ^ After pressing the ü button the current

area, block or step will appear in the

To cancel the programme you will first have

display.

to select the ) "Unlocked" function and

then enter a password to unlock the

See also "Programme structure" in the

programme.

Programming Manual.

After entering the password the following will

Reorganise -> 7 Cottons

show in the display:

Programme stop

Area 2: Main wash e

Unlock programme? S A

S A Area: 2 Main wash

Block 1: Main wash

Press the S "Save" button to return to the Step: Wash time 2 -

normal display and the programme can now S A

be cancelled.

^ Turn the rotary dial to alter the area and

7 Cottons

then press it to confirm your selection.

90 °C Main wash 60 °C

Select 1 Pre-wash, 2 Main wash or 3

Rinse 1 Ready at 12:35

Rinses and confirm your selection.

m K f

^ Turn the rotary dial to alter the block and

Press the f button twice. The programme then press it to confirm your selection.

will finish on the Unclean side. Select Pre-wash 1-10, Main wash 1-10 or

Rinses 1-10 and confirm your selection.

^ Turn the rotary dial to alter the step and

then press it to confirm your selection.

Select the required programme step and

confirm your selection.

^ Press the S "Save" button and then press

START to reorganise the programme order

or press the A "Back" button to override

the programme stop and not change the

programme order.

26 M.-Nr. 07 511 244

Optional modules

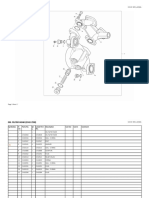

Liquid dispensers To deselect the liquid dispensing system

7 Cottons 90 °C

Dispenser pump Suction pipe

8 Cottons 60 °C

9 Cottons intensive 60 °C

i ä FC A

You can switch off the liquid dispensing

system manually before starting a

programme by setting the ä "Dispensing"

system to off.

Once the programme has started

dispensing will not take place via the

dispenser pumps and the following will

appear in the display:

7 Cottons 10.0/10.0 kg

a c b 90 °C Main wash

Rinses 975 rpm

+i m k m A

d e Dispensing amount

a Hose connection socket (suction side) Please follow the manufacturer's instructions

on the packaging for dispensing

b Hose connection socket (pressure side) requirements.

c Leakage outlet (in case of damaged

hose) ,This is particularly important when

using a combination of cleaning agents

d Suction inlet

and special application products. Only

e Level checker for empty indicator. The use the product for the application

pump and the machine will switch off described by the manufacturer, to avoid

automatically if a liquid agent container is any material damage or the occurrence of

empty.

strong chemical reactions. Confirm with

Dispensing system fault the detergent manufacturer that their

product can be used in combination with

ö Fill dispenser 1 another type of product.

Press the start button

i f Liquid agents should be allowed to settle to

room temperature before use to ensure that

The machine will warn you that the liquid their viscosity level is correct and thus

dispensing agent level is insufficient. ensure the correct amount is dispensed.

The programme can be restarted after

refilling the liquid agent container by

pressing the START button.

M.-Nr. 07 511 244 27

Optional modules

Commissioning the dispensing pumps

Dispenser calibration ~ Main menu

Before the liquid dispensing pumps can be Dispenser pump 1

used the liquid agent must be drawn up into Dispenser pump 2 e

the system and the amount to be dispensed

A

set.

Dispenser calibration ^ Select dispenser pump.

The dispensers need to be calibrated to Dispenser calibration ~ Dispenser pump 1

ensure the dispenser pumps supply the V: 100ml t: 0s no

correct amount of liquid agent.

0/1 S A

To calibrate the dispensers with the machine

switched off:

^ Press button 0/1.

^ Press and hold in button 2. To stop the pump press the 0/1 button

again, or it will switch off automatically

^ Then switch the machine on with the "On" after a period of 60 seconds.

switch.

^ Measure the amount collected in the

Dispenser calibration ~ Main menu measuring flask.

Dispenser pump 1

Dispenser pump 2 e Dispenser calibration ~ Dispenser pump 1

A V: 100ml t: 30s P: 200.0 ml/min

Selection choice: Dispenser pumps 1 to 13 0/1 S A

After selecting a dispenser pump the ^ Enter this value in field "V:". Flow rate P in

following message will appear in the display: ml/min will be calculated electronically.

Dispenser calibration ~ Dispenser pump 1 ^ Press the S "Save" button to save the

V: 100ml t: 0s no values measured in memory.

0/1 S A

^ Reconnect the hose.

Cleaning and maintaining the dispensing

The amount to dispense can be set between

system

0 and 9999 ml in 1 ml increments.

The dispensing system should be flushed

^ Press the 0/1 multi-function button and the

through with clean warm water every two

dispenser hose will start to fill. Press the

weeks and before any longer down-times to

0/1 button again to stop filling the hose.

prevent the risk of blockages and corrosion.

^ Direct the hose of the dispenser pump

^ The suction pipes should be cleaned

being calibrated into a suitable measuring

through with water.

flask.

^ Place the suction pipes in a container of

,Avoid contact with the skin and eyes, hot water (40 - 50°C).

and wear suitable protective clothing.

^ Then use the dispenser calibration system

^ Press the A "Back" button to return to the to operate each pump until the dispensing

main menu. system is thoroughly flushed through.

^ After reconnecting all parts check all

connections, hoses, dispensers and seals

for leakages.

28 M.-Nr. 07 511 244

Optional modules

Peak load cut-out

7 Cottons 90 °C

If the peak-load cut out function is activated

8 Cottons 60 °C

the heating will switch itself off and any

9 Cottons intensive 60 °C

programme running will be stopped. The

i \ FC A

following message will appear in the display:

7 Cottons After pressing the \ button the following

Prog. stopped. Peak load cut-out. will appear in the display:

Programme will continue.

Operating data module

i ü f

Total data

Programme data e

Once the peak load has finished the

\ A

programme will continue automatically as

before.

Selection choice:

– Total data

Communication module In this option all programme data is collated

This machine can be linked to a PC via a and summarised.

communication module. – Programme data

Programme data contains all the data called

up during a programme.

– Delete data

- Module (Total data including programme

data)

- Total data (only delete total data)

- Programme data (only delete programme

data)

The shaft for the communication module is

located on the side of the machine. Pressing the button again deselects the \

"Operating data" option.

An editor programme is available from Miele. If there is no more memory available in the

operating data module a message will

Operating data appear after pressing the START button to

say that the operating data will be

By pressing the \ "Operating data" button

overwritten.

the operating data module can be used to

read or delete operating data either before If you press the A "Back" button or do not

the start of a programme, or after it has press the START button within 30 seconds

finished. the display will revert to the way it was

before starting the programme.

M.-Nr. 07 511 244 29

Optional modules

Total data

Programme data ~ 7 Cottons

Operating data module Date: 21.05.2008 Start time: 11:30

Total data Date: 21.05.2008 Start time: 12:30 e

Programme data e \ A

\ A

Select the required programme start from

After selecting Total data the following the list for programme 7 Cottons and confirm

(example) will appear in the display: your choice by pressing the rotary dial.

Operating data module ~ Total data Programme data ~ 7 Cottons

Total time power on: 200,987 h Date: 21.05.2008 Start time: 11:30

Operating hours: 123456 h e Name: Smith e

\ A \ A

Other options: Other options:

Total time power on: 200,987 h Town: Abingdon

Operating hours: 123,456 h Serial number: 12345678

Duration heating active: 73,456 h Machine type: PW 6163

Duration drive motor active: 93,456 h Amount of laundry: 13 kg

Programme starts: 23,456 + Button: Activated

Programme stops: 567 Starch stop button: Activated

Programme cancellations: 67 Without spin button: Not activated

Water volume: 1,234,567 l Programme start: 11:30

Amount of laundry: 1,234,567 kg Programme finished: 12:05

Liquid agent: 2,345 l Total operating time: 0 h 35 min

Energy: 12,345,678 kWh Electrical energy: 12.5 kWh

Gas energy: 0 kWh

Steam energy: 0 kWh

Total volume of water: 140 l

Programme data

Max. water temperature: 95 °C

Operating data module Max. drain temperature: 45 °C

Programme data Programme change: 2 (after making your selection

Delete data e and pressing the rotary dial only the last 3 stops and starts

will be displayed.)

\ A

Programme fault: None (only the last 3 faults are

saved.)

After selecting Programme data the

Area 1: Pre-wash (after making your selection and

following (example) will appear in the

pressing the rotary dial you can select the area or the

display:

block.)

Operating data module~ Programme data Operating time: 6 min

7 Cottons 90 °C Water volume: 20 l

8 Cottons 60 °C e Dispensing phase 1: Amount ml (after making

your selection and pressing the rotary dial 6 dispensings

\ A

are displayed.)

Max. temperature: 12 °C

Select the programme you want from the list

Holding time: 6 min

and press the rotary dial to call up a list of all

Dispensing phase 2: No

programme starts including date and start

time for that programme (Cottons 90°C in the

example).

30 M.-Nr. 07 511 244

Optional modules

Delete data

Operating data module

Programme data

Delete data e

\ A

After selecting Delete data the following

message will appear in the display:

Operating data module~ Delete data

Module: 21.02.2008

Total data: 12.07.2008 e

\ A

The module menu option can be used to

delete the total data and programme data

from the operating data memory.

The total data option can only be used to

delete the total data from the operating data.

The programme data option can only be

used to delete programme data from the

operating data.

After making your selection and pressing the

rotary dial you will be prompted to enter your

password.

Password: _ _ _ _

ABCDEFGHIJKLMNOPQRSTUVWXYZ

0123456789

K S A

After keying in your password or inserting

your supervisor level key card in the reader

the following security prompt will appear in

the display:

Delete operating data?

S A

After pressing the S button the data will be

deleted!

M.-Nr. 07 511 244 31

Optional modules

Weighing sytem Suds tap connection

If the machine has been equipped with a For analysing suds in the required

weighing system module the weight of the programme stage.

laundry in the machine will be displayed in

0.2 kg increments. The maximum load for

the programme selected will show next to

the actual weight in the drum.

Please make sure that there is nothing on

or leaning against the machine as these

will be weighed with the laundry.

If when the drum is empty the load display is

not showing "00,0", you will need to press

the -> I <- "button to set it to 0".

7 Cottons 00,0/ 16.0 kg

60 °C Main wash

^ Unscrew the suds tap connection cap on

Rinses e

the door with a suitable screwdriver.

+i m k m -> I <- A ^ Guide the hose through the opening (C13

mm).

If after calibrating the sensor to 0 there was

^ Connect a syringe or pipette to the hose

still laundry in the drum the following will

and extract a sample of suds.

appear in the display:

^ Screw the cap back in.

7 Cottons -,- / 16.0 kg

60 °C Main wash

Rinses e

+i m k m -> I <- A

Press the -> I <- button again to set it to 0.

If there is too much laundry in the drum, e.g.

because it is wet, a nominal load will be

calculated after starting the programme and

this value will also be saved by the operating

data module.

At the end of the programme when the drum

has stopped rotating the display will show

the residual moisture content of the laundry.

7 Cottons

Programme finished Residual moisture 60 %

The door can be opened.

m FC A

32 M.-Nr. 07 511 244

Problem solving guide

Power cut during a wash ^ Tighten up the venting screw again and

programme check for leaks (open the water stopcock).

Emergency door release

With a short power cut:

The programme remains in the last position,

and when power is restored the following

message appears in the display:

Power cut

y Programme stop

Press the start button.

f

Press the START button and the programme

selected will continue.

With an extended power cut:

^ Switch the machine off.

^ Switch off the mains supply at the on-site ^ Insert the blade of a screwdriver into the

mains switch. opening underneath the door handle on

the unclean side and turn it anti-clockwise.

^ Close all stopcocks for water, gas and Pull the door handle to open the door on

steam as applicable. the unclean side.

To remove the laundry the drain valve will Do not use force to open the door.

need to be opened manually and the drum ^ Turn the drum by hand until the drum door

door unlocked manually. is accessible.

^ Open the drum door.

,The drum is not stationary and can

turn whilst being unloaded. Take care not

to squash your fingers.

^ Remove the laundry.

^ Open the drain valve by partially opening

the venting screw (spanner size 17 mm) at

the side of the machine. Do not unscrew it

completely. Drain off the suds. Take care

as some water will seep out of the screw

opening (approx. 100 ccm). This should

be collected in a suitable container.

M.-Nr. 07 511 244 33

Problem solving guide

Possible reasons for increased Service interval

levels of foaming If after switching the machine on, the

– Detergent type following message appears in the display

the machine will need to be serviced by the

^ Only use detergents formulated for Miele Service Department.

commercial washer-extractors. Domestic

laundry detergents are not suitable. Service interval 1

– Using too much detergent § Call the Service Department

^ Follow the manufacturer's dosage

recommendations on the packaging and A

take local water hardness levels into

account. The display will go out after 5 minutes.

– Heavy foaming detergent

^ Use a low foaming detergent or contact

your detergent supplier for advice.

– Very soft water

^ In areas with very soft water (hardness

level 1) dispense less detergent as

specified by the detergent manufacturer.

– Soiling level of the laundry

^ For lightly soiled laundry dispense less

detergent in accordance with the

detergent manufacturer's instructions.

– Residues e.g. detergent on the laundry

^ Run a pre-wash without detergent and

without selecting a temperature.

Laundry which has been soaked before

washing must be thoroughly rinsed before

running a wash programme.

– Small loads

^ Reduce the amount of detergent

dispensed according to the size of the

load.

– Drum speed too high during the wash

^ Reduce the drum speed and the wash

rhythm.

34 M.-Nr. 07 511 244

Problem solving guide

Error messages ^ If the programme still will not start please

call the Service Department.

,Repairs to electrical or steam

operated machines may only be carried

out by a suitably qualified person in Heating system fault

accordance with national and local safety § Programme stopped.

regulations. Repairs and other work by Press the start button.

unqualified persons could be dangerous. i f

The manufacturer cannot be held liable

for unauthorised work. ^ To continue the programme with heating

press the START button. If a disinfection

A message will appear in the display if there programme was running the programme

is a problem either before starting a will be cancelled if this message appears.

programme or once it has started. Call the Service Department.

Drive motor fault

m Programme stopped. Press start.

Motor overheating.

i f

The display remains dark. ^ The winding on the motor has overheated.

There is no power to the machine. Let the motor cool down and then press

the "START" button.

^ Check the mains switch and the on-site

fuses.

Imbalance fault

§ Call the Service Department

Power cut if restart does not work.

y Programme stopped. i A

Press the start button.

f The imbalance is too great and the

imbalance switch has been activated.

^ Once power has been restored press the

"START" button. ^ Press the START button.

Water inlet fault Drain valve fault

M q Call the Service Department

Call the Service Department if restart does not work.

if restart does not work.

i f

i f

^ Check the stopcock and then press the ^ Check the on-site drainage system and

"START" button. then press the START button.

A defective drain valve must be repaired by

a Miele Service technician only.

Door lock fault

a Call the Service Department

if restart does not work.

i f

M.-Nr. 07 511 244 35

Problem solving guide

Dispensing system fault Positioning fault

ö §

Fill dispenser 1. Programme finished.

Press start. Water in the drum.

i f q A

^ Replace or replenish the container. Then ^ Switch the machine off and then back on

press the START button. again. If the drum still does not position

itself correctly select the "Drainage" option

and operate the emergency release.

Card fault

§ Card incorrectly inserted in card reader.

Positioning fault

A

§ Programme stopped.

Operate the emergency release.

^ Insert the card the right way round in the i f

card reader.

^ Switch the machine off and then back on

again. Press the START button.

Positioning fault

§ Programme finished

Operate the emergency release.

A

After sales service

^ Switch the machine off and then back on In the event of any faults please contact your

again. If the drum still does not position Dealer or the nearest Service Department.

itself correctly operate the emergency

When contacting the Service Department,

release.

please quote the Model, Serial number (SN)

and Material number (M.Nr) of your

machine.

Positioning fault

§ Call the Service Department if

mains interruption does not work.

Operate the emergency release.

A

^ Switch the machine off and then back on This information can be found on the data

again. If the drum still does not position plate, located above the electrical

itself correctly operate the emergency connection point, or inside the door on the

release. Call the Service Department. unclean side.

Please let the Service Department know any

Positioning fault error message that has appeared in the

§ Programme stopped. display.

Water in the machine.

i f Should you require spare parts ensure that

you only use original Miele Spare Parts

(and remember to let the Spare Parts

Press the START button. If the drum still

Department know the model number and

does not position itself correctly select the

serial number of your machine).

"Drainage" option and operate the

emergency release.

36 M.-Nr. 07 511 244

Cleaning and care

The machine should be cleaned and

checked over immediately after use where

possible.

,Do not use a pressure washer or hose

to clean the machine.

The housing, control panel and any

plastic components should be cleaned

using a suitable mild cleaning agent,

applied with a soft damp cloth. Rub dry with

a soft cloth after cleaning.

To clean the drip channel and the siphons in

Parts of the housing made from stainless the detergent dispenser open out the

steel can be cleaned using a suitable detergent dispenser cover. If a siphon is

proprietary stainless steel cleaning agent. blocked a bottle brush can be used.

Do not use abrasive cleaning agents as

they will damage the surface material. The grille over the suds container ventilation

at the side of the machine should be

checked for soiling from time to time and

cleaned if necessary.

Clean the detergent dispenser, dispenser

compartments and siphons

The detergent dispenser, dispenser The drum closing mechanism should be

compartments and siphons must be cleaned checked regularly to make sure it is working

after each use with warm water to thoroughly properly. Any fluff that has built up around

remove any detergents or other residues. the drum door must be removed.

The siphon in the dispenser compartment for

fabric conditioner should also be cleaned. Rust

The drum and suds container are

manufactured from rust free stainless steel.

Water with a very high iron content, or

foreign objects such as paper clips, metal

buttons etc. which get into the drum with the

laundry can cause superficial rusting in the

drum and suds container.

To prevent this happening the drum and

suds container should be checked and

cleaned regularly and if rusting does occur it

should be removed using a proprietary

cleaning agent for stainless steel.

The door seals should be checked for

foreign objects regularly and cleaned as

Remove the siphon and clean with hot water. described above.

Then put it back in place.

M.-Nr. 07 511 244 37

Cleaning and care

Leave the door on the unclean side ajar

after cleaning to allow the machine to dry.

The filters in the water inlet valves (1) and in

the inlet hoses (2) should be checked from

time to time for soiling and cleaned if

necessary.

Drum bearings

Once the service interval has been reached

the following message will appear in the Before lubricating the drum bearings the

display: venting screw must be unscrewed. The

grease nipples on the left and right hand

Lubricate drum bearings drum bearings must be lubricated after

§ Call the Service Department.

approx. 1000 operating hours with Arcanol

L 100. While lubricating, rotate the drum

three times. Wipe away any old lubricant.

A

Press the A"Back" button to clear the

message from the display. This message will

appear in the display each time you switch

the machine on until the service work has

been carried out by the Miele service

technician.

,Disconnect the machine from the

mains supply.

38 M.-Nr. 07 511 244

Explanation of symbols on the data plate

a

b o p q

c

d r s

e

f t

g

u

i

h j v

k

l w

m

n

1 Model

2 Serial number Noise emissions

3 Article number

4 Material number A-rated sound intensity level

5 Voltage/Frequency at place of use max. EN ISO 11204

6 Mains fuse rating

7 Drive motor PW 6163 70 dB(A)

8 Drum data PW 6243 71 dB(A)

9 Drum diameter/Drum depth PW 6323 71 dB(A)

10 Spin speed

11 Drum volume/Laundry dry weight A-rated sound performance level

12 Kinetic energy at place of use max. EN ISO 9614-2

13 Run-up time

14 Braking time PW 6163 79 dB(A)

15 Heating PW 6243 81 dB(A)

16 Type of machine/year of manufacture PW 6323 81 dB(A)

17 Commissioning date

18 Electric heating

19 Fuse rating (on-site)

20 Steam heating, indirect

21 Steam heating, direct

22 Gas heating

23 Field for test certification/mark

M.-Nr. 07 511 244 39

Notes for the installer

^ The machine can then be screwed to the

This machine must be installed by an floor through the four holes now visible in

authorised technician only. the machine's base frame.

Do not install the machine on carpeted

Installing and securing the machine flooring as the carpet pile can hinder the

free flow of air into the ventilation gaps at the

See also the installation diagram

bottom of the machine.

supplied.

To avoid the risk of frost damage do not Transit fittings

install this machine in a room where there is

a risk of frost occuring.

The machine must be level and secure after

installation.

The machine can be secured to the floor

using the existing drill holes in the base

frame of the machine.

^ To access them both side panels have to

be dismantled.

1 2

The transit fittings, two on the clean side and

two on the unclean side, should not be

removed until the machine is set up in its

final location and is ready for

commissioning.

^ The frequency converter casing has to be

dismanted by undoing 3 screws

(Illustration 1) and then hung to the side

(Illustration 2).

4 transit fittings

Store the transit fittings in a safe place for

future use. They will need to be refitted

should the machine every need to be

moved to another location.

Use a pallet lifter to move the machine

around the room.

^ With steam heated machines the steam Plinth facings are supplied separately with

connection bracket also has to be the machine and must be fitted after it has

dismantled. been set up. The earth lead (green-yellow)

must then be connected.

40 M.-Nr. 07 511 244

Notes for the installer

Transit fittings on the weighing

system

Removing the fittings

Installing the fittings

If the machine is moved again the transit

fittings have to be refitted to the weighing

system. This is to protect the weighing

mechanism.

^ Fit the screws and nuts by hand. Tighten

nut 1 with a suitable spanner. Then adjust

nuts 2 and 3 loosely by hand and then

tighten them up against each other with a

suitable spanner.

M.-Nr. 07 511 244 41

Notes for the installer

Liquid dispensers Hard water

If replacing an inlet hose only use a hose

tested to at least 7000 kPa (70 bar)

pressure, and for a water temperature of at

least 90 °C. This also applies to all fittings.

Miele original parts fulfil these requirements.

Cold water Hot water Cold water

Water taken into the machine must not