T - Thermanit ATS 4 - Ss - en - 5

T - Thermanit ATS 4 - Ss - en - 5

Uploaded by

rusf123Copyright:

Available Formats

T - Thermanit ATS 4 - Ss - en - 5

T - Thermanit ATS 4 - Ss - en - 5

Uploaded by

rusf123Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

T - Thermanit ATS 4 - Ss - en - 5

T - Thermanit ATS 4 - Ss - en - 5

Uploaded by

rusf123Copyright:

Available Formats

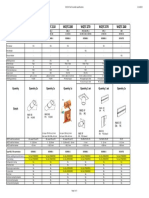

Thermanit ATS 4

TIG rods, high-alloyed, high temperature resistant

Classifications

EN ISO 14343-A EN ISO 14343-B AWS A5.9 Mat. No.

W 19 9 H SS19-10H ER19-10H 1.4948

Characteristics and typical fields of application

High temperature resistant up to 700 °C (1292 °F); resistant to scaling up to 800 °C (1472 °F).

For surfacing and joining applications on matching / similar high temperature resistant steels / cast

steel grades.

Base materials

TÜV-certified parent metal

1.4948 – X6CrNi18-11, 1.4878 – X12CrNiTi18-9, 1.4850 – X6CrNiNb18-10,

AISI 304H, 321H, 347H

Typical analysis of the TIG rods (wt.-%)

C Si Mn Cr Ni

wt-% 0.05 0.4 1.8 18.8 9.3

Structure: Austenite with part ferrite, 5 % max.

Mechanical properties of all-weld metal

Heat- Yield strength Yield strength Tensile strength Elongation Impact work

treatment R p0.2 R p1.0 Rm A (L 0 =5d 0 ) ISO-V KV J

MPa MPa MPa % +20 °C

aw 400 430 600 30 100

Creep rupture properties: In the range of matching high temperature resistant parent metals

Operating data

Stromart: Schutzgas: Kennzeichnung: ø (mm) L mm

DC ( – ) (EN ISO 14175) I 1 W 19 9 H / ER19-10 H 1.0 1000

1.6 1000

2.0 1000

2.4 1000

3.2 1000

Welding instruction

Materials Preheating Postweld heat treatment

Matching / similar steels / None None. To avoid stress corrosion

cast steel grades cracking: 1050 °C (1922 °F) / air

Approvals

TÜV (01616), GL

All information provided is based upon careful investigation and intensive research. 05/2014

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

You might also like

- Thermanit GE-316L PDFDocument1 pageThermanit GE-316L PDFsmpoe017No ratings yet

- L1 34428 en B Boehler-AWS-ER309L Ss en 1Document1 pageL1 34428 en B Boehler-AWS-ER309L Ss en 1Edgar HornusNo ratings yet

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- Bohler Aws Er308lDocument1 pageBohler Aws Er308lJuan ShunaNo ratings yet

- ER316L Ss en 1Document1 pageER316L Ss en 1brayanNo ratings yet

- Thermanit Nimo C 24 (ERNiCrMo3) GTAWDocument1 pageThermanit Nimo C 24 (ERNiCrMo3) GTAWNiranjan Fakirchand YadavNo ratings yet

- 11042016000000T - Thermanit 25 - 09 CuT - Tig RodDocument1 page11042016000000T - Thermanit 25 - 09 CuT - Tig Rodrodrigongr7No ratings yet

- L1 11991 en Thermanit 13 04 Si de en 21Document1 pageL1 11991 en Thermanit 13 04 Si de en 21k.sourenaNo ratings yet

- T - Thermanit 25 - 09 CuT - de - en - 5Document1 pageT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINo ratings yet

- Thermanit Nicro 82: TIG Rods, Nickel-AlloyDocument2 pagesThermanit Nicro 82: TIG Rods, Nickel-AlloyMaximiliano Ezequiel LopezNo ratings yet

- Thermanit 625Document2 pagesThermanit 625Alireza TakrimiNo ratings yet

- T - Thermanit 22 - 09 - de - en - 5Document1 pageT - Thermanit 22 - 09 - de - en - 5brayanNo ratings yet

- T - Thermanit MTS 4 - Se - en - 5Document1 pageT - Thermanit MTS 4 - Se - en - 5bhanu.kiranNo ratings yet

- Thermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicDocument1 pageThermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicbrayanNo ratings yet

- Thermanit 308 Mo 1SE3A00G 3407112 ENDocument1 pageThermanit 308 Mo 1SE3A00G 3407112 ENbrayanNo ratings yet

- Sdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVDocument1 pageSdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVsadiqNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- 20160323014501-20MnCr5 - 20MnCrS5Document1 page20160323014501-20MnCr5 - 20MnCrS5singaravelan narayanasamyNo ratings yet

- 02112015000000B - Boehler FOX DCMS KB - CeDocument1 page02112015000000B - Boehler FOX DCMS KB - CeHamdi HamdiNo ratings yet

- T Thermanit GEW 316L-17 Se en 5Document1 pageT Thermanit GEW 316L-17 Se en 5PubcrawlNo ratings yet

- Stainless-Steel-1.4301-304 - CopieDocument3 pagesStainless-Steel-1.4301-304 - CopieYoucef KherroubiNo ratings yet

- Avesta 310Document1 pageAvesta 310ulasNo ratings yet

- BOEHLER Q T 309L TIG RodDocument1 pageBOEHLER Q T 309L TIG RodbrayanNo ratings yet

- En 1 4057 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4057 - 1408 Valbruna Nordic EnglishDorut_b67No ratings yet

- Martensitic Stainless Steel EN 1.4057, QT 800Document2 pagesMartensitic Stainless Steel EN 1.4057, QT 800LebasNo ratings yet

- L1 13509 en Thermanit 617 1N66170W 3298018 ENDocument1 pageL1 13509 en Thermanit 617 1N66170W 3298018 ENk.sourenaNo ratings yet

- Ceweld - 316H TigDocument1 pageCeweld - 316H TigFilipe CordeiroNo ratings yet

- 1 4501 Super Duplex TubesDocument3 pages1 4501 Super Duplex TubesAlma JakirovićNo ratings yet

- AISI Type 430Document3 pagesAISI Type 430Agus MulyadiNo ratings yet

- L1 - 14983 - en - T - Thermanit Nicro 82 - Se - en - 5Document2 pagesL1 - 14983 - en - T - Thermanit Nicro 82 - Se - en - 5Απόστολος ΣτεργιάδηςNo ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- 308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsDocument1 page308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsFilipe CordeiroNo ratings yet

- Ceweld 308h TigDocument1 pageCeweld 308h TigFilipe CordeiroNo ratings yet

- Böhler Er Ti 2-Ig: Classifications EN ISO 24034 AWS A5.16Document1 pageBöhler Er Ti 2-Ig: Classifications EN ISO 24034 AWS A5.16Thanh TamNo ratings yet

- Thyssenkrupp Materials (UK) LTD Stainless Steel 1.4307 - 304LDocument3 pagesThyssenkrupp Materials (UK) LTD Stainless Steel 1.4307 - 304LpabloNo ratings yet

- 01112015000000B - Boehler FA-IG - Tig Rod1.4820Document1 page01112015000000B - Boehler FA-IG - Tig Rod1.4820ArielNo ratings yet

- Utp 068 HHDocument1 pageUtp 068 HHRoberto_PrrNo ratings yet

- Carbo 4370 Mpr-E307Document1 pageCarbo 4370 Mpr-E307ali torabiNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Utp A 068 HH: ClassificationsDocument1 pageUtp A 068 HH: ClassificationsErickNo ratings yet

- Amecoil InsertDocument2 pagesAmecoil InsertyauctionNo ratings yet

- 19042016000000T - Union I CrMo 910 - Tig RodDocument1 page19042016000000T - Union I CrMo 910 - Tig RodRushita SolankiNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- SS 420 PropertiesDocument2 pagesSS 420 PropertiesmrbookaniNo ratings yet

- Martensitic Stainless Steel EN 1.4021-QT 700Document2 pagesMartensitic Stainless Steel EN 1.4021-QT 700LebasNo ratings yet

- En 1 4021 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4021 - 1408 Valbruna Nordic EnglishmrbookaniNo ratings yet

- T - Thermanit 304 H Cu - Gtaw - 01 - 01 - en PDFDocument1 pageT - Thermanit 304 H Cu - Gtaw - 01 - 01 - en PDFnebojsa70No ratings yet

- Boehler EAS 4 M-IG - Tig RodDocument1 pageBoehler EAS 4 M-IG - Tig RodbrayanNo ratings yet

- Premium 1.2990 ModDocument2 pagesPremium 1.2990 ModbrunizzaNo ratings yet

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocument2 pagesSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- Böhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantDocument1 pageBöhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantSerhii MishchenkoNo ratings yet

- 02112015000000B - Boehler FOX EV 70 - CeDocument1 page02112015000000B - Boehler FOX EV 70 - CeOPAZOSCNo ratings yet

- Scope: Ferritic Heat-Resistant Steel TK 1.4762Document5 pagesScope: Ferritic Heat-Resistant Steel TK 1.4762Siis IngenieriaNo ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Carbofil 3nimocr Oerlikon en TN130181Document1 pageCarbofil 3nimocr Oerlikon en TN130181rusf123No ratings yet

- VAUTID ASW 143 Engl 041016Document1 pageVAUTID ASW 143 Engl 041016rusf123No ratings yet

- Utp A Dur 250Document1 pageUtp A Dur 250rusf123No ratings yet

- 507140565Document1 page507140565rusf123No ratings yet

- Agillo Article Number: 3411320 Identify Number: 11017: Cordless ScytheDocument7 pagesAgillo Article Number: 3411320 Identify Number: 11017: Cordless Scytherusf123No ratings yet

- ABRA Duretal 45Document2 pagesABRA Duretal 45rusf123No ratings yet

- Manual Cdi 3102Document56 pagesManual Cdi 3102rusf123No ratings yet

- Astrup+MDS+1 4418+QT900+v1,4Document1 pageAstrup+MDS+1 4418+QT900+v1,4rusf123No ratings yet

- Doc 01 RO 20181023132955Document2 pagesDoc 01 RO 20181023132955rusf123No ratings yet

- THERMANIT ATS4 Diam 2.0x1000Document1 pageTHERMANIT ATS4 Diam 2.0x1000rusf123No ratings yet

- Welding StandardsDocument14 pagesWelding Standardsrusf123100% (1)

- Verification Statement: Air Liquide Welding France SAF-FRO BrandDocument2 pagesVerification Statement: Air Liquide Welding France SAF-FRO Brandrusf123No ratings yet

- 2016 Torch and Consumables Catalog: For Mechanized Plasma SystemsDocument52 pages2016 Torch and Consumables Catalog: For Mechanized Plasma Systemsrusf123No ratings yet

- Boehler Metal Cored WiresDocument1 pageBoehler Metal Cored Wiresrusf123No ratings yet

- Test For Welder QualificationsDocument1 pageTest For Welder Qualificationsrusf123No ratings yet

- DigiPlus Installation ManualDocument11 pagesDigiPlus Installation Manualrusf123No ratings yet

- 89 Aristorod Rev4 ER120S GDocument2 pages89 Aristorod Rev4 ER120S Grusf123No ratings yet

- Voestalpine - Boehler Cored Wires BrochureDocument6 pagesVoestalpine - Boehler Cored Wires Brochurerusf123No ratings yet

- SEP 1390e 1996 07 PDFDocument3 pagesSEP 1390e 1996 07 PDFrusf123100% (3)

- SHS WeldingDocument42 pagesSHS Weldingrusf123No ratings yet