L1 34264 en T Thermanit MTS 3 Se en v2

L1 34264 en T Thermanit MTS 3 Se en v2

Uploaded by

Enrique MurgiaCopyright:

Available Formats

L1 34264 en T Thermanit MTS 3 Se en v2

L1 34264 en T Thermanit MTS 3 Se en v2

Uploaded by

Enrique MurgiaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

L1 34264 en T Thermanit MTS 3 Se en v2

L1 34264 en T Thermanit MTS 3 Se en v2

Uploaded by

Enrique MurgiaCopyright:

Available Formats

Thermanit MTS 3

Basic coated stick electrode, creep-resistant

Classifications

EN ISO 3580-A EN ISO 3580-B AWS A5.5 AWS A5.5M

E CrMo91 B 42 H5 E6215-9C1MV H5 E9015-B91 H4 E6215-B91 H4

Characteristics and typical fields of application

The basic coated CrMoVNb core wire alloyed electrode is specially designed for welding of creep

resistant tempered martensitic 9 % Cr steels used for turbine and boiler fabrication in thermal

power plants as well as in the chemical industry. Approved for long-term use at service

temperatures up to 650 °C.

Thermanit MTS 3 provides good welding characteristics in all positions except vertical down, a

stable arc, low spattering, good slag detachability and excellent striking and re-striking properties.

The chemical composition is optimized in order to provide a high creep resistant and ductile weld

metal and is characterized by low hydrogen content and low level of trace elements.

Base materials

Modified 9Cr-1Mo steels like 1.4903, X10CrMoVNb9-1, GX12CrMoVNbN9-1, ASTM Grade 91

Typical analysis of all-weld metal

C Si Mn Cr Mo Ni V Nb N

wt.-% 0.10 0.2 0.6 8.5 0.9 0.5 0.2 0.05 0.04

Mechanical properties of all-weld metal at + 20 °C – typical values (min. values in brackets)

Heat- Yield strength Tensile strength Elongation Impact work

treatment Rp0.2 Rm A5 ISO-V

MPa MPa % J

760 °C / 2 h 580 (≥ 530) 710 (≥ 620) 19 (≥ 17) 70 (> 47)

Operating data

Polarity: Electrode identification: ø mm L mm Amperage A

DC + Thermanit MTS 3 E CrMo9 1B 2.5 250 60 – 80

9015-B91 3.2 350 90 – 120

4.0 350 110 – 140

5.0 450 150 – 180

Welding instruction

Preheating / Interpass temperature Cooling down before PWHT Post weld heat treatment

(PWHT)

180 – 300 °C ≤ 100 °C 760 ± 10 °C / 2 h

Re-drying: 300 – 350 °C / 2 h. Not necessary straight from the tin.

Approvals

TÜV (09168), CE

All information provided is based upon careful investigation and intensive research. 12/2016

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

You might also like

- Gcse Sc13 SB AnswersDocument3 pagesGcse Sc13 SB AnswersRana TarekNo ratings yet

- Partsprice PDFDocument602 pagesPartsprice PDFEnrique Murgia50% (2)

- Thermanit P24Document1 pageThermanit P24Branko FerenčakNo ratings yet

- Thermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicDocument1 pageThermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicbrayanNo ratings yet

- 02112015000000B - Boehler FOX DCMS KB - CeDocument1 page02112015000000B - Boehler FOX DCMS KB - CeHamdi HamdiNo ratings yet

- T - Thermanit MTS 4 - Se - en - 5Document1 pageT - Thermanit MTS 4 - Se - en - 5bhanu.kiranNo ratings yet

- T Thermanit GEW 316L-17 Se en 5Document1 pageT Thermanit GEW 316L-17 Se en 5PubcrawlNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- Böhler Fox CM 2 KB: Classifi CationsDocument1 pageBöhler Fox CM 2 KB: Classifi CationsBranko FerenčakNo ratings yet

- Thermanit P23Document1 pageThermanit P23Branko FerenčakNo ratings yet

- B - Boehler FOX CM 9 KB - Se - en - 5Document1 pageB - Boehler FOX CM 9 KB - Se - en - 5misthahNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- 02112015000000B - Boehler FOX EV 70 - CeDocument1 page02112015000000B - Boehler FOX EV 70 - CeOPAZOSCNo ratings yet

- Acfrogb5xupx1uiu51q4qpegob11kinx4cpthkjuzsxe Qrny8qp19zkiaaqlrzp5mtx7fqalib7js6hirn5qet1v1 Jzc9t4e1g1 Ywrk Xx3fgo44x6qxwaembbcmDocument1 pageAcfrogb5xupx1uiu51q4qpegob11kinx4cpthkjuzsxe Qrny8qp19zkiaaqlrzp5mtx7fqalib7js6hirn5qet1v1 Jzc9t4e1g1 Ywrk Xx3fgo44x6qxwaembbcmdodoNo ratings yet

- T - Thermanit 25 - 09 CuT - de - en - 5Document1 pageT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINo ratings yet

- 02112015000000B - Boehler FOX EV 65 - CeDocument1 page02112015000000B - Boehler FOX EV 65 - CeMohamed AdelNo ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- Utp 068 HHDocument1 pageUtp 068 HHRoberto_PrrNo ratings yet

- S-8018 B2Document5 pagesS-8018 B2Abhishek AnandNo ratings yet

- B - Boehler FOX EV 60 - Se - en - 5Document1 pageB - Boehler FOX EV 60 - Se - en - 5Juan Bedolla FloresNo ratings yet

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocument1 pageB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNo ratings yet

- Böhler Fox Dcms KB: Classifi CationsDocument1 pageBöhler Fox Dcms KB: Classifi CationsBranko FerenčakNo ratings yet

- E7015 G T - Phoenix SH Schwarz 3 K - Se - en - 5Document1 pageE7015 G T - Phoenix SH Schwarz 3 K - Se - en - 5rusdi leoNo ratings yet

- Quality 11Smn30: Lucefin GroupDocument1 pageQuality 11Smn30: Lucefin GroupPaulo ZechinNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- 02112015000000B - Boehler FOX DCMS Ti - CeDocument1 page02112015000000B - Boehler FOX DCMS Ti - CeparbinaNo ratings yet

- BÖHLER Alform® 960-IG: Standard Designations EN ISO 16834-A AWS A5.28Document1 pageBÖHLER Alform® 960-IG: Standard Designations EN ISO 16834-A AWS A5.28JORAMNo ratings yet

- 02112015000000B - Boehler FOX CM 5 KB - CeDocument1 page02112015000000B - Boehler FOX CM 5 KB - CejaroNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- 11042016000000T - Thermanit 25 - 09 CuT - Tig RodDocument1 page11042016000000T - Thermanit 25 - 09 CuT - Tig Rodrodrigongr7No ratings yet

- 04042016000000A Avesta 2205 Covered ElectrodesDocument1 page04042016000000A Avesta 2205 Covered Electrodesmeckup123No ratings yet

- 19042016000000T - Union I CrMo 910 - Tig RodDocument1 page19042016000000T - Union I CrMo 910 - Tig RodRushita SolankiNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- 055 PDFDocument1 page055 PDFantonio111aNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- 1%ni For Improved Toughness: Data SheetDocument4 pages1%ni For Improved Toughness: Data Sheetmohamed AdelNo ratings yet

- E 7016 Spezial electrode-oerlikon-en-TN110089Document2 pagesE 7016 Spezial electrode-oerlikon-en-TN110089Khhg AgddsNo ratings yet

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocument2 pagesChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNo ratings yet

- Boehler HL 75 T-MCDocument1 pageBoehler HL 75 T-MCBruno SantosNo ratings yet

- 02112015000000B - Boehler FOX EASN 25 M - CeDocument1 page02112015000000B - Boehler FOX EASN 25 M - CeABNo ratings yet

- Datasheet AVESTA 2205-PW ACDC Stick ElectrodeDocument1 pageDatasheet AVESTA 2205-PW ACDC Stick Electrodemohamed.eldesouky9120No ratings yet

- L1 10913 en BOEHLER X 70 IG 2HA3510G 3376575 ENDocument1 pageL1 10913 en BOEHLER X 70 IG 2HA3510G 3376575 ENk.sourenaNo ratings yet

- 11 SMN PB 37Document1 page11 SMN PB 37RasheshNo ratings yet

- Quality 11Smnpb37: Lucefin GroupDocument1 pageQuality 11Smnpb37: Lucefin GroupPaulo ZechinNo ratings yet

- Carbo 4370 Mpr-E307Document1 pageCarbo 4370 Mpr-E307ali torabiNo ratings yet

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- B_Boehler-er-80-s-ni-1-ig_ss_en_5aDocument1 pageB_Boehler-er-80-s-ni-1-ig_ss_en_5aMuhammed SulfeekNo ratings yet

- L1 34428 en B Boehler-AWS-ER309L Ss en 1Document1 pageL1 34428 en B Boehler-AWS-ER309L Ss en 1Edgar HornusNo ratings yet

- Chromecore-430-G Er430Document1 pageChromecore-430-G Er430peymanNo ratings yet

- ETC PH25S DRYDocument1 pageETC PH25S DRYstefavaNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocument1 pageBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoNo ratings yet

- BOHLER GMA 308LSi ER308LSiDocument1 pageBOHLER GMA 308LSi ER308LSibrayanNo ratings yet

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- AISI416Document2 pagesAISI416shamsi862620No ratings yet

- Tenacito 70Document1 pageTenacito 70Luis Angel Unocc FernandezNo ratings yet

- TIG Bohler S EMK 6 ER70S 6Document1 pageTIG Bohler S EMK 6 ER70S 6mohamedNo ratings yet

- L1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Document1 pageL1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Dimitris NikouNo ratings yet

- BA DL Brustbeinsaege EFA 57 en 02.2020Document34 pagesBA DL Brustbeinsaege EFA 57 en 02.2020Enrique MurgiaNo ratings yet

- Sauer Danfoss Hydraulic Gear Pump Group 3Document33 pagesSauer Danfoss Hydraulic Gear Pump Group 3Enrique Murgia100% (1)

- Gear Pump Shhark Low NoiseDocument2 pagesGear Pump Shhark Low NoiseEnrique MurgiaNo ratings yet

- SS Cnpulse 12132018Document2 pagesSS Cnpulse 12132018Enrique MurgiaNo ratings yet

- Itsupply: Hardware ManualDocument131 pagesItsupply: Hardware ManualEnrique MurgiaNo ratings yet

- Sauer Danfoss Hydraulic Gear Pump Group 4Document23 pagesSauer Danfoss Hydraulic Gear Pump Group 4Enrique MurgiaNo ratings yet

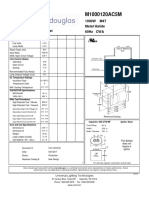

- M1000120AC5MDocument1 pageM1000120AC5MEnrique MurgiaNo ratings yet

- Universal Bugomatic Bro 3 19Document4 pagesUniversal Bugomatic Bro 3 19Enrique MurgiaNo ratings yet

- Mini Squirt Hot Melt Adhesive ApplicatorDocument2 pagesMini Squirt Hot Melt Adhesive ApplicatorEnrique MurgiaNo ratings yet

- Sandvik DTH Drilling Tools: RH550r HammerDocument1 pageSandvik DTH Drilling Tools: RH550r HammerEnrique MurgiaNo ratings yet

- Port Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestDocument3 pagesPort Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestEnrique MurgiaNo ratings yet

- X55-600 BrochureDocument9 pagesX55-600 BrochureEnrique MurgiaNo ratings yet

- 962 Stager Manual Rev BDocument18 pages962 Stager Manual Rev BEnrique MurgiaNo ratings yet

- Danroll Drum MotorDocument112 pagesDanroll Drum MotorEnrique MurgiaNo ratings yet

- AC Motors Asynchronous Servomotors: Operating InstructionsDocument56 pagesAC Motors Asynchronous Servomotors: Operating InstructionsEnrique Murgia100% (1)

- Robotic Shotcrete Applications For Mining and Tunneling: A History of Robotic ApplicatorsDocument6 pagesRobotic Shotcrete Applications For Mining and Tunneling: A History of Robotic ApplicatorsEnrique MurgiaNo ratings yet

- Product Booklet Keen K-200 Welding Electrode Storage OvenDocument12 pagesProduct Booklet Keen K-200 Welding Electrode Storage OvenEnrique MurgiaNo ratings yet

- Section 4 - Operating ProceduresDocument4 pagesSection 4 - Operating ProceduresEnrique MurgiaNo ratings yet

- Valvepac Series 760P Valve Positioner: Installation and Service InstructionDocument69 pagesValvepac Series 760P Valve Positioner: Installation and Service InstructionEnrique MurgiaNo ratings yet

- High Head Drainage PumpsDocument9 pagesHigh Head Drainage PumpsEnrique MurgiaNo ratings yet

- TFP1511 09 2015Document8 pagesTFP1511 09 2015Enrique MurgiaNo ratings yet

- Typ03-04 enDocument438 pagesTyp03-04 enEnrique Murgia100% (1)

- Hydraulic Sealing Products - Size ChartsDocument71 pagesHydraulic Sealing Products - Size ChartsEnrique MurgiaNo ratings yet

- Joucomatic Ersatzteiliste 2010Document46 pagesJoucomatic Ersatzteiliste 2010Enrique MurgiaNo ratings yet

- L 20258Document2 pagesL 20258Enrique MurgiaNo ratings yet

- 1Document28 pages1Enrique MurgiaNo ratings yet

- Cha 4Document5 pagesCha 4Artha fxNo ratings yet

- AwipDocument55 pagesAwipma baNo ratings yet

- Imp Die ArticlesDocument64 pagesImp Die ArticlesprabhuNo ratings yet

- Hyscan II IomDocument33 pagesHyscan II Ioma1gulesNo ratings yet

- ch04 PDFDocument4 pagesch04 PDFFarhan KhanNo ratings yet

- Fastener Selection GuideDocument10 pagesFastener Selection Guidevemanreddy29No ratings yet

- Section 9: Energy Bands: Fig. 1 The Crystal Potential Seen by The ElectronDocument11 pagesSection 9: Energy Bands: Fig. 1 The Crystal Potential Seen by The ElectronbalakrishnanitNo ratings yet

- Question BankSUBRATDocument55 pagesQuestion BankSUBRATमधु हांसदाNo ratings yet

- Basic Technology JSS 3Document3 pagesBasic Technology JSS 3Zainab Abdul100% (1)

- Bio Composite HelmetDocument58 pagesBio Composite HelmetAbhijeet AgarwalNo ratings yet

- Unit-IV Welding Processes of SuperalloysDocument7 pagesUnit-IV Welding Processes of SuperalloysJ Jhansibai100% (1)

- Material Safety Data Sheet: Manufacturer InformationDocument4 pagesMaterial Safety Data Sheet: Manufacturer InformationrockmNo ratings yet

- Femtosecond Laser Structuring of Metal SurfacesDocument18 pagesFemtosecond Laser Structuring of Metal SurfacesamdodehNo ratings yet

- Super Optimal 7018 SH4RDocument1 pageSuper Optimal 7018 SH4RNIZAM NIZAMNo ratings yet

- CH205PeriodicTable StudentDocument49 pagesCH205PeriodicTable Studentpravishek maniNo ratings yet

- The Smar Ttip The Smar Ttip: Aluminium Recycling Aluminium RecyclingDocument2 pagesThe Smar Ttip The Smar Ttip: Aluminium Recycling Aluminium RecyclingBbiesoth AJ100% (1)

- Assignment 3 Due:: May 07, 2020: Z Z Z ZDocument1 pageAssignment 3 Due:: May 07, 2020: Z Z Z ZwatsopNo ratings yet

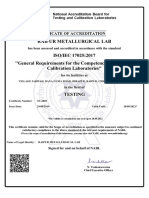

- RML - Lab - NABL Certificate Scope 2021-22Document9 pagesRML - Lab - NABL Certificate Scope 2021-22Subramani ArumugamNo ratings yet

- Reactivity and The Reactions of MetalsDocument53 pagesReactivity and The Reactions of Metalshanthi winkoNo ratings yet

- Skin Effect Heating System: Chromalox ConfidentialDocument9 pagesSkin Effect Heating System: Chromalox ConfidentialMarco SilvaNo ratings yet

- Basic Metal DetectionDocument36 pagesBasic Metal DetectionAnthony ProdeniantaNo ratings yet

- Expanded Metals PDFDocument3 pagesExpanded Metals PDFMichael MirandaNo ratings yet

- SoilDocument16 pagesSoilfatima zafarNo ratings yet

- Alloy: Solid Solution Elements Metallic Matrix HomogeneousDocument10 pagesAlloy: Solid Solution Elements Metallic Matrix HomogeneouswinisanaNo ratings yet

- Electric Refractory MaterialsDocument769 pagesElectric Refractory MaterialsMitone DiazNo ratings yet

- Edc - Piping StandardsDocument11 pagesEdc - Piping StandardsSrikrishnan KrishNo ratings yet

- Q2 - Periodic Table of Elements - IntroDocument40 pagesQ2 - Periodic Table of Elements - IntroPatricia Sofia DizonNo ratings yet

- Energy TechnologiesDocument70 pagesEnergy TechnologiesCurt Octavian100% (1)