Bevel Gear

Bevel Gear

Uploaded by

ADII 2701Copyright:

Available Formats

Bevel Gear

Bevel Gear

Uploaded by

ADII 2701Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Bevel Gear

Bevel Gear

Uploaded by

ADII 2701Copyright:

Available Formats

DESIGN AND MODELING OF BEVEL GEAR

CONTENT

SL INDEX PAGE NO

NO.

1 ABSTRACT 1

INTRODUCTION 1.1

2 ABOUT DOUBLE RIVETED LAP JOINTS 2

DOUBLE RIVETED JOINT 2.1

ADVANTAGES OF DOUBLE RIVETED JOINTS 2.2

DISADVANTAGES OF RIVETED JOINTS: 2.3

APPLICATIONS OF DOUBLE RIVETED JOINTS 2.4

TYPE OF FAILURES IN RIVETED JOINTS: 2.5

3 TYPE OF FAILURES IN RIVETED 3

JOINTS

3.1

PROBLEM

4 TABLE FORM DESIGN DATE 7

HANDBOOK

7.1

CONCLUSION

BEVEL GEAR Page 1

DESIGN AND MODELING OF BEVEL GEAR

Abstract

This chapter provides an overview of riveted joints. In the majority of

built-up structures the several members are united by riveted joints,

and the strength of the joints is just as important as the strength of

the members themselves. Unfortunately, the strength of riveted

joints cannot be calculated with any degree of certainty, and

practical design usually depends on empirical formulae based on

experience. It is evident that, if the rivets are carrying any load, they

must be acting as stops to check the relative movements of the

plates. But, as long as the friction forces are great enough, there will

be no relative movement, and the rivets will not bear any load; as

soon as slip occurs, the rivets are acted on by shearing forces in the

planes separating the cover plates from the main plates. It is

obvious that a uniform distribution of load among the rivets cannot

be attained unless the line of action of the resultant force acting on

the joint passes through the centroid of the rivet-holes, and, at the

same time, the rivets are symmetrically disposed with regard to the

resultant force

BEVEL GEAR Page 2

DESIGN AND MODELING OF BEVEL GEAR

Introduction

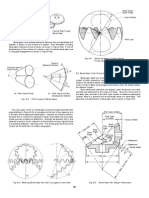

Bevel gears are used to transmit power between two intersecting shafts. There are two common

(a) Straight Bevel Gear (b) Spiral Bevel Gear

The elements of the teeth of the straight bevel gears are straight lines, which converge into a

common apex point. The elements of the teeth of the spiral bevel gears are spiral curves, which

also converge into a common apex point. Involute profile is used for the form of the teeth for

both types of gears. Straight bevel gears are easy to design and manufacture and give reasonably

good service when properly mounted on shafts.

However, they create noise at high-speed conditions. Spiral bevel gears, on the other hand, are

difficult to design and costly to manufacture, for they require specialized and sophisticated

machinery for their manufacture. Spiral bevel gears have smooth teeth engagement, which

results in quiet operation, even at high speeds. They have better strength and are thus used for

high speed-high power transmission.

BEVEL GEAR Page 3

DESIGN AND MODELING OF BEVEL GEAR

In some cases, bevel gears are classified on the basis of pitch angle. Three types of bevel gears

that are based on pitch angle are as follows:

(i) When the pitch angle is less than 90°, it is called external bevel gear.

(ii) When the pitch angle is equal to 90°, it is called crown bevel gear.

(iii) When the pitch angle is more than 90°, it is called internal bevel gear.

There are certain specific categories of bevel gears. They are as follows:

i. Miter Gears:

When two identical bevel gears are mounted on shafts, which are intersecting at right angles,

they are called "miter gears. They are shown in Figure 2.

Miter gears have the following characteristics:

(i) The pitch angles of pinion and gear of miter gears are same and each is equal to 45°.

(ii) The pinion and gear of miter gears rotate at the same speed.

(iii) The pinion and gear have same dimensions, namely, addendum, dedendum, pitch

circle diameter, number of teeth and module.

(iv) The pinion and gear of miter gears are always mounted on shafts, which are

perpendicular to each other.

BEVEL GEAR Page 4

DESIGN AND MODELING OF BEVEL GEAR

ii. Crown Gear:

In a pair of bevel gears, when one of the gears has a pitch angle of 90° then that gear is called

'crown' gear. Such bevel gears are mounted on shafts, which are intersecting at an angle that is

more than 90°. The crown gear is equivalent to the rack in spur gearing. The pitch cone of the

crown gear becomes plane. They are shown in Figure 3.

Crown gear arrangement has the following characteristics:

a) The pitch angle of crown gear is 90º.

b) The bevel pinion and crown gear are always mounted on shafts, which are intersecting at

angle more than 90°.

BEVEL GEAR Page 5

DESIGN AND MODELING OF BEVEL GEAR

iii. Internal Bevel Gears:

When the teeth of bevel gear are cut on the inside of the pitch cone, it is called internal bevel

gear. In this case, the pitch angle of internal gear is more than 90° and the apex point is on the

backside of the teeth on that gear. They are shown in Figure 4. Internal bevel gears are used in

planetary gear trains.

iv. Skew Bevel Gears:

When two straight bevel gears are mounted on shafts, which are non-parallel and non-

intersecting, they are called skew bevel gears. They are shown in Figure 5(b). It is seen that the

apex point of pinion is offset with respect to that of gear.

Skew bevel gears have following characteristics:

1. Skew bevel gears have straight teeth.

2. Skew bevel gears are mounted on nonparallel and non-intersecting shafts.

BEVEL GEAR Page 6

DESIGN AND MODELING OF BEVEL GEAR

Terminology of Bevel Gears

A bevel gear is in the form of the frustum of a cone. The dimensions of a bevel gear are

illustrated in Figure 6(a) and (b).

The following terms are important in terminology of bevel gears:

i. Pitch Cone Pitch cone is an imaginary cone, the surface of which contains the pitch lines

of all teeth in the bevel gear.

ii. Cone Centre The apex of the pitch cone is called the cone centre. It is denoted by O.

iii. Cone Distance Cone distance is the length of the pitch-cone element. It is also called

pitch-cone radius. It is denoted by AO.

iv. Pitch Angle The angle that the pitch line makes with the axis of the gear, is called the

pitch angle. It is denoted by g. The pitch angle is also called centre angle

v. Addendum Angle It is the angle subtended by the addendum at the cone centre. It is

denoted by a

vi. Dedendum Angle It is the angle subtended by the dedendum at the cone centre. It is

denoted by d.

vii. Face Angle It is the angle subtended by the face of the tooth at the cone centre. Face

angle = pitch angle + addendum angle = g+a.

viii. Root Angle It is the angle subtended by the root of the tooth at the cone centre. Root

angle pitch angle - dedendum angle = g-d

ix. Back Cone The back cone is an imaginary cone and its elements are perpendicular to the

elements of the pitch cone.

x. Back Cone Distance It is the length of the back cone element. It is also called back cone

radius. It is denoted by rb

BEVEL GEAR Page 7

DESIGN AND MODELING OF BEVEL GEAR

Design Methodology and Procedure for Bevel Gear Problems:

1) Material Selection:

Select suitable material if not given from Table 12.7. Page No. 234 DDHB

Identifying weaker part (pinion/gear)

If the material used for both pinion and gear is same, then the pinion is weaker

If the material used for both pinion and gear are different, then the strength factor is used

determine the weaker part

Design is based on weaker part

2) Find Module:

a. If the diameter is known, use Eqns. 12.37 (second part) and 12.7(a)

b. If the diameter is unknown, use formula (1) from previous section

c. Check for induced σ in both the cases

d. If induced > permissible value, design is fail. Hence adopt/change the module and repeat

(2(c))

3)Calculate the dynamic load (F)

4)Calculate the endurance limit (F)

For safe design Fex> Fa

5)Calculate the wear load (F)

For safe design. F> Fa

If Fw< Fd then equate Fw=Fd

ie, d1bQK= Fd

Find the value of K and choose suitable material for gear and pinion using Table 12.16, Page No.

239 DDHB

Note: If in the problem, diameter is known and z is unknown, calculate m assuming suitable

value of z. After obtaining m, find the value of z again

BEVEL GEAR Page 8

DESIGN AND MODELING OF BEVEL GEAR

Advantages

This gear makes it possible to change the operating angle.

Differing of the number of teeth (effectively diameter) on each wheel

allows mechanical advantage to be changed. By increasing or decreasing the ratio of

teeth between the drive and driven wheels one may change the ratio of rotations

between the two, meaning that the rotational drive and torque of the second wheel

can be changed in relation to the first, with speed increasing and torque decreasing, or

speed decreasing and torque increasing.

Disadvantages

One wheel of such gear is designed to work with its complementary wheel and no

other.

Must be precisely mounted.

The shafts' bearings must be capable of supporting significant forces.

Application

The bevel gear has many diverse applications such as locomotives, marine applications,

automobiles, printing presses, cooling towers, power plants, steel plants, railway track inspection

machines, etc.

For examples, see the following articles on:

Bevel gears are used in differential drives, which can transmit power to two axles

spinning at different speeds, such as those on a cornering automobile.

Bevel gears are used as the main mechanism for a hand drill. As the handle of the

drill is turned in a vertical direction, the bevel gears change the rotation of the chuck

to a horizontal rotation. The bevel gears in a hand drill have the added advantage of

increasing the speed of rotation of the chuck and this makes it possible to drill a range

of materials.

Spiral bevel gears are important components on rotorcraft drive systems. These

components are required to operate at high speeds, high loads, and for a large number

of load cycles. In this application, spiral bevel gears are used to redirect the shaft

from the horizontal gas turbine engine to the vertical rotor. Bevel gears are also used

as speed reducers

BEVEL GEAR Page 9

DESIGN AND MODELING OF BEVEL GEAR

Conclusion

As can be seen, bevel gears come in various models based on the geometry of the gear plane

and the splines. The straight bevel gear is identical to the zero bevel gear except for the

shape of the spline or teeth. The hypoid bevel gear is identical to the bevel gear except for

the pitch surface of the latter. The adaptation of the geometric form is detected by what the

bevel gear is required for, and what its performance should be within a machine. As of now

we are solved the problem based on the values we design the bevel gear and using the

software anasis analysing the problem based on the result comparing weather the design is

safe or not

A pair of bevel gears transmitting 7.5 kW at 300 rpm is shown in Figure 1. The pressure angle is

20°. Determine the components of the resultant gear tooth force and draw a free-body diagram of

forces acting on the pinion and the gear

Given data

P=7.5KW, N=300rpm, α=20°,D1-=150mm, D2=200mm b=40mm

Using Eqn; find the torque

6 6

9.55∗10 (P) 9.55∗10 (7.5)

T=Mt= n

= 300

Mt=238750N-m =238750N-mm

BEVEL GEAR Page 10

DESIGN AND MODELING OF BEVEL GEAR

Using Eqn; find the delta 1 and 2

d1 150

tan δ1= d 2 = 200

∴ δ1=36.87°

Using Eqn; find the length

d1 150

L= 2sin δ 1 = 2sin 36.87 ° =125mm

Using relation given in Eqn 12.34(c)

L 125

K2= b = 40 =3.125

Using Eqn 12.349(b)

0.5 0.5

Dm=(1- K 2 )d1=(1- 3.125 )150=126

SOLID EDGE MODEL

BEVEL GEAR Page 11

DESIGN AND MODELING OF BEVEL GEAR

BEVEL GEAR Page 12

DESIGN AND MODELING OF BEVEL GEAR

BEVEL GEAR Page 13

You might also like

- Gear Guide1Document57 pagesGear Guide1dedemuamariskandar88100% (1)

- Parametric Modelling of Straight Bevel Gearing System and Analyze The Forces and Stresses by Analytical ApproachDocument5 pagesParametric Modelling of Straight Bevel Gearing System and Analyze The Forces and Stresses by Analytical ApproachseventhsensegroupNo ratings yet

- Bevel GearDocument13 pagesBevel GearADII 2701No ratings yet

- 2 TYPES OF GEARSDocument10 pages2 TYPES OF GEARSsilasally272No ratings yet

- Subject - Machine Design - : Topic - Bevel GearsDocument12 pagesSubject - Machine Design - : Topic - Bevel GearsRohit GhulanavarNo ratings yet

- Calculation of The Tooth Root Load Carrying Capacity of Beveloid GearsDocument10 pagesCalculation of The Tooth Root Load Carrying Capacity of Beveloid GearsdineshkshirsagarNo ratings yet

- CHP 3 Power Transmission GEARSDocument18 pagesCHP 3 Power Transmission GEARSabinmwangiNo ratings yet

- KWGDL KWGDLS AgdlDocument8 pagesKWGDL KWGDLS Agdlalin.butunoi865No ratings yet

- Bevel GearingDocument56 pagesBevel Gearingloosenut100% (4)

- Design of Spindle: 3 Credits (3-0-0) DR C K Biswas Prof., Dept of MEDocument26 pagesDesign of Spindle: 3 Credits (3-0-0) DR C K Biswas Prof., Dept of MEanurag100% (1)

- Tech Sec 8Document6 pagesTech Sec 8Nabende UmarNo ratings yet

- Gear Backlash - KHK Gear ManufacturerDocument7 pagesGear Backlash - KHK Gear Manufacturerprodn123No ratings yet

- Bevel Gear and Worm GearDocument10 pagesBevel Gear and Worm GearJAVIER, Reinnier Jhiro C.No ratings yet

- Me III II DMM II LnotesDocument33 pagesMe III II DMM II LnotesChandu MallamNo ratings yet

- Bevel Gears NBHDocument30 pagesBevel Gears NBHlemebad103No ratings yet

- The Basics of Gear Theory, Part 2: Bevel Gears: by The BookDocument7 pagesThe Basics of Gear Theory, Part 2: Bevel Gears: by The BookFelipe FernandesNo ratings yet

- Mod-3. Spur GearDocument18 pagesMod-3. Spur GearSharthak GhoshNo ratings yet

- ASSAG Cylkro (FACE) Gear Mounting InstructionsDocument6 pagesASSAG Cylkro (FACE) Gear Mounting InstructionscjdengateNo ratings yet

- Helical Gears: DefinitionDocument29 pagesHelical Gears: DefinitionMuthuvel MNo ratings yet

- Bev Gear Design PDFDocument5 pagesBev Gear Design PDFMawan BentzNo ratings yet

- Abstract For Bevel Gear Operated Bi-CycleDocument3 pagesAbstract For Bevel Gear Operated Bi-CycleJagan JJNo ratings yet

- Bevel GearDocument13 pagesBevel Gearsuriya06232No ratings yet

- Bisht-Awasthi2021 Chapter AnalysisOfE-GlassFiberWheelRimDocument13 pagesBisht-Awasthi2021 Chapter AnalysisOfE-GlassFiberWheelRimLtat KøükøüNo ratings yet

- Gear Backlash - KHK GearsDocument7 pagesGear Backlash - KHK Gearsadhytia farma arsalNo ratings yet

- Profile Shift of Involute Gears - Tec-ScienceDocument17 pagesProfile Shift of Involute Gears - Tec-ScienceManoj SinghNo ratings yet

- Introduccion A Los EngranajesDocument22 pagesIntroduccion A Los EngranajesMarco A VelascoNo ratings yet

- 1.2 Types-of-Gear TechnicalData KGSTOCKGEARSDocument5 pages1.2 Types-of-Gear TechnicalData KGSTOCKGEARSraj6062No ratings yet

- Ball Bearing DesignDocument34 pagesBall Bearing DesignKamal UddinNo ratings yet

- Design of Screw JackDocument39 pagesDesign of Screw Jackshreedharkolekar0% (1)

- 3 TYPES OF GEARS & Gear TrainsDocument17 pages3 TYPES OF GEARS & Gear TrainsabinmwangiNo ratings yet

- Bevel Gear CalcsDocument11 pagesBevel Gear Calcsmanish_umdNo ratings yet

- 6th SEM REPORTDocument29 pages6th SEM REPORTRaish KhanjiNo ratings yet

- DME One TwoDocument13 pagesDME One TwoBashu Dev SanjelNo ratings yet

- Section 8 Bevel GearingDocument5 pagesSection 8 Bevel GearingLiniel de JesusNo ratings yet

- Bevel Gears GeometryDocument12 pagesBevel Gears GeometryGabriel IulianNo ratings yet

- Gear Backlash: 6.1 Types of BacklashesDocument13 pagesGear Backlash: 6.1 Types of BacklashesRamazan MERALNo ratings yet

- Program: B.Tech Subject Name: Manufacturing Technology Subject Code: ME-405 Semester: 4thDocument12 pagesProgram: B.Tech Subject Name: Manufacturing Technology Subject Code: ME-405 Semester: 4thROHIT MEHRANo ratings yet

- Power Transmitting ElementsDocument20 pagesPower Transmitting ElementsAsma Khan100% (1)

- Chapter 5Document12 pagesChapter 5Fadhiran Yahya0% (1)

- For The Gear-Like Device Used To Drive A Roller Chain, See - This Article Is About Mechanical Gears. For Other Uses, SeeDocument25 pagesFor The Gear-Like Device Used To Drive A Roller Chain, See - This Article Is About Mechanical Gears. For Other Uses, SeeNasir HadranNo ratings yet

- E92 M3 Chassis & Suspension - SMDocument16 pagesE92 M3 Chassis & Suspension - SMAlbert HangsingNo ratings yet

- Prepare Report On Gear and Its TerminologyDocument12 pagesPrepare Report On Gear and Its TerminologyMadhuri TelangeNo ratings yet

- Unit-4 Bevel GearsDocument27 pagesUnit-4 Bevel GearsMarthande50% (2)

- Unit 3 - 3 Design of Bevel GearsDocument28 pagesUnit 3 - 3 Design of Bevel GearsY20me135 V.LokeshNo ratings yet

- Hellical GearsDocument3 pagesHellical GearsLeon987456321No ratings yet

- Design of Transmission System Unit IIIDocument57 pagesDesign of Transmission System Unit IIIRaj MohanNo ratings yet

- Bevel GearDocument28 pagesBevel Gearmahesh kitturNo ratings yet

- Mod 3 - Helical GearsDocument18 pagesMod 3 - Helical GearsAmith PrinceNo ratings yet

- KTM Unit-7Document76 pagesKTM Unit-7pateldhruv707No ratings yet

- Screw - Design of Screws, Fasteners and PowerDocument39 pagesScrew - Design of Screws, Fasteners and PowerAljen MojeNo ratings yet

- Bevel and Worm GearsDocument6 pagesBevel and Worm Gearsapi-245463593No ratings yet

- Lecture Notes 2Document7 pagesLecture Notes 2Edwin kinyuaNo ratings yet

- Unit 5Document44 pagesUnit 5Manick ThiruNo ratings yet

- Lecture 2 5 JanDocument35 pagesLecture 2 5 JanSaurabh KNo ratings yet

- Mod-3B-Helical GearDocument2 pagesMod-3B-Helical GearSharthak GhoshNo ratings yet

- Ch-5 Toothed Gears - 1Document40 pagesCh-5 Toothed Gears - 1Samar GuptaNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsFrom EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo ratings yet

- Kinematic Differential Geometry and Saddle Synthesis of LinkagesFrom EverandKinematic Differential Geometry and Saddle Synthesis of LinkagesNo ratings yet

- JEE Main and Advanced Combined PDF Chapter Wise Class XI PDFDocument148 pagesJEE Main and Advanced Combined PDF Chapter Wise Class XI PDFexponential spiralNo ratings yet

- Sheet 1 Solution SPC 307Document15 pagesSheet 1 Solution SPC 307Ercan Umut DanışanNo ratings yet

- UntitledDocument8 pagesUntitledJolly James KNo ratings yet

- Non Aq SolventsDocument24 pagesNon Aq SolventsShamil Gada100% (1)

- 3D Holographic Projection Technology: Group NameDocument15 pages3D Holographic Projection Technology: Group NameArvind KumawatNo ratings yet

- Acti9 Isobar P - B Type - SEA9BPN12514S8Document3 pagesActi9 Isobar P - B Type - SEA9BPN12514S8Prit ShahNo ratings yet

- Extra Quiz CT2-1Document3 pagesExtra Quiz CT2-1Punitha ShanmugamNo ratings yet

- CEN444 HW4 Sila Sarochananjeen 6005490Document3 pagesCEN444 HW4 Sila Sarochananjeen 6005490MAY THWE HTUNNo ratings yet

- Laney RB4 - Manual - MLDocument24 pagesLaney RB4 - Manual - MLNicolas AlbertiNo ratings yet

- FIDPDocument7 pagesFIDPMicheal CarabbacanNo ratings yet

- SM Lec 11Document14 pagesSM Lec 11haad.malik007No ratings yet

- EUV Engineering Test Stand EUV EngineeriDocument22 pagesEUV Engineering Test Stand EUV EngineeriMuhammad Hassan BaigNo ratings yet

- Design of Prestressed Precast Pile Splice Using Glass Fiber Reinforced Polymer (GFRP) DowelsDocument12 pagesDesign of Prestressed Precast Pile Splice Using Glass Fiber Reinforced Polymer (GFRP) DowelsPANKAJ GUPTANo ratings yet

- MVD500 4701 A Rev - 01Document19 pagesMVD500 4701 A Rev - 01zinouNo ratings yet

- Wepik Exploring Chord Properties Unveiling The Intricacies of CirclesDocument10 pagesWepik Exploring Chord Properties Unveiling The Intricacies of CirclesRishabh MalhotraNo ratings yet

- Din 115 A, C, Din 116Document12 pagesDin 115 A, C, Din 116Roby MastreNo ratings yet

- Lab 3-MoveraDocument6 pagesLab 3-MoveraMerlynn Taha MoveraNo ratings yet

- VC CatalogDocument36 pagesVC CatalogRazvan SasuNo ratings yet

- EMI60HER 220 V 50-60 HZ 1Document4 pagesEMI60HER 220 V 50-60 HZ 1Walace AlexandreNo ratings yet

- Kaplan Turbine.Document13 pagesKaplan Turbine.Shravani GogawaleNo ratings yet

- Exploration: Multiplying Integers: Two Sets of Three Positive ItemsDocument2 pagesExploration: Multiplying Integers: Two Sets of Three Positive ItemsJuvy Anne SoqueNo ratings yet

- Single Phase Earth-Faults Solutions Using Reclosers To Meet The Demands of The Modern NetworkDocument7 pagesSingle Phase Earth-Faults Solutions Using Reclosers To Meet The Demands of The Modern NetworkSaraMuzaffarNo ratings yet

- Basic Mechanical Engineering MCQ PDF Part 1 - All Exam ReviewDocument17 pagesBasic Mechanical Engineering MCQ PDF Part 1 - All Exam ReviewsabilashNo ratings yet

- JU-88A-1 Tech BriefDocument40 pagesJU-88A-1 Tech BriefKitz100% (1)

- 40 International Chemistry Olympiad: Preparatory ProblemsDocument104 pages40 International Chemistry Olympiad: Preparatory ProblemsLê Hoàng MinhNo ratings yet

- Use of Mobile Unit Substations Muss at Ontario HydroDocument7 pagesUse of Mobile Unit Substations Muss at Ontario HydroSudhir RavipudiNo ratings yet

- Interventional Radiology: The Principles of Subtraction Are Based On The FollowingDocument4 pagesInterventional Radiology: The Principles of Subtraction Are Based On The FollowingAinne Joy DimapilisNo ratings yet

- 07men LCF12560 005 - NoctrlDocument34 pages07men LCF12560 005 - NoctrlCHAMOUXNo ratings yet

- (Elaydi, Saber N) Discrete Chaos, Second EditionDocument441 pages(Elaydi, Saber N) Discrete Chaos, Second EditionMarlene FreitasNo ratings yet

- Ns2-Dh01-P0zen-140005 - Itp For Lighting & Small Power System - Rev.0Document9 pagesNs2-Dh01-P0zen-140005 - Itp For Lighting & Small Power System - Rev.0Anh VàngNo ratings yet