CBLM Smaw Ncii 2023com1

CBLM Smaw Ncii 2023com1

Uploaded by

Marco ArellanoCopyright:

Available Formats

CBLM Smaw Ncii 2023com1

CBLM Smaw Ncii 2023com1

Uploaded by

Marco ArellanoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

CBLM Smaw Ncii 2023com1

CBLM Smaw Ncii 2023com1

Uploaded by

Marco ArellanoCopyright:

Available Formats

Sector:

COMPETENCY BASED

METALS LEARNING MATERIAL

AND ENGINEERING

Qualification title:

SHIELDED METAL ARC WELDING (SMAW) NC II

Unit of Competency:

APPLY SAFETY PRACTICES

Module Title:

APPLYING SAFETY PRACTICES

SAN PEDRO TECHNOLOGICAL INSTITUTE

HOW TO USE THIS COMPETENCY- BASED LEARNING

MATERIALS

Welcome!

The unit of competency, " APPLY SAFETY PRACTICES ", is

one of the competencies of SMAW NCII, a course which comprises

the knowledge, skills and attitudes required for a Welder.

The module, APPLYING SAFETY PRACTICES, contains

training materials and activities related to Welding.

In this module, you are required to go through a series of

learning activities in order to complete each learning outcome. In

each learning outcome are Information Sheets, Self-Checks, Task

Sheets and Job Sheets. Follow and perform the activities on your

own. If you have questions, do not hesitate to ask for assistance

from your trainor.

Remember to:

Read information sheets and complete self-checks. Suggested

references are included to supplement the materials provided in

this module.

Perform the Task Sheets and Job Sheets until you are

confident that your outputs conform with the Performance

Criteria Checklist that follows every sheet.

Submit outputs of the Task Sheets and Job Sheets.

When you feel confident that you have had sufficient practice,

ask your trainer to evaluate you. The results of your assessment

will be recorded in your Progress Chart and Accomplishment

Chart.

You need to complete this module before you can perform the

module on .

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 2 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

SMAW NCII

COMPETENCY-BASED LEARNING MATERIALS

List of Common Competencies

No. Unit of Competency Module Title Code

APPLY SAFETY APPLYING SAFETY MEE721201

1.

PRACTICES PRACTICES

INTERPRETING MEE721202

INTERPRET DRAWINGS

2. DRAWINGS AND

AND SKETCHES

SKETCHES

PERFORMING

PERFORM INDUSTRY MEE721203

3. INDUSTRY

CALCULATIONS

CALCULATIONS

CONTRIBUTE TO CONTRIBUTING TO MEE721204

4.

QUALITY SYSTEM QUALITY SYSTEM

MEE721205

5. USE HAND TOOLS USING HAND TOOLS

PREPARE WELD PREPARING WELD MEE721206

6.

MATERIALS MATERIALS

SETUP WELDING SETTING UP WELDING MEE721207

7.

EQUIPMENT EQUIPMENT

FIT UP WELD FITTING UP WELD MEE721208

8.

MATERIALS MATERIALS

MEE721209

9. REPAIR WELDS REPAIRING WELD

SUMMARY OF LEARNING OUTCOMES

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 3 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

QUALIFICATION: SMAW NCII

UNIT OF COMPETENCY: APPLY SAFETY PRACTICES

MODULE TITLE: APPLYING SAFETY PRACTICES

MODULE DESCRIPTOR: This module covers safety practices applied in the

workplace.

NOMINAL DURATION: 4hrs

LEARNING OUTCOMES:

At the end of this module you MUST be able to:

1. Identify hazardous area

2. Use personal protective clothing and devices

3. Perform safe handling of tools, equipment and materials

4. Perform first aid

5. Use Fire extinguisher

ASSESSMENT CRITERIA:

1. Hazards are identified correctly in accordance with OHS principles.

2. Safety signs and symbols are identified and adhered to.

3. Appropriate protective clothing and devices correctly selected and

used in accordance with OHS requirements or industry/company

policy.

4. Safety procedures for pre-use check and operation of tools and

equipment followed in accordance with industry/ company policies.

5. Tools, equipment and materials handled safely in accordance with

OHS requirements and industry/company policies.

6. First aid treatment of injuries are carried out according to

recommended procedures.

7. Fire extinguisher selected and operated correctly according to the type

of fire.

DETAILS OF LEARNING OUTCOME

LEARNING OUTCOME 1.1 IDENTIFY HAZARDOUS AREA

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 4 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

CONTENTS:

1. Hazard to be avoided in welding

2. Welding safety signs and symbols

3. Occupational safety standards and enterprise safety policies.

ASSESSMENT CRITERIA:

1. Hazards are identified correctly in accordance with OHS

procedures.

2. Safety signs and symbols are identified and adhered to in

accordance with workplace safety procedure.

CONDITIONS:

The students/ trainee should be provided with:

•Safety sign and symbols

•Instructional materials

-Reference book

-Learning modules/manuals

-Safety standards manual

-Enterprise safety policies/guidelines

METHODOLOGIES

Lecture/demonstrations

Self pace learning

Group discussion

ASSESSMENT METHODS

1. Written/oral

2. Direct observation

3. Interview

Learning Experiences

Learning Outcome 1

Learning Activities Special Instructions

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 5 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

Information Sheet 1.1-1

(Hazard to be avoided in welding)

Learning Objectives:

After reading this INFORMATION SHEET, YOU MUST be able to know:

1.Hazards are identified correctly in accordance with OHS procedures.

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 6 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

2.Safety signs and symbols are identified and adhered to in

accordance with workplace safety procedure.

To achieve safe working conditions in the metal fabrication and

welding industry, all personnel should be able to recognise the hazards

which apply to their particular occupation. Welding operators must also

know the correct operating procedures for the equipment.

An operator can be subjected to many safety hazards associated with

the industry. As with any other industrial worker, they may be injured

through incorrect lifting practices, falling or tripping, or incorrect use of

hand tools and machines. The operator will also encounter particular

hazards associated with welding.

A clean, tidy workplace, free from combustible materials, is an

essential requirement for the safety of welding personnel.

Additionally, others working in the vicinity of welding operations are

at risk from hazards such as electrocution, fumes, radiation, burns or flying

slag and noise. They too must be protected if their health and safety is not

to be put at risk.

TYPES OF HAZARDS

1. Electric Shock

2. Fumes

3. Radiation

4. Fire And Explosion

5. Burns

The major hazards associated with arc welding

1. ELECTRIC SHOCK

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 7 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

Electric shock may only cause a minor tingling sensation or it may cause

muscle spasms, or paralysis and this may cause an operator to grip onto the

source of electricity. In the worst case scenario this may contribute to the

welding operator’s death.

In arc welding processes a number of potential electrocution sources can be

identified.

The primary input lead is either 415 V or 240 V and should never be

tampered with, altered, or repaired except by a licensed electrician. The

output circuit of an arc welder is controlled at a ‘safe voltage’ but this safe

voltage can also kill if given ideal conditions. The ancillary circuits of most

welders are also at a safe voltage of either 32 V or 24 V, although some

machine manufacturers also use 110 V on older control circuits.

The prevention of electrical shock from welding equipment relies on three

major principles.

1. That the OCV(Open Circuit Voltage) of welding machines is low

enough to prevent easy passage of current through the body.

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 8 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

Although arc welding machines are capable of supplying a wide range of

current, they generally operate within the following voltage range:

Arc voltage: 16–36 V

To maximise safety for the welding operator, OCV is restricted to:

Maximum OCV for AC machines is 80 V

Maximum OCV for DC machines is 110 V

2. That electrical resistance in the welding circuit is low. The current will

take the path of least resistance.

Maintain insulation on leads and handpiece Avoid moisture and use

insulating gloves

3. That the current path is confined to the welding circuit.

Don’t touch live parts

Don’t put body in current path

To avoid electric shock, the following practices are highly

recommended.

Dry gloves in good repair should

be worn when handling equipment,

particularly when changing

electrodes.

Footwear should be insulating, dry,

and in good condition.

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 9 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

Welding equipment should be in

good repair and fully insulated.

2. FUMES

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 10 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

DETAILS OF LEARNING OUTCOME

LEARNING OUTCOME 1.2 USE PROTECTIVE CLOTHING AND DEVICES

CONTENTS:

1. Personal protective equipment (PPE) for different welding operations

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 11 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

2. Proper uses of different types of personal protective equipment (PPE)

3. Occupational safety standards and enterprise safety policies.

ASSESSMENT CRITERIA:

1. Personal protective clothing/equipment (PPE) identified as per job

requirements

2. Proper wearing of PPE are properly observed in accordance with

workplace safety policies.

3. PPE conformed with the approved occupational safety standards.

CONDITIONS:

1. Personal protective equipment (PPE)

- Hard hat

- Safety shoes

- Gloves

- Goggles

- Welder apron

2. Instructional materials for:

- Reference book

- Learning modules/manuals

- Safety standards

- Enterprise safety policies/guidelines

METHODOLOGIES

• Lecture/demonstrations

• Self pace learning

• Group discussion

ASSESSMENT METHODS

• Written/oral

• Direct observation

• Interview

Information Sheet 1.2-1

(Personal Protective Equipment (PPE) for different welding operations)

Learning Objectives:

After reading this INFORMATION SHEET, YOU MUST be able to know:

1.Personal protective clothing/equipment (PPE) identified as per job

requirements

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 12 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

2.Proper wearing of PPE are properly observed in accordance with workplace

safety policies.

3.PPE conformed with the approved occupational safety standards.

Welding - Personal Protective Equipment

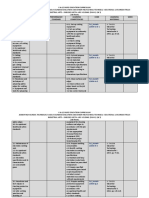

Body Part Equipment Illustration Reason

Eyes and Welding Protects from:

face helmet, hand radiation

shield, or

goggles flying

particles,

debris

hot slag,

sparks

intense

light

irritation

and

chemical

burns

Wear fire

resistant head

coverings under

the helmet where

appropriate

Lungs Respirators Protects against:

(breathing)

fumes and

oxides

Exposed skin Fire/Flame Protects against:

(other than resistant heat, fires

feet, hands, clothing and

and head) aprons burns

radiation

Notes: pants

should not have

cuffs, shirts

should have flaps

over pockets or be

taped closed

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 13 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

Ears-hearing Ear muffs, Protects against:

ear plugs

noise

Use fire resistant

ear muffs where

sparks or splatter

may enter the

ear, rather than

plugs.

Feet and Boots, gloves Protects against:

hands electric

shock

heat

burns

fires

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 14 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 15 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

DETAILS OF LEARNING OUTCOME

LEARNING OUTCOME 1.3 PERFORM SAFE HANDLING OF TOOLS,

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 16 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

EQUIPMENT AND MATERIALS

CONTENTS:

1. Pre-use inspection and checking procedure

2. Safe handling of tools, equipment and materials

3. Equipment and power tools orientation and familiarization

4. Workplace Occupational Health and Safety procedures

ASSESSMENT CRITERIA:

1. Pre-use checking and inspection of tools and equipment are

conducted in accordance with industry/ company policies.

2. Safe handling of tools, equipment and materials are properly

observed in accordance with OHS requirements and industry/ company

policies.

3. Safety label and tag of tools and equipment are strictly followed in

accordance with industry/ company policies.

CONDITIONS:

The students/ trainee should be provided with:

• Equipment/accessories

- Hard hat

- Safety shoes

- Gloves

- Goggles

- Welder apron

• Instructional materials:

- Reference book

- Learning modules/manuals

- Safety standards

- Enterprise safety policies/guidelines

METHODOLOGIES

• Lecture/demonstrations

• Self pace learning

• Group discussion

ASSESSMENT METHODS

• Written/oral

• Direct observation

• Interview

DETAILS OF LEARNING OUTCOME

LEARNING OUTCOME 1.4 PERFORM FIRST AID

CONTENTS:

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 17 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

1. Different types of injuries

2. First aid treatment procedure

3. Emergency hotline number and offices

4. Proper handling of injured individual

ASSESSMENT CRITERIA:

1. First aid treatment of injuries are carried out according to

recommended procedures

2. Emergency hotline and proper authority are accessed and contacted

in accordance with workplace procedure.

CONDITIONS:

The students/ trainee should be provided with:

•Equipment

-First aid kit (different types)

-Oxygen

-Stretcher

-Medicine

•Learning materials

-Video tape, CD’s, transparencies

•Directory hotline number and offices

METHODOLOGIES

• Lecture/demonstrations

• Self pace learning

• Group discussion

ASSESSMENT METHODS

• Written/oral

• Direct observation

• Interview

• Demonstration

DETAILS OF LEARNING OUTCOME

LEARNING OUTCOME 1.5 USE FIRE EXTINGUISHER

CONTENTS:

1. Types of firefighting equipment

2. Types of fire extinguishers

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 18 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

3. Fire hoses

4. Fire hydrants

5. Sources/causes of fires

6. Proper use of firefighting equipment

ASSESSMENT CRITERIA:

1. Fire fighting equipment identified according to types/source of fires.

2. Use of fire fighting equipment demonstrated in accordance with

manufacturer’s instructions.

3. Used fire fighting equipment and accessories are recorded/reported

for replacement/refill in accordance with enterprise approved safety

regulations.

CONDITIONS:

The students/ trainee should be provided with:

•Equipment

-Fire extinguishers (different types)

-Fire hydrants

-Video players/monitors

•Learning materials

-Types of fires/sources

-Types of fire fighting equipment and its operations

-Manuals on fire protection regulations

-Video tape, CD’s, transparencies

-Report cards/checklist

METHODOLOGIES

• Lecture/demonstrations

• Self pace learning

• Group discussion

ASSESSMENT METHODS

• Written/oral

• Direct observation

• Interview

• Demonstration

Information Sheet 1.5-1

(TYPES OF FIREFIGHTING EQUIPMENT)

Learning Objectives:

After reading this INFORMATION SHEET, YOU MUST be able to know:

1.Fire fighting equipment identified according to types/source of fires.

2.Use of fire fighting equipment demonstrated in accordance with

manufacturer’s instructions.

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 19 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

3.Used fire fighting equipment and accessories are recorded/reported

for replacement/refill in accordance with enterprise approved safety

regulations.

There are many different types of fire safety equipment. Each device is

designed specifically to deal with the different classes of fire in a range of

environments. If you’re struggling to figure out which fire safety devices you

need in your building, take a look at the following range of equipment.

Once you have an idea of the fire safety measures in your building, be

sure to take a look at our fire equipment service options. We test and

inspect a wide range of equipment – contact us today to request our

services.

1. Fire Extinguishers

Most buildings contain a variety of hand-held firefighting equipment.

This range of equipment is designed to help contain small fires before they

spread and become too large to control. Portable fire extinguishers are

available with a number of different extinguishing agents to help you combat

a flame. A portable extinguisher may contain the following substance:

water

foam

dry powder

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 20 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

CO2

wet chemical

If you would like to know which fire extinguisher is designed for which

type of fire, check out our other blog post.

2. Fire Blankets

Fire blankets are designed to smother class F fires. That means flame

that is fuelled by cooking oils and fats. Naturally, fire blankets are installed

in kitchen environments, where the chance of a class F fire is the highest.

3. Fire Hose Reels

Fire hose reels are ideal for extinguishing class A fires. That is fires

that are fuelled by paper, rubber, wood, and other non-conductive materials.

As fire hose reels discharge water, they cannot be used to combat electrical

fires. There are other types of fire safety equipment designed to deal with

electrical fires – namely C02 fire extinguishers.

4. Signage

All fire equipment should be accompanied by standard signage. This

helps users identify the location and type of equipment they can access in

an emergency. There is a range of different regulations when it comes to fire

safety signage. Each piece of equipment is accompanied by an Australian

standard for maintenance and installation. The corresponding guide will

contain more information about signage and where it should be located.

5. Sprinklers

When it comes to the design, installation, and maintenance of fire

sprinkler systems in Australia, there are a number of standards that could

apply to your building. The following standards will influence the

implementation of fire sprinklers in your space:

AS 2118.6:2012 Standard for Automatic fire sprinkler systems

Combined sprinkler and hydrant systems in multistorey buildings

AS 2118.1:2017 Standard for Automatic fire sprinkler systems

General systems

AS 1905.1:2005 Standard for Components for the protection of

openings in fire-resistant walls Fire-resistant doorsets

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 21 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

AS 1760:2105 Fire detection, warning, control and intercom systems –

System design, installation and commissioning Fire

6. First Aid Kits

They might not be the first thing to spring to mind when you think of

the different types of fire safety equipment, but first aid kits are essential in

the aftermath of a fire. Having adequate first aid measures on hand will help

with minor injuries sustained during a fire. It’s also a matter of compliance –

as a business owner or manager, you need to provide your staff members

with first aid.

7. Emergency & Exit Signs

Whilst firefighting equipment is important during an emergency when

a flame is out of control, you need to evacuate a building. Emergency and

exit signs will help to provide a clear path to an exit during a fire. Having

clear signage and lighting will help contain panic and guide your team

members to an appropriate exit in time. Emergency and exit lights need to

be maintained according to the AS 2293:2005 (Set) standard for Emergency

escape lighting and exit signs.

8. Smoke Alarms

Some types of fire safety equipment are designed for detection. Smoke

alarms should be installed in all commercial and domestic buildings. If you

are a landlord, the legislation for smoke alarm installation varies from state

to state. You can find more information about your obligations on your state

government website.

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 22 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

Date Developed: Document No. Common 1

SMAW NCII March 2023

Issued by:

Date Revised: Page 23 of 100

APPLY SAFETY

PRACTICES Developed by: Revision #

Marco B. Arellano

You might also like

- DLL - Smaw - Q4 - W1Document7 pagesDLL - Smaw - Q4 - W1Renato Reyes Jr.No ratings yet

- Tesco 15 lp14 PDFDocument7 pagesTesco 15 lp14 PDFbtec1005mNo ratings yet

- Job Description FormDocument2 pagesJob Description Formkay_1001No ratings yet

- Module Title: Learning Outcomes:: Unit of Competency: Practice Occupational Health and Safety ProceduresDocument2 pagesModule Title: Learning Outcomes:: Unit of Competency: Practice Occupational Health and Safety ProceduresArman SantiagoNo ratings yet

- Smaw Lesson Plan DemoDocument5 pagesSmaw Lesson Plan DemoEUNICE RAMAYNo ratings yet

- Smaw 11 LP Feb. 21 2019Document2 pagesSmaw 11 LP Feb. 21 2019ronald curayagNo ratings yet

- Ia Smawnci Shs q1 Las3 FinalDocument7 pagesIa Smawnci Shs q1 Las3 FinalWiljhon Espinola JulapongNo ratings yet

- Smaw NC Ii Trainees Evaluation FormDocument2 pagesSmaw NC Ii Trainees Evaluation FormJulius Balonsong BaldelovarNo ratings yet

- Basic Competencies of SMAWDocument11 pagesBasic Competencies of SMAWRubin vlogsNo ratings yet

- CBC SMAW NCII Blended INTEGRATION 2023Document66 pagesCBC SMAW NCII Blended INTEGRATION 2023thomassolon0912No ratings yet

- Smaw Module 2ndQ 1stDocument6 pagesSmaw Module 2ndQ 1stAdoracion Sales HugoNo ratings yet

- Smaw-Dlp Lo6 6 1 04 14 23Document5 pagesSmaw-Dlp Lo6 6 1 04 14 23Cacho Jane RoselleNo ratings yet

- CBLM SMAWNCI HazelDocument36 pagesCBLM SMAWNCI HazelAnnie Mae Dumot Arcangeles100% (1)

- CBLM SMAW NC II GMTDocument68 pagesCBLM SMAW NC II GMTmikel SeritoNo ratings yet

- September 11-15, 2023 - (Grade 11)Document3 pagesSeptember 11-15, 2023 - (Grade 11)MJ Lim FalcisNo ratings yet

- TVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsDocument9 pagesTVL-SMAW 12 - Week 4 - Lesson 1 - Concept of Welding Codes and StandardsNelPalalonNo ratings yet

- Sto. Niño 3 Skills Training and Assessment CenterDocument19 pagesSto. Niño 3 Skills Training and Assessment CenterEmmerNo ratings yet

- Smaw Work Immersion PortfolioDocument33 pagesSmaw Work Immersion PortfolioAl Patrick ChavitNo ratings yet

- Idea Lesson Smaw NC Ii March 13 To 17, 2023Document11 pagesIdea Lesson Smaw NC Ii March 13 To 17, 2023Emma D. Bentonio100% (2)

- 2nd Sem DLP 23,24 SMAW 11Document16 pages2nd Sem DLP 23,24 SMAW 11Clare GarcesNo ratings yet

- 21st Century CBC SMAW NC IIDocument53 pages21st Century CBC SMAW NC IIvalcyrusNo ratings yet

- Interpret Drawings and SketchesDocument14 pagesInterpret Drawings and SketchesArnel TañecaNo ratings yet

- 1st Periodical Test in Smaw11Document2 pages1st Periodical Test in Smaw11Noli ParolNo ratings yet

- Smaw 11 Module 1Document18 pagesSmaw 11 Module 1Francis Rico Mutia RufonNo ratings yet

- Module On TLE11 Welding Part 4 of 4Document34 pagesModule On TLE11 Welding Part 4 of 4barry bonzoNo ratings yet

- DLP - Final-Demo - Weld DefectsDocument11 pagesDLP - Final-Demo - Weld DefectsTrecita BacoNo ratings yet

- Data Gathering Instrument For Trainees CharacteristicsDocument3 pagesData Gathering Instrument For Trainees CharacteristicsmariettaNo ratings yet

- CBC Smaw NC 1 - 2020 E-LearningDocument80 pagesCBC Smaw NC 1 - 2020 E-LearningAit BiñanNo ratings yet

- Qualification: CARPENTRY NC II Unit of Competency: Participating in Workplace Communication School: GB Construction Training Philippines IncDocument164 pagesQualification: CARPENTRY NC II Unit of Competency: Participating in Workplace Communication School: GB Construction Training Philippines IncYeng LugtuNo ratings yet

- TLE - IA - Shielded Metal Arc Welding SMAWGrades 7-10 04.06.2014 PDFDocument18 pagesTLE - IA - Shielded Metal Arc Welding SMAWGrades 7-10 04.06.2014 PDFRenante Deseo100% (1)

- SHS - SLK - Industrial Arts Smaw Basic Set Up Fo Smaw MachineDocument20 pagesSHS - SLK - Industrial Arts Smaw Basic Set Up Fo Smaw Machineiammhon100% (1)

- TM1 WDDocument124 pagesTM1 WDJohn Wilner DirectoNo ratings yet

- Module 3 Solving or Addressing Genral Workplace ProblemsDocument48 pagesModule 3 Solving or Addressing Genral Workplace ProblemsJa Castañeda PaggaoNo ratings yet

- Training Activity Matrix SMAW NC II COMMONDocument9 pagesTraining Activity Matrix SMAW NC II COMMONEugenio Mates Jr.No ratings yet

- Session PlanDocument4 pagesSession PlanJohn BuenaaguaNo ratings yet

- Technology and Livelihood Education: SMAW NCI-Module 5 Control Hazards and RisksDocument24 pagesTechnology and Livelihood Education: SMAW NCI-Module 5 Control Hazards and RisksMariechile SuicoNo ratings yet

- 2nd Quarter Summative SMAW NC2Document2 pages2nd Quarter Summative SMAW NC2emmabentonioNo ratings yet

- IDEA LESSON SMAW NC II September 11-15, 2023 OkDocument7 pagesIDEA LESSON SMAW NC II September 11-15, 2023 OkEmma D. BentonioNo ratings yet

- COT 4thDocument2 pagesCOT 4thMichael Angelo LumanogNo ratings yet

- Trainees Record Book (TRB)Document4 pagesTrainees Record Book (TRB)Edward LyleNo ratings yet

- A. FIT UP WELD MATERIALS LO 3. Weld Butt Joint (Open) in Flat and Horizontal PositionDocument2 pagesA. FIT UP WELD MATERIALS LO 3. Weld Butt Joint (Open) in Flat and Horizontal PositionJezreel V Sayson100% (1)

- Training Regulations: Shielded Metal Arc Welding (Smaw) NC IiDocument61 pagesTraining Regulations: Shielded Metal Arc Welding (Smaw) NC IiAlberto T. ToledoNo ratings yet

- Content Content Standard Performance Standard Learning Competencies Code Learning Materials Week Prepare Weld Materials (WM) LO 1. Set-Up Cutting EquipmentDocument9 pagesContent Content Standard Performance Standard Learning Competencies Code Learning Materials Week Prepare Weld Materials (WM) LO 1. Set-Up Cutting Equipmentlip100% (1)

- Tle Smaw q4 Mod11 v3Document28 pagesTle Smaw q4 Mod11 v3Lyn VallesNo ratings yet

- I. Objectives:: Detailed Lesson PlanDocument3 pagesI. Objectives:: Detailed Lesson PlanjovelNo ratings yet

- Week 7Document3 pagesWeek 7ABEGRACE LIG-ANGNo ratings yet

- Learning Guide: Ethiopian TVET-SystemDocument20 pagesLearning Guide: Ethiopian TVET-SystemOliver Sy100% (1)

- SESSION PLAN IN SMAW PLATES Michael P IdosDocument4 pagesSESSION PLAN IN SMAW PLATES Michael P Idosellton john pilar100% (1)

- TM1 Dennis CrispinoDocument113 pagesTM1 Dennis Crispinoprofjay2023No ratings yet

- SMAW (3) EditedDocument5 pagesSMAW (3) EditedPrince Neil SeraphimNo ratings yet

- Trainees Record Book NCIIDocument3 pagesTrainees Record Book NCIIlara joey datoyNo ratings yet

- Session Plan Smaw NC IDocument7 pagesSession Plan Smaw NC Igillian marbebeNo ratings yet

- Q2-01, Smaw Teacher's Made LMTDocument8 pagesQ2-01, Smaw Teacher's Made LMTFelix MilanNo ratings yet

- Self - Assessment Guide: Shielded Metal Arc Welding (Smaw) NC Ii Weld Carbon Steel Plates and Pipes Using SMAWDocument1 pageSelf - Assessment Guide: Shielded Metal Arc Welding (Smaw) NC Ii Weld Carbon Steel Plates and Pipes Using SMAWJuliusOuanoNo ratings yet

- Ppe - CotDocument22 pagesPpe - Cotronald curayag100% (1)

- Grade 11 SMAW - q2 w6Document7 pagesGrade 11 SMAW - q2 w6Jhon Vernie Reponte GambitoNo ratings yet

- Shop Lay Out (SMAW NC I)Document1 pageShop Lay Out (SMAW NC I)Marinduque Technical Training Center Inc MTTCINo ratings yet

- Shielded Metal Arc Welding Nc2 Perform Root Pass 8 Hours Study GuideDocument3 pagesShielded Metal Arc Welding Nc2 Perform Root Pass 8 Hours Study GuideMarwin NavarreteNo ratings yet

- TVL-SMAW 12 - Week 5 - Lesson 2 - Acceptable Criteria For Completed WeldsDocument10 pagesTVL-SMAW 12 - Week 5 - Lesson 2 - Acceptable Criteria For Completed WeldsNelPalalonNo ratings yet

- CBC - Smaw NC IDocument56 pagesCBC - Smaw NC ILeo Loquinario Jr.No ratings yet

- Form 4.2 Evidence of Current CompetenciesDocument5 pagesForm 4.2 Evidence of Current CompetenciesvayaNo ratings yet

- CBLM SMAW NC I 1 Common CompetencyDocument58 pagesCBLM SMAW NC I 1 Common CompetencyESTRELLA PALER100% (2)

- Nodejs Mock Test IIIDocument6 pagesNodejs Mock Test IIIramanareddyNo ratings yet

- Zimbra Admin GuideDocument238 pagesZimbra Admin GuideКирилПановNo ratings yet

- Ese 2014Document33 pagesEse 2014Rahul SharmaNo ratings yet

- RetroGameProgramming V 12Document126 pagesRetroGameProgramming V 12Imand8249No ratings yet

- 07human Rights and Peace Educ - Philippines PDFDocument10 pages07human Rights and Peace Educ - Philippines PDFjosemiguelreyesNo ratings yet

- Page Text Book/ Activity Book: 13: Ex: Once, Twice, Three Times and Every DayDocument2 pagesPage Text Book/ Activity Book: 13: Ex: Once, Twice, Three Times and Every DayJho MalarNo ratings yet

- Public Speaking RubricDocument4 pagesPublic Speaking RubricAnonymous gLVHgI7nNo ratings yet

- Maths III - Olesokoine SecondaryDocument3 pagesMaths III - Olesokoine SecondaryKundai ChiwesheNo ratings yet

- WHLP - Eng9 - Q3 - Week1-2 Bias and PrejudiceDocument2 pagesWHLP - Eng9 - Q3 - Week1-2 Bias and Prejudicejhemnits joy guillermeNo ratings yet

- Third WorldDocument11 pagesThird WorldNeha Jayaraman100% (1)

- SLM125Document5 pagesSLM125k2kkhanna105No ratings yet

- Puerta Melguizo: Visualizing ArgumentationDocument34 pagesPuerta Melguizo: Visualizing ArgumentationsuperguarichoNo ratings yet

- PIC Programmer ICSP+StandaloneDocument9 pagesPIC Programmer ICSP+StandaloneFailure RipNo ratings yet

- Logical StructuresDocument53 pagesLogical StructuresKim Francis CorrosNo ratings yet

- Software Cost Estimation in Software EngineeringDocument58 pagesSoftware Cost Estimation in Software EngineeringKarthik Tantri100% (4)

- Math (6.8) Volume Mitsa Tutoring Organization - 2021.v1: Figure 1. A Rubik's CubeDocument6 pagesMath (6.8) Volume Mitsa Tutoring Organization - 2021.v1: Figure 1. A Rubik's CubeGenevieve MelgazoNo ratings yet

- R ProgrammingDocument4 pagesR ProgrammingPriyanka Singla100% (1)

- Solar Gps Tracker With Power Saving Mode GPS Gate Products, Buy Solar Gps Tracker With Power Saving Mode GPS Gate Products From AlibabaDocument3 pagesSolar Gps Tracker With Power Saving Mode GPS Gate Products, Buy Solar Gps Tracker With Power Saving Mode GPS Gate Products From AlibabaCecilia GrunauerNo ratings yet

- Ss. Unit: Lesson Plan Three: Field Trip and Reflection ObjectivesDocument5 pagesSs. Unit: Lesson Plan Three: Field Trip and Reflection Objectivesapi-325193726No ratings yet

- Using Information in HR NABDocument2 pagesUsing Information in HR NABEliza Alexe0% (4)

- Monolithic CMOS Analog Multiplexers: General Description FeaturesDocument12 pagesMonolithic CMOS Analog Multiplexers: General Description Featureslennon rNo ratings yet

- Switching Time Bifurcations in A Thyristor Controlled ReactorDocument10 pagesSwitching Time Bifurcations in A Thyristor Controlled Reactorssmaths069996No ratings yet

- Radiant CircuitsDocument13 pagesRadiant Circuitsantou74100% (2)

- CFT Brochure NEWDocument20 pagesCFT Brochure NEWRahul KhannaNo ratings yet

- Compass Error Using Terrestrial Observations 2Document4 pagesCompass Error Using Terrestrial Observations 2Christelle Lopez100% (2)

- A Colonial Reading of Shakespeare'S The TempestDocument8 pagesA Colonial Reading of Shakespeare'S The TempestMuHammAD ShArjeeLNo ratings yet

- Natural Evil and The Love of GodDocument19 pagesNatural Evil and The Love of GodCristinaNo ratings yet

- Graphs AppendicesDocument13 pagesGraphs Appendiceskeskiin.egeNo ratings yet