Professional Documents

Culture Documents

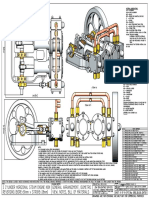

09D 22 00 A3 Sheet 01

09D 22 00 A3 Sheet 01

Uploaded by

RobsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

09D 22 00 A3 Sheet 01

09D 22 00 A3 Sheet 01

Uploaded by

RobsCopyright:

Available Formats

NOTES:

0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS

1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH REGARDS TO HOLE AND SHAFT TOLERANCES.

2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE HOLES SHALL BE APPROXIMATELY 5% TO 8% LARGER THAN THE MATCHING TAPPED HOLE.

3. PREFERABLY ALL TAPPED HOLES AND MATCHING SCREWS AND/OR BOLTS TO BE METRIC FINE (MF)

4. MATERIALS SPECIFIED ON THE DRAWINGS ARE INDICATIVE ONLY. THE BUILDER CAN MAKE HIS/HER OWN MATERIAL CHOICE.

5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM PRESSURE APPLIED TO IT SHALL BE SILVER/HARD SOLDERED.

6. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED STATE (CP), UNCOMPRESSED STATE IS APPROX 40% TO 60% LONGER THEN COMPRESSED STATE.

7. WHERE PREFERRED SCREW OR RIVETED CONNECTIONS CAN BE OMITTED AND PARTS CAN BE BONDED TOGETHER BY USING EITHER HIGH STRENGTH GLUE, EPOXY

RESIN, OR SOLDER.

8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM AND/OR WATER SHOULD BE CONSTRUCTED USING NON-FERROUS OR NON CORROSIVE MATERIAL SUCH AS

BRASS, BRONZE, GUNMETAL, STAINLESS STEEL, COPPER OR MONEL.

9. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED AND THE MODEL IS ASSEMBLED IS ENTIRELY LEFT TO THE BUILDER/MODEL MAKER.

10. A COLOUR SCHEME FOR THIS PROJECT IS ENTIRELY LEFT UP TO THE MODEL MAKER.

11. THE MANNER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED IS ENTIRELY LEFT UP TO THE BUILDER.

12. USE LOCTITE, ON SCREW OR PRESS FIT CONNECTIONS OR SURFACES, WERE DEEMED NECESSARY TO PREVENT PARTS FROM LOOSENING.

13. WASHERS AND/OR SPRINGWASHERS SHALL BE USED WHERE DEEMED NECESSARY.

XX. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE DRAWINGS, DO NOT HESITATE TO CONTACT ME SO THAT THE ERRORS/OMISSIONS CAN BE RECTIFIED.

MATERIAL ABBREVIATIONS:

ALU = ALUMINIUM

HALU= HARD ALUMINIUM

BRS = BRASS

BRZ = BRONZE OR GUNMETAL (BRZ/GM)

CI = CAST IRON

CU = COPPER

GRA = GRAPHITE

MS = MILD STEEL/BRIGHT MILD STEEL

SS = SILVER STEEL OR STAINLESS STEEL

SPS = SPRING STEEL

PEEK= POLYETHER ETHER KETONE OTHER ABBREVIATIONS

SYN = SYNTHETIC MATERIAL SUCH AS VETON, NYLON, TEFLON AS = AS SHOWN

OR RUBBER DP = DEEP

IN GENERAL SYNTHETIC MATERIALS SOULD BE ABLE TO DAA= DRILL AFTER ASSEMBLY

WITHSTAND THE HEAT AND PRESSURE(S) APPLIED TO D&TAA= DRILL AND TAP AFTER ASSEMBLY

THEM. CF = CLOSE FIT (SIZE FOR SIZE)

nnn/nnn MEANS THAT EITHER MATERIAL CAN BE USED PF = PRESS FIT

PFAA= PRESS FIT AFTER ASSEMBLY

PCD = PITCH CIRCLE DIAMETER

RM = REAM

HEX = HEXACON, 6SIDED

STEAM IN CP = COMPRESSED

KNL = KNURLED

CSK = COUNTERSINK

PL = PLACES

DWL= DOWEL

SPF= SPOTFACE

(T)HESOP=(TAPPED)HOLES EQUALLY SPACED ON PCD

(T)HESOC=(TAPPED)HOLES EQUALLY SPACED ON

CIRCUMFERENCE

OD = OUTSIDE DIAMETER

ID = INSIDE DIAMETER

MAX/MIN = CRITICAL DIMENSION

SA-xxx = SUB ASSEMBLY-xxx

QTY. PART NUMBER

1 09D-22-00-1-01-BASE FRAME

1 09D-22-00-1-02-CLINDER BLOCK

1 09D-22-00-1-02-CLINDER BLOCK

1 09D-22-00-1-03-VALVE CHEST

2 09D-22-00-1-04-MAIN BEARING

1 09D-22-00-2-01-CRANKSHAFT

2 09D-22-00-2-02-PISTON+CROSSHEAD

2 09D-22-00-2-03-CON-ROD

2 09D-22-00-2-04-SLIDE VALVE

2 09D-22-00-2-05-SLIDE VALVE GUIDE

2 09D-22-00-2-06-SLIDE VALVE REVERSER LINK

1 09D-22-00-2-07-SLIDE VALVE PARALLEL LINK

2 09D-22-00-2-08-ECCENTRIC

2 09D-22-00-2-09-ECCENTRIC STRAP

1 09D-22-00-2-10-REVERSER HANDLE

93.5 3.7

14 09D-22-00-M3 NUT

16 09D-22-00-M3x12 A-K CYL HEAD SCREW

2 09D-22-00-M3x6 A-K GRUB SCREW

28 09D-22-00-M3x9 A-K CYL HEAD SCREW

1 09D-22-00-M4 DOME NUT

14 09D-22-00-M4 NUT

4 09D-22-00-M4 WASHER-SPECIAL

4 09D-22-00-M4 WASHER

18 09D-22-00-M4x10 A-K CYL HEAD SCREW

4 09D-22-00-M4x14 A-K CYL HEAD SCREW

4 09D-22-00-M4x20 A-K CYL HEAD SCREW

1 09D-22-00-M4x5 A-K GRUB SCREW

275 10.8 STEAM OUT 4 09D-22-00-M5 NUT

190 7.5 4 09D-22-00-M5x14 A-K CYL HEAD SCREW

2 09D-22-00-M6 NUT

NOTES: DESIGNED BY J.A.M. DE WAAL

TITLE PROJECTION

DRAWING CONTENTS PROJECT No 09D-22-00 MODEL SCALE: 1:1

JDWDS

EXPERIMENTAL 2 CYL. HORIZ. STEAM ENGINE GENERAL ARRANGEMENT, NOTES, JDW DRAUGHTING SERVICES

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA

DATE

JANUARY 2021

DWG SCALE: 1:1 @A3 OR AS SHOWN

J.A.M. DE WAAL PAPAKURA NZ

Copyright ©

USING THE SLIDE VALVES AS REVERSER ISOMETRIC VIEW, BILL OF MATERIALS SHEET: 01 OF 04 A3 No: 09D-22-00-SHT01

2110. NEW ZEALAND. PHONE: OO64 09 2988815. MOB:

0211791000 E-MAIL: dewaal@xtra.co.nz.

DRAWINGS ARE FOR PERSONAL USE ONLY NOT FOR COMMERCIAL PURPOSES

You might also like

- Audit of ReceivablesDocument32 pagesAudit of Receivablesxxxxxxxxx96% (55)

- Master of Orion 3Document241 pagesMaster of Orion 3Joep KulderijNo ratings yet

- Structural General NotesDocument1 pageStructural General Notesjuan camiloNo ratings yet

- Steam Tracer Header and Branch Connection DetailsDocument1 pageSteam Tracer Header and Branch Connection DetailsSathiyaseelan Sakthi ShanmugamNo ratings yet

- 07.SOP For Receipt of Raw and Packing MaterialDocument6 pages07.SOP For Receipt of Raw and Packing MaterialBejoy Karim0% (1)

- General Arrangement, Isometric Views, Notes, Bill of Materials A Simple Vertical Steam Engine BORE 24mm STROKE 24mmDocument1 pageGeneral Arrangement, Isometric Views, Notes, Bill of Materials A Simple Vertical Steam Engine BORE 24mm STROKE 24mmTIMEPASS CAPTURENo ratings yet

- 09B 28 00 A3 Sheet 01Document1 page09B 28 00 A3 Sheet 01Abdul MannanNo ratings yet

- Kraby SystemDocument30 pagesKraby SystemSteve VouerNo ratings yet

- ConnectingsDocument5 pagesConnectingsPhillipos 19No ratings yet

- Integrato Tech ZDocument6 pagesIntegrato Tech ZLeo AlNo ratings yet

- Muncaster 11 A3 Sheet 02Document1 pageMuncaster 11 A3 Sheet 02Juan PastorNo ratings yet

- Kraby System 2018Document22 pagesKraby System 2018soga010178No ratings yet

- General Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)Document5 pagesGeneral Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)adil jabaroNo ratings yet

- General Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)Document5 pagesGeneral Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)adil jabaroNo ratings yet

- Apc 6Document9 pagesApc 6Pedro Alexander Alfonso AceroNo ratings yet

- Libra H1 Italiana FerramentaDocument7 pagesLibra H1 Italiana FerramentaOliver Augusto Fuentes LópezNo ratings yet

- 864 Wiring Schematic: S/N 518913001-14999 S/N 516812001-14999 S/N 517512001-14999 (Printed March 2001) V-0072Document6 pages864 Wiring Schematic: S/N 518913001-14999 S/N 516812001-14999 S/N 517512001-14999 (Printed March 2001) V-0072Ataa AssaadNo ratings yet

- Opening Systems For Flap and Drop Down DoorsDocument24 pagesOpening Systems For Flap and Drop Down DoorsPedro Alexander Alfonso AceroNo ratings yet

- Fe-Sbr-41 New Odc-Sbr-FxDocument14 pagesFe-Sbr-41 New Odc-Sbr-Fxrisal septianNo ratings yet

- Drilling Jigs Italiana FerramentaDocument34 pagesDrilling Jigs Italiana FerramentaOliver Augusto Fuentes LópezNo ratings yet

- 1chseaw JDW CompletDocument4 pages1chseaw JDW CompletJesús Los ArcosNo ratings yet

- 1chseaw JDW Complet PDFDocument4 pages1chseaw JDW Complet PDFOrlando Rojas PintoNo ratings yet

- With Slide Valve 1 Cylinder Horizontal Steam Engine and Notes General ArrangementDocument4 pagesWith Slide Valve 1 Cylinder Horizontal Steam Engine and Notes General ArrangementJose Rafael Ramos ChiquilloNo ratings yet

- 01 Vestido de Noiva Tomara Que Caia MoldesDocument1 page01 Vestido de Noiva Tomara Que Caia MoldesAna CristinaNo ratings yet

- 753 Wiring Schematic (With ACS Option) : S/N 515835000 - 515843086 S/N 516222000 - 516225447 (Printed April 2003) V-0261Document6 pages753 Wiring Schematic (With ACS Option) : S/N 515835000 - 515843086 S/N 516222000 - 516225447 (Printed April 2003) V-0261Iliyan VasilevNo ratings yet

- Wiring Schematic (Without ACS Option)Document6 pagesWiring Schematic (Without ACS Option)alexandrNo ratings yet

- 3 Ply BUR Hot-Cold Adhesive Bonded To InsulationDocument2 pages3 Ply BUR Hot-Cold Adhesive Bonded To Insulationfaiyadahamad87No ratings yet

- Kualat Exe Rev2Document6 pagesKualat Exe Rev2acasasasalsabila9024No ratings yet

- Wiring Schematic: 331 (S/N 232511001 AND ABOVE) (S/N 232711001 AND ABOVE) 334 (S/N 232611001 AND ABOVE)Document6 pagesWiring Schematic: 331 (S/N 232511001 AND ABOVE) (S/N 232711001 AND ABOVE) 334 (S/N 232611001 AND ABOVE)Willyas AsNo ratings yet

- 727 Ocampo DR Residence Floor Plan: Lower Cabinetry Upper CabinetryDocument1 page727 Ocampo DR Residence Floor Plan: Lower Cabinetry Upper CabinetryBlitzer ReyesNo ratings yet

- Pole InformationDocument2 pagesPole InformationEliasNo ratings yet

- Foundation Formulas PDFDocument12 pagesFoundation Formulas PDFsayma saraNo ratings yet

- Auditorium RT60 CalculationDocument1 pageAuditorium RT60 CalculationAniket WayalNo ratings yet

- Filter Berms Detail For Spacing BetweenDocument1 pageFilter Berms Detail For Spacing Betweenshafiullah NaseriNo ratings yet

- Me - 04Document1 pageMe - 04zhidane434No ratings yet

- APPROVALDocument32 pagesAPPROVALgirish46No ratings yet

- Talla 14 Anos - Moldes de Vestido de Ninas y Jovencitas Tipo Jardinera Na3082vDocument1 pageTalla 14 Anos - Moldes de Vestido de Ninas y Jovencitas Tipo Jardinera Na3082vyahiNo ratings yet

- Adhea Ppktugasweek5 PDocument1 pageAdhea Ppktugasweek5 PAdhea SeftiNo ratings yet

- Corte y Costura 1 PDFDocument1 pageCorte y Costura 1 PDFyahiNo ratings yet

- Drawing List (II) : Alam Sutera CondominiumDocument1 pageDrawing List (II) : Alam Sutera CondominiumDenyNo ratings yet

- Talla 02 Anos - Moldes de Vestido de Ninas y Jovencitas Tipo Jardinera Na3082vDocument1 pageTalla 02 Anos - Moldes de Vestido de Ninas y Jovencitas Tipo Jardinera Na3082vyahiNo ratings yet

- Analisis Item Kertas Bahasa Inggeris Kertas 1: C C B C B B B B B C B CDocument4 pagesAnalisis Item Kertas Bahasa Inggeris Kertas 1: C C B C B B B B B C B Cabangaziz82No ratings yet

- SCHUDULESDocument1 pageSCHUDULESAya Mahmoud ShedeedNo ratings yet

- Gyro Error GuideDocument2 pagesGyro Error GuideFrancis ParisNo ratings yet

- PassbookDocument1 pagePassbookManpreet SinghNo ratings yet

- Site Plan For The Proposed Residential Building in Rs No: 601/1 Ward No: 10 at Munduparamba of Malappuram MunicipalityDocument1 pageSite Plan For The Proposed Residential Building in Rs No: 601/1 Ward No: 10 at Munduparamba of Malappuram MunicipalityhaneefachgmailNo ratings yet

- RHC0116 033907MDocument3 pagesRHC0116 033907MMitzyNo ratings yet

- Drawing List (I) : Alam Sutera CondominiumDocument1 pageDrawing List (I) : Alam Sutera CondominiumDenyNo ratings yet

- As Built Plan: General NotesDocument1 pageAs Built Plan: General NotesBryll Jude Calaor MartinezNo ratings yet

- Drawing List (I) : Alam Sutera CondominiumDocument1 pageDrawing List (I) : Alam Sutera CondominiumDenyNo ratings yet

- MMMMMMDocument2 pagesMMMMMMAngelo GonzalesNo ratings yet

- Me - 03Document1 pageMe - 03zhidane434No ratings yet

- 46 Income Tax Calculator For Fy 2009 10 FinalDocument16 pages46 Income Tax Calculator For Fy 2009 10 Finalmysteryia007No ratings yet

- 453 Wiring Schematic: S/N 515011001 AND ABOVE S/N 515111001 AND ABOVE (Printed January 2001) V-0060Document2 pages453 Wiring Schematic: S/N 515011001 AND ABOVE S/N 515111001 AND ABOVE (Printed January 2001) V-0060Dumitru IngeauaNo ratings yet

- REKLAMASI 2018 NGS-ModelDocument1 pageREKLAMASI 2018 NGS-ModelAn IkhrandiNo ratings yet

- Wiring Schematic: 335 (S/N A16U11001 AND ABOVE)Document6 pagesWiring Schematic: 335 (S/N A16U11001 AND ABOVE)Willyas AsNo ratings yet

- 2100 Ardalan 1Document1 page2100 Ardalan 1HenryScheinDentalNo ratings yet

- Turbocompressor Control LogicDocument1 pageTurbocompressor Control LogicAngeloluigi MerelliNo ratings yet

- Divine Group LTD.: DB No-35, Unit-2, Tumble Dryer, Finishing SectionDocument1 pageDivine Group LTD.: DB No-35, Unit-2, Tumble Dryer, Finishing SectionMD.ShoyabNo ratings yet

- Rocket Engine Nozzle Concepts: Eads Space Transportation, Munich, Germany Gencorp Aerojet, Sacramento, CaliforniaDocument32 pagesRocket Engine Nozzle Concepts: Eads Space Transportation, Munich, Germany Gencorp Aerojet, Sacramento, CaliforniaSuaif RoomiNo ratings yet

- Seleccion de Partes CumminsDocument2 pagesSeleccion de Partes CumminsSenterver Equipos IndustrialesNo ratings yet

- State Govt. Special Class & Rly. Contractor Plot No - 203, Mahadev Nagar, Jharapada, Bhubaneswar Mob - 9437025830 GSTIN - 21ACLPM0994L1ZADocument6 pagesState Govt. Special Class & Rly. Contractor Plot No - 203, Mahadev Nagar, Jharapada, Bhubaneswar Mob - 9437025830 GSTIN - 21ACLPM0994L1ZATituNo ratings yet

- An Overview of Game Theory and Some Applications: Bellal Ahmed BhuiyanDocument2 pagesAn Overview of Game Theory and Some Applications: Bellal Ahmed BhuiyanpNo ratings yet

- Start A Quick Budget Start A Budget by MonthDocument13 pagesStart A Quick Budget Start A Budget by MonthMichelle PadillaNo ratings yet

- Greek Companies in Uae 2008Document29 pagesGreek Companies in Uae 2008Javeed TajiNo ratings yet

- AREVA INDUSTRIES PRIVATE LIMITED - Company Profile, Directors, Revenue & More - ToflerDocument5 pagesAREVA INDUSTRIES PRIVATE LIMITED - Company Profile, Directors, Revenue & More - ToflerPriyankNo ratings yet

- Prawira IndonesiaDocument2 pagesPrawira IndonesiaYudhistiraNo ratings yet

- American Airlines Inc.: Revenue ManagementDocument11 pagesAmerican Airlines Inc.: Revenue ManagementTanu BansalNo ratings yet

- Directory of Chemical Units 2019-20Document66 pagesDirectory of Chemical Units 2019-20Santosh sNo ratings yet

- Specification For Installation of Underground Conduit SystemsDocument99 pagesSpecification For Installation of Underground Conduit SystemsRazkulNo ratings yet

- The Simple Regression ModelDocument61 pagesThe Simple Regression Model张敏然No ratings yet

- Pfmea CR-V AmefDocument8 pagesPfmea CR-V AmefJose Antonio Santoyo RayaNo ratings yet

- MANUALE D'USO SILOS - Rev. 03 ENGDocument33 pagesMANUALE D'USO SILOS - Rev. 03 ENGRicardo RONo ratings yet

- Multiple Choice 1Document2 pagesMultiple Choice 1Paul MuthamaNo ratings yet

- Operation Manual Automatic Computerized Flat Knitting MachineDocument77 pagesOperation Manual Automatic Computerized Flat Knitting Machinejusty55555No ratings yet

- Run Off Triangles - Chain Ladder (Basic)Document622 pagesRun Off Triangles - Chain Ladder (Basic)aniket dalmiaNo ratings yet

- Dermatomo Zimmer UsuarioDocument22 pagesDermatomo Zimmer Usuariosjurado.nexpNo ratings yet

- Cbse Class 12 Economics Sample Paper Set 1 QuestionsDocument6 pagesCbse Class 12 Economics Sample Paper Set 1 QuestionsSaturo GojoNo ratings yet

- Maharashtra PSU List2014Document4 pagesMaharashtra PSU List2014Anup PrakashNo ratings yet

- University of Stirling Refund FormDocument4 pagesUniversity of Stirling Refund Formomojola seyiNo ratings yet

- Contract NegotiationDocument5 pagesContract NegotiationhehersonlagguiNo ratings yet

- Solution Chapter 14 - Advanced Accounting II 2014 by DayagDocument27 pagesSolution Chapter 14 - Advanced Accounting II 2014 by DayagCindy Pausanos Paradela100% (3)

- IAS 16 QuestionsDocument2 pagesIAS 16 QuestionsMauhammad NajamNo ratings yet

- MOTOR TRAFFIC (AMENDMENT) Act Sri LankaDocument111 pagesMOTOR TRAFFIC (AMENDMENT) Act Sri LankaramaaramaaNo ratings yet

- India Furniture Market, Forecast and Opportunities, FY2027 - ReportDocument135 pagesIndia Furniture Market, Forecast and Opportunities, FY2027 - ReportBlesson JosephNo ratings yet

- Final MRP Jan 2024Document17 pagesFinal MRP Jan 2024pradeep rawatNo ratings yet

- Jaden Lindsay Resume 8Document2 pagesJaden Lindsay Resume 84kqhtgrzc8No ratings yet

- 2.1handout FOHCleaningChecklistDocument3 pages2.1handout FOHCleaningChecklistEzeddinLibyaNo ratings yet