Concrete Pumping Risk Assessment

Concrete Pumping Risk Assessment

Uploaded by

lenindraCopyright:

Available Formats

Concrete Pumping Risk Assessment

Concrete Pumping Risk Assessment

Uploaded by

lenindraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Concrete Pumping Risk Assessment

Concrete Pumping Risk Assessment

Uploaded by

lenindraCopyright:

Available Formats

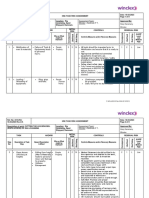

CONCRETE PUMPING RISK ASSESSMENT

Main Task / Activity: Concrete Pumping Risk Assessment

Location: Department: Date of Assessment:

LOGO HERE

RA Reference: Revision: 00 PTW Reference:

Assessment Team:

Client: Contractor Representatives: Page 1 of 5

General Guidelines:

1. Task Risk Assessment (also called Job Safety Analysis) is a qualitative hazard identification technique used for identifying, assessing and controlling major hazard(s) associated with a

specific task or operation where Permit to Work (PTW) precautions are deemed insufficient to execute the job safely.

2. No such work should be allowed to proceed until Risk Assessment has been completed and approved by a competent authority (normally Site Manager/Superintendent).

3. Risk Assessment should be carried out by a competent person and conducted in a team environment, involving all relevant parties.

4. Only trained and experienced staff should be deployed to execute high-risk jobs.

5. Conduct TRA well in advance as part of the work planning process.

6. Address all direct and indirect hazards associated with the task.

7. This TRA shall be conducted in conjunction with the above referenced PTW. A copy of the approved Risk Assessment must be attached to the permit throughout the work duration.

8. Use 5x5 Risk Assessment Matrix (provided separately) to assess the potential risks.

9. When determining safeguards, consider the ‘Hierarchy of Hazard Controls’ provided on this page.

10. Communicate TRA to all relevant personnel through meetings/toolbox talks before starting work.

11. Record Risk Assessment and revise if necessary.

Hierarchy of Hazard Controls:

(In order from most effective to least effective)

Elimination (by design or process changes)

Substitution (with less hazardous material or equipment)

Isolation (with barriers, machine guards)

Engineering Controls (interlocks, ESD system)

Administrative Controls (procedures, job rotations, training)

Warning Systems (signs, labels)

Personal Protective Equipment

HSE Documents-Risk Assessment for Concrete Pumping

*CPO-Concrete Pump Operator

CONCRETE PUMPING RISK ASSESSMENT

S/N Hazard Who Will be Control Measures Residual Additional

Initial Risk Action by

Affected? Risk Recommendation

L S R L S R s

1. Supervisor/CPO

Collapse or settlement of pump Operator, Ensure ground conditions at set up are adequate 1 2 2 Only competent

due to ground conditions / Workers, for a load of pump. personals should be

the overturning of the pump, or Visitors, Provide sufficient support (timbers, steel sheets) assigned the tasks,

the collapse of the boom due to Others 5 3 15 as required and ensure there is adequate space follow complete,

insufficient stability around the pump for the full deployment of Safety personnel

outriggers. surveillance, giving

Ensure outriggers are extended to the appropriate first aid, & proper

position. Sole plates are provided for placement toolbox talk.

below outrigger feet to support the pump. training

2. Crush or impact by the boom, Operator, CPO to operate via remote control unit from a Supervisor/CPO

or struck by placing hose, Workers, position of safety.

during set up or during “off Visitors, Hirer to ensure sufficient setup space and

the boom” placement of Others adequate light levels to ensure safe pump set up.

concrete 4 3 12 Ensure personnel remain clear of the area and 1 3 3

any operative controlling the position of the

placing hose should hold it at arm’s length.

Person(s) shall be nominated to converse with

and signal the CPO for minor boom positioning.

3. Contact with overhead Operator, Industry guidance specifies the minimum safe Supervisor/CPO

cables Workers, working distance from electric cables is

Visitors, 6m, this includes the fully extended boom radius.

Others Exceptions may apply and closer distances may

be permitted where controls are provided, 1 3 3

5 3 15 however, they must be managed by a Written Only competent

Safe System of Work. Where set up cannot be personals should be

clear of overhead cables, consideration should be assigned the tasks,

given to the provision of a ground-level pipeline. follow complete,

4. Vehicle Movements (reversing) Operator, Keep site personnel out of reversing area. Supervisor/CPO Safety personnel

– crushing or trapping of Workers, A competent Traffic Marshall should direct the surveillance, giving

persons when moving the pump Visitors, moving vehicle and look out for anyone in the first aid, & proper

to work in a position Others danger area. toolbox talk.

Vehicles fitted with reversing sirens and amber 1 5 5 training

3 3 9 flashing lights should have these engaged. High

visibility clothing must be worn and do not back

truck on out of view of

mixer driver who will be reversing using mirrors.

5. Back injury due to Operator, 2 3 6 Use of ropes and good manual handling practices 1 5 5 Supervisor/CPO

moving ground pipes Workers, to be adopted

Visitors,

Others

HSE Documents-Risk Assessment for Concrete Pumping

*CPO-Concrete Pump Operator

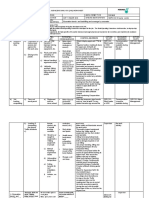

CONCRETE PUMPING RISK ASSESSMENT

6. Washout of pump Operator, The hirer/site management shall provide Supervisor/CPO

Workers, adequate washout facilities for concrete residues.

Visitors, The CPO to only wash out in areas defined and

Others 1 3 3 authorised by site management. If there is no 1 1 1

suitable area washout can be taken away but this

is an extra charge and should be agreed at the

time of booking

7. The collapse of placing boom Operator, All hydraulic rams are fitted with lock valves to Supervisor/CPO

due to failure of hydraulics Workers, limit movement should a failure occur. All

or structural failure of Visitors, 5 2 3 pumps undergo a boom test (which is 1 1 1

pump / boom Others certificated) and are also inspected as part of the

regular servicing schedule.

8. Contact with pump Operator, All moving parts on the concrete pump are fully Supervisor/CPO

moving parts Workers, guarded, ensure the CPO has carried out his Only competent

Visitors, 3 2 3 required daily / weekly checks 1 2 2 personals should be

Others No personnel other than the CPO may operate assigned the tasks,

the pump or climb onto the pump deck. follow complete,

Concrete splashing into Operator, Full PPE to be worn inc, helmet, goggles, gloves, Supervisor/CPO Safety personnel

9.

eyes from the end hose / Workers, safety wellingtons and barrier cream must be surveillance, giving

3 1 3 1 2 2

Concrete burns to hands Visitors, worn first aid, & proper

and feet Others toolbox talk.

10. Potential injury to persons Operator, Ensure that the pour area has adequate protection Supervisor/CPO training

and property damage due Workers, to contain any concrete spray or spillage.

to concrete spillage / Visitors, 2 1 2 1 2 2

splatter (predominantly Others

from upper floors)

11. High-pressure concrete Operator, Only pipes, hoses, clips of sufficient safety rating Supervisor/CPO

and aggregate going Workers, shall be used. Wear and damage

into eyes, face or any Visitors, shall be monitored by the CPO and checked

exposed skin due to Others during scheduled services. Excessively

3 2 6 1 2 2

standing or working damaged/worn components shall be withdrawn.

in front of end hose, or Also, see Blockages section below

opening up pipe joints

when pumping

12. Broken limbs, severe Operator, Do not kink placing hoses in the ground line. Supervisor/CPO

injury caused by Workers, Do not attempt to pump very old concrete or

the whiplash of placing hoses. Visitors, concrete other than a pump mix.

Others 2 3 6 1 2 2

The danger zone is the area around the end hose

in which it can strikeout. The diameter of the

zone is twice the length of the end hose.

13. Injury from splash due Operator, Keep hopper full and inform mixer driver of risk. Supervisor/CPO

to blowback from Workers, Full PPE to be worn. 1 3 3

concrete pump hopper Visitors,

Others

14. Working at height Operator, Access shall be restricted to “short duration” no Supervisor/CPO

(upon pump deck) Workers, hirer personnel shall be permitted to

3 3 9 1 3 3

Visitors, access the pump deck unless express permission

Others is given by the CPO.

HSE Documents-Risk Assessment for Concrete Pumping

*CPO-Concrete Pump Operator

CONCRETE PUMPING RISK ASSESSMENT

15. Potential blockages Operator, Only “single-ended” hoses shall be used – double Supervisor/CPO Only competent

at start or restart of Workers, / steel collared ended hoses shall personals should be

pump, use of suspended Visitors, not be used “off the boom”. assigned the tasks,

hose “of the boom” Others The CPO shall request that all persons remain follow complete,

resulting in hose clear (a radial distance of at least twice the length Safety personnel

whipping into danger 3 2 6 1 2 2

of the hose) of the suspended hose at each start surveillance, giving

area or restart of the pump and until “smooth flow” first aid, & proper

has been achieved. Also, see Blockages section toolbox talk.

below training

Full PPE to be worn.

16. Bursting of pipelines / Operator, Only pipes, hoses, clips of sufficient safety rating Supervisor/CPO

hoses under pressure Workers, shall be used. Wear and damage

Visitors, shall be monitored by the CPO and checked

4 3 12 1 2 2

Others during scheduled services. Excessively

damaged/worn components shall be withdrawn.

Also, see Blockages section below

17. Forceful ejection of air / Operator, Pipe jointing seals shall be clean and in good Supervisor/CPO

concrete from the end Workers, order. Concrete level in the pump hopper O, S

of the pipeline. Air sucked Visitors, must be maintained at the required

into line and compressed Others level, where the CPO is required to

3 4 12 position himself remote of the 1 3 3

pump appoint a competent person

to monitor deliveries and hopper

level (to ensure air is not pumped into the pipe

system).

18. Pressurised concrete Operator, CPO to ensure the pipeline is depressurized Supervisor/CPO

release – dismantling Workers, before freeing jointing clips, hirer personnel must

4 4 16 1 3 3

of line Visitors, not uncouple pipes without the express

Others permission of the CPO

19. Pipeline cleaning with Operator, A demarcated and access restricted area shall be Supervisor/CPO

compressed air – Workers, provided at the end of the pipeline that is to be

pressurised release / Visitors, 2 3 6 air cleansed. 1 3 3

ejection of sponge ball / Others

concrete / water / air

HSE Documents-Risk Assessment for Concrete Pumping

*CPO-Concrete Pump Operator

CONCRETE PUMPING RISK ASSESSMENT

Blockages – Why do they occur? Risk Reduction / Control

Segregation of concrete / aggregates as it is pressurised through the pipeline with It shall be ensured that the appropriate grout mix is used. Maximum pipeline and delivery hose length shall be

the primer / grout considered – grouting may be more successful in shorter sections

Inappropriate concrete mix design or consistency – not suitable for pumping Only concrete that is of “pump mix design” and appropriate quality should be specified for delivery to

Hardening of the concrete in boom / pipeline from standing too long (usually when CPO shall circulate or move the concrete in the hopper / boom / pipeline. Deliveries shall be time managed and

awaiting delivery of fresh concrete) planned appropriately

Flexible placing hose become kinked The hose should never become kinked, it should be suspended vertically when used “off the boom”

Foreign objects delivered from visiting mixer drums The quality of the concrete should be monitored

Blockages – Reacting To

Where possible the CPO will stop the pump action and reverse the pumping direction (this may free the blockage). Before the CPO restarts the pumping action, he should ensure all persons retreat to a safe

distance away from the boom / pipeline. Should the blockage persist, the CPO will stop the pump, depressurize the line and investigate the location of the blockage before taking appropriate action (ie

disconnecting pipework to locate and remove the blockage).

A momentary blockage may occur that frees immediately this is often accompanied by increased engine / pump revs and noise. The CPO shall endeavour where possible to warn persons in the vicinity to

stand clear. However, the release is likely to cause the delivery hose and/or boom to move or “kick” before the pump action can be stopped.

The Risk Matrix Likelihood

Consequences People Assets Environment Reputation

5-Almost Certain Multiple Fatalities Extensive damage Extensive International impact 5 0 5 10 15 20 25

Effect

4-Very Likely Single fatality or Permanent total Severe damage Severe Effect National impact 4 0 4 8 12 16 20

3 0 3 6 9 12 15

Severity

disability

3-Likely Major injury or health effects (long Major damage Major Effect Major impact 2 0 2 4 6 8 10

term or permanent partial disability)

1 0 1 2 3 4 5

2- Unlikely Minor injury or health effects leading Minor effect Minor Effect Minor impact

to LTI/RWC/MTC 0 0 0 0 0 0 0

1- Very Unlikely Single injury or health effects, Slight effect Slight Effect Slight impact 0 1 2 3 4 5

requiring first aid

Risk=Likelihood x Severity

0- Zero to Very

Low

Acceptabl Review Required Unacceptable

Risk Assessment by: e

Date:

HSE Documents-Risk Assessment for Concrete Pumping

*CPO-Concrete Pump Operator

You might also like

- Risk Assessment - Swimming Pool ConstructionDocument32 pagesRisk Assessment - Swimming Pool ConstructionTariq Radwan100% (1)

- 023.risk Asessment For Roof Waterproofing Works Rev-00 - 26.07.2020Document4 pages023.risk Asessment For Roof Waterproofing Works Rev-00 - 26.07.2020hamadNo ratings yet

- Risk Assessment For The Installation of Mobile CrusherDocument6 pagesRisk Assessment For The Installation of Mobile CrusherArsh NazarNo ratings yet

- Decking Risk AssessmentDocument4 pagesDecking Risk AssessmentReagan MukeboNo ratings yet

- 18-JSA Dismantling of Batching PlantDocument5 pages18-JSA Dismantling of Batching Plantmohamed.elkomyNo ratings yet

- Lacan - Case of AimeeDocument8 pagesLacan - Case of AimeeCyril SuNo ratings yet

- Appendix 3 Risk Assessment of Post Fixed Rebar Drill & Fix With Chemical AnchorDocument13 pagesAppendix 3 Risk Assessment of Post Fixed Rebar Drill & Fix With Chemical Anchormohsin.meizaNo ratings yet

- Floor Epoxy PaintingDocument6 pagesFloor Epoxy PaintingHafiz M WaqasNo ratings yet

- Carpets On WallsDocument4 pagesCarpets On WallsRaja NasirNo ratings yet

- 2318-RA 18.03.2023-REV 0A Cutting The Leg Bracing - RIG Rig LovansingDocument9 pages2318-RA 18.03.2023-REV 0A Cutting The Leg Bracing - RIG Rig LovansingHafeez AliNo ratings yet

- Duke, James A - Amazonian Ethnobotanical Dictionary-CRC Press (2018)Document222 pagesDuke, James A - Amazonian Ethnobotanical Dictionary-CRC Press (2018)Leonarda De La Ossa Arias100% (4)

- RS Concrete Pumping Risk AssessmentDocument8 pagesRS Concrete Pumping Risk AssessmentLito PanchoNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- JRA No 11-192 Manual Excavation For Construction of New FoundationsDocument4 pagesJRA No 11-192 Manual Excavation For Construction of New FoundationsAijaz AhmedNo ratings yet

- Concrete Pouring, Rebar, Formwork (Approved)Document2 pagesConcrete Pouring, Rebar, Formwork (Approved)Jixtha SaintNo ratings yet

- Risk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Document6 pagesRisk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Muideen OyedeleNo ratings yet

- Hira Fan & Components Lifting ShiftingDocument4 pagesHira Fan & Components Lifting ShiftingBilal QureshiNo ratings yet

- RA For Backfil Water Proofing For Wet AreaDocument3 pagesRA For Backfil Water Proofing For Wet Areayahiya100% (1)

- Risk Assessment For Concrete Repair WorkDocument3 pagesRisk Assessment For Concrete Repair Workkeshav chaturvediNo ratings yet

- Labor Camp - Erection & Operation Risk AssessmentsDocument2 pagesLabor Camp - Erection & Operation Risk Assessmentshussein aliNo ratings yet

- JSA-Substructure Concrete WorksDocument5 pagesJSA-Substructure Concrete WorksUMUTNo ratings yet

- Risk Assessment SPD (Updated)Document1 pageRisk Assessment SPD (Updated)Ajith Pillerkatill Antony100% (1)

- Risk Assessment For Installation of LV Power Cables and WiresDocument9 pagesRisk Assessment For Installation of LV Power Cables and WiresMohammed Amer Pasha100% (1)

- RISK ASSESSMENT Interlock and KerbstoneDocument20 pagesRISK ASSESSMENT Interlock and Kerbstonekannanjaduzz100% (1)

- Risk AssessmentDocument8 pagesRisk Assessmentm.umarNo ratings yet

- Risk Assesment For Chamber ConstructionDocument5 pagesRisk Assesment For Chamber ConstructionSasi KumarNo ratings yet

- All Work Activities Risk AssessmentDocument45 pagesAll Work Activities Risk Assessmenthaval.khalil98No ratings yet

- Vibration Risk Assessment: (Site/ Building/ Room)Document3 pagesVibration Risk Assessment: (Site/ Building/ Room)Him SiwakotiNo ratings yet

- Risk Assessment For Excavation & BackfillingDocument4 pagesRisk Assessment For Excavation & Backfillingkeshav chaturvedi100% (1)

- Risk Assessment For Installation of Drainage PipesDocument4 pagesRisk Assessment For Installation of Drainage Pipesabdulhanansamo65No ratings yet

- SDS AURAMIX 200 IndiaDocument8 pagesSDS AURAMIX 200 Indiarahul badgujarNo ratings yet

- Job Safety Analysis For Batching Plant Operation (Commissioning) - HSE DocumentsDocument4 pagesJob Safety Analysis For Batching Plant Operation (Commissioning) - HSE DocumentsRaza Muhammad SoomroNo ratings yet

- SWMS-Pipe Instalation Work at Utility 25.01.21Document10 pagesSWMS-Pipe Instalation Work at Utility 25.01.21Ansari FaisalNo ratings yet

- Appendix C - Risk AssessmentDocument2 pagesAppendix C - Risk Assessmentjavedashraf.ptNo ratings yet

- Concure WB309 MSDSDocument7 pagesConcure WB309 MSDSAmeer KhanNo ratings yet

- Aluminium CanopyDocument5 pagesAluminium CanopyRaja NasirNo ratings yet

- Wall Chipping WorkDocument6 pagesWall Chipping WorkRohith KumarNo ratings yet

- Risk Assessment-Raft Casting 12Document19 pagesRisk Assessment-Raft Casting 12huwaise888100% (1)

- Risk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageDocument11 pagesRisk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageFrancis Enriquez TanNo ratings yet

- Risk Assessment For NIGHT WORK 5 JUNEDocument18 pagesRisk Assessment For NIGHT WORK 5 JUNEsak388036No ratings yet

- Risk Assessment For Installation of Roof DrainsDocument11 pagesRisk Assessment For Installation of Roof Drainsahmed ib100% (1)

- Samet Daily Scaffold Safety Inspection ReportDocument1 pageSamet Daily Scaffold Safety Inspection Reportyohanes aprinusNo ratings yet

- Risk Assessment For Scaffolding Works Rev. 1Document15 pagesRisk Assessment For Scaffolding Works Rev. 1muhammad.younisNo ratings yet

- Risk Assessment - Sheet Piling DraftDocument8 pagesRisk Assessment - Sheet Piling DraftSina100% (1)

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETY100% (1)

- Risk Assess T-07 - Mobile Crane OperationsDocument2 pagesRisk Assess T-07 - Mobile Crane OperationsMAB AliNo ratings yet

- Cutting, Griding, WeldingDocument6 pagesCutting, Griding, WeldingAli SalihNo ratings yet

- Risk Assessment Ubderground Electric Power SupplyDocument4 pagesRisk Assessment Ubderground Electric Power SupplySameer Abdul RaufNo ratings yet

- Underground Above Ground Drainage Works and Plumbing Works Risk AssessmentDocument4 pagesUnderground Above Ground Drainage Works and Plumbing Works Risk Assessmentmohsin.meizaNo ratings yet

- Risk Assessment LiftingDocument2 pagesRisk Assessment Liftingmohamed ghalyNo ratings yet

- JSA 08 Laying of Conduit WiringDocument8 pagesJSA 08 Laying of Conduit Wiringsyed khaja misbhuddinNo ratings yet

- BMR - Safety PPT Apr-2023Document17 pagesBMR - Safety PPT Apr-2023shamshad ahamedNo ratings yet

- Attachment 1 Risk AssessmentDocument9 pagesAttachment 1 Risk Assessmentjaouad id boubkerNo ratings yet

- Joinery Carpentry Risk AssessmenmtDocument4 pagesJoinery Carpentry Risk Assessmenmtadeniyi abiolaNo ratings yet

- Hard Land Scape Risk AssessmentDocument4 pagesHard Land Scape Risk AssessmentvivekanandhanNo ratings yet

- Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesGift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- Risk Assessment For Traffic DiversionDocument15 pagesRisk Assessment For Traffic DiversionnvrajkumareceNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument1 pageEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Task /activity: Installation of Abseil HooksDocument10 pagesTask /activity: Installation of Abseil HooksfrancisbautistaNo ratings yet

- Deshuttering WorkDocument1 pageDeshuttering WorkAhmed AbdulfatahNo ratings yet

- AsbestosDocument4 pagesAsbestoskoketsoNo ratings yet

- Risk Assessment For PAS InstallationDocument18 pagesRisk Assessment For PAS Installationjide.atolagbe3737No ratings yet

- Aspects and Impacts Register 2016Document8 pagesAspects and Impacts Register 2016lenindraNo ratings yet

- Fire Drill and or Incident Report FormDocument1 pageFire Drill and or Incident Report FormlenindraNo ratings yet

- Erogonomics Risk AssessmentDocument4 pagesErogonomics Risk AssessmentlenindraNo ratings yet

- Brick Laying Risk Assessment (SWMS)Document8 pagesBrick Laying Risk Assessment (SWMS)lenindra100% (1)

- Present Simple ReadingDocument2 pagesPresent Simple ReadingMatias Adrian PAREJA GARCIA100% (1)

- Emphysema Case Study AnalysisDocument10 pagesEmphysema Case Study AnalysisEfren VisteNo ratings yet

- Gem Carbo NHSDocument2 pagesGem Carbo NHSSyed Touseef AhmedNo ratings yet

- Levy CV Feb 2011Document5 pagesLevy CV Feb 2011jonathan_levy9254No ratings yet

- ARC Pflugerville: Connected CareDocument2 pagesARC Pflugerville: Connected CareSergio Hidalgo BronfmanNo ratings yet

- Chapter 026Document14 pagesChapter 026dtheart282167% (3)

- Generic Name: Classification: Indication:: Candida InfectionsDocument1 pageGeneric Name: Classification: Indication:: Candida Infectionscen janber cabrillos0% (1)

- PE 2 - TABATA Narrative Report Week 3 New Quimio, John Carlo B.Document4 pagesPE 2 - TABATA Narrative Report Week 3 New Quimio, John Carlo B.Christian Joe QuimioNo ratings yet

- Keeping The Dust Down: Impact of Sandstorms On Health & Safety of The PublicDocument38 pagesKeeping The Dust Down: Impact of Sandstorms On Health & Safety of The PublicTonyNo ratings yet

- Certicate 3 Essay1Document3 pagesCerticate 3 Essay1jmmutangaNo ratings yet

- Onoriode Idigun Junior: Curriculum VitaeDocument2 pagesOnoriode Idigun Junior: Curriculum VitaeOnoriode Idigun JuniorNo ratings yet

- A3S Enviro Water & Waste Water Solution (Packaged STP/ETP)Document2 pagesA3S Enviro Water & Waste Water Solution (Packaged STP/ETP)A3S ENVIRONo ratings yet

- تمثّلات الصحة النفسية عند طلبة علم النفس؛ دراسة ميدانية لطلبة علم النفس ماستر جامعة تيارتDocument18 pagesتمثّلات الصحة النفسية عند طلبة علم النفس؛ دراسة ميدانية لطلبة علم النفس ماستر جامعة تيارتToO kaàNo ratings yet

- Seer Light Ambulatory Recorder/Controller: Service ManualDocument86 pagesSeer Light Ambulatory Recorder/Controller: Service ManualJuan CarlosNo ratings yet

- Hypersensitivity: M.G.Rajanandh, Dept. of Pharmacy Practice, SRM College of Pharmacy, SRM UniversityDocument87 pagesHypersensitivity: M.G.Rajanandh, Dept. of Pharmacy Practice, SRM College of Pharmacy, SRM UniversityJulienne Sanchez-SalazarNo ratings yet

- The Demographic/ Epidemiologic/ Urban and Nutrition TransitionsDocument69 pagesThe Demographic/ Epidemiologic/ Urban and Nutrition TransitionsMoreiyamNo ratings yet

- Acknowledgement ReceiptDocument3 pagesAcknowledgement ReceiptSharie ArellanoNo ratings yet

- PortCalls March 18 2020Document12 pagesPortCalls March 18 2020PortCallsNo ratings yet

- Postpartum Exercise ChecklistDocument3 pagesPostpartum Exercise ChecklistCharlie DyNo ratings yet

- Guided Imagery: Mountain Cabin Scene ExerciseDocument2 pagesGuided Imagery: Mountain Cabin Scene ExerciseDuc Luyen NguyenNo ratings yet

- Flyer SV300 - S (2) - 1Document2 pagesFlyer SV300 - S (2) - 1Abo MaramNo ratings yet

- HOPE2 11 Q3 W1 7 Modified AssessmentDocument11 pagesHOPE2 11 Q3 W1 7 Modified AssessmentAloha Reign PaloNo ratings yet

- Navigating Digital Dependency - Exploring Help-Seeking Patterns and Self-Reliance in The Digital AgeDocument45 pagesNavigating Digital Dependency - Exploring Help-Seeking Patterns and Self-Reliance in The Digital AgeStrawberry CubNo ratings yet

- Design Failure Mode Effects Analysis WorksheetDocument2 pagesDesign Failure Mode Effects Analysis Worksheeto_m_bajajNo ratings yet

- Coping Mechanism of SHS Students in Transitioning Adm To F2F Mode ClassesDocument5 pagesCoping Mechanism of SHS Students in Transitioning Adm To F2F Mode ClassesPomelo Tuquib LabasoNo ratings yet

- Public Speaking Anxiety GlossophobiaDocument21 pagesPublic Speaking Anxiety Glossophobiaadel lamNo ratings yet

- KPMG Project Risk ManagementDocument7 pagesKPMG Project Risk ManagementMaverick CardsNo ratings yet

- Feature ArticleDocument2 pagesFeature ArticleCyril CauilanNo ratings yet