Civil

Civil

Uploaded by

ShiyaCopyright:

Available Formats

Civil

Civil

Uploaded by

ShiyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Civil

Civil

Uploaded by

ShiyaCopyright:

Available Formats

SSRG International Journal of Civil Engineering Volume 7 Issue 12, 1-2, December 2020

ISSN: 2348 – 8352 /doi:10.14445/23488352/IJCE-V7I12P101 ©2020 Seventh Sense Research Group®

Experimental Investigation On Polymer Concrete

With Different Volume Division of Bamboo Fiber

R. K. Manikandan1, Dr.K.Shunmugapriya2

1

Assistant Professor, Department of Civil Engineering, Dhanalakshmi Srinivasan Engineering College, Perambalur, India

2

Associate Professor, Department of Civil Engineering, Dhanalakshmi Srinivasan Engineering College, Perambalur, India

Received Date: 07 November 2020

Revised Date: 19 December 2020

Accepted Date: 25 December 2020

Abstract - This paper examines the exploratory Physical (2013) deal with using some fibres as waste solid for

Characteristics of polymer concrete with various fractions' making eco-friendly and green environments. The natural

Bamboo fiber. From this exploratory investigation, it is fibre is purely bio-degradable and recyclable. In that way, it

discovered that the quality increment to some extent, the reduces pollution, endorse biodiversity and the upkeep of

Split tension test result is improved because of the fiber naturally available resources, and as a result, it is

content in the concrete the formation of crack was slowly environmentally friendly. Three fibres, namely Jute, Oil

downed, and the load-carrying capacity is higher for this palm, and Polypropylene fibres are used in concrete, and

polymer concrete with two percent of fiber content. their appropriateness, lifetime, and influence on the

characteristics of concrete were calculated. The % of the

INTRODUCTION fiber used was 0.25 and 0.50 of cement by mass. A total of

From previous studies, Eether Dawood et al. 2012 85 polymer concrete cube samples were prepared for fresh

that the perception of combination with two or more and harden concrete tests such as slump test, compaction

various fibres integrated into a regular cement matrix can factor test, and compression test. The examined results

present added appealing engineering characteristics because showed that for fibers of jute and Oil palm fibres, the best

one fibre gives the more impressive usage of the powerful fibre content percentage was 0.25%, and for Polypropylene

properties for the other fibre. Steel fibre has a significantly fibre, the best fibre content was 0.5%. They all improve in

better length and high Young's modulus of elasticity when strength compared to the common concrete specimen and

related to other fibre-categories. This drives an enhanced have confirmed to pull down the reasonable environmental

flexural rigidity and a great possibility for crack control, waste pollution.

even though it is more volumetric. It is also vital to note Therefore an effort has been made in this

that steel has properties to conduct current and magnetic experimental investigation to read the outcome of adding up

fields, and for this reason, the steel fiber content must be steel fibre at an amount of 1.5% of the total mass of

decreased to some extent. Maximization of physical and concrete as fibres. Metakaolin was used at 8% of cement

conductivity behavior can be attained by mixing various mass as metakaolin, and the adding up of steel fibers at

fibers, such as the natural fibre (palm, sisal, and bamboo 1.5% and 8% of metakaolin. The experiment was done

fibre). The striking benefit of fusion fibres system is that it using an M40 mix, and tests were carried out as per the

gives a system in which a type of fibre, which is stronger recommended procedures by relevant codes. The results

and rigid, enhances the initial crack stress and eventual were compared with control concrete; it was observed that

strength, where another type of fibre, which is more supple concrete blocks incorporated with steel fiber increased their

and ductile, leads to the enhanced hardiness and tension compressive strength by 8.91% and tensile strength by

capability in the post-cracking zone. It also provides a 26.94%. K. Ramesh et al. (2013), the present Experimental

hybrid reinforcement, in which the shorter fibre connects investigation is to study the Mechanical Properties of the

micro-cracks and lowers the crack widths. This gives an Fly ash concrete reinforced with steel fibers. Steel fibers

advanced tensile property of the composite. Another type varied from 0%,0.5%, 1%, and 1.5% by weight of cement.

of fibre is bigger, so it can seize the extension macro cracks Specimens were tested for 28 days, 60 days, and 90 days.

and considerably enhance the composite's robustness. Based on the experimental results, it was found that the

Moreover, most of the research work and fibre number of steel fibers which can be added to the concrete

reinforcement is about a single type of fiber. Using mixed for improving its strength characteristics maybe 1% by

fibres as reinforcement to enhance the performance of weight. The addition of steel fibers more than1% generally

concrete are not often reported. Therefore, the research affects the Compressive strength, Split tensile strength, and

presents the outcome of some characteristics of high Flexural strength of the concrete.

strength concrete equipped with hybrid fibres. Olaoye et al.

This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/)

R. K. Manikandan & Dr.K.Shunmugapriya / IJCE, 7(12), 1-2, 2020

I. MATERIALS fiber reinforcement gives good improvement in concrete

In this project work, Grade 43 ultra tech cement, fine strength, which was influenced by the bamboo fiber content.

aggregate passes 4.75mm IS sieve, and machine crushed stone

as coarse aggregate of angular shaped with 20mm &

Admixture superplasticizer is taken. The mineral admixture of

Flyash and is used in this concrete. The bamboo fiber of an

Average fiber length of 50 mm and an average fiber diameter

of 0.45mm is used in this concrete.

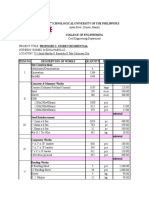

II. MIX PROPORTIONS

TABLE I: MIX PROPORTION WITH A MIX

RATIO OF 1:1.31:2.84.

Mi Cement Epoxy Fly Metakaoli Bamboo

x (OPC)( Resin Ash n Fiber

Rat %) (%) (%) (%) (%)

io

M0 1 0 0 0 0

M1 50 7 2 1 0 Fig. 2. Split tensile test results

M2 530 7 25 10 0.

M3 53. 7 25 10 02. IV. CONCLUSION

M4 53.0 7 25 10 15. The experiment result showed that the

M5 53.0 7 25 10 17. compressive strength was considerably improved by

M6 53.0 7 25 10 105. adding bamboo fiber, tensile strength is also improved

M7 53.0 7 25 10 12. concerning increasing in bamboo fiber ratio in concrete.

M8 53.0 7 25 10 25.

3.0 5 0 7 REFERENCES

[1] IS 456:2000 , Code of Practice for Plain and Reinforced Concrete,

.0 5

Bureau of Indian standards, New Delhi.

0III. RESULT AND DISCUSSIONS [2] IS 10262:2009 ,Recommended Guide Lines for Concrete Mix

A. Compression test Design Bureau of Indian standards, New Delhi.

150mm cube concrete samples with various concrete [3] IS 383:1970 ,Specification for coarse and fine aggregate from

natural sources for concrete Bureau of Indian Standards, New

mix proportion are tested in a compression testing machine to Delhi.

find out their compression strength [4] Olaoye, R.A., Oluremi, J.R., and Ajamu, S.O. The Use of Fibre

Waste as Complement in Concrete for a Sustainable Environment

Special Issue - 2nd International Conferences on Engineering and

Technology Research.,4(9)(2013).

[5] Hawra Alradhawi Reinforcing Smart Home Security System,

International Journal of Engineering Trends and Technology

(IJETT), 57(1)( 2018) 32-39 .

[6] Shelorkar Ajay P, Malode Abhishek and Loya Abhishek

Experimental investigation on steel fibre reinforced concrete

using metakaolin., International Journal of structural and civil

engineering research. 2(2)(2013).

[7] K. Ramesh, Dr.K.Arunachalam, S.Rooban Chakravarthy,

Experimental Investigation on Mechanical Properties of Flyash

Concrete and Flyash Fiber Reinforced Concrete / International

Journal of Engineering Research and Applications, 3(3)(2013)

137-145.

[8] Jane Proszek Gorninski Study of the modulus of elasticity of

polymer concrete compounds and comparative assessment of

polymer concrete and portland cement concrete (2004).

Fig. 1. Compression test results [9] Kou Shi-Cong A novel polymer concrete (PC) was synthesized

by mixing epoxy resins and waste glass as aggregates (2013).

B. Split Tensile Strength:

150 X300 mm cylinder concrete samples with

various concrete mix proportions are tested in the

compression testing machine to determine its split tensile

strength. The split tensile strength test shows that the bamboo

You might also like

- Study The Effect of Polypropylene FiberDocument4 pagesStudy The Effect of Polypropylene FiberHrishikesh GosaviNo ratings yet

- Effect of Recycled Aggregate With Glass Fiber On Concrete PropertiesDocument22 pagesEffect of Recycled Aggregate With Glass Fiber On Concrete PropertiesSuresh KomurajuNo ratings yet

- Experimental Investigation of Steel Fiber Reinforced ConcetreDocument6 pagesExperimental Investigation of Steel Fiber Reinforced ConcetreJETLYNo ratings yet

- "Study of Natural Fibers As An Admixture For Concrete Mix Design" (Chapter 2)Document9 pages"Study of Natural Fibers As An Admixture For Concrete Mix Design" (Chapter 2)JOHN FHILIP ORIT100% (4)

- Behaviour of Different Types of Fibre Reinforced Concrete Without AdmixtureDocument7 pagesBehaviour of Different Types of Fibre Reinforced Concrete Without AdmixtureShruti SharmaNo ratings yet

- Chopped Carbon Fibers Innovative MateriaDocument7 pagesChopped Carbon Fibers Innovative Materiakishor150688No ratings yet

- Structural Behaviour of Fibrous Concrete Using Polypropylene FibresDocument4 pagesStructural Behaviour of Fibrous Concrete Using Polypropylene FibresPatricia ClarkNo ratings yet

- Experimental Strength On Polypropylen Fiber Reinforced ConcreteDocument7 pagesExperimental Strength On Polypropylen Fiber Reinforced ConcreteIJRASETPublicationsNo ratings yet

- Mechanism and Strengthening Effects of Carbon Fiber On Mechanical Properties of Cement MortarDocument6 pagesMechanism and Strengthening Effects of Carbon Fiber On Mechanical Properties of Cement MortarIJAERS JOURNALNo ratings yet

- Proposal CorrectionDocument14 pagesProposal CorrectionjanithaNo ratings yet

- IJSER JournalpaperDocument5 pagesIJSER JournalpaperPatricia LunaNo ratings yet

- Micro Estructural 2Document16 pagesMicro Estructural 2Luis FelixNo ratings yet

- Waste Polyethylene and Tyre Fibres Are Industrial Waste As Well, and by Using Them, We May Slow Down The Deterioration of The EnvironmentDocument5 pagesWaste Polyethylene and Tyre Fibres Are Industrial Waste As Well, and by Using Them, We May Slow Down The Deterioration of The EnvironmentIJRASETPublicationsNo ratings yet

- Study On Strength Properties of Concrete Using PumDocument7 pagesStudy On Strength Properties of Concrete Using PumjoekingaprilNo ratings yet

- A Study On Steel Fiber Reinforced Normal PDFDocument5 pagesA Study On Steel Fiber Reinforced Normal PDFZindagiDeeNo ratings yet

- Strain Hardening HPFRCDocument10 pagesStrain Hardening HPFRCsaiNo ratings yet

- Experimental Study and Analysis On Compressive and Tensile Behavior of Basalt Fibre Reinforced ConcreteDocument15 pagesExperimental Study and Analysis On Compressive and Tensile Behavior of Basalt Fibre Reinforced ConcreteJuan Manuel Fiestas FiestasNo ratings yet

- Flexural Behavior of Hollow RC Beam Using Glass FiberDocument10 pagesFlexural Behavior of Hollow RC Beam Using Glass FiberIJSTENo ratings yet

- Comparison of Strength Between Control Concrete & Rice Husk Ash Cement Concrete On Addition of Polypropylene FiberDocument4 pagesComparison of Strength Between Control Concrete & Rice Husk Ash Cement Concrete On Addition of Polypropylene FiberBRIJESHNo ratings yet

- Experimental Investigation of Silica Fume Based Concrete of M25 GradeDocument7 pagesExperimental Investigation of Silica Fume Based Concrete of M25 GradeIJRASETPublicationsNo ratings yet

- Experimental Study On Human Hair As Fiber Reinforced ConcreteDocument5 pagesExperimental Study On Human Hair As Fiber Reinforced ConcreteYogendra PatilNo ratings yet

- Behaviour of Concrete Utilizing AR Glass Fibre As A Partial Replacement of CementDocument5 pagesBehaviour of Concrete Utilizing AR Glass Fibre As A Partial Replacement of CementdarshanNo ratings yet

- Comparative Study On Durability Properties of Engineered Cementitious Composites With Polypropylene Fiber and Glass FiberDocument19 pagesComparative Study On Durability Properties of Engineered Cementitious Composites With Polypropylene Fiber and Glass Fiberci_balaNo ratings yet

- tmp4D96 TMPDocument5 pagestmp4D96 TMPFrontiersNo ratings yet

- IJSET 10 Strength and WorkabilityDocument13 pagesIJSET 10 Strength and WorkabilitytonydisojaNo ratings yet

- Mechanical Properties of Concrete Using Flyash With Addition of Polypropylene FibresDocument39 pagesMechanical Properties of Concrete Using Flyash With Addition of Polypropylene FibresMohammed AzharuddinNo ratings yet

- Fiber Reinforced ConcreteDocument5 pagesFiber Reinforced ConcreteJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Mechanical Behavior of Strain Hardening Cement Based Composite ConcreteDocument8 pagesMechanical Behavior of Strain Hardening Cement Based Composite ConcreteIJRASETPublicationsNo ratings yet

- Jurnal Studi Karakteristik Mekanik Beton Dengan Menggunakan Agregat Halus Tailing Dengan Variasi Serat BajaDocument13 pagesJurnal Studi Karakteristik Mekanik Beton Dengan Menggunakan Agregat Halus Tailing Dengan Variasi Serat BajaIrsas InsanilNo ratings yet

- Experimental Investigation On Hybrid Fiber Reinforced ConcreteDocument5 pagesExperimental Investigation On Hybrid Fiber Reinforced ConcreteRakeshNo ratings yet

- Investigation of Properties of Fiber Reinforced Concrete Using RubberDocument5 pagesInvestigation of Properties of Fiber Reinforced Concrete Using RubberSumit Geete100% (1)

- Toughness Study On Fly Ash Based Fiber Reinforced Concrete: Originalresearch Open AccessDocument4 pagesToughness Study On Fly Ash Based Fiber Reinforced Concrete: Originalresearch Open AccessvitusstructuresNo ratings yet

- High-Strength Flowable Mortar Reinforced by Steel Fiber: M. Ramli, E. Thanon DawoodDocument7 pagesHigh-Strength Flowable Mortar Reinforced by Steel Fiber: M. Ramli, E. Thanon DawoodvietpineNo ratings yet

- I J Seas 20150422Document6 pagesI J Seas 20150422Dharmaraaj RajalinggamNo ratings yet

- A Comparative Study of Basalt and Polypropylene Fibers Reinforced Concrete On Compressive and Tensile BehaviorDocument6 pagesA Comparative Study of Basalt and Polypropylene Fibers Reinforced Concrete On Compressive and Tensile BehaviorIsha PatelNo ratings yet

- A Study On Strength of Concrete by PartiDocument9 pagesA Study On Strength of Concrete by Partijobcustodio54No ratings yet

- Comparison Between Reinforced Cement Concrete and Fibre Reinforced Beam Using Finite Element MethodDocument2 pagesComparison Between Reinforced Cement Concrete and Fibre Reinforced Beam Using Finite Element MethodEditor IJTSRDNo ratings yet

- Study On The Performance of Concrete Usi PDFDocument4 pagesStudy On The Performance of Concrete Usi PDFBenharzallah KrobbaNo ratings yet

- Behaviour of Hybrid Fibre Reinforced Concrete-FillDocument12 pagesBehaviour of Hybrid Fibre Reinforced Concrete-Fillsbaia amineNo ratings yet

- FibersDocument15 pagesFibersSACHINNo ratings yet

- Kshuboo 2nd PaperDocument5 pagesKshuboo 2nd PaperPriyanshiNo ratings yet

- Suitability of Glass Fibers in High Strength Recycled Aggregate Concrete-An Experimental InvestigationDocument10 pagesSuitability of Glass Fibers in High Strength Recycled Aggregate Concrete-An Experimental InvestigationSuresh KomurajuNo ratings yet

- 1 s2.0 S2214785322033132 MainDocument5 pages1 s2.0 S2214785322033132 Main18h41a0110No ratings yet

- Study On The Effect of Coir Fibre in The Bituminous Concrete MixDocument5 pagesStudy On The Effect of Coir Fibre in The Bituminous Concrete MixIJSTENo ratings yet

- Experimental Study On The Hardened Properties of Concrete by Using Soft Drink Bottle Caps As Partial Replacement For Coarse AggregatesDocument7 pagesExperimental Study On The Hardened Properties of Concrete by Using Soft Drink Bottle Caps As Partial Replacement For Coarse AggregatesSajjad AhmadNo ratings yet

- Strength Properties of Glass Fibre ConcreteDocument6 pagesStrength Properties of Glass Fibre Concreteorpheusivan03No ratings yet

- Investigational Study On Strength of Fiber Concrete Using BambooDocument9 pagesInvestigational Study On Strength of Fiber Concrete Using BambooLood RafaelNo ratings yet

- Study On Strength and Durability Properties of Polypropylene and Carbon Fiber Reinforced Concrete CompositeDocument6 pagesStudy On Strength and Durability Properties of Polypropylene and Carbon Fiber Reinforced Concrete CompositeIJRASETPublicationsNo ratings yet

- An Experimental Study On Flexural Strength EnhancementDocument9 pagesAn Experimental Study On Flexural Strength EnhancementSal SaadNo ratings yet

- Effect of Fibres On The Compressive Stre PDFDocument10 pagesEffect of Fibres On The Compressive Stre PDFjenecil budionganNo ratings yet

- Characteristic Strength of Concrete Using Steel Slag As A Fine AggregateDocument8 pagesCharacteristic Strength of Concrete Using Steel Slag As A Fine AggregateIJRASETPublicationsNo ratings yet

- Deformation Characteristics of Basalt Reinforced Concrete With SuperplasticizerDocument7 pagesDeformation Characteristics of Basalt Reinforced Concrete With SuperplasticizerBanNo ratings yet

- Indonesia's Journal of Social and Technology (Yosia C. Purba)Document15 pagesIndonesia's Journal of Social and Technology (Yosia C. Purba)Yosia Clinton PurbaNo ratings yet

- Performance of Steel Fiber Reinforced Self Compacting ConcreteDocument5 pagesPerformance of Steel Fiber Reinforced Self Compacting ConcreteInternational Journal of computational Engineering research (IJCER)No ratings yet

- Glass Fiber Reinforced Concrete (GFRC) - Strength and Stress Strain Behavior For Different Grades of ConcreteDocument6 pagesGlass Fiber Reinforced Concrete (GFRC) - Strength and Stress Strain Behavior For Different Grades of ConcretePiyush SaxenaNo ratings yet

- International Journal of Chemtech ResearchDocument6 pagesInternational Journal of Chemtech Researchgokul mgkNo ratings yet

- Incorporation of Silica Fume in ConcreteDocument4 pagesIncorporation of Silica Fume in ConcreteNikhil JainNo ratings yet

- International Journal of Engineering Research and DevelopmentDocument4 pagesInternational Journal of Engineering Research and DevelopmentIJERDNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Document 43Document6 pagesDocument 43ShiyaNo ratings yet

- Document 52Document2 pagesDocument 52ShiyaNo ratings yet

- Document 54Document3 pagesDocument 54ShiyaNo ratings yet

- Document 53Document3 pagesDocument 53ShiyaNo ratings yet

- Presented By, N. Vivekha, 19MCO004Document12 pagesPresented By, N. Vivekha, 19MCO004ShiyaNo ratings yet

- Course Plan Model-BEEEDocument9 pagesCourse Plan Model-BEEEShiyaNo ratings yet

- Payload Functions: Selciya Selvan 19MAE002Document13 pagesPayload Functions: Selciya Selvan 19MAE002ShiyaNo ratings yet

- Adaptive Data Rate: Selciya SelvanDocument10 pagesAdaptive Data Rate: Selciya SelvanShiyaNo ratings yet

- Technological University of The Philippines: 2" X 3" X 18' Lumber 120x240cm PlywoodDocument10 pagesTechnological University of The Philippines: 2" X 3" X 18' Lumber 120x240cm Plywoodjoy ceE pabelloNo ratings yet

- Sound Transmission Class Ratings For Concrete Masonry WallsDocument9 pagesSound Transmission Class Ratings For Concrete Masonry WallsrenramaNo ratings yet

- Solarpol Expandable Polystyrene BeadsDocument2 pagesSolarpol Expandable Polystyrene BeadsmurdicksNo ratings yet

- Reinforced Concrete Refresher SetDocument5 pagesReinforced Concrete Refresher SetMark Neil Delgaco Gastilo100% (2)

- Metal Solid IronDocument46 pagesMetal Solid IronImelda SitumorangNo ratings yet

- General Specifications Musngi Residence - As Per SiteDocument8 pagesGeneral Specifications Musngi Residence - As Per SiteJanine Palec100% (1)

- PolymerDocument35 pagesPolymerIrham SyahmiNo ratings yet

- APK (Code) - ProjectName - Cost Plan EstDocument91 pagesAPK (Code) - ProjectName - Cost Plan EstMinh TanNo ratings yet

- Acid PicklingDocument7 pagesAcid PicklingPhan Văn ThạnhNo ratings yet

- Straight Running Belts - 8.7 MM Thick: Chains & Belts Production ProgramDocument31 pagesStraight Running Belts - 8.7 MM Thick: Chains & Belts Production Programchmatias3No ratings yet

- 0138 IBR Brochure 2019 LRDocument4 pages0138 IBR Brochure 2019 LRPieter SteenkampNo ratings yet

- Matrix Installation Guide PDFDocument75 pagesMatrix Installation Guide PDFBrendan PrattNo ratings yet

- High Temperature Metal Sheathed Thermocouples - Type 27: TC LTD For Temperature Sensing, Measurement and ControlDocument4 pagesHigh Temperature Metal Sheathed Thermocouples - Type 27: TC LTD For Temperature Sensing, Measurement and ControlSyed Zakir Hussain ZaidiNo ratings yet

- FB27-11 2015 Guidelines Appearance of IGU Edges in Commercial Applications at Installation 0521Document7 pagesFB27-11 2015 Guidelines Appearance of IGU Edges in Commercial Applications at Installation 0521LEONARDONo ratings yet

- Bill of Quantity For RCC BuildingsDocument16 pagesBill of Quantity For RCC BuildingsAaron SolisNo ratings yet

- Inconel Alloy 751Document4 pagesInconel Alloy 751poulad pousheshNo ratings yet

- Defects in Metal Forming Processes: Prepared By:-Amitkumar R. ShelarDocument22 pagesDefects in Metal Forming Processes: Prepared By:-Amitkumar R. ShelarKarun PeriyasamyNo ratings yet

- The Steel Pipe in Trenchless TechnologyDocument8 pagesThe Steel Pipe in Trenchless TechnologyktsnlNo ratings yet

- Tds Tofil 805 1Document1 pageTds Tofil 805 1ryanNo ratings yet

- Katalog LincolnaDocument612 pagesKatalog LincolnaHaris TrešnjoNo ratings yet

- Bands Dossier RaychemRPGDocument78 pagesBands Dossier RaychemRPGTrujillo TrujilloNo ratings yet

- QC Insulation QuestionaireDocument6 pagesQC Insulation QuestionaireadeelNo ratings yet

- A Study of Erosion Wear Behavior of Inconel-718 Nickel-Based Superalloy at Different Impingement AnglesDocument10 pagesA Study of Erosion Wear Behavior of Inconel-718 Nickel-Based Superalloy at Different Impingement Anglesppic.gapallanNo ratings yet

- Tamper ShieldDocument8 pagesTamper Shieldأبو خالد الأثرىNo ratings yet

- THHN TC FuerzaDocument2 pagesTHHN TC Fuerzajuan pablo castro gallegoNo ratings yet

- Dimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 pageDimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraNo ratings yet

- Cable Tray Catalogue Web PDFDocument64 pagesCable Tray Catalogue Web PDFimranNo ratings yet

- Astm A450-A450m-2021Document10 pagesAstm A450-A450m-2021CarlosNo ratings yet

- Effects of Fine/coarse Aggregate Size and Shape On The Compressive Strength of ConcreteDocument7 pagesEffects of Fine/coarse Aggregate Size and Shape On The Compressive Strength of ConcreteELLA JOTOJOTNo ratings yet