Fundamentals of Rotating Equipment

Fundamentals of Rotating Equipment

Uploaded by

Fery HartantoCopyright:

Available Formats

Fundamentals of Rotating Equipment

Fundamentals of Rotating Equipment

Uploaded by

Fery HartantoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Fundamentals of Rotating Equipment

Fundamentals of Rotating Equipment

Uploaded by

Fery HartantoCopyright:

Available Formats

Technical Training Programme Rotating Equipment

FUNDAMENTALS OF

ROTATING EQUIPMENT

For

Mechanical Technician Trainees

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 1 of 61

Technical Training Programme Rotating Equipment

CONTENTS

CHAPTER 1: BEARINGS

CHAPTER 2: COUPLINGS

CHAPTER 3: PUMPS, PACKING AND MECHANICAL

SEALS

CHAPTER 4: CENTRIFUGAL COMPRESSORS

CHAPTER 5: RECIPROCATING COMPRESSORS

CHAPTER 6: SCREW COMPRESSORS

CHAPTER 7: GAS TURBINES

CHAPTER 8: ENGINES

CHAPTER 9: MOTORS

CHAPTER 10: COMMON PROBLEMS AND MAINTENANCE

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 2 of 61

Technical Training Programme Rotating Equipment

CHAPTER 1

BEARINGS

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 3 of 61

Technical Training Programme Rotating Equipment

CHAPTER 1

BEARINGS & LUBRICATION

CONTENTS Page Number

SECTION – 1.1

Introduction to Bearings

1.1.1 Friction ………………………………………………….… 8

1.1.2 Lubrication ……………………………………………….. 8

1.1.2.1 What are the basic purposes of lubrication ……….. 9

1.1.3 Function of the bearing …………………………….…….. 10

1.1.4 Loads acting on rotating shafts ………………………..… 10

1.1.5 Classification of bearings ……………………………….. 11

1.1.5.1 Bearings according to their function

(according to the load) may be …………………… 11

1.1.5.2 Bearings can be classified also as …………………. 11

1.1.5.2.1 Sliding surface bearings (plain bearings) 11

1.1.5.2.2 Rolling element bearings

(anti – friction bearings) ……………….. 12

SECTION – 1.2

Sliding Surface Bearings

1.2.1 Principle of operation …………………………………….. 13

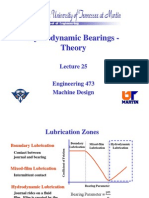

1.2.2 Lubrication of sliding surface bearings …………………... 14

1.2.3 How lubricant is distributed to bearings …………………. 15

1.2.3.1 Distributing the lubricant – oil grooves ………… 15

1.2.3.2 Oil Clearance (running clearance) ……………… 16

1.2.3.3 Bearing surface compatibility …………………... 16

1.2.4 General requirements for bearing materials ……………... 18

1.2.5 Sliding surface bearing materials ………………………... 18

1.2.5.1 Babbitt ………………………………………….. 18

1.2.5.2 Bronzes …………………………………………. 19

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 4 of 61

Technical Training Programme Rotating Equipment

1.2.6 Classification of radial sliding surface bearings with respect

to their configuration …………………………………….. 19

1.2.6.1 Pivoted – pad journal bearing (self tilting pad bearing) 20

1.2.7 Sliding surface bearing as thrust bearing ………………… 22

1.2.7.1 The function of thrust bearing …………………... 22

1.2.7.2 Classification of sliding surface thrust bearings … 22

1.2.7.3 Flat bearings: How does it works? ……………… 22

1.2.7.4 Tapered land bearing ……………………………. 23

1.2.7.5 Tilting pad thrust bearing ……………………….. 24

SECTION – 1.3

Sliding Surface Bearing Failure

1.3.1 Symptoms of bearing failure …………………………..… 25

1.3.2 Reasons of bearing failure ……………………………… 25

1.3.2.1 Metal fatigue …………………………………... 25

1.3.2.2 Dirt ……………………………………………. 25

1.3.2.3 Improper lubrication ………………………….. 26

1.3.2.4 Faulty installation ……………………………… 26

1.3.2.5 Mis-alignments ……………………………….. 26

1.3.2.6 Over loading …………………………………… 27

1.3.2.7 Corrosion ……………………………………… 27

1.3.3 Sliding surface bearing maintenance …………………… 28

1.3.3.1 Introduction to slide surface bearing maintenance 28

1.3.3.2 Bearing clearance (setting) ……………………. 28

1.3.3.3 Bearing high spots repair ……………………… 29

1.3.3.4 Flaking of babbit repair ……………………….. 29

1.3.3.5 Scoring repair …………………………………. 29

1.3.3.6 Wiping repair ………………………………….. 30

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 5 of 61

Technical Training Programme Rotating Equipment

SECTION – 1.4

Rolling Element Bearings (Anti – Friction Bearings)

1.4.1 The basic parts of a rolling element bearings …………… 31

1.4.2 How does it works? …………………………………….. 31

1.4.3 Basic types of rolling elements bearing ………………… 32

1.4.3.1 Ball bearing types ……………………………… 32

1.4.3.2 Roller bearings ………………………………… 34

1.4.3.3 Needle bearings ……………………………….. 36

1.4.4 Rolling element bearing failure ………………………… 37

1.4.4.1 Symptoms of failure …………………………… 37

1.4.4.2 Reasons of bearings failure …………………… 37

SECTION – 1.5

Bearing Installation

1.5.1 Mounting methods for angular contact ball bearings …… 40

1.5.1.1 Back-to-back bearings ………………………… 40

1.5.1.2 Face-to-faces bearings ………………………… 40

1.5.1.3 Tandem bearings ……………………………… 41

1.5.1.4 Fit on shaft for angular contact ball bearings … 41

1.5.2 Shaft and housing preparation ………………………… 42

1.5.2.1 Bearings seats on shaft ……………………….. 42

1.5.2.2 Shaft shoulders ……………………………….. 42

1.5.2.3 Break corner to prevent burrs ………………… 43

1.5.2.4 Check shoulders for off-square ………………. 43

1.5.2.5 Check Housing bore dimensions …………….. 44

1.5.2.6 Recheck dimensions it necessary …………….. 44

1.5.3 Mounting rolling element bearings …………………….. 44

1.5.3.1 Mounting methods for bearings with an interference

fit on the shaft ………………………………… 44

1.5.3.2 Dismounting rolling element bearings ……….. 46

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 6 of 61

Technical Training Programme Rotating Equipment

SECTION – 1.6

What to Look for During Operation

1.6.1 Listen ………………………………………………….. 48

1.6.2 Feel ……………………………………………………. 49

1.6.3 Look …………………………………………………… 50

1.6.4 Lubricate ………………………………………………. 51

1.6.4.1 With grease …………………………………… 51

1.6.4.2 With oil ……………………………………….. 52

1.6.5 Troubleshooting ……………………………………….. 54

SECTION – 1.7

Lubrication System

1.7.1 The importance of lubrication ………………………….. 57

1.7.2 The two common methods of lubrication ……………… 57

1.7.2.1 Splash and ring oilers ………………………… 57

1.7.2.2 Forced circulation oil lubrication system …….. 58

1.7.3 Lubricant storage and handling ………………………… 59

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 7 of 61

Technical Training Programme Rotating Equipment

SECTION – 1.1

INTRODUCTION TO BEARINGS

1.1.1 Friction

Friction is the resistance to motion that exists between two bodies in contact.

In order to move these bodies more easily, friction must be reduced. There are

two kinds of friction that exist between two surface in contact:

1- Rolling friction (figure 1.1).

2- Sliding friction (figure 1.2).

Figure 1.1 Figure 1.2

Rolling friction Sliding friction

Rolling friction is the friction that exists when one body rolls around or within

another.

Sliding friction is the friction that exists when one body slides over another.

The difference between these two is the way related surfaces move in respect to

each other.

Rollers can decrease friction and make an object easier to move. Lubricating a

surface also reduces friction and allows an object to move much more freely.

1.1.2 Lubrication

The purpose of a lubricant is to reduce friction. Lubrication is merely a means

of separating moving surfaces by providing a film for the surfaces to travel on.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 8 of 61

Technical Training Programme Rotating Equipment

Take the simplest case of a flat object m

Dry surfaces in contact Lubricated surfaces

separated by oil film

Figure 1.3

The required force to drive block (A) to slide on the flat surface is too high in

case of dry surfaces (figure 1.3). In the second case (lubricated surfaces) – the

required force will be less.

The applying of lubrication between two sliding surfaces makes the sliding of

one of them over the other becomes too much easier.

1.1.2.1 What are the Basic Purposes of Lubrication?

They are:

1- To reduce friction between sliding surface (as the example which is

mentioned before – figure 1.3)

2- To reduce wear: The wearing down of machine parts is caused by friction.

If you reduce friction through lubrication, you also reduce wear. The

thickness of the lubricant film is important. If the film is not thick enough to

separate the two surfaces, direct contact will happen and the wear will

happen also.

3- Damping shock: The way a lubricant dampens shock is by making use of its

ability to distribute pressure. A practical example of this property is found

in gear lubrication.

4- To cool moving components: The lubrication prevents excessive friction

between moving components. So that less heat will be generated. Lubricants

also carry away some heat from the points where it is generated to coolers,

where it is then dispelled into the air.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 9 of 61

Technical Training Programme Rotating Equipment

5- Corrosion prevention: The lubricants prevent or retard rust and corrosion. It

forms a protective film on metallic machine parts. The film prevent direct

contact of metal with oxygen in air.

6- To seal out dirt, other contaminants: lubricants serve as seals in machines in

two ways:

- Lubricant can seal itself into the place where it is needed.

- Lubricant can also seal out dirt and other contaminants from the

contact areas.

1.1.3 Function of the Bearings

Bearings are machine parts in which other parts turn or slide. They are five

major functions of the bearing in rotating machines;

1. To support a shaft while permitting the shaft to rotate as necessary for

proper operation of the equipment.

2. To keep the shaft in its correct running position with respect to the

machine casing.

3. Reduce friction by providing either sliding contact (sliding surface

bearings) or rolling contact (rolling element bearings). Usually bearings

reduce friction by means of a lubricant in addition to their basic design.

4. Reduce wear, by reducing friction

5. It provides a replaceable wear surface which is more economical to

replace than the shaft which the bearing supports.

1.1.4 Loads Acting on Rotating Shafts

Figure 1.4 Load forces acting on bearings

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 10 of 61

Technical Training Programme Rotating Equipment

Any rotating shaft is subject to two forces (or two loads):

1- Radial loads – which acting in the radial direction.

2- Axial Loads – which acting in axial direction trying to move the shaft

in axial direction.

Because bearings will subjected to these two loads, they are designed to be used

for a specific application.

Radial bearings are used where only radial loads are encountered. Thrust

bearings are made to withstand axial loads.

1.1.5 Classification of Bearings

1.1.5.1 Bearings according to their function (according to the

load) may be:

1- A radial bearings – to carry the radial loads only.

2- Thrust bearings – to carry the axial loads only.

3- Combination bearings – carry some radial load & carry some axial

load.

1.1.5.2 Bearings can be classified also as:

1- Sliding surface bearings (Plain bearings).

2- Rolling element bearings (Anti – friction bearings).

Let us now study the sliding surface bearings and rolling element bearings, and

find out which loads can carry.

1.1.5.2.1 Sliding Surface Bearings (Plain Bearings)

Sliding surface bearings (plain bearings) provide a sliding contact between the

mating surfaces.

The surfaces of both the shaft (as moving surface) and the bearing (as stationary

surface) are lubricated to reduce friction.

Sliding surface bearings (plain bearings), according to their function, maybe:

• Radial bearings: to carry radial loads. Thus, they will keep a shaft from

moving up and down or from side to side, but they will not keep it from

moving in an axial direction

• Thrust bearings: to carry the axial loads only. They are built to surround

a collar on the shaft, called a thrust runner or thrust collar. This

construction transfers any axial loads to the bearing and from the bearing

to the machine casing.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 11 of 61

Technical Training Programme Rotating Equipment

1.1.5.2.2 Rolling Element Bearings (Anti-Friction Bearings)

Rolling contact bearings are designed to support and locate rotating shafts. They

transfer loads between rotating and stationary members and permit relatively

free rotation with a minimum of friction.

They consist of four basic components (figure 1.5)

- Inner ring (inner race) – fixed on the shaft and rotates with it.

- Outer ring (outer race) – fixed to the bearing housing and does not

rotates.

- Rolling element.

- Retainer (keep cage).

Figure 1.5 Rolling element bearing components

Anti – friction bearings, according to their function, may be:

Radial bearings: Carries load (forces) in a radial direction. Thus they

will keep a shaft from moving up and down or from side to side. They

will not keep it from moving in axial direction.

Thrust bearings: These bearings will accept full thrust loads. It can not

accept radial loads. They are usually used in conjunction with radial –

load bearings.

Combination radial and thrust load bearings: This bearings will

support radial loads and thrust loads.

After this introduction, let us now study each type in details.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 12 of 61

Technical Training Programme Rotating Equipment

SECTION – 1.2

SLIDING SURFACE BEARINGS

1.2.1 Principle of Operation

Refer to figure 1.6

Figure 1.6 Sliding surface bearing (journal bearings)

1- In a typical plain journal bearing, the shaft of the equipment is the rotating

element. The portion of the shaft inside the bearing is a highly polished

surface and is reffered to as the bearing journal. The bearing is the part that

surrounds and supports the shaft. This cylindrical part is often called a

sleeve or the bearing shell. In some designs the shell is two – piece

component.

2- The bearing shell is lined with a soft metal alloy called babbitt. This babbitt

takes the wear that would otherwise occur in the shaft (bearing journal).

3- The shaft (bearing journal) surface and the babbit material are separated by

a thin film of lubricant.

4- When the equipment is not operating, the shaft sits at the bottom of the

bearing shell (figure 1-7-a)

5- When the equipment is put into operation and the shaft begins to turn, an

oil wedge develops at the point where the shaft meets the bearing surface

(figure 1-7-b).

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 13 of 61

Technical Training Programme Rotating Equipment

6- As the shaft accelerates, it actually floats up on this oil wedge until it is

supported in the center of the bearing shell by the thin film of oil

(figure 1-7-c).

a- The equipment is not b- The shaft begins to turn c- Full speed

operating

Figure 1.7 Oil wedge development and types of friction

The shaft and the bearing surfaces do not actually touch one another when the

equipment is fully operating. Instead, the shaft rides on the thin film of oil. The

separation between the shaft and the bearing surface permitting the shaft to

rotate easily with minimum wear.

1.2.2 Lubrication of Sliding Surface Bearings

Lubrication are used to reduce friction and wear in bearings. The less friction, of

course, the less wear will result.

Three states of friction or lubricant may exist between the sliding surfaces of the

shaft and the bearing shell:

1- Dry friction: Dry friction is when no lubricant is present between the

contacting surfaces (figure 1.7.a)

2- Boundary Lubrication: It happens when the lubricant is a thin film

between the sliding surfaces (figure 1.7.b)

3- Full Film Lubrication: Full-film lubrication separates the sliding

surfaces completely (figure 1.7.c)

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 14 of 61

Technical Training Programme Rotating Equipment

Full lubrication can only be achieved by a combination of the right lubricant,

good bearing design, and at least a moderate rotary speed (RPM).

1.2.3 How Lubricant is Distributed to Bearings?

The bearing must have three things (characteristics) in order to perform will:

1. It must have a means of distributing the lubricant (oil grooves).

2. Oil clearance must be correct to fit the shaft will.

3. The bearing surface must be compatible with shaft, the lubricant and the

speed of rotation.

1.2.3.1 Distributing the Lubricant – Oil Grooves

Oil grooves are necessary to ensure that the bearing receives adequate

distribution of lubricant. Several designs are shown in figure 8.

Each design is suitable for certain working condition like shaft diameter,

running speed, kind of lubricant and the feeding system.

Figure 1.8 Oil groove designs for sliding surface bearings (plain bearings)

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 15 of 61

Technical Training Programme Rotating Equipment

1.2.3.2 Oil Clearance (Running Clearance)

The space between the shaft (journal) and the inside surface of the bearing shell

when the shaft is centered in the bearing is called the oil clearance, or running

clearance. This small space provides room for the thin oil film that separates the

shaft and the bearing shell when the equipment is operating.

Oil clearance can be expressed in two forms:

I.D. of the bearing shell - O.D of the shaft

- Radial clearance =

2

- Diameteral clearance = I.D of the bearing shell – O.D of the shaft.

Where:

I.D of the bearing shell is the inside diameter of the bearing shell.

O.D of the shaft is the outside diameter of the shaft in the bearing area.

1.2.3.3 Bearing Surface Compatibility

Figure 1.9 shows the three states of lubrication. Each condition is determined

by:

- Viscosity of the lubricant.

- Running speed of the shaft (RPM).

- The Smoothness of mating surfaces.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 16 of 61

Technical Training Programme Rotating Equipment

Surface A

Surface B

SURFACES IN CONTACT

(No enough lubricant and/or rough surfaces)

Surface A

Surface B

SURFACES SEPARATED BY LUBRICANT

(Very thin lubricating film)

Surface A

Surface B

SURFACES SEPARATED BY HYDRODYNAMIC

PRESSURE

Figure 1.9 Lubricant between sliding surface

Case # 1 Surfaces in contact (dry friction):

Is caused by using a light viscosity lubricant to support the shaft or by surfaces

too rough to be separated by the recommended lubricant.

Case # 2 Surfaces separated by lubricant (boundry lubricant):

Is the minimum lubrication requirement to prevent direct contact of mating

surfaces. This condition exists with relatively slow speed of rotation.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 17 of 61

Technical Training Programme Rotating Equipment

Case # 3 Surfaces separated by hydrodynamic pressure:

This is the ideal state of lubrication. The surfaces of the mating parts, the speed

of rotation and the viscosity of the lubricant will all affect the ability to achieve

this condition.

1.2.4 General Requirements for Bearing Materials

Experience shows that a good bearing material is:

1- Score resistance

2- High in compressive strength.

3- High in fatigue strength.

4- Deformable.

5- Corrosion resistance.

6- Low in shear strength.

7- Structurally uniform.

8- Inexpensive.

9- Readily available.

This list of requirements is evidence that selection of a bearing material for a

particular application is always a compromise. No single material has all of

these characteristics in a sufficiently acceptable level.

1.2.5 Sliding Surface Bearing Materials

Most sliding surface bearing are made from the following standard types

1- Babbitt (tin – base, lead – base)

2- Bronze

1.2.5.1 Babbitt

Babbitts are the best known of all bearing materials. Also called white metal.

Babbitt is an alloy comprised of three elements: Tin, antimony and copper.

When babbitt is used in small bearings, Babbitt is applied to the bearings as a

thin coating over steel on bronze. To make larger bearings in heavy – duty

equipment; a thicker layer is used to line a rigid backing or shell of steel, bronze

or cost iron.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 18 of 61

Technical Training Programme Rotating Equipment

1.2.5.2 Bronzes

Bronze alloys have many bearing applications because of their wide range of

properties. Most bearing bronzes are variations of three main types as follows:

a- Lead - bronze

b- Tin - bronze

c- Aluminum - bronze

A fourth type, phosphor – bronze, is also popular. As a group, bronze – alloys

are probably the most economical bearing material of all.

1.2.6 Classification of Radial Sliding Surface Bearings (Plain

Journal Bearings) with Respect to Their Configuration

Radial sliding surface bearings (plain journal bearings) come in many forms.

Their one point common is that they are shaped as cylinders or section of

cylinders. The difference in form simply accommodate various types of

equipments.

Basically, you will find three principal types of construction:

1- Solid plain cylindrical bushing (one piece) with lubricating feed grooves

(figure 1-8)

2- Straight cylindrical bearing (two halves). It is \horizontally split,

replaceable liner sleeve bearing.

3- Titing pad radial bearing.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 19 of 61

Technical Training Programme Rotating Equipment

The following figure (figure 1.10) shows two different type from these three.

Figure 1.10 Connecting rod with solid plain bearing (item # 10) and

straight cylindrical bearing (two halves – item # 11)

1.2.6.1 Pivoted – Pad Journal Bearing (Self Tilting Pad Bearing)

Also called pivoted shoe journal bearing. This design has segmented bearing

surface. The segments are supported so that they can move slightly and adjust to

the best position for proper lubrication (figure 1.11)

Figure 1.11 Tilting pad radial bearing

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 20 of 61

Technical Training Programme Rotating Equipment

This type of tilting pad radial bearing is designed for high peripheral speeds and

shaft stabilization.

Figure 1.12– shows the detail construction of this type.

Figure 1.12

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 21 of 61

Technical Training Programme Rotating Equipment

1.2.7 Sliding Surface Bearing as Thrust Bearing

1.2.7.1 The Function of Thrust Bearing

The basic function of thrust bearing in the rotating machines is to carry the axial

loads and keep the shaft in its correct running position in the axial direction.

A sliding surface thrust bearing (figure 1.13) is used in conjunction with a thrust

collar (thrust runner). Thrust collar is a disc on the shaft. This collar may be a

separate disc attached to the shaft, or an integral part of the shaft.

The thrust bearing is the part that is closest to the thrust collar. Thrust bearings

are generally used in pairs: one bearing is placed on each side of the thrust

collar (figure 1.13). In this way, thrust bearings support axial load in both

directions on the shaft. They prevent the shaft from moving through the bearing.

Figure 1.13 Pair of thrust bearings surrounding thrust collar

1.2.7.2 Classification of Sliding Surface Thrust Bearings

There are three designs of sliding surface bearing as thrust bearing:

1- Flat land bearings

2- Tapered land bearing, and

3- Tilting pad bearing (kingsbury thrust bearing).

1.2.7.3 Flat Bearings: How Does it Work?

Flat land bearing illustrated in figure 1.14. It is one of the simplest types of

thrust bearings. It is a solid piece with no movable parts. Grooves in the bearing

divide it into sections called lands. One edge of each land is curved slightly so

that the lubricant that is pumped into the groove is distributed over the bearing

surface more easily. Lubricant sticks to the thrust collar as the shaft turns and is

drawn over the bearing, creating a film of lubricant between the thrust collar

and the bearing.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 22 of 61

Technical Training Programme Rotating Equipment

Figure 1.14 Cut – away view of a flat land thrust bearing

1.2.7.4 Tapered Land Bearing

The tapered land bearing (or fixed wedge thrust bearing) figure 1.15 looks like

the flat land but each of the lands is slightly tapered to improve bearing

lubrication. Film lubrication takes place between the bearing and the thrust

collar.

Figure 1.15 Construction of a tapered – land thrust bearing

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 23 of 61

Technical Training Programme Rotating Equipment

The direction of rotation of the thrust collar must be in specific direction to get

efficient lubrication.

1.2.7.5 Tilting Pad Thrust Bearing

A typical tilting pad bearing (Figure 1.16) is made up of several parts.

Figure 1.16 Principle of a tilting pad thrust bearing

In this bearing, the thrust collar contact number of segments (also called shoes).

Each segment is supported by a pivot. As the collar begins to rotate, the

lubricant that is in the bearing sticks to the collar and is dragged between the

collar and the individual shoes.

As the speed of the shaft increases, more and more lubricant is drawn between

the shoes and the collar, forming a wedge that causes the shoes to tilt. The

wedge of lubricant increases the load carrying capacity of the bearing.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 24 of 61

Technical Training Programme Rotating Equipment

SECTION – 1.3

SLIDING SURFACE BEARING FAILURE

1.3.1 Symptoms of Bearing Failure

1- Abnormal temperature.

2- Vibration.

3- Noise

or a combination of these signs may indicate that a bearing has failed

or is about to fail. When replacing damaged bearings, it is vital to

determine their cause of failure. Otherwise, failures will happen again

in a very short time.

1.3.2 Reason of Bearing Failure

The most common causes of sliding surface bearing failure are:

1- Metal Fatigue.

2- Dirt.

3- Improper Lubrication.

4- Faulty installation (improper assembly).

5- Misalignment.

6- Overloading.

7- Corrosion.

1.3.2.1 Metal Fatigue

Metal fatigue is a common cause of bearing failure that occurs during normal

bearing operation. All sliding surface bearings are subject to load and vibration,

which cause the metal in the bearing to flex and bend. The metal is gradually

weakened by the flexing and bending. This makes bearing fails, because its

surface breaks up and becomes rough. This roughened surface causes an

increase in the bearing temperature and vibration, which in turn, causes further

damage to the bearing. The process continues until the bearing is too badly

damaged to the function at all, and it fails.

1.3.2.2 Dirt

Large dirt particles can embed in the soft bearing material. This causes wear and

decreases the life of both the bearing and the shaft.

Prevent this by cleaning the area surrounding the bearing during bearing

installation and by proper maintenance of oil filters, if used.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 25 of 61

Technical Training Programme Rotating Equipment

1.3.2.3 Improper Lubrication

The term improper lubrication refers to four different situations:

a) Too little lubrication (oil starvation)

b) Wrong kind of lubricant

c) Contaminated lubricant.

d) Lubricant breakdown due to high operating temperature

1.3.2.4 Faulty Installation

In order to obtain a correct installation, the following points should be taken

into consideration:

a) Match marks must be checked carefully to insure proper orientation of

the lower bearing shell in the lower bearing housing.

b) Gaskets or spacers are installed.

c) The bearing cover is set in position, using care to avoid any damage

either in the shaft or the bearing. The dowel pins should be installed.

d) The retaining nuts for the bearing cover are installed and tightened to

the correct torque value and the specified sequence.

1.3.2.5 Mis-Alignments

A bearing is mis-aligned when the shaft that it supports does not pass through it

correctly, as illustrated in figure 1.17. If the bearing is misaligned, the shaft rubs

against one side of the bearing at one end and against the opposite side of the

bearing at its other end.

Figure 1.17 Mis-aligned bearing.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 26 of 61

Technical Training Programme Rotating Equipment

1.3.2.6 Overloading

Overheating from overloading causes a metal fatigue which breaks away and

voids the surface of the bearing.

1.3.2.7 Corrosion

Corrosion from acid formation in the oil is seen by a finely pitted surface and

large areas of deterioration.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 27 of 61

Technical Training Programme Rotating Equipment

1.3.3 Sliding Surface Bearing Maintenance

1.3.3.1 Introduction to Slide Surface Bearing Maintenance

To perform any maintenance job related to the sliding surface bearings (either

radial or thrust bearings), you should go through three steps:

1- Clean the bearing and the shaft journal.

2- Inspect the parts thoroughly to fined out the reason of failure.

3- Carry out the required action – repair or replace the damaged part.

Carefully inspect bearings and journals for uneven wear or damage. If required,

polish journals using belt-type emery clothe and remove high spots. Sleeve and

thrust bearings should be thoroughly incepted for correct clearance, high spots,

flaking of babbitt, scoring, and using the following procedures.

1.3.3.2 Bearing Clearance (Setting)

• The radial bearings must have clearance between the shaft journal and the

bearing. The amount of clearance necessary depends on the oil viscosity,

the shaft speed, and the bearing loading. Manufacturers’ consider each of

these parameters in calculating a bearing clearance that will produce

hydrodynamic lubrication as well as a flow of oil sufficient to cool the

bearing.

• Measurement of bearing clearances may be done by: Feeler gauges, lead

wire or plastic gauge material. The bearing may be considered

operational as long as the measured clearance does not exceed the design

clearance by more than .004 to .005 in. This value for clearance increase

is acceptable for most applications.

• The thrust bearing clearance provides room for the formation of an oil

film between the bearing face and the thrust collar (or thrust runner) and

for thermal expansion. Normally, wear of the thrust bearing is not very

critical unless it is enough to cause loss of oil pressure in the lubrication

system or allow for rubbing of internal components.

• Measurement of thrust bearing clearance may be done by pushing the

shaft axially to one side of the unit, setting a dial indicator and then

pulling the shaft axial to the other side of the unit against the dial

indicator.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 28 of 61

Technical Training Programme Rotating Equipment

1.3.3.3 Bearing High Spots Repair

• Evidence and location of high spots in the bearing are indicated by bright

spots or areas. These spots are caused by wear resulting from a ruptured

oil film around the high point. Bright spots are slightly scraped and

polished with fine steel wool or emery cloth until they blend in with the

rest bearing.

• To check the bearing contact, install the lower half of the bearing in the

housing with the journal and thrust face clean and dry.

• Check outside diameter of bearing shell with a .0015 in. feeler gauge to

be sure the lower half is seated in the housing.

• Apply a light coat of soft blue (Prussian blue) to the journal and to each

thrust face. The journal should show blue transfer for a minimum of 80

percent of bearing length. Thrust faces should show a minimum contact

of 60 percent of load area. Repeat the checking process until the contact

area is satisfactory.

1.3.3.4 Flaking of babbitt Repair

• Flaking of babbitt in the loaded area of the bearing is caused by vibration

or shock loading of the bearing material. The vibration and shock

loading causes the babbitt to fatigue and break loose from the steel shell.

Not only do the flakes cause scoring as they pass through the bearing, but

they also contaminate the oil.

In the advanced stages of flaking, the load-carrying area of the bearing is

destroyed, and the bearing must be replaced. However, if flaking is

caught in the early stages, the bearing may be repaired be scraping and

polishing. Whatever the case, the cause of vibration or hammering should

be corrected before the unit is put back into service.

1.3.3.5 Scoring Repair

• Scoring is the scratching of the bearing babbitt or the journal riding in the

bearing, or both. It is caused by dirt or metal particles present in the oil

that passes through the bearing. A little scoring is not serious, and the

bearing may be polished with fine steel wool to remove any rough edges

caused by scoring. Any foreign particles imbedded in the babbitt who

could score the journal should be carefully picked out, and that area

should then be polished smooth. Scoring becomes serious when it

significantly reduces the bearing area. In this case, the bearing should be

replaced, and the gear unit or pump drained and flushed out with a

solvent.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 29 of 61

Technical Training Programme Rotating Equipment

1.3.3.6 Wiping Repair

• Wiping is the melting and wiping away of a spot or area of the babbitt

due to the bearing temperature rising above the pour point of the babbitt.

• Abnormally high bearing temperatures can be causes by one or more of

the following.

1- Insufficient bearing clearance.

2- Insuffecient oil (quantity and / or pressure).

3- Excessively high oil temperature in the bearing due to improper

cooling.

4- A high spot (s) in the bearing.

5- Extreme (high) bearing loading cause by poor contact area.

• If wiping is localised in a small spot, the bearing may be repaired by

scraping and polishing the spot until it blends in with the remainder of

the bearing; otherwise, the bearing must be replaced.

Before replacing a wiped bearing, determine the cause of the wipe and

take corrective measures. If new bearings are necessary, the following

precautions should be taken:

1. Remove all nicks and burrs from the housing and bearing shell.

2. Be sure that journal and thrust faces are free of nicks and high spots.

These spots can be removed using a fine hone and polishing with fine

emery cloth.

3. Obtain the proper bearing contact as described previously.

4. After the bearings are fitted and the lower half is installed in the

housing (on both sides), check the radial clearance using plastic

gauge. Check thrust clearance by moving shaft axially in both

directions while an indicator pointer is positioned against the shaft. In

many cases it may be necessary to use a small hydraulic jack to move

the large rotors axially to check the axial (thrust) clearance.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 30 of 61

Technical Training Programme Rotating Equipment

SECTION – 1.4

ROLLING ELEMENT BEARINGS

(ANTI–FRICTION BEARINGS)

1.4.1 The Basic Parts of a Rolling Element Bearings

Figure 1.18 shows the basic parts. They are:

1- Two hardened steel rings called races. The inner ring (inner race) is

normally fixed on a shaft, and the outer ring (outer race) fits in a bearing

housing. Shaped raceways are machined in the rings to confine and

guide the rolling elements.

2- Hardened steel balls, rollers or needles which roll between the races.

3- Separators (keep cage) made of steel, bronze or plastic which space the

rolling elements around the races.

Figure 1.18 Basic parts of rolling element bearings

1.4.2 How Does it Works?

The load is transmitted from the inner race to the outer race through the rolling

elements to the bearing housing. The accurate distribution of the rolling

elements between the inner race and the outer race prevents any radial

movement of the shaft out of the correct running position.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 31 of 61

Technical Training Programme Rotating Equipment

1.4.3 Basic Types of Rolling Element Bearing

There are three basic types of rolling element bearings:

1.4.3.1 Ball bearings

1.4.3.2 Roller (Cylindrical) bearings

1.4.3.3 Needle roller bearings

Each one of these three types is divided into different designs.

1.4.3.1 Ball Bearing Types

There are four basic designs of ball bearings (with respect to the load)

1- Deep groove ball bearing: (figure 1.19.a)

- Carry radial load and some axial load

2- Angular contact ball bearing (figure 1.19.b,c )

- These bearings will support radial load and thrust loads.

3- Double row self aligning ball bearing (figure 1.19-d)

- Carry radial load and very little axial loads. These bearings allow

(accept) some misalignment.

-

a b c d

Figure 1.19 Types of ball bearings

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 32 of 61

Technical Training Programme Rotating Equipment

Ball bearing as thrust bearing

These bearings will accept full thrust load and very light radial loads. They are

usually used in conjunction with radial load bearings (figure 1.20).

Figure 1.20 Thrust load ball bearings

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 33 of 61

Technical Training Programme Rotating Equipment

1.4.3.2 Roller Bearings

The principal difference between ball bearings and roller bearings (cylindrical

bearings) is the shape of the rolling element itself.

In ball bearings the rolling element is a ball. In roller bearings the rolling

element is cylinder.

Roller bearings can support greater loads because of their larger contact area.

There are five basic types of roller bearings. They are:

1. Radial-load, straight roller bearing. (figure 1.21.a)

2. Radial and thrust-load, tapered roller bearings (figure 1.21.b)

3. Self-aligning, radial and thrust-load, spherical roller bearing (figure 1.21.c)

4. Self aligning, radial and thrust-load, concave roller bearing (figure 1.21.d)

5. Thrust load roller bearings (figure 1.22)

a b c d

Figure 1.21 Basic types of roller bearings

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 34 of 61

Technical Training Programme Rotating Equipment

Figure 1.22 Thrust – load roller bearings

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 35 of 61

Technical Training Programme Rotating Equipment

1.4.3.3 Needle Bearings

Needle bearings are a separate form of roller bearing. They differ from other

roller bearings in two ways:

1- The roller’s length is at least twice as long as its diameter – four to six

times as long is common, and the roller is much smaller in diameter than

other rollers. This long, thin shape gives them their name of “needles”.

2- The second difference is that many needle bearings have no cage or

separators.

Refer to figure 1.23 for the terms used to describe basic needle bearing

construction. The needle bearing shown is the drawn-cup type.

Figure 1.23 Nomenclature of common needle roller bearing

Figure 1.24 Types of needle roller bearing bearings

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 36 of 61

Technical Training Programme Rotating Equipment

1.4.4 Rolling Element Bearing Failure

1.4.4.1 Symptoms of Failure

There are five symptoms gives indication that the rolling element bearings has

been failed. They are:

1- High temperature: Hot bearings indicates bearing failure.

2- High vibration level.

3- Noisy bearings.

4- Lubricant leaks outside the bearing housing contaminated with metallic

particles which indicates rubbing between different components inside

the bearings housing.

5- Clear movement of the shaft from its original position movement. This

happens in an advanced stage of failure. The rolling elements lost its

uniform distribution between inner and outer races.

1.4.4.2 Reasons of Bearing Failure

The most common causes of rolling element bearing failure are:

1- Improper maintenance technique (faulty mounting practices).

2- Incorrect shaft and housing fit.

3- Misalignment.

4- Defective bearing seats on shafts and/or in housing.

5- Inadequate lubrication.

6- Ineffective sealing.

7- Vibration.

8- Passage of electric current through the bearing.

Let us study each one of these reasons of bearing failure to find out the proper

way to prevent it.

1- Improper maintenance technique (faulty mounting practice): Improper

maintenance technique covers the following:

a- Foreign mater in the bearing installation (not properly cleaned). Clean

all bearing components before installation and keeping the work area

clean are essential.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 37 of 61

Technical Training Programme Rotating Equipment

b- Overheating the bearing during the heating to expand the bearing.

Correct heating method must be used and the suitable heating

temperature should be kept.

When heating a bearing for mounting, an oil path should be used if

available.

c- Impact damage handling or mounting resulting in brinelling.

d- The required force to install the inner race of the bearing on the shaft

must be applied directly and evenly on the inner race.

If this force is applied on the outer race it will destroy the bearing.

If you use hydraulic press during bearing installation, the force must

be applied slowly and evenly.

2- Incorrect Shaft and Housing Fit:

A bearing may need to be fitted either with an interference fit or a slip fit on the

shaft and the housing depending on the conditions present. The degree of

tightness or looseness in the bearing is governed by the magnitude of the load,

the speed (r.p.m) and the arrangement of the bearing.

3- Misalignment

Misalignment is a source of premature bearing failure. This condition generally

occurs when:

• The inner race of bearing is seated against a shaft shoulder that is not

square with the shaft centerline.

• The outer race is seated against a housing shoulder that is out of

square with the housing bore.

4- Defective bearing seats on shaft and/or in housing

For bearings to have long trouble – free life, the inner race of the bearing and

the outer race should be seated properly, that means

• The shaft (in the area of inner race) should be round and smooth.

• The bearing housing bore should be round, free of taper.

• Both shaft and bearing bore must be concentric (i.e. must have the

same center line)

• The dimensions of the shaft and bearing housing must be correct.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 38 of 61

Technical Training Programme Rotating Equipment

5- Inadequate Lubrication

The presence of proper lubricant is essential. The rollers must carry lubricant to

lubricate the tracks. Without proper lubricant (kind and quantity), the bearing

motion can be very detrimental.

6- Ineffective Sealing

The function of bearing seals (which are installed on the bearing housing) is to

prevent dirty to enter the bearing housing and to prevent the lubricant to escape

to outside.

Effective sealing means prevent lubricant to leake out side the bearing housing

and prevention of contaminants to enter the bearing housing.

7- Vibration

There are two sources of vibration:

a) Vibration from the machine itself (due to several reasons like

unbalanced rotor, coupling misalignment, …etc).

b) Vibration transferred from another source through piping system or

steel structure.

These two sources will cause rapid failure and sever damage to the

bearing.

8- Passage of Electric Current Through the Bearing

In certain applications where electrical machinery is in use, there is the

possibility that electric current will pass through a bearing.

Current that seeks ground through the bearing can be generated from magnetic

field in the machinery or can be caused by welding on some parts of the

machine with the ground attached so that the circuit is required to be completed

through the bearing.

When the current is broken at the contact surfaces between rolling elements and

the raceways, marking results; this marking produces localized high

temperature, and consequently, the surfaces are damaged. This damage will

appear as small pits on the raceways and the rollers.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 39 of 61

Technical Training Programme Rotating Equipment

SECTION – 1.5

BEARING INSTALLATION

1.5.1 Basic Mounting Methods for Angular Contact Ball Bearings

Angular contact ball bearings can be mounted in three different ways to suit

different loading conditions. The three ways are:

1.5.1.1 Back-to-Back Bearings

Are placed so that the high shoulders of the outer rings are together. In this

position, the contact angle lines diverge inwardly (figure 1.25).

Figure 1.25 Back-to-back bearings are placed so that the high shoulder

of the outer rings is together

1.5.1.2 Face-to-Face Bearings

Are placed so that the low shoulders of the outer rings are together. Contact

angle lines of the bearing will then converge inwardly, toward the bearing axis

(figure 1.26).

Figure 1.26 Face-to-face bearings are placed so that the low shoulder of

the outer ring is together

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 40 of 61

Technical Training Programme Rotating Equipment

1.5.1.3 Tandem Bearings

Are placed so that the stamped back of one bearing is in contact with the

unstamped face of the other bearing. In this case the contact angle lines of the

bearings are parallel (figure 1.27)

Figure 1.27 Tandem bearings are placed so that the stamped back of one

bearing is in contact with the unstamped face of the other bearing

1.5.1.4 Fit on Shaft for Angular Contact Ball Bearings

Angular contact ball bearings generally have a looser fit on the shaft than other

standard types of bearings. “Push” fits; (finger pressure fits) are generally

employed. This helps prevent a change of internal characteristics and facilities

removal and remounting of the bearings.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 41 of 61

Technical Training Programme Rotating Equipment

1.5.2 Shaft and Housing Preparation

1.5.2.1 Bearing Seats on Shaft

The inner ring must be tight enough not to turn or creep significantly under

load.

Figure 1.28

1.5.2.2 Shaft Shoulders

The shoulder in figure 1.29.A is tapered (inclined). This results in poor seating

of the bearing against the corner of the inner ring.

The shaft shoulder in figure 1.29.B is so low that the shoulder actually contacts

the bearing corner rather than the locating face of the bearing.

With the condition shown in figure 1.29.C, contact between the shoulder and the

bearing face is not sufficient. Under heavy thrust loads, the shoulder might

break down.

Figure 1.29.D is exaggerated to illustrate distortion of the inner ring when

forced against off-square shoulder. An off-square bearing shortens bearing life.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 42 of 61

Technical Training Programme Rotating Equipment

Figure 1.29 Incorrect installation

1.5.2.3 Break Corner to Prevent Burrs

When the shaft shoulder or bearing seat is repaired by regrinding, it is desirable

to break the corner on the shaft. This will help prevent burrs and nicks, which

may interfere with the proper seating of the inner ring face against the shaft

shoulder. If left sharp, shoulder corner is easily nicked, producing raised

portions, which, in turn, may create an off-square condition in bearing location.

The usual procedure to break a corner is to use a file or an abrasive stone.

Figure 1.30 Incorrect installation

1.5.2.4 Check Shoulders for Off-Square

The shaft shoulder runout should be checked with an indicator contacting the

bearing locating surface on the shaft shoulder while the shaft is still supported

on centers (or V-blocks) with the center of the shaft against a stop. Tolerances

have been established for this. If the runout is outside these tolerances, the inner

ring of the bearing will be misaligned causing vibration when the shaft is in

operation.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 43 of 61

Technical Training Programme Rotating Equipment

1.5.2.5 Check Housing Bore Dimensions

The housing bore dimensions and shoulder should be checked to make sure that

they are within the recommended tolerance for size, out-of-round, taper, and

off-square. The gauge commonly used for this purpose is an dial gauge test

indicator type

1.5.2.6 Recheck Dimensions it Necessary

It is important to be absolutely sure that all dimensions are correct before any

assembly is begun.

1.5.3 Mounting Rolling Element Bearings

1.5.3.1 Mounting Methods for Bearings with an Interference Fit

on the Shaft

It is possible to use either a cold or warm mounting method. In general it is

better to use warm mounting as this method is the easiest and eliminates the

danger of damage to the shaft.

If this is not possible bearings may be mounted using the cold method. If a

hydraulic press is available, it is possible to mount larger bearings.

Some types of bearings in particular those with double seals and "greased for

life" must only be mounted using the cold method.

• Cold Mounting

The mounting force must be applied evenly on the inner ring. It is advisable to

use a mounting tool, which can be made from a piece of pipe.

The shaft area under the bearing inner ring (inner race) should be coated with

anti – size lubricant to be easy for future disassemble.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 44 of 61

Technical Training Programme Rotating Equipment

Figure 1.31 Cold mounting of bearings

The contact face must be perfectly flat and the head of the mounting tool should

either rounded or has a raised portion in the centre. The mounting tool should be

placed against the inner ring the bearing is then slide along the shaft using a

press or by means of light taps with a hammer.

During this operation constant checks should be made to ensure that the bearing

is at right angles to the shaft centre line.

• Warm Mounting

By heating the bearing it is possible to expand the bore so that it is larger than

the shaft. This means that the bearing can be slide on the shaft without any

problem. Bearings can be heated to a maximum of 120, ºC for a short period.

Above this temperature the hardness of the bearing material will be adversely

affected. The bearing should be heated in an oil bath.

Figure 1.32 Bearing hanging free in a warm oil bath

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 45 of 61

Technical Training Programme Rotating Equipment

The heated bearing can be fitted onto the bearing surface without difficulty and

care should be taken to ensure that the side face of the inner ring is in complete

contact with the shoulder of the shaft or a spacer.

1.5.3.2 Dismounting Rolling Element Bearings

1. Dismounting Bearings from the Shaft

When a bearing is being removed from a shaft the force should be applied as

evenly as possible onto the inner ring. If possible a ball bearing puller should be

used.

Figure 1.33 Puller which bears against the inner ring

2. Dismounting a Bearing from its Housing

If the bearing remains in the housing after the shaft has been removed, it is

possible to use a bearing puller (figure 1.34)

Figure 1.34 Remove bearing from the housing

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 46 of 61

Technical Training Programme Rotating Equipment

• Bearings with a Tapered Bore

Large forces have to be- applied in order to dismount bearings, which have a

tapered bore. The forces, which are released when these bearings are

dismounted, can also be very high. It is recommended that some method is used

to brake (or slow down) these bearings.

• Bearings Mounted on a Tapered Shaft

The locating ring (end plate or shaft nut) should be loosened but kept in place as

a stop. The bearing can then be dismounted by carefully tapping the

dismounting tool or punch with a hammer.

It is also possible to use the oil injection method to remove a bearing. As large

forces are released when this type of system is used (in particular with tapered

bearing seats or adapter bushes) it is important to arrange a suitable stop.

• Single Row Deep Groove Bearings

It is generally impossible to dismount this type without destroying it. It is

possible to cut through the outer ring, but an alternative is to remove the cage so

that the balls can be collected together. It will then be possible to remove the

inner ring by using only a slight force.

• Single Row Angular Contact Bearings

The only way to dismount this type of bearing is either to force the outer ring

over the balls or cut through it. There are a few types, which are easily

separable.

• Dismounting Using Heat

In order to dismount the inner ring of large cylindrical bearings, which have

been mounted onto the shaft using an interference fit, use is made of a special

tool, which heats the ring. The tool is heated to about 200°C and then clamped

to the inner ring, which comes loose within a few seconds. It is possible to use

electric tools, which heat the ring by either induction or radiant heat. Direct

heating with a naked flame (open flame like oxy – actylen tourch)may never be

used.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 47 of 61

Technical Training Programme Rotating Equipment

SECTION – 1.6

WHAT TO LOOK FOR DURING OPERATION

Bearings are being brought into focus, since they constitute a vital factor in all

machines with rotating parts. Condition monitoring represents a rapidly

growing activity in the field of preventive maintenance. Early indications of

bearing damage allow bearings to be replaced during regularly scheduled

equipment maintenance and thus avoid unscheduled equipment downtime due

to bearing failure.

Bearings in critical machinery or in bad (harsh) environments should be

checked frequently. Many systems and/or instruments are available on the

market today for monitoring bearings. Most of these are based on the

measurement of vibrations.

However, for practical reasons, not all machines or machine functions are

monitored using advanced instrumentation. In these instances, the machine

operator or the maintenance engineer must remain alert for bearing "trouble

signs," such as noise, increases in temperature and vibration. "Listen", "feel"

and "look" are three important factors.

1.6.1 Listen

A common way of identifying an irregularity in running is by listening.

Abnormal noise can be detected and even traced to an individual machine

component by an experienced operator. Bearings in good operating condition

produce a soft purring noise. Grinding, squeaking and other irregular sounds

usually point to bearings in poor operating condition.

Bearing damage can be detected by listening but the damage will often have

reached such an extent that an immediate bearing change has to be carried out.

Therefore, a better method is to use some of the electronic condition monitoring

devices, for instance.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 48 of 61

Technical Training Programme Rotating Equipment

Figure 1.35 Monitoring bearing conditions

These new devices proved a much safer and more accurate prediction than the

early method of placing one end of a wooden stick or a screwdriver against the

bearing housing, and putting one's ear to the other end.

1.6.2 Feel

High temperatures often indicate that the bearing is acting abnormally. High

temperatures can be detrimental to the bearing lubricant. Overheating can

sometimes be attributed to the bearing lubricant. Running for extended periods

at temperatures in excess of 125 ºC (260 ºF) can reduce bearing life. Causes of

high bearing temperatures include:

1- Insufficient or excessive lubrication.

2- Impurities in the lubricant.

3- Over loading.

4- Bearing damage.

5- Insufficient clearance.

6- High friction in the seals.

It is therefore necessary to check the temperature continually, both at the

bearing itself and at other vital components. Any change in temperature can be

an indication of malfunction if the running conditions have not been altered

(changed).

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 49 of 61

Technical Training Programme Rotating Equipment

Bearing temperature can be routinely and accurately checked with a surface

thermometer. Critical bearings, which cause equipment downtime when they

fail, should ideally be equipped with a heat probe.

Figure 1.36 High temperature bearing

It is important to note that a natural temperature rise lasting one or two days will

occur immediately after lubrication and relubrication.

1.6.3 Look

Properly lubricated bearings that are adequately protected from dirt and

moisture should not exhibit wear. However, it is advisable to visually check a

bearing when it is uncovered, and to periodically check the seals. Check the

condition of seals near the bearing to ensure that they do not permit hot or

corrosive liquids and gases to penetrate along the shaft. Replace worn felt and

rubber seals as soon as possible.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 50 of 61

Technical Training Programme Rotating Equipment

Figure 1.37 Lubricant leakage

In addition to preventing the entry of dirt, seals are also important for keeping

lubricant in the bearing housing. Lubricant leaks at seal locations should be

inspected immediately for worn seals, seals defects and loose plugs. Leaks can

also result from a slackening of the joint between the mating surfaces of the

bearing housing, or from the grease breaking down by churning and releasing

free oil, thus overlubricating.

Check automatic lubricating systems so they perform properly by filling them

with oil or grease and ensuring that the right amount of lubricant is released.

Also take a good look at the lubricant. Discoloration or darkening are usually

signs that the lubricant contains impurities.

1.6.4 Lubricate

1.6.4.1 With Grease

Relubricate bearing arrangements according to guidelines supplied by the

equipment manufacturer, or by following the lubricating instructions.

Relubrication is best performed during planned periods of equipment downtime.

You can relubricate with small quantities per schedule. Periodically, you should

clean out used grease or purge out through drain plugs. Wipe lubrication

nipples clean before injecting fresh grease. If the bearing housing is not

equipped with nipples, you will need to remove the housing cap or end cover in

order to remove the used grease. Next, apply fresh grease of the same type.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 51 of 61

Technical Training Programme Rotating Equipment

Figure 1.38 Lubrication with grease

1.6.4.2 With oil

When inspecting the oil level of a bearing, check to ensure that the right type of

oil is in use and that the oil level gauge air vent is unobstructed (figure 1.39)

Figure 1.39 Adding oil

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 52 of 61

Technical Training Programme Rotating Equipment

Take a small sample of the oil and compare it with fresh oil. If the sample looks

cloudy, then it is mixed with water and should be replaced. Dark or thick oil is

a sign of dirt or indicates that the oil has started to carbonize. Change the oil

completely and, if possible, clean the bearing by flushing it with fresh oil.

When changing the oil, be sure that you are using the same type of oil, and that

you refill to the required level.

A more reliable method of determining the oil condition is to analyze a sample.

If the oil is contaminated it may be worthwhile to change the seals or consider

filtration.

Oil in oil bath lubrication systems requires a change only once each year,

providing that the operating temperature does not exceed 50 to 60 ºC (1 20 to

140 ºF), and the oil does not become contaminated. Change the oil four times

each year for operating temperatures of 1 00 ºC (210 ºF); monthly for operating

temperatures of 120 ºC (250 ºF); and weekly for operating temperatures of

130 ºC (265 ºF).

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 53 of 61

Technical Training Programme Rotating Equipment

1.6.5 Troubleshooting

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 54 of 61

Technical Training Programme Rotating Equipment

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 55 of 61

Technical Training Programme Rotating Equipment

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 56 of 61

Technical Training Programme Rotating Equipment

SECTION – 1.7

LUBRICATION SYSTEMS

In this section the following points will be covered:

1- The importance of lubrication.

2- Two common methods for oil lubrication in most of plant equipment.

3- Forced circulation method, the component and their functions.

4- Lubricant storage and handling.

5- Lubricant storage and handling check list

1.7.1 The Importance of Lubrication

The purpose of a lubrication is to reduce friction between the moving parts

beside other functions are covered in page 3 of this chapter.

1.7.2 Common Methods of Lubrication

There are two methods of lubrication are commonly used in different equipment

in the plant. They are:

1.7.2.1 Splash and Ring Oilers (or Bath Oilers)

Figure 1.40 shows several types of splash and bath oilers

Oil ring

A B

Figure 1.40 Splash and bath oilers

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 57 of 61

Technical Training Programme Rotating Equipment

In these systems, a portion of the machine housing is used as an oil sump (tank).

This sump holds the oil at a specified level, allowing some of the moving parts

to be partially immersed. As these parts move or rotate, they transfer the

lubricant to the area requiring lubrication.

The examples in figure 1.38 are:

• Splash lubrication in gear box used to drive equipment (a). One or more

gears extend into the oil in the bottom of the gear case. As the gears

revolve, they pick up oil and deposit it on other gears and on the shafts.

• Ring oiler (b) which is usually used with bearings. In this system, a

loose ring (about 1 ½ times the diameter of the shaft) on the shaft. As

the shaft rotates, the ring rotates, it picks up oil from the sump and

deposit it on the upper surface of the shaft and through oil (splash) to

the bearings.

• In small reciprocating machines (compressor for example), there is

scoop fixed to the big end bearing of the connecting rod (c). As the

crankshaft rotates, these scoops spread oil to all internal components

requiring lubrication.

1.7.2.2 Forced Circulation Oil Lubrication System (or Pressurized

Oil System)

Figure 1.41 shows this system in its simple shape. The lower part of the

machine is used as an oil sump (tank). The oil is drawn from the sump by an oil

pump, pressurized, and then distributed to the various lubricating points.

Figure 1.41 Forced circulation oil lubrication system

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 58 of 61

Technical Training Programme Rotating Equipment

If the forced circulating system has to handle a large amount of oil and the

equipments subject to heat or contaminants, then additional components will

have to be added to the simple system.

The components of forced circulation system are:

• Main oil pump – which is driven by the machine itself.

• Auxiliary oil pump – which is driven by an electric motor (A.C or D.C).

The function of auxiliary oil pump is to make continuous circulation of

the oil from the oil tank through the system during start up period and

shutdown period until the machine becomes completely cooled.

• Oil filters, strainers in the lubricating oil system to remove suspended

solids from the system.

• Oil coolers to make cooling for the lubricating oil.

• Pressure relief valves, non-return valves, oil spliters to control the system

pressure and the flow direction of the lubricating oil within the system.

• Pressure gauges and sight glasses to show the oil pressure and the flow of

oil in the system.

Sometimes the system includes a purifier or some other means of mechanically

reclaiming the oil. Usually, this is accomplished by centrifuging (separation of

suspended particles by centrifugal force).

1.7.3 Lubricant Storage and Handling

Importance of Proper Storage

Regardless of how much lubricating you actually do, you probably know where

the lubricants are stored in your plant. Figure 1.42 shows examples of good and

poor lubricant storage.

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 59 of 61

Technical Training Programme Rotating Equipment

Figure 1.42 Examples of good and poor lubricant storage

Because lubricant are combustible materials, they are sometimes stored in paint

storage areas where there is suitable fire protection.

Storage racks or shelves should be positioned so that all of the lubricants are

easily accessible. Figure 1.43 show example of a good inside lubricant store

room.

Figure 1.43 Good inside lubricant storeroom

High standards of cleanliness are extremely importance in lubricant storage

areas.

On the following page there is lubricant storage and handling checklist

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 60 of 61

Technical Training Programme Rotating Equipment

TriStar T.S – M - RE – (Rev. .3) May 2004 Page 61 of 61

You might also like

- MSJ Maintenance Company End User Presentation Rev1Document25 pagesMSJ Maintenance Company End User Presentation Rev1Ashish yedkeNo ratings yet

- Operating Manual Parker Filtration UnitDocument27 pagesOperating Manual Parker Filtration Unitjjlameda9112100% (2)

- Bearing Design in Machinery (Avraham Harnoy)Document654 pagesBearing Design in Machinery (Avraham Harnoy)zzjjh100% (15)

- RCA - Mechanical - Seal - 1684971197 2Document20 pagesRCA - Mechanical - Seal - 1684971197 2HungphamphiNo ratings yet

- API Plan 53-Accumulator Bladder ChargingDocument11 pagesAPI Plan 53-Accumulator Bladder Chargingsumantabal_uceNo ratings yet

- Maintenance of BCHDocument44 pagesMaintenance of BCHdoanducbao100% (1)

- 6-1 Explanation of Cold AlignmentDocument18 pages6-1 Explanation of Cold AlignmentTuhoyoTarahao67% (3)

- Telehandler New Machine and Pre Delivery Inspection Report PDFDocument1 pageTelehandler New Machine and Pre Delivery Inspection Report PDFMONICA LILIANA DURAN CHACONNo ratings yet

- 342 Mechanical and Fluid Drive Maintenance Course DescriptionDocument2 pages342 Mechanical and Fluid Drive Maintenance Course Descriptionaa256850No ratings yet

- Lube Oil Flushing ProcedureDocument18 pagesLube Oil Flushing ProcedureKevin Chen100% (2)

- Lincoln Industrial Quicklub Automated Lubrication System Reference GuideDocument31 pagesLincoln Industrial Quicklub Automated Lubrication System Reference Guidealejandre_mexNo ratings yet

- Ariel Start-Up Check List (Er-10.4.0)Document6 pagesAriel Start-Up Check List (Er-10.4.0)Jose RattiaNo ratings yet

- Atlas Copco gx7 Air Compressor ManualDocument6 pagesAtlas Copco gx7 Air Compressor ManualCommunications ShipyardNo ratings yet

- Sample Report Rotating Equipment PerformanceDocument12 pagesSample Report Rotating Equipment PerformancelectroliteNo ratings yet

- Maintenance and Repair of Centrifugal PumpsDocument3 pagesMaintenance and Repair of Centrifugal PumpsRohan NaikNo ratings yet

- Operating Dry Screw CompressorsDocument3 pagesOperating Dry Screw Compressorskamal arabNo ratings yet

- Laser Alignment MethodDocument3 pagesLaser Alignment MethodManeesh BhartiNo ratings yet

- Microsoft Word - WET GAS COMPRESSOR OVERHAULING REPORTDocument8 pagesMicrosoft Word - WET GAS COMPRESSOR OVERHAULING REPORTAbhi SharmaNo ratings yet

- Backfill Material Specification1Document7 pagesBackfill Material Specification1yusrey yusohNo ratings yet

- SP-1246 Part-3Document26 pagesSP-1246 Part-3Rajkumar ANo ratings yet

- Pumps, Compressors, Turbines Operation, Maintenance & TroubleshootingDocument2 pagesPumps, Compressors, Turbines Operation, Maintenance & Troubleshootingm_alodat6144100% (2)

- Shop Test Procedure For TurbineDocument9 pagesShop Test Procedure For TurbineAbdulNo ratings yet

- Centrifugal CompressorDocument33 pagesCentrifugal CompressorRizwan Bangash80% (5)

- Gas Turbine - Compressor AlignmentDocument2 pagesGas Turbine - Compressor AlignmentNazmiNo ratings yet

- 04-Bearing Retention and Clearances PDFDocument31 pages04-Bearing Retention and Clearances PDFchanayireNo ratings yet

- Operation Manual PDFDocument28 pagesOperation Manual PDFPanagiotis PanagosNo ratings yet

- Flange Managment ProcedureDocument47 pagesFlange Managment ProcedureIBRAHIMNo ratings yet

- Hydrocom: Experience Real Capacity Control and Energy SavingsDocument8 pagesHydrocom: Experience Real Capacity Control and Energy SavingsVignesh Dheenakumar100% (1)

- Equipment RotaticDocument9 pagesEquipment Rotaticverall_averusNo ratings yet

- ES9-414 Leveling Install - CDocument29 pagesES9-414 Leveling Install - CIfran Sierra100% (1)

- Commissioning Hp450 Air CompressorDocument38 pagesCommissioning Hp450 Air CompressorHoracio CapingalaNo ratings yet

- What Is The Basic Principle of CompressorDocument2 pagesWhat Is The Basic Principle of CompressorannoymouspersonNo ratings yet

- Sop Installing PumpDocument4 pagesSop Installing Pumpilham100% (1)

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument8 pagesContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualJayvee Baradas ValdezNo ratings yet

- 18F46-DOMI of Rotating Equipment Level 1Document3 pages18F46-DOMI of Rotating Equipment Level 1ehabwardaNo ratings yet

- 4na - Assembly & Disassembly - Flypartsguy - Com - 1.2019Document90 pages4na - Assembly & Disassembly - Flypartsguy - Com - 1.2019Kurd SkorvskiNo ratings yet

- Maintenance Management - Lecture SlideDocument37 pagesMaintenance Management - Lecture SlideMamunur Rashid MashukNo ratings yet

- Centrifugal Pump MRT Mechanical Run Test Procedure 1721480887Document8 pagesCentrifugal Pump MRT Mechanical Run Test Procedure 1721480887Moustafa Salim Salim100% (1)

- Instruction Manual: Dosing Pump MaxroyDocument26 pagesInstruction Manual: Dosing Pump Maxroyenedanielcristian100% (1)

- Section 5 Lubrication: Rt540E Operator'S Manual LubricationDocument13 pagesSection 5 Lubrication: Rt540E Operator'S Manual LubricationYuri FaroNo ratings yet

- API RP 687-2001 (2015) Ut BabbitpdfDocument1 pageAPI RP 687-2001 (2015) Ut BabbitpdfudomNo ratings yet

- LEWA OperatingInstructionsDocument11 pagesLEWA OperatingInstructionsDaniel Erasmo Avellaneda Sanchez100% (1)

- HYDRATIGHT-Bolt TensionersDocument27 pagesHYDRATIGHT-Bolt TensionerstMoC StructureNo ratings yet

- Installation Procedure For Vertical Glandless Process PumpDocument22 pagesInstallation Procedure For Vertical Glandless Process PumpYoutube For EducationNo ratings yet

- 07 - Inspection of Flame ArrestersDocument5 pages07 - Inspection of Flame Arrestersanuram66No ratings yet

- EQPT-02-21 Pipe Strain For Rotating EquipmentDocument2 pagesEQPT-02-21 Pipe Strain For Rotating EquipmentAmanSharmaNo ratings yet

- LV05 - Routine Maintenance - Issue 1Document53 pagesLV05 - Routine Maintenance - Issue 1Đức Hòang100% (1)

- GEN 3018 HANDING OVER CENTRIFUGAL COMPRESSORS FOR MAINTENAàDocument3 pagesGEN 3018 HANDING OVER CENTRIFUGAL COMPRESSORS FOR MAINTENAàBikas SahaNo ratings yet

- 02-SAMSS-006 Extend Revision CycleDocument17 pages02-SAMSS-006 Extend Revision CycleSyed Zain AliNo ratings yet

- 3115-BWK-PRQ-021.5 Lube Oil Cleaning Procedure - B1Document16 pages3115-BWK-PRQ-021.5 Lube Oil Cleaning Procedure - B1Dannis AnantoNo ratings yet

- Compressor Turbo-Air API a4-IRDocument12 pagesCompressor Turbo-Air API a4-IRMachineryengNo ratings yet

- WE 204 - Bearing Root Cause Failure AnalysisDocument2 pagesWE 204 - Bearing Root Cause Failure AnalysisJurun_BidanshiNo ratings yet

- Overhaul of Centrifugal Gas CompressorDocument61 pagesOverhaul of Centrifugal Gas CompressorAvinash Kulkarni100% (1)

- BakerHughes ReciprocatingCompressors Overview-030321Document16 pagesBakerHughes ReciprocatingCompressors Overview-030321ganesh upadhyaya100% (2)

- Troubleshooting, Root Cause AnalysisDocument5 pagesTroubleshooting, Root Cause AnalysisZeeshan HaiderNo ratings yet

- Maintenance & Operation of Rotating MachineryDocument3 pagesMaintenance & Operation of Rotating MachineryElsayed AmerNo ratings yet

- ECITB Mechanical Joint IntegrityDocument1 pageECITB Mechanical Joint IntegrityMircea Dan StanciuNo ratings yet

- E 728 GDocument155 pagesE 728 Gbee140676No ratings yet

- E728g PDFDocument155 pagesE728g PDFMai Thế ToanNo ratings yet

- Rolling Bearings PDFDocument84 pagesRolling Bearings PDFAziful AimanNo ratings yet

- Peerless PumpDocument44 pagesPeerless PumpYeraldin SalinasNo ratings yet

- Bearing InstabilityDocument37 pagesBearing InstabilityErlangga Yudha PratamaNo ratings yet

- AB Series - Oil Free Compressors-13Document1 pageAB Series - Oil Free Compressors-13Ismail AliNo ratings yet

- Spherical Bearing KugelDocument13 pagesSpherical Bearing Kugelsidik_212040658No ratings yet

- Mechanical Machine DesignDocument25 pagesMechanical Machine DesignshahfaraazNo ratings yet

- Biomechanics of The Articular CartilageDocument43 pagesBiomechanics of The Articular Cartilagepicilivi100% (1)

- Kingsbury BearingDocument28 pagesKingsbury Bearingkalam2k2100% (1)

- Gearbox Efficiency and LubricationDocument6 pagesGearbox Efficiency and Lubricationrashm006ranjanNo ratings yet