Structural Drawings 2

Structural Drawings 2

Uploaded by

Makenson MuscadinCopyright:

Available Formats

Structural Drawings 2

Structural Drawings 2

Uploaded by

Makenson MuscadinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Structural Drawings 2

Structural Drawings 2

Uploaded by

Makenson MuscadinCopyright:

Available Formats

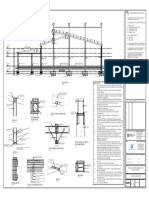

NOTES

1. ALL LEVELS AND DIMENSIONS TO BE CHECKED ON SITE.

Note : This piling design is 'preliminary' ALL PILES ARE PRESSURE GROUTED

2. THIS DRAWING TO BE READ IN CONJUNCTION WITH

and will be subject to review and re-design CONTINUOUS FLIGHT AUGURED (CFA) PILES THE ARCHITECTURAL DRAWINGS.

3. ALL CONCRETE WORK TO COMPLY WITH SABS 1200G.

based on the results of the borehole 4. CONCRETE CLASS :-

investigation currently being carried a) PILECAPS & GROUND BEAMS = 25 MPa

b) STRIP FOOTINGS & BASES = 25 MPa

out on site. c) COLUMNS, SHEAR & LIFT WALLS = 30 MPa

d) SLABS, BEAMS & STAIRCASES = 25 MPa

e) RETAINING WALLS = 25 MPa

1 2 3 1 2 3 f) SURFACE BEDS = 30 MPa

g) BLINDING = 10 MPa

440 5400 5400 5. COVER TO REINFORCEMENT :-

340 5400 5400 AS INDICATED ON DRAWING

100 340

Existing

Building 6. ALL FOUNDATION EXCAVATIONS TO BE INSPECTED BY

Line of Existing Building Line of Existing Building Line of Existing Building THE ENGINEER PRIOR TO CASTING OF CONCRETE.

Line of Line of new r.c. foundation.

7. ALL REINFORCING FIXING TO BE INSPECTED BY

Existing Building THE ENGINEER PRIOR TO CASTING OF CONCRETE.

F F F F

8. SIX CUBES TO BE TAKEN PER POUR.

830

Line of

830

830

830

220 500 10mm polystyrene isolation joint 500mm x 220mm 500mm x 220mm THREE TO BE TESTED AT SEVEN DAYS, THE

s.o.p. Existing Building 220 280 between existing building r.c. column. r.c. column. REMAINDER AT TWENTY EIGHT DAYS. THE RESULTS

G G G G TO BE FORWARDED TO THE ENGINEER.

220

360

360

465 360 350

and new r.c. foundation.

220

220

10

10

9. CONTRACTOR TO CONSTRUCT A BLINDING LAYER

P2 P3 P5 P6 IF SOIL CONDITIONS RESULT IN REINFORCEMENT

700

700

Line of new r.c. foundation. s.o.p.

480

480

480

350 150 500 COVER NOT BEING MAINTAINED.

P1 P7

110

P4 10. ALL STRUCTURAL CONCRETE TO BE CURED FOR

100 500 100 10mm polystyrene isolation joint A MINIMUM OF FIVE DAYS.

500mm x 220mm 10mm polystyrene isolation joint

between existing building between existing building

100 340 260 r.c. column. 11. BRICKWORK SHOWN HATCHED ARE LOAD BEARING.

and new r.c. foundation. and new r.c. foundation. ALL LOAD BEARING BRICKWORK TO BE 14MPa NFX.

700 4690 700 3755 700 465 10 TOP OF ALL BRICKWORK TO RECEIVE 2 LAYERS OF

11010 o/a concrete 10 3 PLY MALTHOID ON SMOOTH RENDERED SURFACE.

UNLESS OTHERWISE NOTED

3070

12. ALL SINGLE SKIN BRICKWORK TO BE STOPPED 2

A A

5745

5745

5745

5745

3195

100 220 380 Line of new r.c. foundation. COURSES BELOW SOFFIT OF SLAB AND COMPLETED

ALL R.C. GROUND BEAMS ARE : AFTER PROPS HAVE BEEN REMOVED.

4335

800mm deep x 700mm wide 13. ALL CONCRETE PLASTER AND BRICKWORK PLASTER

450 250 INTER-FACES TO RECEIVE V-JOINTS.

with t.o.c. @ + 1349,235 lvl.

240

14. THE ENGINEER REQUIRES 24HRS NOTICE FOR ALL

INSPECTIONS.

P8 P9 10mm polystyrene isolation joint

700

700

220

220 between existing building

and new r.c. foundation.

500mm x 220mm

240

4690 320 380

1265

565

350

250

250

100

100

r.c. column.

380 220 100

9900

P 10 P 11 P 12 P 13

30 320

500mm x 220mm

700

500

700

500

700

Gx Gx Gx r.c. column. Gx

500mm x 220mm

10770

250

r.c. column.

250

500 130

100

350

100

220 220 260

13350

13350

100 340 260 100 220 380

Existing

700 4690 700 3755 700 465 10

Note : Brickwork Strapping : Building

11010 o/a concrete

4225

3525

3525

All brickwork to be 'strapped/tied' to r.c. columns,

4635

4635

4635

4635

shear walls and other concrete vertical elements with

30mm wide x 1,2mm thk. x 800mm long galvanised steel Line of new r.c. foundation.

straps. 100mm of steel strap shot fired to column and

700mm of steel strap built into brick wall every 3rd course. 100 700 1015

700

Each brick skin (at every 3rd course) to be tied to r.c. 465 550

columns, shear walls and other concrete vertical elements. 220 220 260 700mm x 220mm 350 350 Line of Existing

120

120

120

220 120

r.c. column. Building

Line of new

P 14 P 15 P 16

340

340

r.c. foundation.

60 640

700

700

700

10

1170

1170

640

640

410

10

J J J 100 1170mm x 220mm J

240

240

1170mm x 220mm

530

530

1105

870

950

810

810

810

830

r.c. shear wall.

830

830

830

100 r.c. shear wall. 100

100

P 17

220

80

BRICKWORK NOTES : 10mm polystyrene isolation joint

K K K K

100

between existing building

100

220

135

- All brickwork (solid brick walls or cavity brick walls) below surface bed level 100

2690

and new r.c. foundation.

3870

to have brickforce in every course. 110 110

- All solid brick walls above surface bed level are 220mm wide or 110mm wide 340 220 140

3390

2870mm x 220mm

1880

1880

1880

2285

with brickforce built in every 3rd course. r.c. shear wall.

350 250

2400

2580

- All parapet walls are 220mm wide or 110mm wide with brickforce built in

2500

2500

10

every course. 100 220 380 4460

230

100

- All cavity brick walls above surface bed level are 340mm wide with 110mm

P 18 P 19 wide outer skin brickwork with 120mm central cavity with 3,15mm Ø x 300mm

700

700

500

700

long galvanised butterfly wire ties built vertically into brickwork every 3rd

course and horizontally at max. 500mm centres above surface bed level

and built vertically into brickwork in every course below surface bed level and

100

100

210 295 horizontally at max. 500mm centres. 240 220 240

- All brickwork to Architect's detail in Class 2 mortar.

250 2100 2225 855 975 2215 970 705 340 900 4490 700 200 4260 700 310

100 195

90 5400 5400

900 1010

450

5390 5860

1 2 3 11560

440 5400 5400 320

PILING LAYOUT

1 2 3

PILING NOTES :-

1. ALL PILING TO BE CARRIED OUT IN ACCORDANCE WITH SABS 1200F.

FOUNDATION LAYOUT

2. THE RESPONSIBILITY FOR THE DESIGN AND PERFORMANCE OF ALL PILES

SHALL LIE WITH THE PILING CONTRACTOR AND THE PILING CONTRACTOR SHALL

SUPPLY A 'PILING GUARANTEE' OR A 'PILING LIABILITY INSURANCE POLICY' IN THIS REGARD. REV DESCRIPTION BY DATE

THE 'PILING GUARANTEE OR A 'PILING LIABILITY INSURANCE POLICY' IS TO BE IN PLACE FOR

A MINIMUM PERIOD OF 3 YEARS AFTER THE FINAL PILE HAS BEEN INSTALLED. THE PILING

CONTRACTOR'S PILE DESIGN ENGINEER MUST SUBMIT A 'CERTIFICATE OF STABILITY'

TO THE PRINCIPAL STRUCTURAL ENGINEER ON COMPLETION OF THE PILING CONTRACT.

3. THE 'PILING LIABILITY INSURANCE POLICY' SHOULD HAVE INSURANCE COVER

FOR THE FOLLOWING SECTIONS :-

PILING KEY T1 FOR TENDER PURPOSES S.A. 24/06/2020

a) PUBLIC LIABILITY COVER. PILE TYPE PILE NUMBER PILING PLATFORM LEVEL PILE 'CUT OFF' LEVEL TOTAL professional person M.NAIR PrTechEng registration 200670211

b) GENERAL CONSTRUCTION LIABILITY COVER.

c) FOUNDATION FAILURE INDEMNITY COVER. P1 - P19 +1349,530 lvl +1348,485 lvl 19 PILES PROJECT MANAGER | PRINCIPAL AGENT

d) PRODUCTS AND DEFECTIVE WORKMANSHIP LIABILITY COVER.

e) THE 'CERTIFICATE OF INSURANCE' IS TO BE SUBMITTED TO THE PRINCIPAL STRUCTURAL

ENGINEER FOR APPROVAL.

f) THE LIMIT OF INDEMNITY AND THE REQUIRED INSURANCE COVER AMOUNTS WILL BE AS

Ø450mm PRESSURE 2

GROUTED CONTINUOUS

STIPULATED IN THE PILING TENDER DOCUMENT OR AS ADVISED BY THE APPOINTED

FLIGHT AUGER (CFA) PILE

QUANTITY SURVEYOR.

WITH A SERVICE 220 130

LOAD OF 790 kN.

4. CONCRETE STRENGTH FOR ALL PILES AT 28 DAYS IS 30 MPa. CONCRETE CUBE TESTS TO BE

(19 No. Off) 220mm wide brickwall.

CARRIED OUT ON PILE GROUT FOR EVERY 20 PILES INSTALLED. 6 CUBES TO BE TAKEN AFTER 10mm I.J. CLIENT

EVERY 10 PILES INSTALLED (3 CUBES TO BE TESTED AT 7 DAYS AND 3 CUBES TO BE TESTED AT See detail on

28 DAYS). RESULTS OF THE CUBE TESTS TO BE SUBMITTED TO THE PRINCIPAL STRUCTURAL 10mm I.J. Dwg. No. : 200-309-301

ENGINEER FOR APPROVAL. See detail on

Dwg. No. : 200-309-301

5. PILE TYPE IS Ø450mm PRESSURE GROUTED CONTINUOUS FLIGHT AUGER (CFA) PILE t.o.c. @ 150mm thk.

150mm thk.

WITH A SERVICE LOAD OF 790 kN. +1349,830 lvl. r.c. surface bed slab.

150

r.c. surface bed slab.

150

6. PILE CUT-OFF LEVEL TO BE 50mm ABOVE SOFFIT OF THE GROUND BEAM OR AS INDICATED

ON THE PILING LAYOUTS WITH 500mm PILE REBAR PROJECTION. PROJECT

DPM 595 t.o.c. @ DPM

445

7. PILE INTEGRITY TESTING IS TO BE CARRIED OUT ON ALL PILES BY AN INDEPENDENT +1349,235 lvl. UMALUSI OFFICES

GEOTECHNICAL ENGINEER. NO 'IN-HOUSE' INTEGRITY TESTING BY THE PILING CONTRACTOR

WILL BE ACCEPTED.

ADDITIONS AND ALTERATIONS

800mm deep x 700mm wide

CL

8. ALL PILE SETTING OUT IS TO BE CARRIED OUT BY THE PILING CONTRACTOR AND VERIFIED BY r.c. ground beam.

750

pile DETAILS

800

THE MAIN CONTRACTOR WHOM ASSUMES FULL RESPONSIBILITY FOR THE PILE SETTING OUT. Pile cut-off level.

ALL PILE POSITIONS ARE TO BE SET OUT BY THE PILING CONTRACTOR'S REGISTERED

ENGINEERING SURVEYOR.

See Piling Key. NEW ABLUTIONS BUILDING

PILING & FOUNDATION

50

9. THE FINAL PILING DESIGN IS TO BE SUBMITTED BY THE PILING CONTRACTOR TO THE

APPOINTED GEOTECHNICAL ENGINEER FOR APPROVAL. THE COST FOR THIS APPROVAL 450 250 STRUCTURAL LAYOUT & DETAILS

PROCESS IS TO BE PROVIDED FOR BY THE PILING CONTRACTOR. THE PILING CONTRACTOR 450 Ø pile

700

CAN ONLY COMMENCE WITH PILING, PENDING THE APPROVAL OF THE FINAL PILE DESIGN

350 350

FROM THE APPOINTED GEOTECHNICAL ENGINEER AND THE APPROVAL FROM THE

PRINCIPAL STRUCTURAL ENGINEER.

10. THE MAXIMUM PERMISSIBLE DEVIATION OF THE PILE POSITIONS SHALL BE 50mm.

225 225

11. ALL PILES ARE TO BE NEATLY TRIMMED TO PILE CUT-OFF LEVEL. THE TOP SURFACE OF ALL

TRIMMED PILES IS TO BE FINISHED 'LEVEL AND SMOOTH'. AN APPROVED NON-SHRINK

LEVELING CONCRETE GROUT MUST BE ALLOWED FOR THE BY CONTRACTOR TO ACHIEVE SECTION A - A

SUITE 106, ESSENVIEW BUILDING, STRATHMORE PARK,

THE 'LEVEL AND SMOOTH' FINISH REQUIREMENT NOTED ABOVE.

305 MUSGRAVE ROAD, DURBAN, 4001

e-mail : admin@mapafrica.co.za

12. TWO COPIES OF AN 'AS-BUILT' LOCATION DRAWING SIGNED BY THE PILING CONTRACTOR

FAX (031) 3092929 TEL. (031) 3095831

SHOWING THE PRECISE POSITION OF EVERY PILE SHALL BE SUPPLIED TO THE PRINCIPAL

STRUCTURAL ENGINEER. ANY PILE OUTSIDE THE TOLERANCE LIMITS SPECIFIED SHALL BE

CLEARLY HIGHLIGHTED ON THE 'AS-BUILT' LAYOUT. DESIGNED K.L. SCALES

COPYRIGHT RESERVED

DRAWN K.L. 1:50 1:25

APPROVED M.N. PL DATE 29/01/2020

FOR TENDER PURPOSES DRAWING No.

200-309 / 300 REV

T1

NOTES

Face of first floor

1 2 3 r.c. beam above. J 1. ALL LEVELS AND DIMENSIONS TO BE CHECKED ON SITE.

2. THIS DRAWING TO BE READ IN CONJUNCTION WITH

1500 640 THE ARCHITECTURAL DRAWINGS.

3. ALL CONCRETE WORK TO COMPLY WITH SABS 1200G.

340

4. CONCRETE CLASS :-

110 120 110 220 905 220 a) PILECAPS & GROUND BEAMS = 25 MPa

220mm wide 220mm wide

All 110mm wide single skin walls b) STRIP FOOTINGS & BASES = 25 MPa

Existing brickwork 340mm wide brickwork. brickwork.

are to be constructed directly c) COLUMNS, SHEAR & LIFT WALLS = 30 MPa

cavity brickwork.

See onto the top of the surface bed 200mm thk. d) SLABS, BEAMS & STAIRCASES = 25 MPa

150mm thk. 150mm thk. e) RETAINING WALLS = 25 MPa

Detail 'A' slab (typical). surface bed slab. Paving to

10mm I.J. 10mm I.J. surface bed slab. 10mm I.J. 10mm I.J. surface bed slab. f) SURFACE BEDS = 30 MPa

150mm thk. Architects

F F surface bed slab. t.o.c. @ 250 1490 10 t.o.c. @

150mm thk.

t.o.c. @ details and t.o.c. @

g) BLINDING = 10 MPa

walkway slab.

etails. +1349,830 lvl +1349,830 lvl 170mm +1349,830 lvl +1349,830 lvl 5. COVER TO REINFORCEMENT :-

itects d

500mm

step up

h See t.o.c. @ specifications.

to A r c lvl.

Paving + 1 3 4 9 ,3 3 0 Detail 'A' +1349,680 lvl fall AS INDICATED ON DRAWING

150

200 150

150

150

150

ving @

G t.o . p a G

150

6. ALL FOUNDATION EXCAVATIONS TO BE INSPECTED BY

sawcut joint

500

t.o. paving @

595

595

595

I.D.T. t.o.c. @ t.o.c. @ t.o.c. @ THE ENGINEER PRIOR TO CASTING OF CONCRETE.

445

445

+1349,330 lvl

sawcut joint

245

+1349,235 lvl +1349,235 lvl +1349,235 lvl 7. ALL REINFORCING FIXING TO BE INSPECTED BY

3500

See

THE ENGINEER PRIOR TO CASTING OF CONCRETE.

500mm x 220mm r.c. Detail 'A' 500mm x 220mm r.c.

240 220 240 100 220 380 8. SIX CUBES TO BE TAKEN PER POUR.

sawcut joint

column above & below. column above & below.

120 340 240 THREE TO BE TESTED AT SEVEN DAYS, THE

2515 REMAINDER AT TWENTY EIGHT DAYS. THE RESULTS

800mm deep x 700mm wide

800

800

800

500mm x 220mm r.c. TO BE FORWARDED TO THE ENGINEER.

column above & below. r.c. ground beam.

9. CONTRACTOR TO CONSTRUCT A BLINDING LAYER

All 110mm wide single skin walls 150mm thk. x 30MPa powerfloated concrete

IF SOIL CONDITIONS RESULT IN REINFORCEMENT

are to be constructed directly surface bed reinforced with mesh ref. 193

sawcut joint COVER NOT BEING MAINTAINED.

onto the top of the surface bed (min. 300mm laps) placed at 45mm cover from

top on 250µm SABS approved DPM on 10. ALL STRUCTURAL CONCRETE TO BE CURED FOR

slab (typical).

800mm deep x 700mm wide 800mm deep x 700mm wide A MINIMUM OF FIVE DAYS.

2 engineered layerworks as per Civil Engineers layouts. 700

r.c. ground beam.

700 565 700

r.c. ground beam. 11. BRICKWORK SHOWN HATCHED ARE LOAD BEARING.

Soil to be poisoned in accordance with SABS 1165.

See Certificate must be provided. T.o.c. @ +1349,830 lvl. ALL LOAD BEARING BRICKWORK TO BE 14MPa NFX.

450mm Ø pile 450mm Ø

150mm thk. x 30MPa powerfloated concrete Detail 'A' TOP OF ALL BRICKWORK TO RECEIVE 2 LAYERS OF

surface bed reinforced with mesh ref. 193 pile. 3 PLY MALTHOID ON SMOOTH RENDERED SURFACE.

(min. 300mm laps) placed at 45mm cover from 10mm wide Isolation Joint 12. ALL SINGLE SKIN BRICKWORK TO BE STOPPED 2

3500

top on 250µm SABS approved DPM on between new surface bed COURSES BELOW SOFFIT OF SLAB AND COMPLETED

ils.

ects deta

500mm

step up

engineered layerworks as per Civil Engineers layouts. it 2645 and existing surface bed. AFTER PROPS HAVE BEEN REMOVED.

Soil to be poisoned in accordance with SABS 1165. Paving

to A

g

r

@

c h

+1349,3

30 lvl.

All 110mm wide single skin walls See typical Isolation Joint detail. SECTION 1 - 1 SECTION 2 - 2 13. ALL CONCRETE PLASTER AND BRICKWORK PLASTER

t.o. pa v in

Certificate must be provided. T.o.c. @ +1349,830 lvl. are to be constructed directly 500mm x 220mm r.c. INTER-FACES TO RECEIVE V-JOINTS.

onto the top of the surface bed column above & below.

14. THE ENGINEER REQUIRES 24HRS NOTICE FOR ALL

I.D.T. slab (typical). INSPECTIONS.

See sawcut joint

500mm x 220mm r.c.

column above & below. 2 Detail 'A'

1

See

Detail 'A'

250 1720 10

All 110mm wide single skin walls 10mm deep x 10mm wide

250

250

Existing brickwork

are to be constructed directly 500mm x 220mm r.c. 'Dow Corning 813C' silicone

onto the top of the surface bed sealant (or equally approved)

column above & below.

slab (typical). on 10mm wide polystyrene backing. 10

150mm

step up

sawcut joint

2515 250

700mm x 220mm r.c.

sawcut joint

200mm thk. x 30MPa powerfloated concrete surface bed

1490

1500

mesh rebar

sawcut joint

column above & below. reinforced with 2 layers of mesh ref. 245 (min. 300mm laps)

150mm mesh rebar t.o.c. @ mesh rebar t.o.c. @

See placed at 60mm cover from top and 30mm cover from the

See step up 170mm fall +1349,830 lvl +1349,830 lvl

Detail 'B' bottom on 250µm SABS approved DPM on engineered

Detail 'B' E.D.T.

45

45

45

layerworks as per Civil Engineers layouts.

1170mm x 220mm r.c.

10

150

150

150

Top mesh will be sitting on R10 stools (90mm high)

wall above & below.

t.o.c. @ +1349,830 lvl @ 800mm c/c and each leg of the stool will be supported

J 350mm x 350mm

J on B1 bar of the bottom mesh.

edge thickening. 950mm x 220mm r.c. Soil to be poisoned in accordance with SABS 1165.

500

DPM DPM

wall above & below. 1 Certificate must be provided. T.o.c. @ +1349,680 lvl.

595

See detail.

K K Paving to

foundation Architects details

2755 t.o. paving @

cavity brickwork and specifications.

+1349,330 lvl

150mm thk. x 30MPa powerfloated concrete 3870mm x 220mm r.c. foundation

t.o.c @

walkway slab (to fall) reinforced with mesh ref. 193 brickwork

wall above & below. +1349,235 lvl

sawcut joint

170mm

170mm

170mm

(min. 300mm laps) placed at 45mm cover from

top on 250µm SABS approved DPM on EXTERNAL DOOR THRESHOLD (E.D.T.)

fall

fall

fall

engineered layerworks as per Civil Engineers layouts. 800mm deep x 700mm wide

Soil to be poisoned in accordance with SABS 1165. r.c. ground beam.

Certificate must be provided.

t.o.c. @ +1349,660 lvl

Existing brickwork

500mm x 220mm r.c.

column above & below. 350mm x 350mm INTERNAL DOOR THRESHOLD (I.D.T.)

edge thickening.

1 2 See detail. 3

Existing brickwork

SURFACE BED SLAB

10mm deep x 10mm wide

REINFORCING SCHEDULE : STOOLS FOR TOP MESH SUPPORT 'Dow Corning 813C' silicone

sealant (or equally approved)

No BARS TOTAL BENDING on 10mm wide polystyrene backing

MEMBER PER DIA. LENGTH NUM- MARK S C

10mm Isolation joint between all 10

OF MEMB BER A B C D E/r

load bearing brickwork / r.c. columns Paving to

STOOLS 1 10 R10 1150 10 01 83 350 90 350 and r.c. surface bed. mesh rebar Architects details mesh rebar

t.o. paving @

FOR and specifications.

See Typical Isolation Joint Detail (I.J). 170mm fall +1349,330 lvl

200mm THK.

SURFACE

45

45

BED

150

150

8 10 12 16 20 25 32 40 TOT

Note : Brickwork Strapping :

350

R 7 7 All brickwork to be 'strapped/tied' to r.c. columns,

Y shear walls and other concrete vertical elements with DPM

200

REV DESCRIPTION BY DATE

TOT 7 7 30mm wide x 1,2mm thk. x 800mm long galvanised steel DPM

Load bearing

straps. 100mm of steel strap shot fired to column and

50

brick wall /

700mm of steel strap built into brick wall every 3rd course.

r.c. column /

Each brick skin (at every 3rd course) to be tied to r.c. 50 r.c. shear wall.

columns, shear walls and other concrete vertical elements.

100 350

TYPICAL ISOLATION T1 FOR TENDER PURPOSES S.A. 24/06/2020

BRICKWORK NOTES :

- All brickwork (solid brick walls or cavity brick walls) below surface bed level 350mm x 350mm JOINT DETAIL (I.J.) professional person M.NAIR PrTechEng registration 200670211

to have brickforce in every course. PROJECT MANAGER | PRINCIPAL AGENT

- All solid brick walls above surface bed level are 220mm wide or 110mm wide

with brickforce built in every 3rd course.

EDGE THICKENING DETAIL

- All parapet walls are 220mm wide or 110mm wide with brickforce built in

every course.

- All cavity brick walls above surface bed level are 340mm wide with 110mm

wide outer skin brickwork with 120mm central cavity with 3,15mm Ø x 300mm

long galvanised butterfly wire ties built vertically into brickwork every 3rd

course and horizontally at max. 500mm centres above surface bed level

and built vertically into brickwork in every course below surface bed level and CLIENT

horizontally at max. 500mm centres.

- All brickwork to Architect's detail in Class 2 mortar.

PROJECT

30mm wide x 1,2mm thk. 8mm wide x 13mm deep

30mm wide x 1,2mm thk. galvanised steel strap

strap fixed to connecting 3mm wide x 40mm deep sawcut joint

'Dow Corning 813C' silicone sealant UMALUSI OFFICES

strap fixed to connecting wall with 'Hilti' drive pin reamed out to 8mm wide.

galvanised steel strap

built into brickwork every

10 joint

wall with 'Hilti' drive pin

built into brickwork every 10 joint

(or equally approved)

(or equally approved). ADDITIONS AND ALTERATIONS

10mm deep x 10mm wide 3rd course.

(or equally approved) shot fired into wall.

3rd course. Ø10mm backing

'Dow Corning 813C' silicone 340 8

shot fired into wall. cord. mesh rebar DETAILS

sealant (or equally approved)

applied to both sides of wall. 700 220 10mm deep x 10mm wide 700 110 120 110 NEW ABLUTIONS BUILDING

'Dow Corning 813C' silicone

40

45

sealant (or equally approved) GROUND FLOOR

150

75 75

applied to both sides of wall.

external wall

SURFACE BED SLAB

internal wall

100

100

external wall

40

40

internal wall

30

DPM STRUCTURAL LAYOUT & DETAILS

110

110

30

30

internal wall internal wall 450 450

internal wall internal wall

10mm wide polystyrene 10mm wide polystyrene

spacer strip. 700 700

spacer strip.

PLAN SECTION PLAN SECTION

TYPICAL SAW-CUT

JOINT DETAIL

DETAIL 'A' DETAIL 'B'

SUITE 106, ESSENVIEW BUILDING, STRATHMORE PARK,

305 MUSGRAVE ROAD, DURBAN, 4001

110mm INTERNAL WALL TO 110mm INTERNAL WALL TO

e-mail : admin@mapafrica.co.za

FAX (031) 3092929 TEL. (031) 3095831

220mm INTERNAL WALL CONNECTION DETAIL 340mm EXTERNAL CAVITY WALL CONNECTION DETAIL DESIGNED Y.R. SCALES

COPYRIGHT RESERVED

DRAWN Y.R. 1:50 1:25 1:10

APPROVED M.N. PL DATE 27/01/2020

FOR TENDER PURPOSES DRAWING No.

200-309 / 301 REV

T1

NOTES

1. ALL LEVELS AND DIMENSIONS TO BE CHECKED ON SITE.

1 2 3 2. THIS DRAWING TO BE READ IN CONJUNCTION WITH

1190 THE ARCHITECTURAL DRAWINGS.

3. ALL CONCRETE WORK TO COMPLY WITH SABS 1200G.

10920 o/a existing building 220

4. CONCRETE CLASS :-

970 a) PILECAPS & GROUND BEAMS = 25 MPa

Line of Existing Building b) STRIP FOOTINGS & BASES = 25 MPa

220 5400 5400

1 10mm wide isolation joint between

2 3 120 10790 10

c) COLUMNS, SHEAR & LIFT WALLS = 30 MPa

d) SLABS, BEAMS & STAIRCASES = 25 MPa

existing and new building. e) RETAINING WALLS = 25 MPa

Line of existing building

See Isolation Joint Note. (Typical). 5400 f) SURFACE BEDS = 30 MPa

5975 3845 970 10 g) BLINDING = 10 MPa

10920 o/a existing building 220

Line of existing building. 500 345 3865 (existing building) 500 230 5. COVER TO REINFORCEMENT :-

220 5400 5170 230 10mm wide isolation joint between

220 280 Existing existing and new building. 470 280 220 AS INDICATED ON DRAWING

120 10790 o/a concrete 10

Building See Isolation Joint Note. (Typical). 345 10 10 460 10 220 10mm wide isolation joint between

6. ALL FOUNDATION EXCAVATIONS TO BE INSPECTED BY

350 150

Line of Existing Building existing and new building. THE ENGINEER PRIOR TO CASTING OF CONCRETE.

500 4770 500 4520 500 230 Line of Existing Building

Line of Existing Building See Isolation Joint Note. (Typical).

7. ALL REINFORCING FIXING TO BE INSPECTED BY

110

110

10

THE ENGINEER PRIOR TO CASTING OF CONCRETE.

F F F F

220 280 Existing 220 280 280 220 8. SIX CUBES TO BE TAKEN PER POUR.

10

o/a concrete

500mm x 220mm 500mm x 220mm VOID la b

1180

830

830

Line of Existing Building

Building t f l o or s Line of Existing Building THREE TO BE TESTED AT SEVEN DAYS, THE

1180

1180

r.c. col. below. Line of Existing Building r.c. col. below. .c . f i r s

1070

1070

830

.

t h k . r 5 2 ,8 0 5 lv l

350

m REMAINDER AT TWENTY EIGHT DAYS. THE RESULTS

m

G G Line of existing building. G 25 5

@+1

3 G TO BE FORWARDED TO THE ENGINEER.

220

t.o .c .

350

350

10 350

350

220

100

10

10

10

10

10

10

10

9. CONTRACTOR TO CONSTRUCT A BLINDING LAYER

220

80

Line of IF SOIL CONDITIONS RESULT IN REINFORCEMENT

275

Line of 765mm deep x 220mm wide r.c. upstand beam

220

765mm deep x 220mm wide r.c. upstand beam

765mm deep x 220mm wide

510mm deep x 220mm wide r.c. d/stand beam

Existing Building 510mm deep x 220mm wide r.c. d/stand beam 510mm deep x 220mm wide r.c. d/stand beam 500mm x 220mm COVER NOT BEING MAINTAINED.

Existing Building t.o.c. @ + 1356,630 lvl. t.o.c. @ + 1356,630 lvl.

510mm deep x 220mm wide r.c. d/stand beam

t.o.c. @ + 1352,805 lvl. t.o.c. @ + 1352,805 lvl.

1000

10 960 10 r.c. col. above and below. 10. ALL STRUCTURAL CONCRETE TO BE CURED FOR

t.o.c. @ + 1356,630 lvl.

275 500mm x 220mm A MINIMUM OF FIVE DAYS.

10mm wide isolation joint between 500mm x 220mm 970 10mm wide isolation joint between

765mm deep x 220mm wide r.c. upstand beam

355 3845 o/a concrete

r.c. upstand beam

r.c. col. above and below.

2295

existing and new building. r.c. col. above and below. existing and new building. 11. BRICKWORK SHOWN HATCHED ARE LOAD BEARING.

t.o.c. @ +1357,310 lvl 500mm x 220mm o/a conc.

10 220 See Isolation Joint Note. (Typical). ALL LOAD BEARING BRICKWORK TO BE 14MPa NFX.

See Isolation Joint Note. (Typical).

r.c. col. above and below.

1000

TOP OF ALL BRICKWORK TO RECEIVE 2 LAYERS OF

510mm deep x 220mm wide

FBOs to Architect's details Sleeves cast in r.c. slab to

and specifications. (Typical). Architect's setting out and details. 510mm deep x 220mm wide r.c. d/stand beam 3 PLY MALTHOID ON SMOOTH RENDERED SURFACE.

t.o.c. @ + 1356,120 lvl.

la b

t.o.c. @ + 1352,805 lvl.

130 Existing t.o.c. @ + 1352,805 lvl.

f s lv l. n g , All sleeve diameters and positions 12. ALL SINGLE SKIN BRICKWORK TO BE STOPPED 2

t.o.c. @ + 1352,805 lvl.

o

ro 0 o f i s

5745

5745

5745

5745

5745

220mm x 220mm Building to approved by the structural engineer COURSES BELOW SOFFIT OF SLAB AND COMPLETED

.c . 6 , 1 2 p r o ta i l

r.c. d/stand beam

1000

220

4915

4915

4915

r.c. col. above. r

. 5 r e prior to casting r.c. slab. 10 220 AFTER PROPS HAVE BEEN REMOVED.

thk 13 wate t's d ).

t.o.c. @ + 1356,630 lvl.

t.o.c. @ +1357,310 lvl m + s, ec ns 13. ALL CONCRETE PLASTER AND BRICKWORK PLASTER

Overflow rain water pipes to be 5 m @ l l h i t ti o

2 5 o .c . t o f a A r c fi c a INTER-FACES TO RECEIVE V-JOINTS.

9900 o/a existing building

installed into parapet brick wall REV. P2 t . e d to e c i Existing

s sp 14. THE ENGINEER REQUIRES 24HRS NOTICE FOR ALL

along Grid '1', all to Architect's details

A A c re O Building

10790 (S F B a n d

1000

and specifications. 10790 INSPECTIONS.

2400

&

9600 o/a concrete

Note : Isolation Joint :

220 5050 220 5080 220

10mm isolation joint between existing building and new building. 220 5050 220 5080 220

Rainwater side outlet to Architect's 10mm deep x 10mm wide 'Dow Corning 813C' silicone sealant 500mm x 220mm

510mm deep x 220mm wide 510mm deep x 220mm wide

details and specifications.

10550 o/a concrete

(or equally approved) on all exposed edges on 10mm wide polystyrene backing.

10380

r.c. d/stand beam r.c. d/stand beam 510mm deep x 220mm wide r.c. d/stand beam 510mm deep x 220mm wide r.c. d/stand beam r.c. col. above and below.

10550

9900

250

250

250

500

500

220

220

220

250

220

220

1430

275

t.o.c. @ + 1356,120 lvl. t.o.c. @ + 1356,120 lvl. t.o.c. @ + 1352,805 lvl. t.o.c. @ + 1352,805 lvl.

30

Note : Brickwork Strapping :

500

500

500

500

Gx Gx Gx Gx

280

280

345

All brickwork to be 'strapped/tied' to r.c. columns,

30

765mm deep x 220mm wide r.c. upstand beam 30

30

30

500mm x 220mm 500mm x 220mm 500mm x 220mm 500mm x 220mm

10680

10680

10680

10550

r.c. col. below. r.c. col. below. shear walls and other concrete vertical elements with

250

250

r.c. col. above and below. r.c. col. above and below.

280

250

510mm deep x 220mm wide r.c. d/stand beam

250

500

14320

570

30mm wide x 1,2mm thk. x 800mm long galvanised steel

765mm deep x 220mm wide r.c. upstand beam

500 280 220 130

2025

500mm x 220mm

straps. 100mm of steel strap shot fired to column and 10 220

r.c. col. above and below. b 500

700mm of steel strap built into brick wall every 3rd course. s la

510mm deep x 220mm wide

1725

130

510mm deep x 220mm wide

t.o.c. @ +1357,310 lvl Line of Existing Building r 510mm deep x 220mm wide r.c. d/stand beam

510mm deep x 220mm wide

o

1000

30 220 Each brick skin (at every 3rd course) to be tied to r.c.

t f lo l v l .

t.o.c. @ + 1352,805 lvl.

s t.o.c. @ + 1352,805 lvl.

75mm Ø overflow pipe. fir 8 05

t.o.c. @ + 1352,805 lvl.

columns, shear walls and other concrete vertical elements. D D

t.o.c. @ + 1356,120 lvl.

220mm x 220mm (Typical). Flashing between the new r.c. upstand beams .r c. 52,

. 3

r.c. d/stand beam

th k + 1

r.c. d/stand beam

r.c. col. above. and the existing brickwork parapet walls, all 510mm deep x 220mm wide

3745

3745

3745

220

r.c. d/stand beam

t.o.c. @ + 1356,630 lvl.

t.o.c. @ + 1352,805 lvl.

m @

5m c.

4635

4635

4635

4635

4635

t.o.c. @ +1357,310 lvl to Architect's details & specifications. r.c. d/stand beam

25 t.o.

t.o.c. @ + 1356,630 lvl.

1000

220

10 1015 o/a

t.o.c. @ + 1352,805 lvl.

1170mm x 220mm wide 700 existing building Void for Lift

350 350

r.c. shear wall above and below.

B 10mm wide isolation joint between C Line of Existing Building

1800

350 350 700mm x 220mm 1170mm x 220mm wide existing and new building. 700

1500

t.o.c. @ +1357,310 lvl

r.c. col. below. See Isolation Joint Note. (Typical).

1000

275 r.c. shear wall below. 510mm deep x 220mm wide 220 480

510mm deep x 220mm wide r.c. d/stand beam 510mm deep x 220mm wide r.c. d/stand beam r.c. d/stand beam 700mm x 220mm 10mm wide isolation joint between

220

220

765mm deep x 220mm wide

220

220

220

existing and new building.

275

t.o.c. @ + 1356,120 lvl. t.o.c. @ + 1356,120 lvl. t.o.c. @ + 1352,805 lvl. r.c. col. above and below.

r.c. upstand beam Outside face of See Isolation Joint Note. (Typical).

80

1170

520

t.o.c. @ + 1356,630 lvl. new brickwork pier.

1170

640

220

120

220mm x 220mm

1170

220mm x 220mm

1170

1170

310 420

420

950

950

730

10

950mm x 220mm wide

1070

r.c. col. above. r.c. col. above. 1170mm x 220mm wide

J J J J

730

950

r.c. shear wall below. r.c. shear wall above and below.

210

650

t.o.c. @ +1357,310 lvl t.o.c. @ +1357,310 lvl

C

530

650

650

10 1015

830

830

830

830

3650

950mm x 220mm wide Steel support angle for brickwork.

120

300

300

220

r.c. shear wall above and below. See detail and Section C - C and Section D - D.

220

K K K 240 240 K

120

120

220mm x 220mm

r.c. shear wall above and below.

300

180

180

765mm deep x 220mm wide

180

765mm deep x 220mm wide 220mm x 220mm

r.c. col. above.

3870

r.c. upstand beam r.c. upstand beam r.c. col. above. Steel support angle for brickwork. 220 5050 220 2880 220 1500 220

Outside face of Steel support angle for brickwork. Outside face of new

t.o.c. @ + 1356,630 lvl. t.o.c. @ +1357,310 lvl t.o.c. @ + 1356,630 lvl. t.o.c. @ +1357,310 lvl

3650

See detail and Section C - C

2200

700

3870mm x 220mm wide

new brickwork pier. See detail and Section A - A brickwork pier.

110 110

and Section B - B. B and Section D - D.

10790 o/a concrete

2400

220 2535 220 2535 220 2310 220 2310 220 795 220 Line of Existing Building

2580

230

11805 10

Line of entrance canopy r.c. slab above.

5400 5400 10mm wide isolation joint between BRICKWORK NOTES :

500

existing and new building. - All brickwork (solid brick walls or cavity brick walls) below surface bed level

See Isolation Joint Note. (Typical). to have brickforce in every course. 500mm x 220mm

- All solid brick walls above surface bed level are 220mm wide or 110mm wide r.c. col. above and below.

1 2 3 with brickforce built in every 3rd course. 130

Line of Existing Building

- All parapet walls are 220mm wide or 110mm wide with brickforce built in 220 5080 220 1025

every course. 5520 230

ROOF SLAB PLAN - All cavity brick walls above surface bed level are 340mm wide with 110mm

wide outer skin brickwork with 120mm central cavity with 3,15mm Ø x 300mm

350

long galvanised butterfly wire ties built vertically into brickwork every 3rd

course and horizontally at max. 500mm centres above surface bed level

340 340 and built vertically into brickwork in every course below surface bed level and

1 2 3

horizontally at max. 500mm centres.

+ 1357,310 lvl. + 1357,310 lvl. - All brickwork to Architect's detail in Class 2 mortar.

230mm wide parapet wall.

230

230mm wide parapet wall.

230

FIRST FLOOR SLAB PLAN

110 120 110 120

r.c. column behind. r.c. column behind.

680

680

110 110 CL CL CL

75mm Ø rainwater

t.o.c. @ + 1356,630 lvl. overflow pipe. t.o.c. @ + 1356,630 lvl. anchor anchor anchor

765mm deep x 220mm wide 765mm deep x 220mm wide

Screed to falls to Architect's r.c. upstand beam. Brickwork to be 'strapped/tied' to r.c. beam with Screed to falls to Architect's r.c. upstand beam. Brickwork to be 'strapped/tied' to r.c. beam with 500 500 500 500

specification and details. 30 30mm wide x 1,2mm thk. x 200mm long galvanised specification and details. 30mm wide x 1,2mm thk. x 200mm long galvanised centres 100 centres All structural steel angles and flats

1445

1445

t.o.c. @ t.o.c. @

510

510

typical typical

75

255mm thk. r.c. 50 50 to be grade S355JR hot-dipped

765

765

+ 1356,120 lvl. steel straps. 100mm of steel strap shot fired to r.c. beam + 1356,120 lvl. steel straps. 100mm of steel strap shot fired to r.c. beam

50

100

100

100

255mm thk. r.c.

55

55

50

50

roof slab. and 100mm of steel strap built into brick wall every and 100mm of steel strap built into brick wall every galvanised to ISO 1461 or EN 10240.

roof slab.

2nd course @ 750mm centres. 2nd course @ 750mm centres.

255

255

255

CL CL

200

200

150

150

REV DESCRIPTION BY DATE

510

50

50

50

150

200

100

100

100

255

100x100x10mm thk. flat fixed to r.c. beam

Brickwork Steel Support Angle : 100x100x10mm thk. flat fixed to r.c. beam 2 3

with 1 No. M20 chemical anchor. with 1 No. M20 chemical anchor. 220

Brickwork Steel Support Angle : 220 950 Brickwork Steel Support Angle : 100x100x10L welded to Line of

See chemical anchor specification. 510mm deep x 220mm wide See chemical anchor specification.

100x100x10L welded to 100x100x10L welded to 100x100x10mm thk. flat with Existing Building

110 120 110 r.c. d/stand beam. 350 5400

340mm wide cavity wall. 100x100x10mm thk. flat with 100x100x10mm thk. flat fixed to r.c. beam 100x100x10mm thk. flat with 6mm full penetration bevel weld.

See brickwork notes. 6mm full penetration bevel weld. with 1 No. M20 chemical anchor. 6mm full penetration bevel weld. 5520 10 220

340 T1 FOR TENDER PURPOSES S.A. 24/06/2020

(See brickwork steel support angle detail). See chemical anchor specification. (See brickwork steel support angle detail). Line of Existing Building

700 1170mm x 220mm wide

Soffit of steel angle @ +1355,865 lvl. Soffit of steel angle @ +1355,865 lvl. C

340mm wide cavity wall.

See brickwork notes.

110 120 110 TYPICAL BRICKWORK STEEL 240 220 4600 r.c. shear wall above. 220

10mm wide isolation joint between

professional person M.NAIR PrTechEng

PROJECT MANAGER | PRINCIPAL AGENT

registration 200670211

SECTION A - A 340

SUPPORT ANGLE DETAIL 950mm x 220mm wide

240

510mm deep x 220mm wide r.c. upstand beam

existing and new building.

220

220

r.c. shear wall above and below. See Isolation Joint Note. (Typical).

t.o.c. @ + 1354,335 lvl.

SECTION B - B

220

640

700mm x 220mm b

640

y s la

r.c. col. above and below. p l.

J no J

950

,

460 . c a 8 0 lv f in g

1170

1170

340 c o

950

. , 0

M20 CHEMICAL ANCHOR SPECIFICATION : 240 220 .r 4 p ro ils

120

th k + 1 3 5 a te r d e ta

830

830

110 120 110 Fischer M20 (8.8) galvanised H.D. Anchor Studs m w c t 's .

M20 CHEMICAL ANCHOR SPECIFICATION : 5m @ s, C

2 5 . o . c . o f a l l c h it e i o n s )

220

340mm wide cavity wall.

(with embedment length = 200mm) with Fischer

FIS-V-360 Chemical Mortar or equally approved Fischer M20 (8.8) galvanised H.D. Anchor Studs K t dt

e e t

r

o A c if ic a

t K CLIENT

r s

Screed to falls to Architect's (S c F B O d s p e

3430

3870

3870

Chemical Anchors with 'ETA' ( European Technical (with embedment length = 200mm) with Fischer

t.o.c. @ + 1354,335 lvl. specification and details. FIS-V-360 Chemical Mortar or equally approved 510mm deep x 220mm wide

& an

Approval).

2200

t.o.c. @ 220 240

2480

Chemical Anchors with 'ETA' ( European Technical r.c. downstand beam.

1860

255mm thk. r.c. canopy slab.

2700

3870mm x 220mm wide

255

2580

+ 1354,080 lvl. Screed to falls to Architect's t.o.c. @

2400

2400

Approval). 255mm thk. r.c. canopy slab. 460

r.c. shear wall below.

510

specification and details. + 1354,080 lvl.

340 F

255

255

110 120 110 500mm x 220mm

E E PROJECT

280

510mm deep x 220mm wide r.c. col below UMALUSI OFFICES

500

340mm wide cavity wall.

r.c. upstand beam. 340

ADDITIONS AND ALTERATIONS

220

220

220

110 120 110 340mm wide cavity wall. 220mm wide 510mm deep x 220mm wide

r.c. shear wall. 130 Line of Existing Building

r.c. downstand beam. DETAILS

220 120

220 120

220 5080 220

NEW ABLUTIONS BUILDING

255mm thk. r.c. first floor slab t.o.c. @

1530

+ 1352,805 lvl. 220 5520 230 ROOF SLAB,

55

255mm thk. r.c. first floor slab t.o.c. @

100

50

+ 1352,805 lvl. 350 1025 ENTRANCE CANOPY SLAB &

255

255

CL

55

200

100

50

SECTION E - E FIRST FLOOR SLAB

510

510

F

255

255

CL 2 3

200

50

150

100

255

255

STRUCTURAL LAYOUT & DETAILS

510

510

50

150

100

255

255

Brickwork to be 'strapped/tied' to r.c. beam with

510mm deep x 220mm wide

30mm wide x 1,2mm thk. x 200mm long galvanised

510mm deep x 220mm wide

Brickwork to be 'strapped/tied' to r.c. beam with

30mm wide x 1,2mm thk. x 200mm long galvanised

r.c. d/stand beam.

steel straps. 100mm of steel strap shot fired to r.c. beam

Screed to falls to Architect's

ENTRANCE CANOPY SLAB PLAN

r.c. d/stand beam. 100x100x10mm thk. flat fixed to r.c. beam and 100mm of steel strap built into brick wall every t.o.c. @

steel straps. 100mm of steel strap shot fired to r.c. beam specification and details. 255mm thk. r.c. canopy slab.

with 1 No. M20 chemical anchor. 2nd course @ 750mm centres. + 1354,080 lvl.

100x100x10mm thk. flat fixed to r.c. beam and 100mm of steel strap built into brick wall every

See chemical anchor specification. 110 120 110

with 1 No. M20 chemical anchor. 2nd course @ 750mm centres.

255

See chemical anchor specification. 110 120 110 340 Brickwork Steel Support Angle :

510

100x100x10L welded to

255

340 Brickwork Steel Support Angle : 100x100x10mm thk. flat with

SUITE 106, ESSENVIEW BUILDING, STRATHMORE PARK,

305 MUSGRAVE ROAD, DURBAN, 4001

100x100x10L welded to 6mm full penetration bevel weld. 510mm deep x 220mm wide

e-mail : admin@mapafrica.co.za

100x100x10mm thk. flat with (See brickwork steel support angle detail). r.c. downstand beam.

220 FAX (031) 3092929 TEL. (031) 3095831

6mm full penetration bevel weld. Soffit of steel angle @ +1352,550 lvl.

(See brickwork steel support angle detail).

Soffit of steel angle @ +1352,550 lvl.

SECTION D - D DESIGNED K.L.

COPYRIGHT RESERVED

SCALES

SECTION C - C SECTION F - F DRAWN K.L. 1:50 1:25

APPROVED M.N. PL DATE 27/01/2020

FOR TENDER PURPOSES DRAWING No.

200-309 / 302 REV

T1

NOTES

2 3 4 1. ALL LEVELS AND DIMENSIONS TO BE CHECKED ON SITE.

2. THIS DRAWING TO BE READ IN CONJUNCTION WITH

THE ARCHITECTURAL DRAWINGS.

5400 5400 3. ALL CONCRETE WORK TO COMPLY WITH SABS 1200G.

4. CONCRETE CLASS :-

a) PILECAPS & GROUND BEAMS = 25 MPa

b) STRIP FOOTINGS & BASES = 25 MPa

c) COLUMNS, SHEAR & LIFT WALLS = 30 MPa

Existing r.c. Existing r.c. Existing r.c. d) SLABS, BEAMS & STAIRCASES = 25 MPa

column column column e) RETAINING WALLS = 25 MPa

A f) SURFACE BEDS = 30 MPa

Existing brick wall. Existing brick wall. g) BLINDING = 10 MPa

830

Existing brick wall.

5. COVER TO REINFORCEMENT :-

B AS INDICATED ON DRAWING

6. ALL FOUNDATION EXCAVATIONS TO BE INSPECTED BY

THE ENGINEER PRIOR TO CASTING OF CONCRETE.

See Detail 'A' for brickwork

strapping to r.c. column. strap fixed to connecting 7. ALL REINFORCING FIXING TO BE INSPECTED BY

wall with 'Hilti' drive pin THE ENGINEER PRIOR TO CASTING OF CONCRETE.

bed (or equally approved) 8. SIX CUBES TO BE TAKEN PER POUR.

ce 10mm deep x 10mm wide

110 110 su rfa shot fired into wall. THREE TO BE TESTED AT SEVEN DAYS, THE

ti ng 'Dow Corning 813C' silicone REMAINDER AT TWENTY EIGHT DAYS. THE RESULTS

E xis sealant (or equally approved) TO BE FORWARDED TO THE ENGINEER.

Existing r.c. column

applied to both sides of brick wall. 9. CONTRACTOR TO CONSTRUCT A BLINDING LAYER

New 220mm wide brickwork

IF SOIL CONDITIONS RESULT IN REINFORCEMENT

to be constructed on existing

COVER NOT BEING MAINTAINED.

220

6260

surface bed.

10. ALL STRUCTURAL CONCRETE TO BE CURED FOR

A MINIMUM OF FIVE DAYS.

10mm thk. polystyrene

300 10 11. BRICKWORK SHOWN HATCHED ARE LOAD BEARING.

New brick wall spacer strip

ALL LOAD BEARING BRICKWORK TO BE 14MPa NFX.

PLAN. strap fixed to connecting TOP OF ALL BRICKWORK TO RECEIVE 2 LAYERS OF

wall with 'Hilti' drive pin 3 PLY MALTHOID ON SMOOTH RENDERED SURFACE.

concertina ties : (or equally approved) 12. ALL SINGLE SKIN BRICKWORK TO BE STOPPED 2

30mm wide x 1,2mm thk. shot fired into wall. COURSES BELOW SOFFIT OF SLAB AND COMPLETED

See Detail 'B' for brickwork galvanised steel strap AFTER PROPS HAVE BEEN REMOVED.

strapping to r.c. column. built into brickwork every

13. ALL CONCRETE PLASTER AND BRICKWORK PLASTER

3rd course.

150

INTER-FACES TO RECEIVE V-JOINTS.

14. THE ENGINEER REQUIRES 24HRS NOTICE FOR ALL

Existing r.c. Existing r.c. Existing r.c.

D column column column 300

INSPECTIONS.

be d

ce

su rf a See Detail 'B' for brickwork new brick wall Existing r.c. column

ng New 220mm wide brickwork

ti

E x is to be constructed on existing strapping to r.c. column.

surface bed. ELEVATION

Existing brick wall.

DETAIL 'A'

BRICKWORK STRAPPING TO

New 220mm wide brickwork to

Existing brick wall.

Existing brick wall. EXISTING R.C. COLUMN

existing 220mm wide brickwork REV DESCRIPTION BY DATE

connection. See Detail 'C'.

T1 FOR TENDER PURPOSES S.A. 24/06/2020

PART PLAN SHOWING NEW BRICK WALL

professional person M.NAIR PrTechEng registration 200670211

CAST ON EXISTING GROUND FLOOR SURFACE BED PROJECT MANAGER | PRINCIPAL AGENT

Existing

r.c. column. Strap fixed to connecting r.c. CLIENT

10mm deep x 10mm wide column with 'Hilti' drive pin

'Dow Corning 813C' silicone (or equally approved)

sealant (or equally approved) shot fired into r.c. column.

strap fixed to connecting

applied to both sides of brick wall.

New brick wall. 30mm wide x 1,2mm thk. wall with 'Hilti' drive pin

30 40

galvanised steel strap built 10 joint (or equally approved)

shot fired into wall.

220

220

into brickwork every 3rd course.

40 30

PROJECT

10mm deep x 10mm wide

'Dow Corning 813C' silicone

New brick wall.

700 10 10mm wide polystyrene

sealant (or equally approved) 700 230

UMALUSI OFFICES

spacer strip.

ADDITIONS AND ALTERATIONS

existing brick wall

applied to both sides of wall.

PLAN

40

existing brick wall

Strap ties : Strap fixed to connecting r.c.

100

30mm wide x 1,2mm thk. Varies column with 'Hilti' drive pin

30

DETAILS

galvanised steel strap built (or equally approved)

EXISTING MAIN BUILDING

230

into brickwork every 3rd course. shot fired into r.c. column.

30

New brick wall. new brick wall

NEW BRICK WALL CAST ON

EXISTING GROUND FLOOR SURFACE BED

150

40

new brick wall

700

10mm thk. polystyrene

STRUCTURAL LAYOUT & DETAILS

700 10

New brick wall. spacer strip. SECTION

Existing

PLAN

r.c. column DETAIL 'C'

ELEVATION NEW 230mm WALL TO EXISTING

230mm WALL CONNECTION DETAIL

DETAIL 'B' SUITE 106, ESSENVIEW BUILDING, STRATHMORE PARK,

305 MUSGRAVE ROAD, DURBAN, 4001

BRICKWORK STRAPPING TO e-mail : admin@mapafrica.co.za

FAX (031) 3092929 TEL. (031) 3095831

EXISTING R.C. COLUMN

DESIGNED Y.R. SCALES

COPYRIGHT RESERVED

DRAWN Y.R. 1:25 1:10

APPROVED M.N. PL DATE 20/01/2020

FOR TENDER PURPOSES DRAWING No.

200-309 / 303 REV

T1

NOTES

1. ALL LEVELS AND DIMENSIONS TO BE CHECKED ON SITE.

2. THIS DRAWING TO BE READ IN CONJUNCTION WITH

THE ARCHITECTURAL DRAWINGS.

3. ALL CONCRETE WORK TO COMPLY WITH SABS 1200G.

3 4 4. CONCRETE CLASS :-

9 10 a) PILECAPS & GROUND BEAMS

b) STRIP FOOTINGS & BASES

= 25 MPa

= 25 MPa

c) COLUMNS, SHEAR & LIFT WALLS = 30 MPa

d) SLABS, BEAMS & STAIRCASES = 25 MPa

e) RETAINING WALLS = 25 MPa

N N G G f) SURFACE BEDS = 30 MPa

g) BLINDING = 10 MPa

5. COVER TO REINFORCEMENT :-

AS INDICATED ON DRAWING

6. ALL FOUNDATION EXCAVATIONS TO BE INSPECTED BY

THE ENGINEER PRIOR TO CASTING OF CONCRETE.

3730

3820

7. ALL REINFORCING FIXING TO BE INSPECTED BY

THE ENGINEER PRIOR TO CASTING OF CONCRETE.

A A 8. SIX CUBES TO BE TAKEN PER POUR.

EXISTING FIRST FLOOR SLAB

THREE TO BE TESTED AT SEVEN DAYS, THE

3360 o/a steel angle

3015 o/a steel angle REMAINDER AT TWENTY EIGHT DAYS. THE RESULTS

180 500 500 500 500 500 500 180 TO BE FORWARDED TO THE ENGINEER.

200 500 500 500 500 500 315 M20 chemical anchors @ 500mm centres as shown. 9. CONTRACTOR TO CONSTRUCT A BLINDING LAYER

M20 chemical anchors @ 500mm centres as shown.

185

IF SOIL CONDITIONS RESULT IN REINFORCEMENT

I.J.

See chemical anchor specification. (Typical)

10

140

I.J.

See chemical anchor specification. (Typical)

10

COVER NOT BEING MAINTAINED.

l l 10. ALL STRUCTURAL CONCRETE TO BE CURED FOR

ne ne

500

500

a Slab Infilll Steel Support Angle : a

ll p

i ll p

i

A MINIMUM OF FIVE DAYS.

in f 100x100x10L welded to A in f

2850 o/a concrete slab

2760 o/a concrete slab

2870 o/a steel angle

A

2780 o/a steel angle

b b 11. BRICKWORK SHOWN HATCHED ARE LOAD BEARING.

s la s .

500

a

500

Slab Infilll Steel Support Angle : sl s 100x100x10mm thk. flat with

100x100x10L welded to r .c. n gle 6mm full penetration bevel weld .r c. ngle ALL LOAD BEARING BRICKWORK TO BE 14MPa NFX.

) a a) el a TOP OF ALL BRICKWORK TO RECEIVE 2 LAYERS OF

P a te e l

10380

10380

P

2870

500

2780

100x100x10mm thk. flat with fixed to the side of the existing r.c. slab M te

500

M

25 s (2 5 o n s 3 PLY MALTHOID ON SMOOTH RENDERED SURFACE.

6mm full penetration bevel weld k . ( d on with M20 chemical anchors. .

th k rte d

t h te 12. ALL SINGLE SKIN BRICKWORK TO BE STOPPED 2

m p or m

500

fixed to the side of the existing r.c. slab See chemical anchor specification. o

500

m A A 5m u pp A A COURSES BELOW SOFFIT OF SLAB AND COMPLETED

with M20 chemical anchors. 2 5 5 su

p

A Soffit of steel angle @ +1352,550 lvl. w

2 5 s A AFTER PROPS HAVE BEEN REMOVED.

ew Ne

500

See chemical anchor specification. (Typical).

500

N

Soffit of steel angle @ +1352,550 lvl. 13. ALL CONCRETE PLASTER AND BRICKWORK PLASTER

INTER-FACES TO RECEIVE V-JOINTS.

(Typical).

I.J.

I.J.

10

10

14. THE ENGINEER REQUIRES 24HRS NOTICE FOR ALL

185

140 INSPECTIONS.

200 500 500 500 500 500 315

3005 o/a concrete slab 10

180 500 500 500 500 500 500 180

3015 o/a steel angle I.J. 2510

3350 o/a concrete slab 10

EXISTING FIRST FLOOR SLAB I.J.

3360 o/a steel angle 2040

3780

3780

125 5400 5400

A A

REV DESCRIPTION BY DATE

O O J J

3 4

9 10 T1 FOR TENDER PURPOSES S.A. 24/06/2020

professional person M.NAIR PrTechEng registration 200670211

PLAN PLAN PROJECT MANAGER | PRINCIPAL AGENT

R.C. SLAB INFILL PANEL ON EXISTING FIRST FLOOR R.C. SLAB INFILL PANEL ON EXISTING FIRST FLOOR

M20 CHEMICAL ANCHOR SPECIFICATION :

Fischer M20 (8.8) galvanised H.D. Anchor Studs CLIENT

(with embedment length = 200mm) with Fischer

FIS-V-360 Chemical Mortar or equally approved

Chemical Anchors with 'ETA' ( European Technical

Approval).

CL CL CL

anchor anchor anchor

PROJECT

500 500 500 500 10mm deep x 10mm wide

centres centres 'Dow Corning 813C' silicone UMALUSI OFFICES

typical typical

All structural steel angles and flats New 255mm thk. (25MPa)

sealant (or equally approved) ADDITIONS AND ALTERATIONS

on 10mm thk. polystyrene backing.

100 to be grade S355JR hot-dipped r.c. slab infill panel

First floor t.o.c. Existing first floor slab. galvanised to ISO 1461 or EN 10240. supported on steel angles. First floor t.o.c. Existing first floor slab.

50 50 DETAILS

@ + 1352,805 lvl. @ + 1352,805 lvl.

EXISTING MAIN BUILDING

55

55

NEW R.C. SLAB IN-FILL PANELS

50 50

100

100

CL CL

ON THE EXISTING FIRST FLOOR SLAB

255

255

50

200

255

150

200

150

STRUCTURAL LAYOUT & DETAILS

100

100

Slab Infill Steel Support Angle : 100x100x10mm thk. flat fixed to the side of the

100x100x10L welded to existing r.c. slab with 1 No. M20 chemical anchor. Slab Infilll Steel Support Angle : 100x100x10mm thk. flat fixed to the side of

100x100x10mm thk. flat with 100x100x10L welded to r.c. slab with 1 No. M20 chemical anchor.

6mm full penetration bevel weld.

Soffit of steel angle @ +1352,550 lvl.

TYPICAL ELEVATION See chemical anchor specification.

100x100x10mm thk. flat with See chemical anchor specification.

6mm full penetration bevel weld

R.C. SLAB INFILL PANEL fixed to the side of the existing r.c. slab

with M20 chemical anchors.

SUITE 106, ESSENVIEW BUILDING, STRATHMORE PARK,

STEEL SUPPORT ANGLE DETAIL See chemical anchor specification.

Soffit of steel angle @ +1352,550 lvl.

305 MUSGRAVE ROAD, DURBAN, 4001

e-mail : admin@mapafrica.co.za

FAX (031) 3092929 TEL. (031) 3095831

SECTION A - A DESIGNED K.L.

COPYRIGHT RESERVED

SCALES

DRAWN K.L. 1:25 1:10

APPROVED M.N. PL DATE 30/01/2020

FOR TENDER PURPOSES DRAWING No.

200-309 / 304 REV

T1

1060 CL

existing r.c. column

existing r.c. column

NOTES

STRUCTURAL STEEL NOTES : & new UB rafter 1. ALL LEVELS AND DIMENSIONS TO BE CHECKED ON SITE.

2. THIS DRAWING TO BE READ IN CONJUNCTION WITH

1. ALL WORK IN ACCORDANCE WITH SANS 1200 H. 220 THE ARCHITECTURAL DRAWINGS.

2. ALL WELDS TO BE MIN. 6mm CONTINUOUS FILLET WELDS (U.O.N.) Note : All flashings, fascias, gutters &

3. ALL STRUCTURAL STEELWORK TO BE GRADE S355JR 3. ALL CONCRETE WORK TO COMPLY WITH SABS 1200G.

rwdp to Architects details & specifications. Face of existing

(UNLESS OTHERWISE NOTED). 4. CONCRETE CLASS :-

4. ALL PURLINS AND GIRTS TO BE COMMERCIAL GRADE AND TO BE r.c. column. Face of existing a) PILECAPS & GROUND BEAMS = 25 MPa

GALVANISED IN ACCORDANCE WITH SANS 4998 / ISO 4998:1996 r.c. column. b) STRIP FOOTINGS & BASES = 25 MPa

FOR 'STRUCTURAL QUALITY'. 4575 extent of structural steel canopy 203x133x25 c) COLUMNS, SHEAR & LIFT WALLS = 30 MPa

d) SLABS, BEAMS & STAIRCASES = 25 MPa

50

5 ALL BOLTS TO BE GRADE 8.8 BOLTS AND TO BE UB rafter.

HOT DIPPED GALVANISED TO SANS 121:2011 (ISO 1461:2009(E)). e) RETAINING WALLS = 25 MPa

Existing face brickwork to be

200

6. ALL COMMERCIAL QUALITY H.D. BOLTS, PURLINS AND GIRTS Existing r.c. column f) SURFACE BEDS = 30 MPa

carefully removed and replaced g) BLINDING = 10 MPa

TO HAVE A MIN. GRADE STRESS OF 200 MPa.

300

400

after CHS tube tie end plate is CL

7. ALL STRUCTURAL STEELWORK, H.D BOLTS, NUTS installed. 5. COVER TO REINFORCEMENT :-

200

UB rafter

AND WASHERS TO BE HOT DIPPED GALVANISED 0,55mm thk. 'Klip-Tite Zincal / Colorplus AZ150' 16mm thk. plate cleat 31 8 AS INDICATED ON DRAWING

TO SANS 121:2011 (ISO 1461:2009 (E)). ALL STRUCTURAL roof sheeting at 2° pitch. Colour of sheeting with 1 No. 28mm Ø hole 240

50

STEEL TUBES ARE TO BE HOT-DIPPED GALVANISED TO to Architects specification. for M24 bolt. 6. ALL FOUNDATION EXCAVATIONS TO BE INSPECTED BY

SANS 32 / EN 10240. 220x400x20mm thk. end plate Existing THE ENGINEER PRIOR TO CASTING OF CONCRETE.

130x16mm thk. plate cleat

GALVANISING CERTIFICATE FOR ALL STEELWORK IS TO slot welded to tube tie with See CHS tube tie with 2 No. M24 chemical anchors. r.c. column. 7. ALL REINFORCING FIXING TO BE INSPECTED BY

BE SUBMITTED TO THE ENGINEER ON COMPLETION. 1 No. 28mm Ø hole for M24 bolt. End Plate Detail '2'. See chemical anchor specification. s.o.p THE ENGINEER PRIOR TO CASTING OF CONCRETE.

8. IF THE GALVANISING IS DAMAGED OR SCRATCHED DURING 130x16mm thk. plate cleat 220 8. SIX CUBES TO BE TAKEN PER POUR.

THE INSTALLATION PROCESS, IT MUST BE 'TOUCHED UP' WITH slot welded to tube tie with THREE TO BE TESTED AT SEVEN DAYS, THE

1 No. 28mm Ø hole for M24 bolt. e t ie 240

'PLASCON PLASCOZINC POLY GALV PRIMER' OR EQUALLY

. CH S tu b REMAINDER AT TWENTY EIGHT DAYS. THE RESULTS

APPROVED. ,5 m m th k radius = 65mm UB Rafter TO BE FORWARDED TO THE ENGINEER.

x4 Flashing to

9. 2 SETS OF FABRICATION SHOP DRAWINGS (HARDCOPIES) ARE 115 mm Ø

TO BE DELIVERED TO THE ENGINEER'S OFFICES FOR REVIEW AND

315 290 Architects details END PLATE DETAIL '1' 9. CONTRACTOR TO CONSTRUCT A BLINDING LAYER

Flashing to and specifications. IF SOIL CONDITIONS RESULT IN REINFORCEMENT

APPROVAL BEFORE COMMENCING WITH ANY FABRICATION. Architects details COVER NOT BEING MAINTAINED.

radius = 65mm and specifications.

13 0

NOTE : EMAIL SUBMISSION OF ELECTRONIC (PDF) COPIES OF SHOP 10. ALL STRUCTURAL CONCRETE TO BE CURED FOR

13.0°

DRAWINGS WILL NOT BE ACCEPTED. See Purlin to Brickwork CL A MINIMUM OF FIVE DAYS.

2° fall

10. CERTIFICATES CONFIRMING THE GRADE STRESS OF ALL End Plate Detail '3'.

existing 11. BRICKWORK SHOWN HATCHED ARE LOAD BEARING.

STEELWORK, PURLINS, GIRTS, H.D BOLTS AND BOLTS SPECIFIED r.c. column ALL LOAD BEARING BRICKWORK TO BE 14MPa NFX.

IS TO BE SUBMITTED TO THE ENGINEER ON COMPLETION. TOP OF ALL BRICKWORK TO RECEIVE 2 LAYERS OF

150

310

11. THE STRUCTURAL STEELWORK CONTRACTOR IS TO 220 3 PLY MALTHOID ON SMOOTH RENDERED SURFACE.

50 s lo t See UB rafter

VERIFY ALL SETTING OUT DIMENSIONS ON SITE

End Plate Detail '1'. 12. ALL SINGLE SKIN BRICKWORK TO BE STOPPED 2

PRIOR TO FABRICATION. 203x133x25 UB rafter COURSES BELOW SOFFIT OF SLAB AND COMPLETED

240x100x8mm thk.

plate stiffners. AFTER PROPS HAVE BEEN REMOVED.

600 13. ALL CONCRETE PLASTER AND BRICKWORK PLASTER

50

16mm thk. plate cleat welded Existing face brickwork to be INTER-FACES TO RECEIVE V-JOINTS.

555 300 to UB rafter with 1 No. carefully removed and replaced s.o.p

50

28mm Ø hole for M24 bolt. after UB rafter end plate is installed. 14. THE ENGINEER REQUIRES 24HRS NOTICE FOR ALL

M24 CHEMICAL ANCHOR SPECIFICATION :

100

INSPECTIONS.

Fischer M24 (8.8) galvanised H.D. Anchor Studs 235 16mm thk. plate cleat

950

(with embedment length = 350mm) with Fischer 1600 with 1 No. 28mm Ø hole

410

210

310

410

1600 for M24 bolt.

FIS-V-360 Chemical Mortar or equally approved 200

Chemical Anchors with 'ETA' ( European Technical

100

4585

Approval).

50

410x220x20mm thk. Existing

M12 CHEMICAL ANCHOR SPECIFICATION : end plate with 2 No. r.c. column.

150 M24 chemical anchors.

Fischer M12 (8.8) galvanised H.D. Anchor Studs Existing r.c. column

See chemical anchor 240x100x8mm thk.

(with embedment length = 220mm) with Fischer 35 80 35 110 110 REV DESCRIPTION BY DATE

Existing specification. plate stiffners.

FIS-V-360 Chemical Mortar or equally approved Face of existing

typical purlin cleat brick wall. 220

55 90 40

Chemical Anchors with 'ETA' ( European Technical r.c. column.

welded to rafter

185

Approval). 150x185x10mm thk.

plate with 4 No. M12 bolts. CHS Tube Tie

END PLATE DETAIL '2'

3230

203x133x25 UB rafter T1 FOR TENDER PURPOSES S.A. 24/06/2020

professional person M.NAIR PrTechEng registration 200670211

PURLIN CLEAT DETAIL

PROJECT MANAGER | PRINCIPAL AGENT

220 10 1060 175x70x10mm thk. plate cleat

extent of existing welded to end plate with

r.c. column 2 No. M12 bolts.

220

Face of existing 70

2 3 4 r.c. column. 70 40 30

30

38

11490

CLIENT

210

100

175

150

345 5400 5400 345

37

rafter bracing:

30

100x100x8L fixed to10mm thk. plate 30 145 30

gussets welded to rafter web A 4 rows 175x75x20x2,5mm thk.

CRLC purlins.

with 2 No. M20 bolts each end. 205 210x205x10mm thk. end plate

with 4 No. M12 chemical anchors

existing concrete thru' brickwork cladding, into existing

concrete. See chemical anchor specification. PROJECT

surface bed

@ +1349,830 lvl

PURLIN TO BRICKWORK UMALUSI OFFICES

Existing paving

Existing paving END PLATE DETAIL '3' ADDITIONS AND ALTERATIONS

50x50x3L false rafter

203x133x25 UB rafter

203x133x25 UB rafter

203x133x25 UB rafter

50x50x3L false rafter

DETAILS

See End Plate Detail '1' sag angles: 50x50x3L with EXISTING MAIN BUILDING

& End Plate Detail '2'. end cleats:50x50x3L with

2 No. M12 bolts for each NEW STRUCTURAL STEEL CANOPY

See End Plate Detail '1' cleat (typical).

& End Plate Detail '2'. See End Plate See End Plate Detail '1'

STRUCTURAL DETAILS

See End Plate See End Plate

220

Detail '3'. Detail '3'. & End Plate Detail '2'.

220

220

Detail '3'.

A A

See End Plate

SECTION A - A

130

130

130

1290

1290

830

830

Detail '3'.

110

110

B B

220

110

110

220

Existing Existing Existing Existing

r.c. column. brickwork. r.c. column. r.c. column.

690 4710 690 4710 690 SUITE 106, ESSENVIEW BUILDING, STRATHMORE PARK,

305 MUSGRAVE ROAD, DURBAN, 4001

345 345 345 345 345 345 e-mail : admin@mapafrica.co.za

FAX (031) 3092929 TEL. (031) 3095831

5400 5400

DESIGNED S.M. SCALES

COPYRIGHT RESERVED

2 A 3 4 DRAWN S.M. 1:15 1:50

APPROVED M.N. PL DATE 28/01/2020

PLAN ON STRUCTURAL STEEL CANOPY FOR TENDER PURPOSES DRAWING No.

200-309 / 500 REV

T1

830 150x75x10L cleat fixed to side of existing concrete slab

Existing 1

brickwork. 110 110 A B 150x75x10L cleat fixed to

side of existing concrete slab

Existing first Line of existing

Top of 'Vastrap' floor plate

to be constructed flush with

with M12 chemical anchors at 300mm centres. See chemical

anchor specification.

NOTES

floor slab. first floor slab. 1100 o/a 75 735 o/a 1. ALL LEVELS AND DIMENSIONS TO BE CHECKED ON SITE.

1070 220 with M12 chemical anchors at existing first floor slab finishes.

110

t.o.c @ 'Vastrap' plate 'Vastrap' plate

345

1420 o/a 300mm centres. See chemical +1352,805 lvl. 2. THIS DRAWING TO BE READ IN CONJUNCTION WITH

'Vastrap' plate anchor specification. t.o. 'Vastrap' plate 500 235 110 t.o.c. floor finish

110

t.o.c. @ THE ARCHITECTURAL DRAWINGS.

10

220

1 1 @ +1352,805 lvl @ +1352,835 lvl +1352,805 lvl 3. ALL CONCRETE WORK TO COMPLY WITH SABS 1200G.

30

30

690

345

345

115

335

4. CONCRETE CLASS :-

110

CL

255

50x50x5L cleat a) PILECAPS & GROUND BEAMS = 25 MPa

80

'Vastrap' plate

b) STRIP FOOTINGS & BASES = 25 MPa

735 o/a

110

s.o.p End plate detail, CL End plate detail, as shown on CL CL c) COLUMNS, SHEAR & LIFT WALLS = 30 MPa

Existing as shown on Section B - B. 200 PFC stringer d) SLABS, BEAMS & STAIRCASES = 25 MPa

post post Hand / knee rail. post Existing first floor

500

500

r.c. column. CL Section B - B. 180 PFC beam See balustrade note. e) RETAINING WALLS = 25 MPa

Hand / knee rail. r.c. slab.

post 200 PFC post Remove existing face brickwork Stitch weld f) SURFACE BEDS = 30 MPa

See balustrade note. 200 PFC

200 PFC post 200 PFC stringer 200 PFC post carefully and re-construct 'Vastrap plate

Existing stringer. g) BLINDING = 10 MPa

brickwork after the 150x75x10L on site.

75

cleat is installed. brickwork. 5. COVER TO REINFORCEMENT :-

280

C C

75

1910

110 115 110 AS INDICATED ON DRAWING

50x50x5L cleat below TREAD :

335 10

B

180 PFC cross-beam

180 PFC cross-beam

'Vastrap' plate. Stitch 7,6mm / 6mm thk.

SECTION A - A

200 PFC end beam

6. ALL FOUNDATION EXCAVATIONS TO BE INSPECTED BY

20

weld plate to cleat under pattern

'Vastrap' plate

30

THE ENGINEER PRIOR TO CASTING OF CONCRETE.

180 PFC cross-beam

345

30

'Vastrap' plate

1100 o/a

on site. Angle cleat

(or equally approved). 7. ALL REINFORCING FIXING TO BE INSPECTED BY

bolted to stringer / beam

THE ENGINEER PRIOR TO CASTING OF CONCRETE.

with M12 bolts @ max.

250mm centres (typical). 50x50x5L cleat 60 130 30 8. SIX CUBES TO BE TAKEN PER POUR.

welded to steel tread THREE TO BE TESTED AT SEVEN DAYS, THE

with 2 No. M12 bolts 220 10 REMAINDER AT TWENTY EIGHT DAYS. THE RESULTS

Hand / knee rail. 200 PFC post fixed to stringer. TO BE FORWARDED TO THE ENGINEER.

See balustrade note.

9. CONTRACTOR TO CONSTRUCT A BLINDING LAYER

200 PFC stringer TYPICAL STEEL TREAD IF SOIL CONDITIONS RESULT IN REINFORCEMENT

75

Hand / knee rail. Hand / knee rail. COVER NOT BEING MAINTAINED.

200 PFC post 200 PFC post 200 PFC post

1180 110 See balustrade note. See balustrade note.

10. ALL STRUCTURAL CONCRETE TO BE CURED FOR

1125 2900 2300 100 1 Remove existing face brickwork A MINIMUM OF FIVE DAYS.

1290 75 200 345

CL CL CL 200 PFC stringer. carefully and re-construct 11. BRICKWORK SHOWN HATCHED ARE LOAD BEARING.

350 830 385 post post 130x150x10mm thk end plate 130 235 110 brickwork after the 180 PFC ALL LOAD BEARING BRICKWORK TO BE 14MPa NFX.

post

1565 A 280 with 4 No. M12 bolts.

30 70 30 810

end plate is installed. TOP OF ALL BRICKWORK TO RECEIVE 2 LAYERS OF

3 PLY MALTHOID ON SMOOTH RENDERED SURFACE.

CL PLAN ON STRUCTURAL STEEL STAIRCASE 400mm x 360mm x 40 200 40

40 70 40

12. ALL SINGLE SKIN BRICKWORK TO BE STOPPED 2

A B post 70

1200mm high r.c. plinth. 200 200

150

COURSES BELOW SOFFIT OF SLAB AND COMPLETED

60

120

75

40

82

75 200x75x12mm thk. end plate 30 40 'Vastrap' floor plate AFTER PROPS HAVE BEEN REMOVED.

37

200x75x12mm thk. end plates with 2 No. M20 bolts. 35 flush with top of stringer.

40 35 40 13. ALL CONCRETE PLASTER AND BRICKWORK PLASTER

240

160

360

75 500

75

with 2 No. M20 bolts. CL

INTER-FACES TO RECEIVE V-JOINTS.

38

post 180 PFC tie fixed Existing first floor

45 90 45 6

210

120

83

14. THE ENGINEER REQUIRES 24HRS NOTICE FOR ALL

40

flush with underside of r.c. slab.

55 90 55

55 90 55

55 90 55

60

'Vastrap' plate notch 30 150 30 INSPECTIONS.

200 PFC end beam 280x240x16mm thk. base plate

186

60 280 60

200

200

200

PFC tie to suit.

105

200 PFC post with 4 No. M20 chemical anchors.

200 PFC stringer 400 See chemical anchor specification.

180

CL 110 115 110

75

180x70x10mm thk. end plate 180 PFC cross-beam post 335 10 70

200 PFC stringer 200 PFC stringer

with 2 No. M20 bolts. top flush with u/s 'Vastrap' plate. SECTION B - B

STRINGER SPLICE DETAIL TYPICAL BASE PLATE 345

END BEAM TO STRINGER DETAIL 210x180x12mm thk.

CONNECTION DETAIL CROSS-BEAM TO STRINGER A B CL CL CL end plate with 2 No. M16

chemical anchors. See

CONNECTION DETAIL steel

post

steel

post

steel

post chemical anchor specification.

REV DESCRIPTION BY DATE

180 PFC beam 830 385 1125 2900 2300 CL

s.o.p. steel

500

1560 2250 850 1965 post

1525 1 1

537 345

345

35

landing

360 100

257

257

t.o. first floor finish 200 PFC T1 FOR TENDER PURPOSES S.A. 24/06/2020

1060 300 2000

280

280

280

280

beam

centre

@ +1352,835 lvl

plinth

line

typ.

CL

professional person M.NAIR PrTechEng registration 200670211

75

steel

200

200 PFC stringer post 100 400 400 100 300 400 300 300 400 300

typical

PROJECT MANAGER | PRINCIPAL AGENT

1175

1175

1175

1735

1175

1735

1175

815

1735

200 200 200 200

180 PFC beam

centre

plinth

360

typ.

75 100 200

line

BALUSTRADE NOTE : CL

280

280

280

50x50x5L cleats 'Mentis' Ball and Tube heavy duty steel

100

9 risers @ 180mm

shop welded to 'Vastrap' industrial hand rail / knee rail and posts post

280

100

85 1725 2100 1000 1300 1000

plate (or equally approved) (or equally approved). Fixed to top of

bolted to stringer/beam with stringers as per manufacturer's centre centre centre centre

1620

CL

20 specification and details (typical). line line line line

M12 bolts @ max. 250mm 0P post

FC 1735x1725x300mm deep

centres (typical). plinth plinth plinth plinth

st r r.c. base with 4 No. CLIENT

in g 350 830 385

er CL 400x360x1200mm high 1735x1000x300mm deep

1565 r.c. plinths. r.c. base with 2 No.

1130 35 steel

post 400x360x1200mm high

30 landing

A B FOUNDATION PLAN r.c. plinths.

780 35 2000

180 PFC t.o.c. r.c. bases @ +1348,375 lvl

STRUCTURAL STEEL NOTES :

3175

3175

200 PFC stringer beam.

3260

3260

CL t.o.c. r.c. plinths @ +1349,575 lvl

3035

180 PFC beam 280

typ 1. ALL WORK IN ACCORDANCE WITH SANS 1200 H. PROJECT

post

2. ALL WELDS TO BE MIN. 6mm CONTINUOUS FILLET WELDS (U.O.N.)

50x50x5L cleat 250

3. ALL STRUCTURAL STEELWORK TO BE GRADE S355JR UMALUSI OFFICES

(UNLESS OTHERWISE NOTED).

180

ADDITIONS AND ALTERATIONS

typ

100 100 100 100 shop welded to 'Vastrap' plate

8 risers @ 180mm

(or equally approved) bolted to 4. ALL PURLINS AND GIRTS TO BE COMMERCIAL GRADE AND TO BE

stringer with M12 bolts. Stringer 30 GALVANISED IN ACCORDANCE WITH SANS 4998 / ISO 4998:1996

splice. 100 100 20

1440

0P typ FOR 'STRUCTURAL QUALITY'.

FC M12 CHEMICAL ANCHOR SPECIFICATION : DETAILS

200 PFC post

s tr 5 ALL BOLTS TO BE GRADE 8.8 BOLTS AND TO BE

in g HOT DIPPED GALVANISED TO SANS 121:2011 (ISO 1461:2009(E)). Fischer M12 (8.8) galvanised H.D. Anchor Studs EXISTING MAIN BUILDING

1415

er

200 PFC post

200 PFC post

(with embedment length = 220mm) with Fischer

6. ALL COMMERCIAL QUALITY H.D. BOLTS, PURLINS AND GIRTS

FIS-V-360 Chemical Mortar or equally approved

NEW STRUCTURAL STEEL

See Typical See Typical TO HAVE A MIN. GRADE STRESS OF 200 MPa.

Base Plate Detail. Base Plate Detail.

t.o.c. r.c. plinth

7. ALL STRUCTURAL STEELWORK, H.D BOLTS, NUTS Chemical Anchors with 'ETA' ( European Technical FIRE ESCAPE STAIRCASE

See Typical Approval).

AND WASHERS TO BE HOT DIPPED GALVANISED

t.o. paving @ @ +1349,575 lvl Base Plate Detail. STRUCTURAL DETAILS

115

175

TO SANS 121:2011 (ISO 1461:2009 (E)). ALL STRUCTURAL

25

(typical). 200 PFC

+1349,660 lvl post. STEEL TUBES ARE TO BE HOT-DIPPED GALVANISED TO M16 CHEMICAL ANCHOR SPECIFICATION :

85

SANS 32 / EN 10240.

Fischer M16 (8.8) galvanised H.D. Anchor Studs

GALVANISING CERTIFICATE FOR ALL STEELWORK IS TO

85

grout

25

85

grout

85

25

grout

25

(with embedment length = 250mm) with Fischer

200

See Typical BE SUBMITTED TO THE ENGINEER ON COMPLETION.

100 100 FIS-V-360 Chemical Mortar or equally approved

Base Plate Detail. 8. IF THE GALVANISING IS DAMAGED OR SCRATCHED DURING

1125 2900 2300 Chemical Anchors with 'ETA' ( European Technical

THE INSTALLATION PROCESS, IT MUST BE 'TOUCHED UP' WITH

Approval).

r.c. plinth (typical)

'PLASCON PLASCOZINC POLY GALV PRIMER' OR EQUALLY

CL CL CL CL

APPROVED.

post post post 25mm thk. non shrink post

1200

grout below base plate 9. 2 SETS OF FABRICATION SHOP DRAWINGS (HARDCOPIES) ARE M20 CHEMICAL ANCHOR SPECIFICATION : SUITE 106, ESSENVIEW BUILDING, STRATHMORE PARK,

(typical). TO BE DELIVERED TO THE ENGINEER'S OFFICES FOR REVIEW AND Fischer M20 (8.8) galvanised H.D. Anchor Studs 305 MUSGRAVE ROAD, DURBAN, 4001

APPROVAL BEFORE COMMENCING WITH ANY FABRICATION. (with embedment length = 300mm) with Fischer e-mail : admin@mapafrica.co.za

t.o.c. r.c. bases NOTE : EMAIL SUBMISSION OF ELECTRONIC (PDF) COPIES OF SHOP FIS-V-360 Chemical Mortar or equally approved

FAX (031) 3092929 TEL. (031) 3095831

400x360x1200mm high

@ +1348,375 lvl r.c. plinth (typical). DRAWINGS WILL NOT BE ACCEPTED. Chemical Anchors with 'ETA' ( European Technical

(typical) 10. CERTIFICATES CONFIRMING THE GRADE STRESS OF ALL Approval). DESIGNED S.M. SCALES

STEELWORK, PURLINS, GIRTS, H.D BOLTS AND BOLTS SPECIFIED COPYRIGHT RESERVED

Note : 50mm blinding to all foundation DRAWN S.M. 1:10 1:20 1:50

r.c. base

(typical)

excavations. The bottom of all IS TO BE SUBMITTED TO THE ENGINEER ON COMPLETION.

300

foundation excavations is to be plate 11. THE STRUCTURAL STEELWORK CONTRACTOR IS TO PL 29/01/2020

APPROVED M.N. DATE

compacted to 90% Mod AASHTO, VERIFY ALL SETTING OUT DIMENSIONS ON SITE

prior to installing reinforcement. PRIOR TO FABRICATION.

SECTION C - C FOR TENDER PURPOSES DRAWING No.

200-309 / 501 REV

T1

NOTES

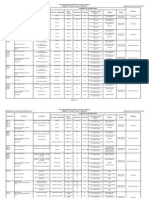

GENERAL

EXISTING

CONSERVANCY

KEY SAINT GOBAIN PRODUCT No

2934OR SIMILAR APPROVED 1. ALL CIVIL WORKS SETTING OUT TO BE

TANK CONTRACTOR TO 300 X 300 CAST IRON LIGHT UNDERTAKEN BY A REGISTERED

PROVE INVERT LEVEL EXISTING WATER LINE DUTY COVER AND FRAME

PROFESSIONAL SURVEYOR.

EXISTING CONSERVANCY TANK TO BE OF TANK

SERVICED (EMPTIED OUT) AND HIGH 2. ALL BUILDING WORKS SETTING OUT TO BE

EXISTING SEWER LINE 20MPA CONCRETE APRON

PRESSURE CLEANED TO UNDERTAKE AROUND GRATING UNDERTAKEN IN ACCORDANCE WITH

CONDITIONAL ASSESSMENTS 450 X 600 TYPE 9D MEDIUM

NEW 32mm Ø HDPE PE 100 PN 12.5 WATER LINE FGL DUTY CAST IRON COVER ARCHITECT'S DETAILS.

115mm NFX LOAD BEARING AND FRAME 3. PROVE ALL SERVICES PRIOR TO CONSTRUCTION.

NEW 160mm Ø CL 34 uPVC SEWER PIPE BRICKWORK TO SABS 227

MAX. 1200

4. ALL WORK AREAS TO BE REINSTATED (PREMIX,

DEEP

MORTAR BENCHING

450 X 450 LIGHT DUTY / FRL CONCRETE, ETC.)

100

NEW 250mm Ø CL 34 UPVC STORMWATER PIPE (1 SAND : 3 SAND)

1:10 FALL 110 Ø CL 34 UPVC PIPE 450 X 600 HEAVY DUTY 5. MUNICIPALITY TO EXECUTE ALL CONNECTIONS INTO

COBBLE

NEW 110mm Ø CL34 LAID AT 1:80 GRADE TO CAST IRON GRID INLET

NEW TYPE A SEWER PRECAST RING MANHOLE GRATING AND FRAME

BRICKWORK TO MUNICIPAL LINES.

SEWER PIPE CLOSEST STORMWATER MH SUIT GRATING

6. SUPPLY AND INSTALLATION TO COMPLY WITH SANS

230

NEW STORMWATER 150mm THICK 25MPA