0 ratings0% found this document useful (0 votes)

130 viewsFifo Procedure

Fifo Procedure

Uploaded by

Luke BilisThe document outlines a FIFO procedure for storing products and materials in a warehouse. It describes receiving deliveries and inspecting for damage before tagging items with receiving dates and placing them in storage using FIFO rotation to ensure the oldest items are used first.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Fifo Procedure

Fifo Procedure

Uploaded by

Luke Bilis0 ratings0% found this document useful (0 votes)

130 views1 pageThe document outlines a FIFO procedure for storing products and materials in a warehouse. It describes receiving deliveries and inspecting for damage before tagging items with receiving dates and placing them in storage using FIFO rotation to ensure the oldest items are used first.

Original Title

FIFO PROCEDURE

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The document outlines a FIFO procedure for storing products and materials in a warehouse. It describes receiving deliveries and inspecting for damage before tagging items with receiving dates and placing them in storage using FIFO rotation to ensure the oldest items are used first.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

130 views1 pageFifo Procedure

Fifo Procedure

Uploaded by

Luke BilisThe document outlines a FIFO procedure for storing products and materials in a warehouse. It describes receiving deliveries and inspecting for damage before tagging items with receiving dates and placing them in storage using FIFO rotation to ensure the oldest items are used first.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

FIFO PROCEDURE

Objective: To store products and materials in a rotational manner, and to prevent contamination of

materials and products. All products will be rotated based on receiving date of the product.

Person responsable: Warehouse manager and trained designate

Frequency: Ongoing.

Procedure:

Warehouse manager upon receipt of all supplies will:

1. Receive only one delivery at a time from approved suppliers

2. Check delivery invoice against the items delivered, and the purchase order.

3. Inspect all pallets/boxes for broken packages, mold, incomplete labels, and other visible

signs of damage.

4. If any damages are found, warehouse must notify quality inspector and all damages need to

be recorder in CMR.

5. Tag all pallets with the receiving date before placing in storage (The office will supply

sticker tags).

6. Use First In First Out (FIFO) inventory rotation of materials in all storage areas to assure

that oldest materials are used first. Products with the earliest use-by or expiration dates are

stored in front of products with later dates.

7. Keep materials in original packages until use.

Revision History

Date Rev.# Comments

July 18, 2023 1 Initial publication as a company procedure

Revision Date: July 18, 2023

Edition 1

Internal Reference: B/FIFO-001

Page 1 of 1

You might also like

- IQA Report Summary Sheet - Bolt & Zest Front Strut: 1 Mounting of PartDocument33 pagesIQA Report Summary Sheet - Bolt & Zest Front Strut: 1 Mounting of PartJetesh DevgunNo ratings yet

- Procedure - For The StoresDocument2 pagesProcedure - For The Storesparshuram malvekarNo ratings yet

- BGC Packing InstructionsDocument8 pagesBGC Packing InstructionsRajendraNo ratings yet

- The Company'S Factory Production Control System (FPC) FPC 0: BackgroundDocument7 pagesThe Company'S Factory Production Control System (FPC) FPC 0: BackgroundSandy D. RockNo ratings yet

- Extrusion ToolingDocument31 pagesExtrusion ToolingsvedanthNo ratings yet

- Disciplinary Action Record FormDocument1 pageDisciplinary Action Record FormklinecNo ratings yet

- Sop Mig WelderDocument1 pageSop Mig Weldervinoth madhavanNo ratings yet

- Advanced Standing Application Form - v1.0 - UpdatedDocument3 pagesAdvanced Standing Application Form - v1.0 - UpdatedVraj ShahNo ratings yet

- Surface Tester Work InstructionsDocument1 pageSurface Tester Work InstructionsAbdul AhadNo ratings yet

- Quality Specifications For Purchased PartsDocument29 pagesQuality Specifications For Purchased PartsDheeraj Kumar100% (1)

- Procedure For PurchaseDocument3 pagesProcedure For Purchaseparshuram malvekarNo ratings yet

- Finished Product Transfer NoteDocument1 pageFinished Product Transfer NoteBejoy Karim0% (1)

- Work Instruction For Straightness Testing: To Cover CDT TUBEDocument1 pageWork Instruction For Straightness Testing: To Cover CDT TUBENeeraj SinghNo ratings yet

- Nipfrg-Cqe002 4M Change RegulationDocument10 pagesNipfrg-Cqe002 4M Change RegulationRalph Jason AlvarezNo ratings yet

- Controlling The Defects of Paint Shop PDFDocument4 pagesControlling The Defects of Paint Shop PDFRahul SasidharanNo ratings yet

- Procedure For Packing & Dispatch: Spectraa Technology Solutions LTDDocument4 pagesProcedure For Packing & Dispatch: Spectraa Technology Solutions LTDAshokkumar ThangarajNo ratings yet

- Production Scheduling PDFDocument21 pagesProduction Scheduling PDFRaajithaNo ratings yet

- Scope Purpose Objective References Responsibility Details of Procedure AnnexDocument5 pagesScope Purpose Objective References Responsibility Details of Procedure AnnexmimiNo ratings yet

- 8.4.4 Instron Tensile Tester SOPDocument1 page8.4.4 Instron Tensile Tester SOPDarby BrownNo ratings yet

- SOP Name Date Issued: 1 ScopeDocument20 pagesSOP Name Date Issued: 1 Scopeswapon kumar shillNo ratings yet

- GPCB Category of IndustriesDocument3 pagesGPCB Category of IndustriestanayasahaNo ratings yet

- Product Safety ProcedureDocument1 pageProduct Safety ProcedureMoulding MeharNo ratings yet

- Rules HostelDocument3 pagesRules HostelsajalgiriNo ratings yet

- Ahai Tool Masterlist 2020Document39 pagesAhai Tool Masterlist 2020carl reevesNo ratings yet

- Preventive Maintenance - Clinical MicrosDocument3 pagesPreventive Maintenance - Clinical MicrosBem GarciaNo ratings yet

- Quality Circles: Prepared byDocument40 pagesQuality Circles: Prepared bySheila Mae MalesidoNo ratings yet

- Sample Quality Assurance Plan For Nuts ANNEXURE-1Document2 pagesSample Quality Assurance Plan For Nuts ANNEXURE-1x yNo ratings yet

- 14 Sop Production Planning and Process ControlDocument2 pages14 Sop Production Planning and Process ControlSumit TyagiNo ratings yet

- Sharp Tool PolicyDocument7 pagesSharp Tool PolicyVijay Baskar SNo ratings yet

- Blasting & Painting Inspection For Onshore and Offshore Fabrication Procedure PSP No. 06Document6 pagesBlasting & Painting Inspection For Onshore and Offshore Fabrication Procedure PSP No. 06AbhishekNo ratings yet

- Grade Certificate 004dp44Document1 pageGrade Certificate 004dp44Krishna Aashray EximNo ratings yet

- Sop 091-15Document2 pagesSop 091-15m_armoutiNo ratings yet

- Proper Handling and Storage of Chemicals: December 2014Document54 pagesProper Handling and Storage of Chemicals: December 2014Qais AlzamelNo ratings yet

- Sursagar Dairy: WadhwanDocument2 pagesSursagar Dairy: Wadhwanbhavesh1994No ratings yet

- 5s Checklist RevisedDocument4 pages5s Checklist RevisedMarvelous MartinezNo ratings yet

- Spray Painting SOPDocument7 pagesSpray Painting SOPAndrewNo ratings yet

- Inspection Equipment InstructionDocument21 pagesInspection Equipment InstructionSaravana kumar NagarajanNo ratings yet

- Saudi Aramco Manufacturing Plant Evaluation Questionnaire (RV0)Document16 pagesSaudi Aramco Manufacturing Plant Evaluation Questionnaire (RV0)شیخ صادقNo ratings yet

- Essae 8.03.23Document4 pagesEssae 8.03.23Parthiban DNo ratings yet

- Forklift Inspection Checklist 2021Document1 pageForklift Inspection Checklist 2021muhammad anasNo ratings yet

- ICAT SOP AIS - 137 - 2-Wheeler PDFDocument325 pagesICAT SOP AIS - 137 - 2-Wheeler PDFTushar Ballabh BMLNo ratings yet

- Factory Production ControlDocument7 pagesFactory Production ControlErkanNo ratings yet

- In House Test Report 3.2mmDocument3 pagesIn House Test Report 3.2mm胡大威No ratings yet

- AKW-IMSP-006-Product RecallDocument5 pagesAKW-IMSP-006-Product RecallAdil AbdulkhaderNo ratings yet

- 04) Incident Reporting ProcedureDocument2 pages04) Incident Reporting Procedureemeka2012No ratings yet

- Ceramic Injection MouldingDocument8 pagesCeramic Injection Mouldingsaritha339No ratings yet

- FSC COC Application FormDocument11 pagesFSC COC Application FormC P TiwariNo ratings yet

- Format Issue RecordDocument4 pagesFormat Issue RecordBharatNo ratings yet

- Observation No Observation Detail Visit Date Observation TypeDocument6 pagesObservation No Observation Detail Visit Date Observation TypeSafety DeptNo ratings yet

- Epoxy Resin Systems Bhorbond® Epch - 2 Part Epoxy Saturant: Product DescriptionDocument3 pagesEpoxy Resin Systems Bhorbond® Epch - 2 Part Epoxy Saturant: Product DescriptionIshan KakadNo ratings yet

- Declaration For AsbestosDocument1 pageDeclaration For AsbestosMadhusudhan ModemNo ratings yet

- Chain of Custody Certification: FSC-STD-40-004 V3-1 ENDocument52 pagesChain of Custody Certification: FSC-STD-40-004 V3-1 ENIsabel MarquesNo ratings yet

- Wi-Stores & ProductionDocument9 pagesWi-Stores & ProductionRanjit SinghNo ratings yet

- CM-001-013 Micrometer Calibration Work SheetDocument2 pagesCM-001-013 Micrometer Calibration Work SheetMuath FawwazNo ratings yet

- Vrutti Annual ReportDocument40 pagesVrutti Annual ReportAtish100% (1)

- Msds Stainless SteelDocument11 pagesMsds Stainless Steelrakesh marwahNo ratings yet

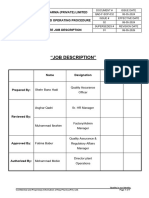

- Qad-F-Sop-032-I Job Description SopDocument8 pagesQad-F-Sop-032-I Job Description SopFatima BaburNo ratings yet

- Self Appraisal Check ListDocument48 pagesSelf Appraisal Check ListDilip.V.PancholiNo ratings yet