Alco 4v-Ventil

Alco 4v-Ventil

Uploaded by

Diogo PintoCopyright:

Available Formats

Alco 4v-Ventil

Alco 4v-Ventil

Uploaded by

Diogo PintoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Alco 4v-Ventil

Alco 4v-Ventil

Uploaded by

Diogo PintoCopyright:

Available Formats

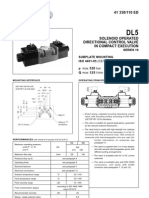

4 01RD STEEL RE VERSING VALVES

ALVES

4-WAY STEEL RE VERSING VAL VE

ALVE

FOR RE VERSE-CYCLE SYS TEMS

ALCO 401RD Series 4-Way Reversing Valves are

designed for use on energy-conserving, reverse-cycle

comfort systems.

Heating Cycle (see Figure 1 below)

The system is on the heating cycle with discharge gas

flowing thru ports “D” to “C2”, making the indoor coil the

condenser. The suction gas is flowing from the outdoor

coil (evaporator) thru reversing ports “C1” to “S” and back UL file number MP604

CSA file number LR44912

to the compressor. With the 4-way solenoid pilot de-

energized, the slide’s position connects the port “D1” to

F EATURES

EATURES

“B” and “A” to “S1”. ¶ High efficiency and higher capacity through

Cooling Cycle (see Figure 2 below) suction and discharge

When the coil is energized, the slide in the pilot solenoid ¶ All stainless steel pilot enclosing tube for longer life

valve shifts, now connecting pilot ports “D1” to “A” and ¶ Connections to fit your system

“B” to “S1”. The system has now changed over to the

cooling cycle with the discharge gas flowing thru revers- S PECIFIC

PECIFICAATIONS

ing valve ports “D” to “C1”, making the outdoor coil the ¶ Maximum working pressure: 500 psig

condenser. The suction gas is now flowing thru port “C2” ¶ Compatible with R134a, R22, R404A, R507, and the

to “S”, thus making the indoor coil the evaporator. new CFC, HCFC & HFC refrigerants

CAUTION: Depending on the manner in ¶ MOPD: 400 psig

which the reversing valve is piped into ¶ Coil style: Open frame

the system, power failure to the pilot

solenoid valve coil will cause the system FIGURE 1 FIGURE 2

to “fail-safe” on either the heating or

cooling cycle. In the diagrams shown

below, the valve is piped to fail-safe on

heating. In order to fail-safe on cooling,

the indoor coil would be connected to

the reversing valve port “C1” and the

outdoor coil connected to port “C2”.

N OMENCL ATURE

example: 401RD 10F79

401R D 10 F 7 9

Valve Design Nominal Rating F=ODF Discharge Suction

Series Series (in tons) connections Connection Connection

(in 1/8’’) (in 1/8’’)

401R CAPACITY TABLE VALVE

VALVE NOMINAL CAPACITIES** ASSEMBLY

TYPE R134A R22 R404A/R507

401RD10 7.2 11.5 8.7

401RB15 15.2

** Based on 100°F condensing temperature, 40°F evaporator

and a 2 PSI pressure drop across the valve suction ports.

ALCO CONTROLS 113

TYPICAL 401R PIPING DIAGRAMS

HEATING CYCLE (401 DE-ENERGIZED) COOLING CYCLE (401 ENERGIZED)

4 01R 401RB

401RD-10

DIMENSIONAL DATA

VALVE TYPE CAPACITY* CONNECTIONS

PCN NUMBER(TONS) DISCHARGE “1”, “S”,“2” A B C E F G H J K L M N

048017 401RD10F46 11.5 1/2 ODF 3/4 ODF 7/16 11/16 1-5/16 1-3/4 3-7/8 3-7/32 7-3/32 3-3/8 4-15/32 8-15/16 3-1/16 3-11/32

048018 401RD10F47 11.5 1/2 ODF 7/8 ODF 7/16 13/16 1-5/16 1-3/4 3-7/8 3-7/32 7-3/32 3-3/8 4-15/32 8-15/16 3-1/16 3-11/32

046356 401RD10F57 11.5 5/8 ODF 7/8 ODF 9/16 13/16 1-5/16 1-3/4 4-3/8 4-3/8 8-3/4 4-3/8 4-15/32 8-15/16 3-1/16 3-11/32

048019 401RD10F59 11.5 5/8 ODF 1-1/8 ODF 9/16 31/32 1-5/16 1-3/4 3-7/8 3-7/32 7-3/32 3-3/8 4-15/32 8-15/16 3-1/16 3-11/32

048020 401RD10F67 11.5 3/4 ODF 7/8 ODF 11/16 13/16 1-5/16 1-3/4 3-7/8 3-7/32 7-3/32 3-3/8 4-15/32 8-15/16 3-1/16 3-11/32

048000 401RD1069 11.5 3/4 ODM 1-1/8 ODF 3/4 31/32 1-5/16 1-3/4 3-7/8 3-7/32 7-3/32 3-3/8 4-15/32 8-15/16 3-1/16 3-11/32

046357 401RD10F69 11.5 3/4 ODF 1-1/8 ODF 11/16 31/32 1-5/16 1-3/4 3-7/8 3-7/32 7-3/32 3-3/8 4-15/32 8-15/16 3-1/16 3-11/32

048009 401RD10F79 11.5 7/8 ODF 1-1/8 ODF 13/16 31/32 1-5/16 1-1/2 3-7/8 3-7/32 7-3/32 3-3/8 4-15/32 8-15/16 3-1/16 3-11/32

048032 401RD10F711 11.5 7/8 ODF 1-1/8 ODF 13/16 1-1/32 1-1/2 1-1/2 5-57/64 4 9-57/64 4-35/64 4-15/32 8-15/16 3-1/16 3-11/32

044554 401RB15F711 15.2 7/8 ODF 1-3/8 ODF 7/8 3/4 1-5/8 1-29/32 5-1/2 4 9-1/2 4-1/2 4-1/2 9 2-61/64 2-7/32

044555 401RB15F911 15.2 1-1/8 ODF 1-3/8 ODF 1-1/8 29/32 1-5/8 1-29/32 5-1/2 4 9-1/2 4-1/2 4-1/2 9 2-61/64 2-7/32

* Nominal Capacity R-22 All capacities shown are at 40°F Evaporator Temperature. For other temperatures, refer to correction factor table on page 112.

ALL VALVE TYPE NUMBERS ABOVE ARE VALVE LESS COIL.

114 ALCO CONTROLS

4 01RD RE VERSING VALVES

ALVES

4 01R SUC TION GA S EX TENDED CAP

UCTION ACIT Y TABLE — T ONS

APA

PRESSURE DROP ACROSS VALVE – PSI

EVAPORATOR VALVE R134A R22 R404A/R507

TEMP. °F TYPE 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

401RD10 5.2 7.2 8.6 9.8 10.6 7.8 11.5 13.1 15.1 16.7 5.5 8.7 10.9 12.5 14.1

+ 40°F

401RB15 8.6 11.5 13.9 16.3 17.3 10.4 15.2 17.6 20.0 22.0 6.8 10.9 13.5 15.6 17.4

401RD10 4.1 5.6 6.7 7.6 8.2 6.3 8.8 10.5 11.9 13.2 4.6 7.0 8.6 9.9 10.9

+ 20°F

401RB15 6.7 9.1 11.0 12.5 13.4 8.8 11.6 14.0 15.6 17.6 5.6 8.6 10.6 12.2 13.5

401RD10 3.2 4.3 5.1 5.7 6.1 5.1 6.7 8.2 9.2 10.1 3.7 5.5 6.6 7.5 8.3

0°F

401RB15 5.3 7.2 8.2 9.1 9.6 6.8 8.8 10.8 12.0 13.6 4.5 6.5 7.9 9.0 9.9

401RD10 2.4 3.2 3.7 4.0 4.1 3.8 5.1 6.1 6.8 7.4 2.9 4.1 5.0 5.6 6.1

– 20°F

401RB15 3.8 5.3 5.8 6.2 6.7 5.2 6.8 8.0 8.8 10.0 3.5 4.9 5.9 6.7 7.3

Valve capacities are based on 100°F condensing temperature. For temperatures other than 100°F, use the multiplier factors below.

CONDENSING TEMPERATURE °F 70 80 90 100 110 120 130 140

MULTIPLIER 1.15 1.10 1.05 1.00 .95 .90 .85 .80

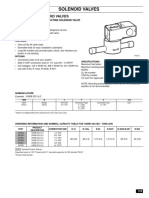

RV RE VERSING VALVES

ALVES

RV SUC TION GA S EX TENDED CAP

UCTION ACIT Y TABLE IN T ONS FOR R22 AND R4

APA 10A

R41

PRESSURE DROP ACROSS VALVE – PSI

EVAPORATOR VALVE R22 R410A

TEMP. °F TYPE 1 2 3 4 5 1 2 3 4 5

RV2 1.66 2.35 2.87 3.32 3.71 2.14 3.03 3.71 4.29 4.56

RV3 2.23 3.15 3.86 4.46 4.99 2.88 4.07 4.99 5.76 6.16

+ 45°F

RV4 3.24 4.58 5.61 6.48 7.25 4.19 5.92 7.25 8.37 8.69

RV6 4.51 6.38 7.81 9.02 10.08 5.83 8.24 10.09 11.65 12.31

RV2 1.36 1.92 2.35 2.71 3.03 1.75 2.48 3.03 3.50 3.92

RV3 2.65 3.75 4.59 5.30 5.92 2.35 3.33 4.08 4.71 5.26

+ 25°F

RV4 2.57 3.63 4.45 5.13 5.74 3.42 4.84 5.93 6.84 7.65

RV6 3.69 5.21 6.39 7.37 8.25 4.76 6.73 8.25 9.52 10.65

RV2 1.09 1.54 1.88 2.06 2.27 1.41 1.99 2.44 2.64 2.90

RV3 1.46 2.07 2.53 2.78 3.02 1.89 2.67 3.27 3.54 3.83

+ 5°F

RV4 2.12 3.00 3.68 3.93 4.27 2.75 3.88 4.76 5.01 5.42

RV6 2.95 4.18 5.12 5.57 6.08 3.82 5.41 6.62 7.11 7.75

RV2 0.86 1.21 1.39 1.56 1.70 1.11 1.57 1.77 1.98 2.14

RV3 1.15 1.63 1.87 2.06 2.19 1.49 2.10 2.35 2.57 2.71

– 15°F

RV4 1.67 2.37 2.64 2.91 3.11 2.16 3.06 3.33 3.65 3.86

RV6 2.33 3.29 3.75 4.17 4.49 3.01 4.26 4.75 5.26 5.62

Valve capacities are based on 120°F liquid, saturated evaporator, and 10°F superheat at the valve inlet.

RV2 & RV3 DIMENSIONAL DATA

RV3

RV CONNECTIONS A B

VALVE DISCHARGE “1”, “S”,“2” MIN. MIN. C D E F

RV2F45 1/2 ODF 5/8 ODF 3/8 1/2 2.79 2.39 .95 15

RV2F46 1/2 ODF 3/4 ODF 3/8 5/8

RV2F36 3/8 ODF 3/4 ODF 5/16 5/8 3.42 3.25 1.27 20

RV2F46D1* 1/2 ODF 3/4 ODF 3/8 5/8

RV2F35 3/8 ODF 5/8 ODF 5/16 1/2

RV2F45D1* 1/2 ODF 5/8 ODF 3/8 1/2 2.79 2.39 .95 15

RV2F35D1* 3/8 ODF 5/8 ODF 5/16 1/2

RV2F36D1* 3/8 ODF 3/4 ODF 5/16 5/8 3.42 3.25 1.27 20

RV3F45 1/2 ODF 5/8 ODF 3/8 1/2 2.79 2.39 .95 15

RV3F46 1/2 ODF 3/4 ODF 3/8 5/8

RV3F36 3/8 ODF 3/4 ODF 5/16 5/8 3.42 3.25 1.27 20

RV3F46D1* 1/2 ODF 3/4 ODF 3/8 5/8

RV3F35 3/8 ODF 5/8 ODF 5/16 1/2

RV3F45D1* 1/2 ODF 5/8 ODF 3/8 1/2 2.79 2.39 .95 15

RV3F35D1* 3/8 ODF 5/8 ODF 5/16 1/2

RV3F36D1* 3/8 ODF 3/4 ODF 5/16 5/8 3.42 3.25 1.27 20

* “D” denotes Discharge Tube is off-center.

ALCO CONTROLS 115

RV BR A SS RE VERSING VALVES

ALVES

4-WAY BR A SS RE VERSING VAL VE

ALVE

FOR RE VERSE-CYCLE SYS TEMS

ALCO RV Series 4-Way Reversing Valves are designed for

use on energy-conserving, reverse-cycle comfort systems.

The RV has an all brass body and stainless steel slide for

long-life and resistance to corrosion. Featuring fewer parts,

a high capacity pilot and a greater tolerance to system

contaminants, the ideal reversing valve for your system is

the ALCO RV. The heating and cooling cycles of a reverse-

cycle comfort system and the 4-way reversing valve’s pilot UL file number MP604

responses are illustrated on page 113. CSA file number LR44912

S PECIFIC

PECIFICAATIONS

F EATURES

EATURES Nominal 2, 3, 4 & 6 ton sizes

¶ Stainless steel internals Non-corrossive construction – brass body with stainless

– Corrosion resistant steel internals

– Reduced potential for hydrogen

Maximum working pressure: 500 psig

embrittlement

¶ High strength slide carrier MOPD: 400 psig

¶ Fewer parts Minimum operating pressure differential: 10 psi

¶ High capacity pilot Maximum operating temperature: 250°F

– Greater tolerance to contaminates External leakage: 0.1 oz/yr

¶ Low heat transfer bathtub Tube connection sizes:

¶ Greater wear resistance of seals Discharge 1/2 and 5/8 ODF/ODM

¶ Stainless steel pilot bracket Suction & Coil 3/4 and 7/8 ODF

N OMENCL ATURE

example: RV 4F46

RV 4 F 4 6

Valve Nominal Rating F=ODF Discharge Suction

Series (in tons) connections Connection Connection

(omit for ODM) (in 1/8’’) (in 1/8’’)

RV4 & RV6 DIMENSIONAL DATA

RV6

TYPE DISCHARGE C1, S, C2 A MIN. B MIN.

RV456 5/8 ODM 3/4 ODF 1/2 1/2

RV4F46 1/2 ODF 3/4 ODF 3/8 1/2

RV4F47 1/2 ODF 7/8 ODF 3/8 7/8

RV6F46 1/2 ODF 3/4 ODF 3/8 1/2

RV6F47 1/2 ODF 7/8 ODF 3/8 7/8

RV6F57 5/8 ODF 7/8 ODF 1/2 7/8

O RDERING INFORMATION FOR RV SERIES VALVES

PCN DESCRIPTION

062796 RV 2 - F 34 VLC

062199 RV 2 - F 35 VLC

061795 RV 3 - F 35 VLC

061790 RV 3 - F 45 VLC

061792 RV 3 - F 46 VLC

062168 RV 4 - F 46 VLC

062173 RV 4 - F 47 VLC

062162 RV 4 - 56 VLC

062176 RV 4 - F 57 VLC

062181 RV 6 - F 46 VLC

062270 RV 6 - F 47 VLC

062190 RV 6 - F 57 VLC

116 ALCO CONTROLS

You might also like

- DAEWOO RefrigeradorDocument83 pagesDAEWOO RefrigeradorMihaela Caciumarciuc100% (2)

- Charge Air Cooler Pressure Drop MeasurementDocument12 pagesCharge Air Cooler Pressure Drop MeasurementMuhammad Waleed Tariq100% (1)

- Spor LanDocument30 pagesSpor LanKumar sssssNo ratings yet

- 200RE SOV Data Sheet-FinalDocument8 pages200RE SOV Data Sheet-FinalVictor Hugo RojasNo ratings yet

- Guide Specifications: EC Series 1/2-6 Ton R-410ADocument19 pagesGuide Specifications: EC Series 1/2-6 Ton R-410AlundmechNo ratings yet

- Hidraulica, Compones, Partes, para Uso en La Oleodinamica (118) MDocument10 pagesHidraulica, Compones, Partes, para Uso en La Oleodinamica (118) Mcarlosmedina111No ratings yet

- FR390Document18 pagesFR390Rayen RamzaanNo ratings yet

- Refrig Alco Solenoid 2004Document10 pagesRefrig Alco Solenoid 2004Luis alberto Garcia villanuevaNo ratings yet

- 1400-0172-4Document5 pages1400-0172-4juan saezNo ratings yet

- 160.69-AD4-Application Data-YD Mod C Refrigerant Relief Valve Vent SizingDocument8 pages160.69-AD4-Application Data-YD Mod C Refrigerant Relief Valve Vent SizingMohamed AskarNo ratings yet

- M04000344Document13 pagesM04000344aldo sanchez figueroaNo ratings yet

- Evaporator/ Indoor Units: Suspension Type Air CoolerDocument4 pagesEvaporator/ Indoor Units: Suspension Type Air CoolerSEABIRD SALESNo ratings yet

- Catalogo Sporlan IIDocument29 pagesCatalogo Sporlan IIAdán Castro GallegosNo ratings yet

- DSV 100 34TRDocument2 pagesDSV 100 34TRsgfdrfNo ratings yet

- 407-SF6 Circuit BreakerDocument7 pages407-SF6 Circuit BreakerSARAVANAN ANo ratings yet

- FRS 2431Document62 pagesFRS 2431infoNo ratings yet

- DCV 03 hk66t102Document15 pagesDCV 03 hk66t102seaqu3stNo ratings yet

- Electrohydraulic: Solenoid ValvesDocument16 pagesElectrohydraulic: Solenoid ValvesluisbottonNo ratings yet

- Catálogo TXV Ove 201 - 072011Document76 pagesCatálogo TXV Ove 201 - 072011Rodrigo SantosNo ratings yet

- SIRIUS IC10 Chap04 English 2012Document62 pagesSIRIUS IC10 Chap04 English 2012Szabolcs SzabolcsNo ratings yet

- Mixing Valve 34C I644000 JDocument2 pagesMixing Valve 34C I644000 JblablablaNo ratings yet

- Installation Use and Maintenance: Cooling-Only, Heat Pump and Free-Cooling VersionsDocument64 pagesInstallation Use and Maintenance: Cooling-Only, Heat Pump and Free-Cooling VersionsВасилий КонстантиновNo ratings yet

- Erf 331 MMDocument29 pagesErf 331 MMilan_shaniNo ratings yet

- 19 400E 3D RL FinalDocument4 pages19 400E 3D RL FinalJose Omar ZaragozaNo ratings yet

- 5 3 Way Ss ValveDocument12 pages5 3 Way Ss ValveGopinath GunasekaranNo ratings yet

- R407C Air-Cooled Split SystemsDocument30 pagesR407C Air-Cooled Split SystemsTerry GunawanNo ratings yet

- Solenoid Select ChartDocument47 pagesSolenoid Select Chartسامح الجاسم100% (1)

- IMI Herion 97105 NAMUR Electromagnetic ValveDocument8 pagesIMI Herion 97105 NAMUR Electromagnetic ValveSina MahmoudiNo ratings yet

- Uniflair BREx1612A-2812A Technical DataDocument24 pagesUniflair BREx1612A-2812A Technical DataSargurusiva0% (1)

- Singhania-CO2 INERTISATION SYSTEM DataDocument12 pagesSinghania-CO2 INERTISATION SYSTEM DataAnandharaj .KNo ratings yet

- 410 Ycal-1099Document90 pages410 Ycal-1099Al Dizdar NazarNo ratings yet

- TH Ermostatic Expansion Valves: Type T 2 and TE 2Document20 pagesTH Ermostatic Expansion Valves: Type T 2 and TE 2JasminkoCvitešićNo ratings yet

- Manual Valvula Divisora Comb LiqDocument20 pagesManual Valvula Divisora Comb Liqdaniel triana palciosNo ratings yet

- 1070xl PartsDocument10 pages1070xl PartsFrancisco ArellanoNo ratings yet

- Solenoid Valves 3/2 551 553Document12 pagesSolenoid Valves 3/2 551 553frghertyertyergfhdftyertyNo ratings yet

- M-32 Emergency Shut-Off ValveDocument19 pagesM-32 Emergency Shut-Off Valveramdayal bhairaNo ratings yet

- AlkatreszDocument2 pagesAlkatreszgia maxniashviliNo ratings yet

- Automated Ball Valves, 3-Way SS Flange: Electric and Pneumatic ActuatorsDocument1 pageAutomated Ball Valves, 3-Way SS Flange: Electric and Pneumatic ActuatorsGilberto Meneses NavarroNo ratings yet

- Water Cooling CoilsDocument20 pagesWater Cooling CoilsWalter J Naspirán CastañedaNo ratings yet

- Ty 5131Document4 pagesTy 5131Mohamed El-AyouttiNo ratings yet

- Ras-10ukv-E SVM-020007Document79 pagesRas-10ukv-E SVM-020007Para Club MilazzoNo ratings yet

- Normally Closed Solenoid Valves PDFDocument55 pagesNormally Closed Solenoid Valves PDFrahulNo ratings yet

- CATALOGUE SOLENOID-DISTRIBUTEUR NORGRE-Nen - 5 - 2 - 550 - UM - 22000Document14 pagesCATALOGUE SOLENOID-DISTRIBUTEUR NORGRE-Nen - 5 - 2 - 550 - UM - 22000romuald konhawoNo ratings yet

- Ev DG05Document14 pagesEv DG05mtbecerrapNo ratings yet

- TS 90 100 01Document4 pagesTS 90 100 01Lakee911No ratings yet

- Valvulas SporlanDocument24 pagesValvulas SporlanCesar VillarNo ratings yet

- Parker 3 Way SolenoidDocument8 pagesParker 3 Way SolenoidFlavius DumitrescuNo ratings yet

- Henry 001Document1 pageHenry 001pdmsNo ratings yet

- Asco Keystone CompatibilityDocument2 pagesAsco Keystone CompatibilityalexmontellNo ratings yet

- F113-6RFP, F1113-6RFP Specification SheetDocument16 pagesF113-6RFP, F1113-6RFP Specification SheetWattsNo ratings yet

- Vickers Valve DG4SDocument16 pagesVickers Valve DG4SZMCONTROL100% (1)

- Critical Spare 11.04.24Document7 pagesCritical Spare 11.04.24rahulsigma9264No ratings yet

- Io Checklist1Document15 pagesIo Checklist1KALPUSHNo ratings yet

- Liquid Refrigerant Receivers: Vertical, ULDocument17 pagesLiquid Refrigerant Receivers: Vertical, ULDianaNo ratings yet

- Atlasco ManualDocument248 pagesAtlasco ManualAyoade Lanre BexNo ratings yet

- WRP22G Oea5 - 400 P 121121 e 00Document4 pagesWRP22G Oea5 - 400 P 121121 e 00Eng-Mohammed SalemNo ratings yet

- Dokumen - Tips Uniflair Brex1612a 2812a Technical DataDocument24 pagesDokumen - Tips Uniflair Brex1612a 2812a Technical DataJim JonesjrNo ratings yet

- Powerhead: Section 4B - CoolingDocument10 pagesPowerhead: Section 4B - CoolingDr. Centelha Mecânica NaúticaNo ratings yet

- 200rb Solenoid-Valves-Catalog-En-Us-4763170Document4 pages200rb Solenoid-Valves-Catalog-En-Us-4763170desenvolvimentoNo ratings yet

- EK Liquid Line Filter Drier and Capacity TableDocument4 pagesEK Liquid Line Filter Drier and Capacity TablenagisetsuNo ratings yet

- Conclusion, Discussion and RecommendationDocument2 pagesConclusion, Discussion and RecommendationThaungShanHtet PalatarNo ratings yet

- Fluid MechanicsDocument182 pagesFluid Mechanicsreddy331No ratings yet

- Engine AssamblyDocument232 pagesEngine AssamblySergey Sergeev100% (1)

- ASME Section III Fatigue Calc ML093360330Document29 pagesASME Section III Fatigue Calc ML093360330Paldex100% (1)

- PRC 14222 Ventilationoffirepumproomsv 1Document3 pagesPRC 14222 Ventilationoffirepumproomsv 1Afsal JhNo ratings yet

- Intro 1a ThermochemistryDocument50 pagesIntro 1a ThermochemistryFatin IziantiNo ratings yet

- Truck Bus Bias TyresDocument24 pagesTruck Bus Bias TyresabhibawaNo ratings yet

- (Ball Control Valve) Rev4Document11 pages(Ball Control Valve) Rev4sergioNo ratings yet

- Price ListDocument12 pagesPrice ListAgung Pramu AjiNo ratings yet

- 6 Pushover AnalysisDocument6 pages6 Pushover AnalysisUALU333No ratings yet

- Online TRG CourseDocument12 pagesOnline TRG Coursegreyphen greyNo ratings yet

- VleDocument42 pagesVleFatien ZakariaNo ratings yet

- SWING DEVICE: HYUNDAI: R320LC-7 (#1275 ) Key# Part No Part Name Q'ty RemarkDocument1 pageSWING DEVICE: HYUNDAI: R320LC-7 (#1275 ) Key# Part No Part Name Q'ty RemarkLeão tratoresNo ratings yet

- Sustainability 15 11312 v5Document41 pagesSustainability 15 11312 v5Felipe GouveiaNo ratings yet

- Shift Report BookDocument5 pagesShift Report BookmasudalamupplNo ratings yet

- Valvetronic EngineDocument5 pagesValvetronic EngineHafis SayedNo ratings yet

- Introduction To Power ScrewsDocument14 pagesIntroduction To Power Screwsاوبنتو العراقيNo ratings yet

- Material Comparison ChartDocument2 pagesMaterial Comparison Chartg_sanchetiNo ratings yet

- Walrus hq800 Water Pressure PumpDocument2 pagesWalrus hq800 Water Pressure PumpDenata Machmud SugandhiNo ratings yet

- Glenfield 3700 ES 50-300Document2 pagesGlenfield 3700 ES 50-300huzaifaksa435No ratings yet

- Motor Gear Box SelectionDocument6 pagesMotor Gear Box SelectionymsyaseenNo ratings yet

- ITube LinksDocument12 pagesITube Linksrahman.alam787No ratings yet

- Final Year Project IntroductionDocument10 pagesFinal Year Project IntroductionsudhakarNo ratings yet

- Thesis Spot WeldingDocument8 pagesThesis Spot Weldingdwsmpe2q100% (1)

- SGT2000Document10 pagesSGT2000Simon Caceres100% (1)

- Wind Turbine Terminology and Components: Morten Hartvig HansenDocument10 pagesWind Turbine Terminology and Components: Morten Hartvig HansenVikram KotharuNo ratings yet

- Part Kit Final 3406, 3408, 3126Document85 pagesPart Kit Final 3406, 3408, 3126Johny WijanarkoNo ratings yet

- Center of Mass: AP Physics C Mrs. CoyleDocument24 pagesCenter of Mass: AP Physics C Mrs. CoyleiskenderbeyNo ratings yet

- Instruction Sppa6 Pa50 Pa60 Pa64 enDocument10 pagesInstruction Sppa6 Pa50 Pa60 Pa64 enoperativotechnitestNo ratings yet