Modbus Us

Uploaded by

Alex HenriqueModbus Us

Uploaded by

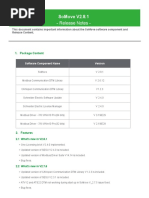

Alex HenriqueModicon Modbus Driver

Filename Modbus.dll

Manufacturer Modicon

Devices Any device compatible with Modbus protocol v1.1b

Protocol Modbus v1.1b

Version 4.0.11

Last Update 08/30/2023

Platform Win32 and Windows CE (Pocket PC ARM, HPC2000 ARM,

HPC2000 X86, and HPC2000 MIPS)

Dependencies None

Superblock Readings Yes

Level 0

Introduction

This Driver implements the Modbus protocol, which allows an Elipse Software application to communicate with any slave

device that implements this protocol in ASCII, RTU, or TCP modes.

This Driver always works as a master of a Modbus network. If users want to to communicate with master devices, then

Elipse Software's Modbus Slave Driver must be used, which can be downloaded at company's website.

This Driver, starting with version 2.0, was developed using Elipse Software's IOKit library. This library is responsible for

implementing the physical layer access (Serial, Ethernet, Modem, or RAS). For more information about IOKit library

configuration, please check topic Documentation of I/O Interfaces.

It is recommended to start by reading topic Quick Configuration Guide if the device is fully compliant with standard

Modbus protocol, defined by the Modbus Organization (modbus.org), and if users only want to read or write bits and

registers, without using more advanced features of this Driver.

For a complete understanding of all this Driver's functionality, it is recommended to start reading, in this order, chapters

Adding a Driver to an Elipse Software Application and Configuration.

To create large scale applications, it is also recommended to read topic Optimization Tips.

If users are not familiar with the protocol, please check topics The Modbus Protocol, Recommended Websites,

Supported Functions, and Special Functions.

Quick Configuration Guide

This topic describes all necessary steps to configure this Driver for communication with devices compliant with the

standard protocol defined by the Modbus Organization, considering the most common configuration options.

If a device is fully compliant with the standard protocol, and users only want to read or write registers or bits, the topics

Inserting a Driver, Configuring a Driver, and Configuring I/O Tags are probably sufficient to configure this Driver.

Inserting a Driver

If using E3 or Elipse Power, please check topic Adding a Driver to an Elipse Software Application - E3 or Elipse Power.

If using Elipse SCADA, please check topic Adding a Driver to an Elipse Software Application - Elipse SCADA.

Modicon Modbus Driver v4.0.11

Then, check the next step on this Manual, which shows how to configure this Driver using its configuration window for the

most common cases.

Adding a Driver to an Elipse Software Application

This section describes how to add this Driver to E3 or Elipse Power and Elipse SCADA applications.

E3 or Elipse Power

On Organizer, right-click the Server Objects - Drivers and OPC item, select the Insert I/O Driver in option, and then

select a project.

Adding a Driver to an E3 or Elipse Power application

On the window that opens, select a Driver (this file must be extracted to a folder on the computer in use) and click Open.

Modicon Modbus Driver v4.0.11

Selecting a Driver

The configuration window of this Driver opens automatically, as shown on the next figure.

Configuration window of this Driver

Modicon Modbus Driver v4.0.11

On the second step of topic Quick Configuration Guide, there is a procedure for a basic configuration of this Driver, for

the most common usages. On topic Properties this configuration is presented in details.

This Driver's configuration window can also be opened, later, by clicking Driver settings , as shown on the next figure.

Driver settings option

After configuring this Driver's properties, click OK to open Tag Browser window, allowing to insert pre-defined Tags in the

application, based on the most used settings. The next figure shows Tag Browser's window. To add Tags, drag them from

the list Tags available from driver to the list Current project tags.

Tag Browser window

Tags available in Tag Browser are Tags configured using Strings, a new method that does not use the old concept of

operations. Insert the most adequate ones to the application, editing their fields as needed. Tag Browser window can be

opened later by clicking Tag Browser .

Elipse SCADA

On Organizer, select the Drivers item and click New.

Modicon Modbus Driver v4.0.11

Adding a new Driver to Elipse SCADA

On the window that opens, select a Driver (this file must be extracted to a folder on the computer in use) and click Open.

Selecting a Driver

This Driver is then added to the application.

Modicon Modbus Driver v4.0.11

Driver in Organizer

For this Driver to work correctly, users still need to configured it on its configuration window. To open this window,

showed on the next figure, click Extra.

Modicon Modbus Driver v4.0.11

Configuration window of this Driver

The second step of topic Quick Configuration Guide shows how to configure this Driver for the most common usages,

for devices complying to default Modbus protocol requirements. On topic Properties that configuration is described in

details, including advanced configuration resources.

Configuring a Driver

After inserting this Driver in an application, users must open Driver's configuration window, as explained on topics E3 or

Elipse Power or Elipse SCADA. With this configuration window open, follow these steps:

1. Configure communication's physical layer:

a. On the Setup tab, select a physical layer (Serial, Ethernet, Modem, or RAS) to use when connecting with a device.

b. Configure the selected physical layer on its corresponding tab (Serial, Ethernet, Modem, or RAS).

c. For more information about configuring a physical layer, please check topic Documentation of I/O Interfaces.

2. On the Modbus tab, select the protocol mode (RTU, ASCII, or TCP) used by the device. As a general rule, users must

select RTU or ASC (for most devices it is RTU) for Serial or Modem physical layers, or TCP for Ethernet or RAS

physical layers. The other options usually can be kept with their default configurations. For more information about all

options on this tab, please check topic Modbus Tab.

NOTE

For new applications, it is strongly recommended to avoid using ModbusRTU (RTU mode) encapsulated in an Ethernet

TCP/IP layer. However, if by any reason, for legacy applications, users must use ModbusRTU encapsulated in TCP/IP,

please do not forget to enable the Reconnect after Timeout option, described on topic Modbus Tab.

Modicon Modbus Driver v4.0.11

3. When creating applications for newer Elipse Software products, such as E3, Elipse Power, or Elipse OPC Server,

users can use Tag configuration by Strings (Device and Item fields). If this is the case, please go to the next step of

this guide.

4. If users still need to use the old numerical configuration (N/B parameters), used by Elipse SCADA, it is important to

check the Operations tab. There are default operations already pre-configured on this Driver. Operations are

configurations of functions and data formats that later are referenced by application's Tags. These default operations,

already available when this Driver is loaded for the first time, are the most common ones. Evaluate all reading and

writing functions and the data types used for each operation, and check which ones are needed for the application. If

these pre-defined operations do not fit the application needs, users must edit them or even create new operations. If

this is the case, please check topic Operations Tab. The next table lists all pre-defined operations.

Pre-defined operations

OPERATION READING WRITING DATA TYPE PURPOSE

1 3: Read Holding 16: Write Multiple Word Reading and writing

Registers Registers unsigned 16-bit

integers

2 3: Read Holding 16: Write Multiple DWord Reading and writing

Registers Registers unsigned 32-bit

integers

3 3: Read Holding 16: Write Multiple Int16 Reading and writing

Registers Registers signed 16-bit integers

4 3: Read Holding 16: Write Multiple Int32 Reading and writing

Registers Registers signed 32-bit integers

5 3: Read Holding 16: Write Multiple Float Reading 32-bit

Registers Registers floating point values

6 3: Read Multiple Coils 15: Write Multiple Bit Reading and writing

Coils bits

7 2: Read Discrete None Bit Reading bits from a

Inputs data block of Discrete

Inputs

NOTE

These default operations are configured assuming that a device complies with Modbus' default byte order, big endian, in

which the most significant bytes come first. If a device does not comply with that standard, please check topic

Operations Tab for more information about configuring operations for different byte orders.

For more information about configuring this Driver, please check topic Configuration.

The next step demonstrates how to configure I/O Tags based on pre-defined operations.

Configuring I/O Tags

This section describes how to configure I/O Tags in E3, Elipse Power and in old Elipse SCADA for the most common

usages.

Tag Configuration in E3 and in Elipse Power

Modicon Modbus Driver v4.0.11

Configuring I/O Tags in E3 and in Elipse Power can be performed using the new String configuration method or using

the old numerical configuration method, compatible with Elipse SCADA. For new projects, it is recommended to use

String configuration, which improves application's legibility and maintenance.

Next there is a description of the recommended procedures for String configuration and also for the old numerical

configuration, if it is needed for legacy applications.

String Configuration

To add String-configured Tags, users have an option to import Tag Browser's pre-defined models, as explained on topic

Adding a Driver to an Elipse Software Application. To do so, users must keep the Show Operations in Tag Browser

option disabled on the Operations tab and then open Tag Browser by clicking Tag Browser .

To add a new Tag to an application without using Tag Browser, follow these steps:

1. On Organizer, double-click this Driver, select the Design tab, click Add , and then select the I/O Tag item, according

to the next figure.

Adding a new I/O Tag

2. On the Adding IOTag window, configure the Quantity field with value 1 (one) and specify a name for this Tag in the

Name field. Click OK to create a new Tag.

3. On the Device column, type the numerical value of device's Slave Id to communicate, followed by a colon, such as "1:"

for a Slave Id equal to 1 (one). Notice that, in an Ethernet TCP/IP layer, this value is sometimes ignored, and only the

IP address is used and the TCP/IP port configured on the Ethernet tab, which must be declared on device's

documentation.

4. On the Item column, specify a mnemonic for the address space (a set of reading and writing Modbus functions)

followed by the register's or bit's address. For Holding Registers, the address space is "hr" or "shr", and this last one

does not allow writing in blocks, because it uses the writing function 06 (Write Single Register), while the "hr" address

space uses the writing function 16 (Write Multiple Registers). Both use the reading function 03 (Read Holding Registers).

For Coils use "cl" or "scl". Again, the difference is that the last one, which uses function 05 (Force Single Coil), does not

write to blocks. Next, there are some examples of configurations for the Item column.

a. Reading or writing Holding Register 150 using functions 03 and 16 (writing multiple registers): Item must be equal

to "hr150".

b. Reading or writing Holding Register 150 using functions 03 and 06 (writing simple registers): Item must be equal to

"shr150".

c. Reading or writing a Coil with address FFF0h (65520) using functions 01 and 15 (writing multiple bits): Item must be

equal to "cl65520" or "cl&hFFF0" (prefix "&h" can be used to provide addresses in hexadecimal format).

d. Reading or writing a Coil with address FFF0h (65520) using functions 01 and 05 (writing simple bits, one by one):

Item must be equal to "scl65520" or "scl&hFFF0" (prefix "&h" can be used to provide addresses in hexadecimal

format).

Modicon Modbus Driver v4.0.11

5. For more information about other features of String configuration, such as other Modbus functions, special functions,

and different data types, please check topic String Configuration.

6. Tag addressing must correspond to the Modbus address map on the device, which must be declared on

manufacturer's documentation. When in doubt, please check topic Addressing Tips (Modbus Convention).

Prefer simple Tags, called PLC Tags in Elipse SCADA, rather than Block Tags, keeping the Superblock feature enabled,

that is, the EnableReadGrouping property set to True, leaving group optimization to the application and to this Driver.

For more details, please check topic Superblock Reading (Grouping).

As an example, the next figure shows Tags configured by Strings.

Example of Tags configured by Strings

Numerical Configuration

For E3 or Elipse Power, users can use Tag Browser to create Tags with pre-defined operations, numerically configured.

To do so, select the Show Operations in Tag Browser option on the Operations tab.

Tag Browser's window, shown on the next figure, is opened when clicking OK on this Driver's configuration window.

Tag Browser for numerical configuration of Tags

To add a new Tag to an application, follow these steps:

Modicon Modbus Driver v4.0.11

1. Drag Tags from the list Tags available from driver to the list Current project tags, as described on topic E3 or

Elipse Power. For many devices, operation 1, the most common, should be sufficient, so just drag Op1<word> Tag to

the list of project Tags. Notice that, assuming that several Tags are needed with the same operation, which is a normal

situation, users can drag the same Tag several times. Notice that an application adds sequential numbers to the

default name. Users can also add a Tag from each operation and then later create other copies in Organizer.

2. Close Tag Browser and configure the N4/B4 parameter of each Tag with the register or bit address to read or write,

according to device's register map. This address map must be described on manufacturer's documentation. When in

doubt, please check topic Addressing Tips (Modbus Convention).

3. Also configure the N1/B1 parameter of each Tag with device's address (Slave Id) to access in each case. This

parameter is usually configured on the device and, to determine it, please check manufacturer's documentation or

technical support when in doubt.

4. Rename all Tags, if needed, with a more significant name for the application.

Configure simple Tags, called PLC Tags in old Elipse SCADA, rather than Block Tags, keeping the Superblock feature

enabled, that is, the EnableReadGrouping property set to True, leaving group optimization to the application and to this

Driver. For more information, please check topic Superblock Reading (Grouping).

Tag Configuration in Elipse SCADA

Elipse SCADA does not support Tag Browser, thus it is necessary to configure I/O Tags manually. Users must create Tags

with the following configuration:

· N1/B1: Device address (Slave Id)

· N2/B2: Operation Code

· N3/B3: Not used, leave it 0 (zero)

· N4/B4: Address of a Modbus register or bit

Notice that, for this Driver, simple Tag's N parameters have the same meaning as Block Tag's B parameters, so they are

described together.

When in doubt about which value to configure in the N4/B4 parameter, please check topic Addressing Tips (Modbus

Convention).

As Elipse SCADA does not support Superblocks, it is recommended to create Block Tags, grouping adjacent or close

registers, to read the maximum number of registers in the smallest number of protocol requests.

Also notice that, once a device supports default protocol limits for the size of a communication frame, due to

Automatic Block Partition feature, there is no need to worry about exceeding the maximum block size supported by this

protocol, because this Driver already creates the appropriate subdivisions during communication.

Final Considerations

If users only want to use this Driver's default operations, and if a device complies with the standard protocol defined by

Modbus Organization, the steps presented in this Quick Configuration Guide should be sufficient to configure this Driver.

For larger applications, it is recommended to check topic Optimization Tips.

More details on I/O Tag configuration are provided on topic Configuring an I/O Tag.

Modicon Modbus Driver v4.0.11

The Modbus Protocol

The Modbus Protocol was initially developed by Modicon in 1979, and today it is an open standard, maintained by the

Modbus Organization (modbus.org), and implemented by hundreds of manufacturers in thousands of devices. Schneider

Electric, current controller of Modicon, transferred protocol rights to the Modbus Organization in April 2004, and

committed to keep Modbus as an open protocol. Its specification can be downloaded for free at Organization's website,

www.modbus.org, and protocol's usage is free of licensing fees.

This protocol is based on command and response messages, positioned at layer 7 of the OSI model, the application

layer, which provides client and server communication among devices connected to different types of networks. It offers

services with functions defined by an eight-bit code. The existing categories of function codes are the following:

· Public function codes: Protocol's well-defined functions, guaranteed to be unique, validated by the Modbus

community, and publicly documented in MB IETF RFC. They can assume values ranging from 1 to 64, from 73 to 99,

and from 111 to 127

· User-defined function codes: Non-standard functions, which do not need Modbus.org approval, without any

guarantee of being unique, and freely implementable. They can assume values ranging from 65 to 72 and from 100

to 110

· Reserved function codes: Codes with values inside the range of public functions, currently used by some

manufacturers for legacy products, and not publicly available anymore. Examples are 9, 10, 13, 14, 41, 42, 90, 91, 125,

126, and 127 codes. For more information, please check Annex A of protocol's specification, version 1.1b, which is

available at protocol's official website

This Driver currently implements 11 of all 19 public functions defined on the current version of protocol's specification,

1.1b, as well as some specific manufacturer's functions or related to this Driver's specific features, known as Special

Functions. All public functions implemented are described on topic Supported Functions. The following protocol's public

functions are not yet supported:

· Function 08: Diagnostic

· Function 11: Get Com event counter

· Function 12: Get Com Event Log

· Function 17: Report Slave ID

· Function 22: Mask Write Register

· Function 23: Read/Write Multiple Registers

· Function 24: Read FIFO queue

· Function 43: Read Device Identification

If users want to implement one of these functions, please contact Elipse Software's sales department.

Recommended Websites

Modicon Modbus Driver is available for download, at no cost, at Elipse Software's Drivers download area.

More information about the Modbus protocol can be found at www.modbus.org, protocol's official website.

Elipse Modbus Simulator is available for download, at no cost, at Elipse Software's E3 download area.

Modsim Modbus Slave Simulator, probably the best known in its category, can be purchased at www.win-

tech.com/html/modsim32.htm. This software emulates a device, allowing communication with this Driver.

Modicon Modbus Driver v4.0.11

There is also a free alternative called Free Modbus PLC Simulator, available for download at www.plcsimulator.org.

Other alternatives for simulators and software tools related to this protocol can be found at protocol's official website.

Supported Functions

Modbus protocol functions supported by this Driver are described next.

Reading functions

· 01: Bit Reading (Read Coil Status - 0x)

· 02: Bit Reading (Read Input Status - 1x)

· 03: Word Reading (Read Holding Registers - 4x)

· 04: Word Reading (Read Input Registers - 3x)

· 07: Status Reading (Read Exception Status)

· 20: File Record Reading (Read File Register - 6x)

Writing functions

· 05: Bit Writing (Force Single Coil - 0x)

· 06: Simple Word Writing (Preset Single Register - 4x)

· 15: Bit Writing (Force Multiple Coils - 0x)

· 16: Word Writing (Preset Multiple Registers - 4x)

· 21: File Record Writing (Write File Register - 6x)

Detailed information about each one of these functions can be found on Modbus protocol's specification, available for

download at Modbus Organization's website.

In addition to protocol's standard functions, as already stated, this Driver also implements special functions, not defined

by the protocol, usually related to mass memory readings. A list of all supported special functions can be checked on

topic Special Functions. A complete configuration of this Driver is described on topic Configuration.

If users want to add support to a new function in this Driver, please contact Elipse Software's sales department.

Special Functions

Special reading and writing functions are this Driver's functions not defined by the standard Modbus protocol. They were

developed to meet specific features of certain devices, or else to provide, in a standardized way by this Driver, features

not available in the standard protocol. This Driver, in its current version, includes the special functions described next.

Reading Functions

· 65 03: Mass Memory Reading (ABB MGE 144), described in details on topic Reading Mass Memory Registers from

ABB MGE 144 Meters

· GE SOE: Event Reading (GE PAC RX7 Systems), described in details on topic Reading an Event Buffer from GE PAC

RX7 Controllers

Modicon Modbus Driver v4.0.11

· SP SOE: Event Reading (Schneider Electric SEPAM series Relays), described in details on topic Reading Events from

Schneider Electric Relays from SEPAM 20, 40, and 80 Series

· GenSOE: SOE reading with a generic algorithm, implemented by a resident software in the slave device (PLC),

described in details on topic Elipse Software's Generic SOE Reading Algorithm

Writing Functions

· 65 01: Restarts, that is, performs a reset operation, a power meter (ABB MGE 144). This command is sent as a Tag's

simple writing command (Write). Tag's Value field is ignored by this Driver and can be kept in 0 (zero). For more

information, please check that device's manual

· 65 02: Zeroes the maximum and minimum memory (ABB MGE 144). This command is sent as a Tag's simple writing

command (Write). Tag's Value field is ignored by this Driver and can be kept in 0 (zero). For more information,

please check that device's manual

Notice that this Driver's special functions, except for the writing function 65 01, are directly or indirectly related to mass

memory reading of registers of their respective devices. For more information, please check topic Mass Memory

Reading. For a description on how to configure operations and Tags using these functions, please check topic

Configuration.

Configuration

This section describes how to configure this Driver. The topics Properties , Configuring Tags, and Mass Memory

Reading are discussed.

Properties

This Driver's properties can be configured at design time or at run time. A runtime configuration is also called an Offline

Mode Configuration, and it is described on a specific topic.

At design time, this Driver can be configured using its configuration window, displayed on the next figure.

Modicon Modbus Driver v4.0.11

Configuration window of this Driver

To open this Driver's configuration window in E3 or Elipse Power, double-click the Driver object on Organizer and click

Driver settings , as shown on the next figure.

Driver settings option

In Elipse SCADA, on the other hand, this Driver's configuration window can be opened by clicking Extra, on application's

Organizer.

This configuration window is divided into several tabs, some of them for IOKit library configuration, and others are

Driver-specific. For this Driver, the Modbus, Operations, and Gen SOE tabs are specific. All other tabs are for IOKit

library configuration, and they are not described on this Manual. For more information about IOKit library configuration,

please check topic Documentation of I/O Interfaces.

The topics Modbus Tab, Operations Tab, Gen SOE Tab, and Offline Mode Configuration describe this Driver's specific

tabs and also its runtime configuration, in Offline Mode, using scripts.

Modicon Modbus Driver v4.0.11

Modbus Tab

The Modbus tab allows configuring parameters for this Driver and for the protocol, as shown on the next figure.

Modbus tab on this Driver's configuration window

The next sections describe all configuration options available on this tab.

Protocol Options

This group of options gathers options referring to variations on protocol's standards, according to the next table.

Available protocol options on the Modbus tab

OPTION DESCRIPTION

Modbus Mode On this option, users can select a protocol mode to use.

Protocol modes are variations defined by the standard for a

better adaptation to different physical layers, such as Serial,

Ethernet TCP/IP, or RAS, among others. The available

options are the following:

· RTU mode: Default mode for use in serial

communications. Includes a 16-bit CRC

· ASCII mode: Also used in serial communications, it is

used in simpler devices, which do not support RTU mode

requirements. It uses ASCII characters for transmission,

where each byte contains two ASCII characters, one per

nibble, thus it is less efficient than RTU mode, and rarely

Modicon Modbus Driver v4.0.11

OPTION DESCRIPTION

found on the market. Uses LRC (Longitudinal Redundancy

Checking) for error checking

· ModbusTCP mode: Used for communication in TCP/IP

mode. Includes a field for transaction check and does not

have an error check system. The transaction field allows

discarding delayed responses, thus avoiding that this

Driver assumes as a valid response for the current

command the response frames from previous commands.

This situation may occur if previous modes are

encapsulated in TCP/IP

Customize Max. PDU Size If enabled, this option allows defining a maximum custom

size for PDU (Protocol Data Unit). A PDU is a part of the

protocol that does not vary between modes ModbusTCP,

ASCII, and RTU and contains a data area. The number of

data bytes supported in each communication is given by this

value minus the header bytes, which depend on the Modbus

function used. If disabled, the maximum considered size is

the default value defined by the Modbus protocol

version 1.1b, with 253 bytes. This is the recommended

option for most devices

Use Gateway Modbus/TCP In Ethernet mode, via Modbus TCP, this option indicates

the presence of a Modbus Gateway to access a Serial RS-485

network, reserving the Slave ID with a value of 0 (zero) for

Broadcast mode. If users want to directly communicate with

a device in Ethernet mode, disable this option to use a

Slave ID with value 0 (zero)

Enable CMS Addressing This option must be only used in devices that support the

TeleBUS protocol. If enabled, this Driver accepts a 16-bit

Word as its slave address, that is, users can define values

above 255 and below 65535 as a slave address. In this case,

a slave address is then defined in the protocol by three

bytes. In addition, the Default Slave Address option stops

working

Data Address Model Offset This option enables or disables the default protocol's data

offset, by one unit. Available options are:

· Data is addressed from 1 (default): The address

provided (address of the Item field in String

configuration or the N4/B4 parameter in numerical

configuration) is decremented by 1 (one) before sending

it to a device. This offset is part of protocol's

specification, therefore this is the default option

· Data is addressed from 0: The user-provided address is

used in protocol requests, without changes

As a general rule, select the first option if device's register

mapping starts at 1 (one) and the second option if it starts

at 0 (zero). Also check if the manufacturer uses additional

offsets from the old Modbus Convention. For more

information, please check the next section.

Modicon Modbus Driver v4.0.11

TIP

Avoid using protocol's RTU mode encapsulated in Ethernet TCP/IP layer. If there is a need to encapsulate serial

communication for devices using Modbus RTU in TCP/IP, there are gateways available on the market that not only

encapsulate serial communication in Ethernet TCP/IP, but also convert Modbus RTU to Modbus TCP. As a last option,

if using Modbus RTU in an Ethernet TCP/IP layer is inevitable, remember to enable the Reconnect after Timeout

option, described on the next table.

Data Address Model Offset

This configuration option, described on the previous table, is a source of frequent doubts when addressing I/O Tags,

because there are many variations in how it is implemented by manufacturers. Next there is more information about this

addressing.

In protocol's standard data model, four data blocks are defined, or address spaces: Discrete Inputs, Coils, Input Registers,

and Holding Registers. In each one of these blocks, data elements are addressed starting at 1 (one). On the other hand, the

communication frame's specification defines a PDU with addresses that range from 0 (zero) to 65535. The relationship

between the address provided by the PDU and the address of data elements, therefore, has an offset of 1 (one), that is, if

in a request's PDU there is an address 0 (zero), the data element to access is the address 1 (one).

With this option on the Modbus tab, users can select whether this Driver sets that value automatically, thus allowing the

use of data element's address on Tags, the default option, or the value sent in the PDU is the same provided on Tag

configuration, the N4/B4 parameter in numerical configuration. There are devices that comply with Modbus standard in

their address maps, starting at one, and other devices that map their values without a default offset, directly using the

value of the address on communication's frame, starting at 0 (zero).

In addition to this single offset, there are still devices that use the old offset standard used by Modicon, the company that

created the protocol, which is known as Modbus Convention, detailed on topic Addressing Tips (Modbus Convention).

Please check device's manual for information on the register map used. When in doubt, please check manufacturer's

technical support.

NOTE

The Data Address Model Offset option used to be named Use Older Address on versions earlier than version 2.03,

where the Data is addressed from 1 option is equivalent to the old Use Older Address option enabled, and the Data is

addressed from 0 option is equivalent to the Use Older Address option disabled.

Other Options

The next table describes all other options on this tab, referring to this Driver's behavior.

Other available options on the Modbus tab

OPTION DESCRIPTION

Default Slave Address This feature allows configuring a default address for

slaves, so that it is not necessary to configure them in each

Tag. To use this feature, configure the Slave Id, the N1/B1

parameter on numerical configuration or the Device field

on String configuration, as 1000, that is, all Tags with

their Slave Id equal to 1000 have this value replaced by the

value configured in the Default Slave Address option.

Users can also force using a default address in all Tags,

Modicon Modbus Driver v4.0.11

OPTION DESCRIPTION

regardless of the value configured in Slave Id, by selecting

the Use Default Address option

Wait Silence on error If this option is enabled, after every communication error

this Driver remains in loop, receiving data until a time-out

occurs. This clears the reception channel and prevents

problems in future communications due to the reception of

delayed bytes still in transit at the time of the error, and

which may be confused with a response to a new

command

Reconnect after Timeout (Ethernet only) With this option enabled, after any time-out error in

device's frame reception, this Driver performs a

disconnection and a reconnection to the physical layer,

clearing the connection from possible delayed frames still

in transit, which may affect future requests. This option

must be always enabled if using Modbus RTU in an

Ethernet TCP/IP layer is inevitable in legacy systems, as

the RTU mode does not have a transaction control,

therefore it is not always possible to distinguish a correct

response frame from a delayed one resulting from a

previous reading, possibly from another address, which

failed by a time-out. For new projects, it is strongly

recommended NOT using Modbus RTU or Modbus ASC

modes in an Ethernet TCP/IP layer. Notice that users must

keep the Retry failed connection every option enabled on

IOKit's Setup tab, so that this Driver reconnects after a

time-out. Otherwise, this time-out only generates a

disconnection and the application is responsible for

managing this new connection

NOTE

The old Swap Address Delay option was removed from the configuration window in version 2.08. This Driver still

supports it in pre-existing applications and allows enabling it by script. For more information, please check topic Offline

Mode Configuration. For new applications, it is recommended to use the Inter-frame Delay option on IOKit's Serial

tab, which replaces this old option with benefits.

Operations Tab

This topic describes how to configure the Operations tab on this Driver's configuration window, where all operations

used on I/O Tags are defined, as shown on the next figure.

Configuring operations is no longer used when configuring Tags by Strings, it is only used in the old numerical

configuration, the N/B parameters, on Elipse SCADA.

Modicon Modbus Driver v4.0.11

Operations tab on this Driver's configuration window

Operations

For a proper usage of this Driver, users must define which reading and writing Modbus functions are used for each I/O

Tag. To do so, if Tag configuration is performed using the old N/B numerical parameters in Elipse SCADA, select the

Operations tab on the configuration window.

For this Driver, Operations are configurations defining how each I/O Tag performs data writings and readings to and

from a device.

An operation is simply a definition of a pair of protocol functions, one for writing and another one for reading,

and a specification for additional conversions on the format of data that can be linked to application Tags. In other

words, in this Driver the N or B numerical parameters of I/O Tags do not directly reference protocol functions, but rather

pre-configured operations, which by their turn not only inform functions, protocol's native or even special ones, to use

when communicating, as well as the way native protocol data must be interpreted.

Configuration of I/O Tag parameters is described later on topic Configuring an I/O Tag. Next, there is a description of

the configuration of operations, which must be later linked to each I/O Tag.

NOTE

Operations work only as a template to configure I/O Tags, and user can, and usually want to, set a single operation to

several Tags, which have in common the same value for their N2/B2 parameters.

Functions

Modicon Modbus Driver v4.0.11

The Modbus protocol defines reading and writing functions, which can access distinct address spaces on a device, and

with specific data types. Functions 03 and 16, for example, protocol's most used ones, are responsible for reading and

writing Holding Registers, which are simply 16-bit unsigned integer values (Words).

Modbus protocol's default functions provide data only in basic 16-bit Bit and Word formats. There are no additional data

formats in protocol's specification.

A list of all Modbus functions supported by this Driver, which can be set to the configured operations, can be checked on

topic Supported Functions.

In addition to protocol functions, this Driver also contains some Special Functions that are not part of protocol's

standard, with a proprietary format and commonly used for reading events (SOE).

Data Formatting

In addition to allow linking functions, from the protocol or special ones, to specific Tags, operations also allow defining an

additional formatting to apply to data, providing support to additional data types, not specified by the protocol, such as

32-bit (Float) and 64-bit (Double) floating point values. Supported data types are described on topic Supported Data

Types.

It is important to notice that, when 32- and 64-bit data types are defined in operations, users must define protocol

functions that work with 16-bit registers. This way, reading data with more than 16 bits results in reading several 16-bit

Modbus registers from a device, that is, to read a Tag linked to an operation defining a 32-bit Float data type, this Driver

must read two consecutive 16-bit registers from a device, concatenate them, and then perform a conversion to a Float

format.

Users can also define eight-bit data types, Byte, Int8, or Char, in operations. Notice that, as protocol functions do not

allow reading and writing isolated bytes, for each two Block Elements of eight-bit data types, this Driver is forced to

access a distinct 16-bit register on a device. For that reason, this Driver does not allow writing eight-bit data types to

Tags, to isolated Block Elements, or to Blocks with odd or unitary sizes. Writing eight-bit data types must be always

performed with even-size Blocks.

User-Defined Data Types

In addition to pre-defined data types, native or built-in data types, described on topic Supported Data Types, this Driver

also allows user-defined data types. These data types must be declared on a specific window, by clicking User Defined

Types on the Operations tab. Such data types are structures created from pre-defined data types. For more information

about user-defined data types, please check topic User-Defined Data Types.

Byte Order

In addition to protocol's reading and writing functions and the data type used, each operation also allows setting

additional manipulations to bytes, related to a byte order, that is, the order of bytes inside every value. These are called

swap options, Swap Bytes, Swap Words, and Swap DWords. Such options only need to be enabled for devices that do not

respect protocol's default byte order.

The Modbus protocol defines that its 16-bit values always use a byte order known as big endian, also known as Motorola,

because it is used by that manufacturer. The big endian standard always defines a byte order so that the most significant

byte of each value comes first. Thus, as an example, when reading the hexadecimal value 1234h, the device first sends the

most significant byte 12h and then the least significant one, 34h.

For devices that do not implement protocol's default byte order, and use another one known as little endian or Intel, data

is sent with the least significant bytes first. Users must then enable those swap options to reverse that byte order.

There are also devices that use different byte orders for 32- and 16-bit types. For devices that, for example, use Modbus'

default byte order (big endian) for 16-bit types, but provide 32-bit data with the least significant Word first (little endian),

Modicon Modbus Driver v4.0.11

users must only enable the Swap Words option, leaving the Swap Bytes option deselected. Possible situations are the

following:

· For devices that provide data using Modbus' default byte order, Motorola or big endian, with the most significant

bytes first, users must left all swap options disabled. This is the most common situation

· For devices using another byte order standard, with the least significant bytes first, little endian, users must enable all

swap options referring to the data type used, that is, for 16-bit types, enable the Swap Bytes option. For 32-bit data

types, enable the Swap Bytes and Swap Words options. For 64-bit types, all these swap options must be enabled

· In the least common case, devices that use different byte orders for different data sizes, providing, for example, the

most significant byte of each Word first, but the least significant Word of each DWord first, then users must evaluate

in which case each swap option must be enabled, so that it converts a value returned by a device to protocol's

default big endian format

NOTE

All mentioned swap options have no effect for Bit data types or for data types with an eight-bit size, Byte, Char, and

Int8. Swapping occurs inside every data type, that is, the Swap Words option has no effect for 16-bit data types, as well

as the Swap DWords option has no effect for 32-bit data types. BCD data types also do not allow swapping.

To check if a device uses some unusual byte order format, check its manufacturer's documentation. In case this

information is not found on that documentation, please contact manufacturer's technical support.

The topic Frequently Asked Questions contains tips on byte order configurations for some devices that are known to

use swap options.

Bit Mask

The Use Bit Mask option is an advanced feature, used in specific and unusual cases where users want to read only a bit

from the value returned by a device, but they cannot use application's bit mapping.

For most users, application's bit mapping fields are the best alternative to access bit masks, and there is no need to use

this Driver's feature.

This feature was initially created to allow reading bits from Holding Registers by specialized E3 libraries, in situations that

prevented the usage of application's bit mapping.

In this case, this Driver reads a value from a device normally and then masks it, to return to Tag's Value field only the

specified bit, 0 (zero) or 1 (one). The definition of a bit number to return is performed on I/O Tag's N3/B3 parameter.

The Use Bit Mask option can only be used with integer data types with 16 bits or more (Int16, Int32, Word, or DWord).

In addition, operations that enable this option can only be used for reading. The Modbus function for writing operations

(Write) that use this mask option can be defined as None.

Driver's Default Operations

By default, when a new Driver is added to an application, that Driver is already created with default operations, described

on the next table.

Default operations

OPERATION READING WRITING DATA TYPE PURPOSE

1 3 - Read Holding 16 - Write Multiple Word Reading and writing

Registers Registers unsigned 16-bit

Modicon Modbus Driver v4.0.11

OPERATION READING WRITING DATA TYPE PURPOSE

integers

2 3 - Read Holding 16 - Write Multiple DWord Reading and writing

Registers Registers unsigned 32-bit

integers

3 3 - Read Holding 16 - Write Multiple Int16 Reading and writing

Registers Registers signed 16-bit integers

4 3 - Read Holding 16 - Write Multiple Int32 Reading and writing

Registers Registers signed 32-bit integers

5 3 - Read Holding 16 - Write Multiple Float Reading an writing 32-

Registers Registers bit floating point

values

6 1 - Read Coil Status 15 - Write Multiple Bit Reading and writing

Coils bits

7 2 - Read Discrete None Bit Reading bits from a

Inputs Discrete Input data

block

These operations are the most commonly used, and operation 1 (one) is the most common one. For most devices,

select all operations needed among the ones provided by default, there is no need to create new operations or change

the configuration of these default operations.

Defining New Operations

To add a new operation to this Driver, click Add.

Modicon Modbus Driver v4.0.11

Adding a new operation

To configure this new operation, select a number for it, used on I/O Tag's N2/B2 parameter, which function to use for

reading, and which function to use for writing, as well as informing a data type to be read or written by this Driver. Notice

that, when clicking Add, this Driver already suggests a value that is not in use for this new operation.

For more information about supported data types, please check topic Supported Data Types. All other fields can be

configured as needed. The next table contains a description of these fields.

Field options for operations

OPTION DESCRIPTION

Size A size in bytes of each element of the selected data type

must be informed. This field is automatically filled in for

fixed-size data types, such as Byte, Word, and Int16, and it

must be filled in for String and BCD data types. For

Strings, this size defines exactly the number of bytes sent

or received for each String value, that is, for each Tag or

Block Element. If the String read or written has a shorter

size, the remaining bytes are filled in with zeroes to

complete its configured size. The String data type in this

Driver has no defined maximum limit size, this limit is the

maximum allowed by the protocol for frame's data area

of a certain function

Swap Bytes Indicates that this Driver must reverse the byte order, one

by one, to retrieve a value

Swap Words Indicates that this Driver must reverse the byte order, two

by two, in Words, to retrieve a value

Modicon Modbus Driver v4.0.11

OPTION DESCRIPTION

Swap DWords Indicates that this Driver must reverse the byte order, four

by four, in DWords, to retrieve a value

Use Bit Mask Enables a bit masking of registers, using the N3/B3

parameter. This option only affects readings and can only

be used with integer data types, signed or unsigned, with

at least 16 bits of size, Int16, Int32, Word, or DWord.

Operations with this option enabled cannot be used for

writing. For most users, it is recommended to use

application's bit mapping, and leave this option

deselected. For more information, please check the

specific section

Protocol functions that can be configured in operations' Read and Write fields are described on topic Supported

Functions. The next table describes each one of the available options.

Available options on the Operations tab

OPTION DESCRIPTION

Import Configuration This option allows importing configurations for operations

from versions prior to Modbus Master/Slave Driver

version 2.0, which stored these configurations on a

modbus.ini file. This Driver does not use INI files anymore

to store such configurations, which are now stored on the

application file. For more information, please check topic

Import and Export Operations

Export Configuration This option executes the opposite operation of the

previous option, generating an INI file containing all

operation configurations, in the current format or in the

same format of this Driver's previous versions. This way,

users can store operation configurations of a certain

device on a file, and these configurations can be used by

other applications. For more details, please check topic

Importing and Exporting Operations

Show Operations in Tag Browser If this option is not selected (default), templates of Tags

configured by Strings (Device and Item fields) are

displayed on Tag Browser. If it is selected, templates of

Tags numerically configured (N/B parameters) are

displayed on Tag Browser. When creating new instances of

this Driver, this option is deselected by default. In legacy

applications, when this Driver's version is updated from a

version previous to 3.1, this option is already selected,

keeping the behavior of previous versions

Add Adds a new operation to the list

Edit Updates the selected operation on the list, which is

equivalent of double-clicking an item

Remove Removes the selected operation from the list

Modicon Modbus Driver v4.0.11

NOTE

The Swap Bytes, Swap Words, and Swap DWords options, as already explained, were added to provide compatibility

with devices that do not comply with Modbus protocol's standard on data encoding (byte order). If these options

remain disabled, this Driver's behavior corresponds to protocol's standard, which is the recommended option for

most devices.

Supported Data Types

The next table lists this Driver's native data types, which can be defined when configuring I/O Tags.

As explained on topics String Configuration and Operations Tab, the Modbus protocol itself only supports Bit and

Word data types (16 bits) for the most commonly used functions implemented by this Driver (the only exception is

currently function 7). All other data types of this Driver are converted to Word at protocol's level, for reading from or

writing to a device or slave device.

Also notice that this Driver supports User-Defined Data Types, defined as structures with elements composed by the

native data types listed on the next table.

On the next table, data types use the same denominations of mnemonics for the data type field, when Tags are

configured by Strings. For the old numerical configuration, the same denominations are also used on Data column of

this Driver's configuration window, on the Operations tab. In some cases, frequent alternative denominations are

displayed between parentheses.

Available options for data types

DATA TYPE RANGE DESCRIPTION

Char -128 to 127 Eight-bit word, character. Writing must

always occur in blocks with even size

(Words)

Byte 0 to 255 Unsigned eight-bit word. Writing must

always occur in blocks with even size

(Words)

Int8 -128 to 127 Signed eight-bit word. Writing must

always occur in blocks with even size

(Words)

Int16 -32768 to 32767 Signed 16-bit integer

Int32 -2147483648 to 2147483647 Signed 32-bit integer

Word (or UInt) 0 to 65535 Unsigned 16-bit integer

DWord (or ULong) 0 to 4294967295 Unsigned 32-bit integer (Double

Word)

Float -3.4E38 to 3.4E38 32-bit floating point (IEEE 754) (four

bytes: EXP F2 F1 0). Handling of non-

normalized values: Float Underflow

returns 0 (zero), Float Overflow

returns NULL, and Float NaN returns

NULL

Float_GE -1.427E+45 to 1.427E+45 32-bit floating point used by GE, not

compatible with IEEE 754. It is used in

GE GEDE UPS devices, with an eight-bit

exponent 2[-128 ... +127] and 24-bit

Modicon Modbus Driver v4.0.11

DATA TYPE RANGE DESCRIPTION

mantissa [-223 ...+(223-1)]. (four bytes:

EXP F2 F1 F0). For more information,

please check device's documentation

Double (or Real) -1.7E308 to 1.7E308 64-bit floating point (IEEE 754)

String Does not apply Text in ANSI format, with a determined

number of eight bit ASCII characters

(Chars)

BCD Check description BCD (Binary-Coded Decimal) numerical

value. When using this data type, an

application must provide a positive

and integer decimal value, sent in BCD

format, respecting the specified size.

The Size field, for BCD types, refers to

the number of bytes sent to represent

a value. As in BCD encoding each

figure is converted to a nibble, then

the allowed values must have a

maximum number of figures equal to

double the size of the value specified

in the Size field, that is, if a value of 2

(two) is selected for the Size field, the

maximum value that can be sent is

9999. Likewise, if Size is equal to 4

(four), the maximum value is then

99999999. Allowed values for the Size

field for BCD types are two (two,

Word) and four (four, Double Word).

For more information about the BCD

encoding, please check topic BCD

Encoding

GE_events Check description Data type used when reading an event

buffer (SOE) from a GE PAC RX7 PLC.

Its definition is only allowed for

operations that use the special reading

function GE SOE. These events are

returned as blocks with two Elements,

with timestamps defined by the

controller. For more information,

please check topic Reading an Event

Buffer from GE PAC RX7 Controllers

Bit 0 (zero) or 1 (one) This data type is automatically selected

when a bit-access function is selected.

Bit-access functions are 01, 02, 05, and

15. The Size field is not used for Bit

types. When using this data type, each

Tag or Block Tag Element represents a

bit

SP_events Check description Data type used when reading events

(SOE) in Schneider Electric relays from

SEPAM 20, 40, and 80 series. Its

definition is only allowed for

operations that use the special reading

function SP SOE. These events are

Modicon Modbus Driver v4.0.11

DATA TYPE RANGE DESCRIPTION

returned as a three-Element Block, with

a device-provided timestamp. For

more information, please check topic

Reading Events from Schneider

Electric Relays from SEPAM 20, 40,

and 80 Series

GenTime 1/1/1970 00:00 to 31/12/2035 Date and time type composed by an

23:59:59.999 (please check the next eight-bit structure, originally created

note) for use when reading events using

generic SOE algorithm (GenSOE).

This data type can be used with other

Modbus protocol functions, in addition

to GenSOE. This format is read

internally as a structure of Words, and

the only valid swap function for this

type is Swap Bytes. Representation of

this type in PLC memory is described

on topic GenTime Data Type. For

more information about this type,

please check topic Elipse Software's

Generic SOE Reading Algorithm

Sp_time 1/1/1970 00:00 to 31/12/2035 Date and time data type composed by

23:59:59.999 (please check the next an eight-byte structure, used by

note) Schneider Electric relays from SEPAM

20, 40, and 80 series, usually to

represent a timestamp. For more

information, please check device's

documentation

UTC64d 1/1/1970 00:00 to 31/12/2035 Date and time data type represented

23:59:59.999 (please check the next in Double format (64-bit IEEE 754),

note) with seconds since 1/1/1970 00:00

UTC32 1/1/1970 00:00 to 31/12/2035 Date and time data type represented

23:59:59.999 (please check the next as an unsigned 32-bit integer, DWord

note) or UInt, with seconds since 1/1/1970

00:00. This format does not represent

milliseconds, which are always

considered as 0 (zero)

Int16_sm -32767 to 32767 Signed 16-bit integer, with magnitude

signal

Int32_sm -2147483647 to 2147483647 Signed 32-bit integer, with magnitude

signal

Int52 and UInt52 -9007199254740992 to 52-bit integers converted to Double

9007199254740992 (floating point)

Str_I64 "-9223372036854775808" to 64-bit signed integers converted to

"9223372036854775807" String (text) format

Str_U64 "0" to "18446744073709551615" 64-bit, unsigned integers converted to

String (text) format

Modicon Modbus Driver v4.0.11

NOTES

· Although the representation of date and time data types on the previous table can represent dates greater than

12/31/2035, this limit is displayed on the table because Elipse Software applications do not currently support ranges

of values that exceed this limit for timestamps.

· The Int52 and UInt52 data types process data equivalent to 64-bit integers, that is, they process 4 (four) Modbus

registers with 8 (eight) bytes per value, limiting the range of values represented by 52-bit integers, due to a

conversion to a Double data type. This Driver does not support 64-bit integer data types natively.

· The Str_I64 and Str_U64 types are handled as text only by SCADA applications. For devices, this data is automatically

converted to a number format by this Driver.

GenTime Data Type

GenTime is a date and time data type originally defined and added to this Driver for use with Elipse Software's Generic

SOE Reading Algorithm. It is, however, a generic data type that can be easily used with almost any PLC.

In an application, that is, in values of Tags and Block Tag Elements, as well as in Tag's Timestamp field, this data type, as

well as all other date and time data types of this Driver, is represented by an application's native date and time data type.

For more information about other date and time data types supported by this Driver, please check topic Supported Data

Types. For more information about application's date and time data types, please check their respective user's manual,

because there are some differences between VBScript used in Elipse SCADA and VBScript used in E3 and Elipse Power.

In the PLC or slave device, this data type is represented by a structure composed by four 16-bit registers, or eight bytes,

as displayed on the next table.

Structure of registers

OFFSET CONTENT BIT MAPPING (16 BITS) RANGE (DECIMAL)

0 Year AAAAAAAA AAAAAAAA Between 0 and 65535

1 Day and Month DDDDDDDD Between 0 and 65535

MMMMMMMM

2 Hour and Minute HHHHHHHH Between 0 and 65535

MMMMMMMM

3 Second and Millisecond SSSSSSMM MMMMMMMM Between 0 and 65535

The base address, offset 0 (zero), for attribution on Tag's N4/B4 parameter accessing data, contains the year. The next

register, offset 1 (one), contains the day as the most significant byte and the month as the least significant byte. The offset

2 (two) contains the hour represented in the most significant byte and the minutes in the least significant byte. The fourth

register contains the four most significant bits of the Word representing seconds, and the remaining bits, the two least

significant of the most significant and the integer's least significant byte, representing milliseconds.

Notice that each Tag referencing this data type forces this Driver to read a block of four Modbus registers in a device to

represent the value of each Tag or Block Element to return a valid value.

Advantages of this data type are its simplicity, because it is easily generated in a PLC ladder, its milliseconds precision,

and its relative compression, as it does not need native support by the PLC or slave device.

Modicon Modbus Driver v4.0.11

NOTE

Although the GenTime data type itself is an eight-byte size, or four Words, the only effective swap option is Swap Bytes.

This happens because, as already explained on this topic, this data type is structured in the PLC memory as having four

Words, and it is not a device's native data type, rather a Driver's data type. More information about swap options (byte

order) can be found on topic Operations Tab.

User-Defined Data Types

User-defined data types, or structures, after configured on the User Defined Types configuration window, can be used by

this Driver's operations the same way as pre-defined data types.

These data types are in fact structures whose elements may have different native data types, that is, a user-defined data

type is merely a structure defined based on this Driver's pre-defined data types, native or built-in data types, allowing

users to configure Block Tags where each Element may have a different native data type.

Users can use almost all data types pre-defined by this Driver in their structures. The only data types not allowed are Bit

data types, eight-bit data types, variable-size data types, such as String and BCD, and event data types linked to specific

SOE functions.

Once a data type is defined, users can link it to any Tag, as long as it uses Modbus functions supporting Words, that is, it

is not allowed to link a user-defined data type to an operation that defines as its reading function (Read) the 01 function,

for example, because that function only reads bits.

In addition to the definition of structure elements, whose values are returned in Block Elements, users can also define the

type of a Tag's timestamp, as well as the default address for that structure, address that is used for the B4 parameter of

Tags available using E3's or Elipse Power's Tag Browser.

Applications

User-defined data types were originally implemented for use with Elipse Software's Generic SOE Reading Algorithm

(Gen SOE), as this algorithm performs a reading on data structure tables.

In addition to using with SOE's generic algorithm, this feature can also be used to group different data types on a single

Block Tag, optimizing communication in applications without Superblocks, such as Elipse SCADA, or if the device in use

for some reason does not allow using Superblocks. For more information, please check topic Superblock Reading

(Grouping).

Configuring User-Defined Data Types

Configuration of user-defined data types is performed on a specific window, by clicking User Defined Types on the

Operations tab of this Driver's configuration window, as shown on the next figure.

Modicon Modbus Driver v4.0.11

Operations tab of this Driver's configuration window

This window to configure user-defined data types allows editing files with structure configurations. When opening this

window for the first time, it displays the default configuration file, with comments, which defines three example types that

appear commented with multiple-line comments "/*" and "*/", as explained later.

The next figure displays the configuration window for user-defined data types, with a small file defining these three

example data types.

Modicon Modbus Driver v4.0.11

Configuration of user-defined data types

Notice that line comments always start with "//", identifying what is on the right, on the same line, as a comment, following

the pattern for line comments of the C++ programming language, which is also used for other languages such as Java

and C#.

Comments with multiple lines are also supported, still following the same C++ language syntax, starting by "/*" and

finishing by "*/". Notice that the example file that accompanies this Driver already applies that comment format to its

example types, leaving them commented by default. Remove the lines indicated by "/* Sample types entirely commented

by default" and "*/", without quotation marks, so that all three example data types are ready to use.

As the text of the configuration file changes, the status bar displays the result of this file's syntactical analysis, in real-time.

This status bar displays a "Status: OK!" message if no errors are detected in this file.

The line and column of cursor position in the edit box are always displayed on the right side of the status bar. Errors

displayed on the status bar always reference the line and column number where it was detected.

This check can be also fully performed by clicking Verify and, in case of any error, cursor is then automatically placed on

the error line.

The definition of each type has the following syntax, in which the elements inside brackets are optional:

struct <Type Name>

{

[timestamp = <date and time type>;]

[DefaultAddress = <address>;]

<type> [name of element 1];

<type> [name of element 2];

<type> [name of element 3];

[...]

<type> [name of element n];

}

Where:

· struct: Keyword, lower case, starting the definition of a user-defined data type.

Modicon Modbus Driver v4.0.11

· <Type Name>: Name by which this new data type is identified by this Driver. This is the name displayed on the Data

option, when configuring operations. Its maximum size is six characters

· timestamp: Optional field indicating that this structure contains a device-defined timestamp, which must be returned

in Tag's Timestamp property. Each structure can have only one timestamp. The order in which it appears on this

structure affects the position in which this field is read in the frame returned by a device. Notice that in Tags this value

is returned only in the Timestamp property. Any date and time data types supported by this Driver can be defined. In

the current version, this Driver supports date and time data types GenTime, Sp_time, UTC64d, and UTC32. For more

information about data types, please check topic Supported Data Types

· DefaultAddress: Optional field specifying a default address value, used to fill the B4 parameter of Tags in Tag

Browser referencing operations containing this structure. Address values can be provided in decimal or hexadecimal

format. To use the later format, users must precede the number with the "0x" prefix, such as using "0x10" to encode

the decimal value 16 to hexadecimal

· <date and time type>: Pre-defined date and time data types for this Driver, which can be used as a timestamp by a

slave device. In the current version of this Driver, native data types GenTime, Sp_time, UTC32, and UTC64d are

accepted

· <type>: Element's data type. It must be defined as one of the pre-defined data types of this Driver, and written as it

appears on the Data option, on the configuration window for operation parameters, respecting lower and upper

case. Bit data types, eight-bit data types, and variable-size data types, such as BCD and String, are not allowed

· [name of element]: Optional parameter defining a name for each Block Element. If defined, determines a name for

Block Elements in Tags displayed in E3's or Elipse Power's Tag Browser. If not defined in structure's declaration, this

Driver then sets default names to Elements in Tag Browser, with the keyword "Element" followed by the index of that

Element in the Block, such as "Element1", "Element2", and so on

Importing and Exporting

The Import File and Export File options allow importing and exporting a configuration file with user-defined data types

to text files on disk. These options can be used to create backup copies of a file, or to share it among several Drivers.

This file is always saved and read in Windows default ANSI format, using the Windows-1252 character set. Future versions

of this Driver may include support for other formats.

In addition to copying a file to disk, users can also use shortcut keys CTRL + A (Select All), CTRL + C (Copy), and CTRL +

V (Paste) to copy and paste this file's content to another Text Editor.

The Load Default Configuration option loads the default configuration file again in the editor, the same file loaded when

the configuration window is opened for the first time.

NOTE

When clicking Cancel, all changes performed on the file are discarded by this Driver. By clicking OK, this file is then

stored in the application. This operation performs a full check on this file and if any error is identified, this error is then

displayed and this window is not closed. If users want to save these changes with pending errors, export this file or copy

and paste it to another Text Editor.

Using User-Defined Data Types with Tags Configured using Strings

Names for user-defined data types can be used as mnemonics for the Type field in the Item field, such as with Driver's

native data types, as long as this name has been previously declared, as defined earlier in this topic.

Modicon Modbus Driver v4.0.11

IMPORTANT

As in E3 the Item field is not case-sensitive, to use user-defined data types in this field, the user-defined data types must

not be case-insensitive, that is, users must not define, for example, a data type named as "type1" and another one as

"TYPE1". If this happens, users cannot use that user-defined data type in the Item field until that name is fixed.

For more information on Tag configuration using Strings, please check topic String Configuration. Example:

1. Read or write Holding Registers (functions 03 and 06) of address 100 from a device with Id 5, interpreted as a user-

defined data type named "mytype", with Slave Id in the Item field:

a. Device: "" (empty String)

b. Item: "5:shr100.mytype"

NOTE

Swap options, or byte order, for user-defined data types are only effective on the elements of the defined structure, not

on the entire structure, that is, if the Swap Words option is enabled, all elements with more than 16 bits have their

Words swapped. 16-bit elements, however, are not changed.

Using User-Defined Data Types on Numerical Configuration

After defining new data types in the configuration file on the User-Defined Types window, these data types are available

for use in this Driver operations. Remember that only operations that use Modbus functions for access to 16-bit registers,

such as functions 03, 04, 06, and 16, allow user-defined data types.

The next figure displays the configuration of a new operation that uses a user-defined data type, or structure, named

TYPE3, showed on the previous example, after clicking Add.

Modicon Modbus Driver v4.0.11

Adding a user-defined data type

NOTE

Swap options for user-defined types are only effective on the elements of the defined structure and not on the entire

structure, that is, if the Swap Words option is enabled, all elements with more than 16 bits have their Words swapped.

16-bit elements, however, are not changed.

After defining a new operation, by using the new type TYPE3, define a Block Tag with that same data type and size equal

to the number of elements of that structure, as shown on the next figure.

Declaring Tags using structures in E3 or Elipse Power

Modicon Modbus Driver v4.0.11

If a name was defined for each element of this structure, then users can use E3's or Elipse Power's Tag Browser to include

a Block Tag referring the desired data type in an application, without typing it again. To use this feature, users must select

the Show Operations in Tag Browser option on the Operations tab. The next figure shows how to perform this

procedure.

Using Tag Browser to define Tags using structures

As this figure suggests, click on this Driver's Design tab to open Tag Browser and drag the desired data type from

the list Tags available from driver to the list Tags from current project.

Event-Reported Reading

User-defined data types or structures are generally used to define events in a PLC's memory, and can be used with Elipse

Software's Generic SOE Reading Algorithm. However, if users want to read events organized in a PLC's memory, such as

a sequence of structures, in an operation that only uses protocol's public reading function, that is, without using special

functions with the SOE algorithm, such procedure can be performed in these ways:

· Block Reading: Create a Block with a number of Elements that is a multiple of the number of elements of user's data

structure. For example, a user-defined data type or structure with two elements that represent events collected on an

arrangement in a PLC's memory. If users want to read a block with five events, they must define a Block Tag with 10

Elements. Thus, a single reading from this Tag retrieves all events at once

· Event-Reported Reading: Uses a sequence of Tag's OnRead events to read a data block. With it, considering the

example on the previous item, instead of creating a Tag with 10 Elements, users only need to create a single Block

Tag with two Elements, configuring its B3 parameter as "5". This way, when performing a Tag reading, E3 calls Tag's

OnRead event five times, and at each call the Elements and properties of this Block Tag contain data related to a

specific event. The most common usage for Tags reported by events is storing events read directly from a historical

database. This is easily performed using Historic's WriteRecord method previously linked to this Tag, on the OnRead

event of the event-reported Tag. For more information, please check topic about Event-Reported Tags on E3 User's

Manual

In other words, every I/O Tag using structures and using a protocol's public reading function, because this resource

does not work for special SOE functions, becomes an Event-Reported Tag if its B3 parameter is configured with a non-

null value.

Modicon Modbus Driver v4.0.11

In case of special SOE functions, such as the Gen SOE function, the event-reported return is defined by the function's

proprietary algorithm itself.

For more information about I/O Tag configurations, please check topic Configuring an I/O Tag.

IMPORTANT

When reading mass memory events in event-reported Tags in E3 or Elipse Power, disable Tag's dead band, that is, the

EnableDeadBand property configured as False, and also the linked Historic object, that is, the DeadBand property

equal to 0 (zero), to avoid loosing events with close values. It is also important to disable the historic by scan, that is,

configure the ScanTime property as 0 (zero) in E3 or Elipse Power. This ensures that new events are only stored using

the WriteRecord method, executed in Tag's OnRead event, thus avoiding duplicated events.

Importing and Exporting Operations

Importing and exporting operations can be performed on this Driver's Operations tab, by clicking Import Configuration

or Export Configuration, as shown on the next figure.

Options for importing and exporting operations

These options allow importing and exporting operation configurations displayed on the Modbus Operations frame to INI

files.

On versions previous to 2.00 of this Driver, the configuration of operations were performed on a modbus.ini file, which

was loaded during the initialization of a Driver object. modbus.ini files of these old versions still can be loaded on this

Driver's current version, by using the import option.

Modicon Modbus Driver v4.0.11

NOTE

This Driver's operations used to be called Driver Functions in initial versions. This name was then changed to Driver

Operations due to some cases when users confused it with Protocol Functions.

Importing

Importing configuration files is very simple. Click Import Configuration and select an INI file. This Driver must load

operation configurations, which immediately appear on the Modbus Operations frame. This Driver allows importing files

generated by previous versions.

Exporting

Exporting files with operation configurations can be performed to share the same operation configurations among

different Driver objects, as well as performing backup copies of operation configurations of a certain device.

Another possible use is exporting configurations to a modbus.ini file compatible with previous versions of this Driver,

allowing to load these configurations on previous versions. This is not advisable but, if inevitable in case of legacy

applications, users must notice the next considerations.

When clicking Export Configuration, a window with the options shown on the next figure is opened.

Export options

On this window, users must select between exporting based on the new format, the New format with type mnemonics

option, with displayed data types defined as Strings (mnemonics), or based on the old format, the Old format with