TDS LF-361

TDS LF-361

Uploaded by

ofershochetCopyright:

Available Formats

TDS LF-361

TDS LF-361

Uploaded by

ofershochetCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

TDS LF-361

TDS LF-361

Uploaded by

ofershochetCopyright:

Available Formats

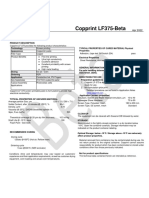

Copprint LF-361

Sep 2022

Technical Data Sheet

PRODUCT DESCRIPTION The above drying is a guideline recommendation. Conditions (time

Copprint LF-361 provides the following product characteristics: and temperature) may vary based on customers' experience and their

Technology Screen printing application requirements, as well as customer drying equipment, oven

Appearance Copperish paste loading and actual oven temperatures.

Filler Type Copper

Product Benefits ● High conductivity

● Excellent adhesion TYPICAL PROPERTIES OF CURED MATERIAL

Physical Properties

● Thin layer deposition

● High metal loading Adhesion, (tape test 3M Scotch 234) pass

● High flexibility

Cross cut test ISO 2409-2007 4-5 b

● Low temperature sintering

Drying Hot air

Sintering Hot roller or Hot press Electrical Properties - Sheet resistivity

Application Conductive Ink Hot roller @ 190ºC, 20sec ohm/sq/25 µm <0.005

Key Substrates PET, PC Hot press @ 160ºC, 120sec ohm/sq/25 µm <0.006

Typical Assembly Printed electronics

Applications

Copprint LF 361 screen printable paste is formulated to provide high GENERAL INFORMATION

electrical conductivity. For safe handling information on this product, consult the Safety

Data Sheet, (SDS).

TYPICAL PROPERTIES OF UNCURED MATERIAL

DIRECTIONS FOR USE

Average particle Size, µm D50 < 1.0, D90 < 3.0

Preparation guidelines

Solids Content, after 10 minutes @ 150ºC, % 84±4

1. Copprint LF-361 is supplied as “Sinter ready” formulation

Density, g/ml 3.4±0.1

ready for use.

Viscosity @ 250C , DVEHA Brookfield spindle 14,

2. Mix formulation prior print.

100rpm, mPa∙s (cps) 2000-3000

*Detailed procedure can be found in Application Notes

www.copprint.com

Theoretical coverage @ 5µm dry film thickness, 31 m²/kg Application (screen properties)

Shelf Life @ -10°C, days 180 Emulsion, Solvent and Water resistant emulsion, µm 10 to 40

Pot life @ 25°C, Hours 72 Squeegee Shore Hardness 70 to 90

Flash Point - See SDS Screen Type, Polyester screen, mesh 150 to 250

RECOMMENDED CURING

CLEAN-UP

Drying cycle The equipment can be cleaned with Dowanol DB (CAS# 112-34-5)

120sec @700C (Hot air, Reflow oven) followed by water.

STORAGE:

Sintering cycle Store product in the tightly closed container in a dry location below

20 sec @ 180°C-210°C (Hot roller) -100C. Open the container carefully. Storage information may be

indicated on the product container labeling.

120 sec @ 160°C-200°C (Hot press)

Optimal Storage: below -10°C. Storage above -10°C can adversely

Relaxation cycle affect product properties.

PET: 120 sec @ 140C (Hot air, Reflow oven)

Material removed from containers may be contaminated during use. Do

PC: 120 sec @ 110C (Hot air, Reflow oven) not return product to the original container. Copprint cannot assume

responsibility for product which has been contaminated or stored under

conditions other than those previously indicated.

Not for product specifications

The technical data contained herein are intended as reference only

You might also like

- Electronics-I: For Dae 1 YearDocument311 pagesElectronics-I: For Dae 1 YearSuleman AsifNo ratings yet

- Pla 2002d Data SheetDocument3 pagesPla 2002d Data SheetErick Ricardo Encalada InsuastiNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (10)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Borealis ART399 WeldingDocument19 pagesBorealis ART399 WeldingBasanth VadlamudiNo ratings yet

- TDS LF-350Document1 pageTDS LF-350Ofer ShochetNo ratings yet

- TDS LF-371 - Dec22Document2 pagesTDS LF-371 - Dec22ofershochetNo ratings yet

- TDS LF-371Document1 pageTDS LF-371Ofer ShochetNo ratings yet

- TDS LF-301Document1 pageTDS LF-301Ofer ShochetNo ratings yet

- TDS LF-370Document2 pagesTDS LF-370ofershochetNo ratings yet

- TDS LF-390Document1 pageTDS LF-390Ofer ShochetNo ratings yet

- TDS LF-370Document1 pageTDS LF-370Ofer ShochetNo ratings yet

- TDS LF-360Document2 pagesTDS LF-360Ofer ShochetNo ratings yet

- TDS LF-375Document2 pagesTDS LF-375Ofer ShochetNo ratings yet

- TDS LF-300Document1 pageTDS LF-300Ofer ShochetNo ratings yet

- TDS LF 360 Draft 3 3 21Document2 pagesTDS LF 360 Draft 3 3 21Juan Carlos del ReyNo ratings yet

- Araldite CY209 IN Aradur HY909 IN - TDSDocument6 pagesAraldite CY209 IN Aradur HY909 IN - TDSMannepalli SrihariNo ratings yet

- LOCTITE 3811 Eccobond Uf 3811 enDocument2 pagesLOCTITE 3811 Eccobond Uf 3811 enHector GarciaNo ratings yet

- CRP 100NDocument2 pagesCRP 100NbaharehestekiNo ratings yet

- 30% Glass Fiber Reinforced PA66: Features ApplicationsDocument2 pages30% Glass Fiber Reinforced PA66: Features ApplicationssuhoanganNo ratings yet

- Barrier 80 PDFDocument5 pagesBarrier 80 PDFBalaji GuruNo ratings yet

- TechnicalDataSheet 4032D Films PDFDocument3 pagesTechnicalDataSheet 4032D Films PDFP StuartNo ratings yet

- PP Trilene Hi10hoDocument2 pagesPP Trilene Hi10hoLaili AzkiyahNo ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetSantosh JayasavalNo ratings yet

- HYPERDESMO PB 2K MinDocument3 pagesHYPERDESMO PB 2K Minvelmurug_balaNo ratings yet

- PDS SikaTherm 4225 eDocument2 pagesPDS SikaTherm 4225 eMarian ComaniciNo ratings yet

- Greblon C2+: Technical DataDocument1 pageGreblon C2+: Technical DatanpdNo ratings yet

- TDS 48342 Jotatemp 1000 Euk GBDocument5 pagesTDS 48342 Jotatemp 1000 Euk GBhenryNo ratings yet

- TDS Polidan TA HF V 1.0 June 2017Document3 pagesTDS Polidan TA HF V 1.0 June 2017valdecirnasatoNo ratings yet

- Tds hd5403pdfDocument2 pagesTds hd5403pdfAthonioMourinhoNo ratings yet

- Ingeo™ Biopolymer 8052D Technical Data Sheet Foam GradeDocument3 pagesIngeo™ Biopolymer 8052D Technical Data Sheet Foam Grademajid mehrabiNo ratings yet

- TDS Polidan TA LV V 1.0 June 2017Document3 pagesTDS Polidan TA LV V 1.0 June 2017Subhadip RoyNo ratings yet

- TDS SCGC PP P303S Rev Mar2022Document3 pagesTDS SCGC PP P303S Rev Mar2022y.s.6saputroNo ratings yet

- Certificate HDPE SNI - 6 Juni 2023Document25 pagesCertificate HDPE SNI - 6 Juni 2023Nurul HudaNo ratings yet

- TDS PP 305 HF10TQ 02Document2 pagesTDS PP 305 HF10TQ 02Lungkoneng HRDNo ratings yet

- TDS SCGC PP P348S Rev Mar2022Document3 pagesTDS SCGC PP P348S Rev Mar2022y.s.6saputroNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Carboguard 690: Selection & Specification Data Selection & Specification DataDocument2 pagesCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadNo ratings yet

- PP Trilene He2.0tfDocument2 pagesPP Trilene He2.0tfLaili AzkiyahNo ratings yet

- Electrodag 725a (6s-61) - enDocument2 pagesElectrodag 725a (6s-61) - enjccaleffiNo ratings yet

- TDS PP 310 Hi50tn 01Document2 pagesTDS PP 310 Hi50tn 01Adrianto GNo ratings yet

- JotunDocument5 pagesJotunraza.slietNo ratings yet

- Ingeo™ Biopolymer 2003D Technical Data Sheet For Fresh Food Packaging and Food ServicewareDocument4 pagesIngeo™ Biopolymer 2003D Technical Data Sheet For Fresh Food Packaging and Food ServicewareAmir HamedNo ratings yet

- Sigmazinc 109 HS: Description Principal CharacteristicsDocument4 pagesSigmazinc 109 HS: Description Principal CharacteristicsАлексейNo ratings yet

- Hempadur Multi Strenght - 35530Document4 pagesHempadur Multi Strenght - 35530891629No ratings yet

- ChemflakeDocument5 pagesChemflakeManohar SeetharamNo ratings yet

- MultimediaDocument4 pagesMultimediaabdulrahimtahir100No ratings yet

- Tankguard Zinc Jotun PaintDocument5 pagesTankguard Zinc Jotun PaintGurdeep Sungh AroraNo ratings yet

- TDS 37942 Barrier 80 S Euk GBDocument5 pagesTDS 37942 Barrier 80 S Euk GBHung Mai VanNo ratings yet

- TDS PP 301 HF2.0BM 03Document2 pagesTDS PP 301 HF2.0BM 03Donny SinagaNo ratings yet

- PP h4120 TdsDocument2 pagesPP h4120 TdsengrmfawadazharNo ratings yet

- 3M Neoprene High Performance Rubber & Gasket Adhesive 1300LDocument6 pages3M Neoprene High Performance Rubber & Gasket Adhesive 1300LIventNo ratings yet

- Simacover EP Unicoat 2401-00 PDFDocument3 pagesSimacover EP Unicoat 2401-00 PDFAdnan FrrNo ratings yet

- Sikalastic 836DW en GR 01 2020 2 1Document3 pagesSikalastic 836DW en GR 01 2020 2 1nabilhajjajiNo ratings yet

- Loctite Eccobond Fp4530 en GLDocument2 pagesLoctite Eccobond Fp4530 en GLHalilibrahim CanNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- TDS PP 503 Bi5.0gn 02Document2 pagesTDS PP 503 Bi5.0gn 02Adrianto GNo ratings yet

- TDS 48342 Jotatemp 1000 Euk GBDocument5 pagesTDS 48342 Jotatemp 1000 Euk GBHani AyyadNo ratings yet

- Semi-Hard Flexible Ebonite: Technical Data SheetDocument2 pagesSemi-Hard Flexible Ebonite: Technical Data Sheethoangvubui4632No ratings yet

- Solutions of Problem Set 5Document15 pagesSolutions of Problem Set 5yasin yttNo ratings yet

- Surah YasinDocument3 pagesSurah YasinMuhammad AmirulNo ratings yet

- Chapter 1 IntroductionDocument33 pagesChapter 1 IntroductionNumair HussainNo ratings yet

- CSECDocument41 pagesCSECRoland IrishNo ratings yet

- Properties of GasesDocument11 pagesProperties of GasessalasineNo ratings yet

- Sarana Fasilitas Lab BPPTDocument73 pagesSarana Fasilitas Lab BPPTNovirita Aryani AnshoriNo ratings yet

- Magneto Optics and Electro OpticsDocument2 pagesMagneto Optics and Electro Opticskanchankonwar100% (1)

- Strength of Materials by S.K.mondalDocument429 pagesStrength of Materials by S.K.mondalKrishna Prakash100% (1)

- Dual Active Bridge DC-DC Converter Using Both Full and Half Bridge Topologies To Achieve High Efficiency For Wide LoadDocument8 pagesDual Active Bridge DC-DC Converter Using Both Full and Half Bridge Topologies To Achieve High Efficiency For Wide LoadKenil BrahmbhattNo ratings yet

- 2023-Nickelplatinghandbooka5 Printablepdf PDFDocument104 pages2023-Nickelplatinghandbooka5 Printablepdf PDFKodagnanaso kodagNo ratings yet

- WS410Document7 pagesWS410Martin OusephNo ratings yet

- 305 - 1987 Seminars - Some Current Developments Aust Pipe Industry+ PDFDocument64 pages305 - 1987 Seminars - Some Current Developments Aust Pipe Industry+ PDFChen YishengNo ratings yet

- Prestress Lecture NotesfsfsfsDocument153 pagesPrestress Lecture NotesfsfsfsAlzhammer ManupacNo ratings yet

- For Training Purpose Only Rev: 00 B1.1 Basic/ M6-Materials and Hardware October 2019Document349 pagesFor Training Purpose Only Rev: 00 B1.1 Basic/ M6-Materials and Hardware October 2019haider aliNo ratings yet

- LASERDocument30 pagesLASERanilm130484meNo ratings yet

- IMIR Consumable IndexDocument9 pagesIMIR Consumable IndexMangesh KoliNo ratings yet

- Nano ScaleDocument28 pagesNano ScaleRahulNo ratings yet

- Uh 51 XXDocument2 pagesUh 51 XXjoshdax2No ratings yet

- CIGRE Fingerprinting and Testing Methods of RTV Silicone-Coatings For Glass InsulatorsDocument11 pagesCIGRE Fingerprinting and Testing Methods of RTV Silicone-Coatings For Glass InsulatorsMalik Shoaib khalidNo ratings yet

- Young's ModulusDocument2 pagesYoung's Modulus530 B Y ManojNo ratings yet

- 2 EHS Technical Data SheetDocument1 page2 EHS Technical Data SheetLim Chee SiangNo ratings yet

- Exam Replica Version 2Document14 pagesExam Replica Version 2Owais MalikNo ratings yet

- Motivation Letter For PHD ApplicationDocument1 pageMotivation Letter For PHD ApplicationSakhawat Hussain100% (4)

- Thyssenkrupp s355jr Product Information Precision Steel en PDFDocument2 pagesThyssenkrupp s355jr Product Information Precision Steel en PDFjackcan501No ratings yet

- Portfolio - ZAN HD OT 20Document2 pagesPortfolio - ZAN HD OT 20fredNo ratings yet

- Code Title AuthorDocument45 pagesCode Title AuthorfoiaxxoNo ratings yet

- Unleash The Scientist Within YouDocument4 pagesUnleash The Scientist Within YouGleynne MilloradaNo ratings yet

- To Determine The V Curve of A Synchronous MotorDocument3 pagesTo Determine The V Curve of A Synchronous MotorAthay khanNo ratings yet