Professional Documents

Culture Documents

Kriwan Ops 1 Oil Pressure Sensor

Kriwan Ops 1 Oil Pressure Sensor

Uploaded by

alasad4everOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kriwan Ops 1 Oil Pressure Sensor

Kriwan Ops 1 Oil Pressure Sensor

Uploaded by

alasad4everCopyright:

Available Formats

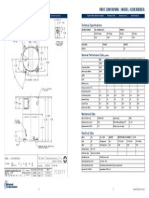

Oil Pressure Differential Switch OPS1

Technical data:

Supply voltage AC 50/60 Hz 230V +/− 10% 10VA

Ambient temperature range -30…..+60°C

Time delay 120 s

Cut-in pressure (fixed) 0,95 bar +/- 0,15 bar

Cut-out pressure (fixed) 0,63 bar +/- 0,15 bar

Switching capacity AC 250 V, max. 2,5A, 720 VA ind.

Refrigerant compatibility yes (brass)

Protection class according EN 60529 IP54

Reset manual

Connection cable 2

4xAWG20 (0,5 mm ), L=1m colour

coded cores

Application: Weight ca. 200 g

Monitoring the oil differential pressures in refrigeration

compressors. The pressure sensor of the oil differential Installation Advice:

switch is directly screwed into the pump housing of the

compressor. Internal channels link the switch to the suction 1. Evacuate the compressor and close the shut-off valves.

and discharge ports of the oil pump. No capillary connections Follow the correct codes of practice for refrigeration sys-

are necessary. The electronic switch can be fitted or removed tems.

without opening the refrigeration circuit.

2. Remove the blind plug from the oil pump housing, clean

Functional description: the thread.

The differential pressure monitor is activated when the supply

voltage is applied via an auxiliary contact of the motor 3. Screw the OPS1 screw-unit with O-ring and Cu- washer

contactor K1. A red LED signals insufficient differential oil very carefully into the pump housing (Caution! O-ring!).

pressure immediately. Once the pre-set value has been Tightening torque appr. 75 Nm.

reached, the LED is extinguished. The output contact remains

closed when the set value is reached/ exceeded. If the oil 4. Screw the OPS1 electronic-unit into the cleaned blind hole

differential pressure remains or drops below the set value for and tighten by hand (appr. 10 Nm). Pay attention to the di-

longer than the time delay time, the output contact opens and rection of the electrical leads.

locks out mechanically. Depressing the reset button can

reactivate the switch. Shorter periods of insufficient differen- 5. Make the electrical connections according to wiring dia-

tial pressure are also recognised by the internal microproces- gram.

sor circuitry and lead to a trip and lockout after correspond-

ingly extended delay time. (integration). 6. Evacuate the compressor again to extract the air from it,

open the service valves after proper evacuation and check

the oil pressure switch connection for tightness.

Commissioning:

1. Switch on the compressor and wait until the achieved stable

operating conditions have been obtained.

2. If insufficient oil differential pressure is built up during start

up, or during operation and, after the time delay expires, the

output contact switches off and mechanically locks out. The

power supply to the contactor coil is interrupted and the com-

pressor is switched off.

3. Restart is possible after approximately 3 minutes allowing

cool down and manual reset.

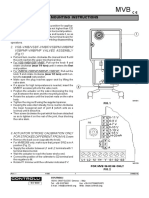

Wiring diagram

Subject to technical modifications without notice!

ATrained electrical personnel must connect the unit. All

valid standards for connecting electrical and refrigeration

equipment must be observed. Limit values for the supply

voltage of the unit may not be exceeded. The oil differential 0700-30000XX

switch needs no maintenance.

You might also like

- Info Iec61800-3 (Ed4.0) BDocument21 pagesInfo Iec61800-3 (Ed4.0) BRohit GoyalNo ratings yet

- DCB31 Eng.Document15 pagesDCB31 Eng.Aimad ChamsaouiNo ratings yet

- Copeland Scroll Compressors Specifications AC Models Only PDFDocument32 pagesCopeland Scroll Compressors Specifications AC Models Only PDFDang Anh Tuan100% (1)

- Body + ElectricalDocument259 pagesBody + Electricalnels26No ratings yet

- WDH-SL3 Product Information SP13L002GB-04 - 1542713324933Document2 pagesWDH-SL3 Product Information SP13L002GB-04 - 1542713324933irwantino susiloNo ratings yet

- Fxaq-Avm Wall Mounted Type 60 HZDocument18 pagesFxaq-Avm Wall Mounted Type 60 HZsander1234silvaNo ratings yet

- Samsung Floor Standing TypeDocument101 pagesSamsung Floor Standing TypeJievejel BibonNo ratings yet

- Dorin H2Document6 pagesDorin H2frigoremontNo ratings yet

- Comp Carly Semi Accy 2004Document26 pagesComp Carly Semi Accy 2004Deco DluxeNo ratings yet

- Compresseur Danfoss Secop sc21cl PDFDocument2 pagesCompresseur Danfoss Secop sc21cl PDFOscar MendozaNo ratings yet

- 30hxyhxc-High Cop 2012Document12 pages30hxyhxc-High Cop 2012Luciano Lopes Simões100% (2)

- Electrical Components Aspera PDFDocument40 pagesElectrical Components Aspera PDFFrancisco Edivando Agostinho AraujoNo ratings yet

- Air Cooled Screw Chiller: Model: EKAS093 EKAS420 Apollo SerialDocument52 pagesAir Cooled Screw Chiller: Model: EKAS093 EKAS420 Apollo SerialIb es100% (1)

- H23A383DBEADocument1 pageH23A383DBEABruno Monteiro0% (1)

- Technical Manual For Air-Cooled Rooftop Package - (FDXA04-2020,21B)Document32 pagesTechnical Manual For Air-Cooled Rooftop Package - (FDXA04-2020,21B)yusuf mohd sallehNo ratings yet

- Plethysmometer Instraction ManualDocument39 pagesPlethysmometer Instraction ManualJaime Ferrer100% (1)

- DVMDocument104 pagesDVMNha TrangNo ratings yet

- z0011134-Ix-Ahtc Water Cooled ChillerDocument50 pagesz0011134-Ix-Ahtc Water Cooled Chillerarif1993100% (1)

- Kappa V EvoDocument100 pagesKappa V EvoBaltik2672No ratings yet

- Manual Equipo 1Document200 pagesManual Equipo 1Wakko20IPNNo ratings yet

- York DXS Parts BreakdownDocument10 pagesYork DXS Parts Breakdownernesto adan aroche paulNo ratings yet

- 40LX Ceiling Concealed CCAC InstallationDocument17 pages40LX Ceiling Concealed CCAC Installationjeferson binayNo ratings yet

- Hitachi RPIZ PDFDocument21 pagesHitachi RPIZ PDFLuis Leiva SanchezNo ratings yet

- SVM-16004 Ras-20s3acv-Id PDFDocument78 pagesSVM-16004 Ras-20s3acv-Id PDFdafrie rimba0% (1)

- Daikin Screw CompressorsDocument4 pagesDaikin Screw CompressorsJevgenijs KoževnikovsNo ratings yet

- Controls Operation and TroubleshootingDocument138 pagesControls Operation and TroubleshootingAnup SurendranNo ratings yet

- Water-Cooled Screw Chiller - WZY SeriesDocument11 pagesWater-Cooled Screw Chiller - WZY SeriesAbdulSattar100% (1)

- 002 Selection Danfoss. TE5, TE55 PDFDocument27 pages002 Selection Danfoss. TE5, TE55 PDFIskandar FirdausNo ratings yet

- Kcn430Lal-Bxxxh B330H, B331H: Emerson Climate Technologies (India) LimitedDocument6 pagesKcn430Lal-Bxxxh B330H, B331H: Emerson Climate Technologies (India) LimitedRaja Velu100% (1)

- Copeland WeldedDocument198 pagesCopeland WeldedjnamatheNo ratings yet

- VCV WesperDocument12 pagesVCV Wesperciperu55No ratings yet

- APCYDocument64 pagesAPCYChachou MohamedNo ratings yet

- Henry: Soft Copper Capillary TubingDocument3 pagesHenry: Soft Copper Capillary Tubingikhsan centralacNo ratings yet

- 5998 - 5998 - Carrier 30 GH 100 PDFDocument16 pages5998 - 5998 - Carrier 30 GH 100 PDFbilal almelegyNo ratings yet

- Acson Catalogue Air Handling Unit (1201)Document12 pagesAcson Catalogue Air Handling Unit (1201)William Ball50% (4)

- Parts List PC CompressorDocument20 pagesParts List PC CompressorSyed Ali KhanNo ratings yet

- Expansion Valve - 100-20-1Document12 pagesExpansion Valve - 100-20-1Edimar Luz FilhoNo ratings yet

- Manual Controlli MVB56Document2 pagesManual Controlli MVB56dwNo ratings yet

- SAB 193-233-283 Screw Compressor Unit: Spare Parts ManualDocument58 pagesSAB 193-233-283 Screw Compressor Unit: Spare Parts ManualMário OliveiraNo ratings yet

- Product Data: Features/BenefitsDocument60 pagesProduct Data: Features/BenefitsBJNE01No ratings yet

- OVUR-type Oil Separator: Installation, Operation and Maintenance ManualDocument8 pagesOVUR-type Oil Separator: Installation, Operation and Maintenance Manualmiguel callata0% (1)

- RTWS - 265kW - Product ReportDocument2 pagesRTWS - 265kW - Product ReportPham Thien TruongNo ratings yet

- KKTchillers KPC115-L-U S 224Document106 pagesKKTchillers KPC115-L-U S 224Eduardo JoseNo ratings yet

- Bitzer CSH Series To Fusheng BSR SeriesDocument39 pagesBitzer CSH Series To Fusheng BSR SeriesLiviu Popa100% (2)

- JT Pressure SwitchesDocument5 pagesJT Pressure SwitchesPHÁT NGUYỄN THẾNo ratings yet

- FD310 Apf189575 IbDocument100 pagesFD310 Apf189575 Ibbui vietNo ratings yet

- TecumsehDocument6 pagesTecumsehAndi SantikaNo ratings yet

- Danfoss Production PDFDocument68 pagesDanfoss Production PDFBach Nguyen Van67% (3)

- Electronic Expansion Valves Type TQPHTQDocument2 pagesElectronic Expansion Valves Type TQPHTQvickersNo ratings yet

- Viscosity Index When Selecting A LubricantDocument6 pagesViscosity Index When Selecting A LubricantANGEL MURILLONo ratings yet

- Field Connections Model Yk Chillers (Style F and G) With Variable Speed DriveDocument10 pagesField Connections Model Yk Chillers (Style F and G) With Variable Speed DriveJose CuevasNo ratings yet

- Installation Operation Maintenance: Air-Cooled Scroll ChillersDocument276 pagesInstallation Operation Maintenance: Air-Cooled Scroll ChillersCésarVanegasNo ratings yet

- PA65H1E-4Document28 pagesPA65H1E-4أبو زينب المهندسNo ratings yet

- ZXV Launch Presentation - Jan, 2020Document22 pagesZXV Launch Presentation - Jan, 2020Dương Tấn TàiNo ratings yet

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideFrom EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideRating: 5 out of 5 stars5/5 (1)

- DELTA-P Oil Differential Pressure Switch: ApplicationDocument1 pageDELTA-P Oil Differential Pressure Switch: ApplicationWALTER RUEDANo ratings yet

- A5e02261863a 02 201210291111411944Document7 pagesA5e02261863a 02 201210291111411944Lucas Fuzeto VizoniNo ratings yet

- Water Level Limiter 932 (Instruction of Use)Document2 pagesWater Level Limiter 932 (Instruction of Use)Miraz RahmanNo ratings yet

- En TI D070801 OilPressureSafety 0Document10 pagesEn TI D070801 OilPressureSafety 0Miguel MartinezNo ratings yet

- PT810C - Control de PresiónDocument12 pagesPT810C - Control de PresiónAndrey VegaNo ratings yet

- P7810C Pressuretrol® Controller: FeaturesDocument12 pagesP7810C Pressuretrol® Controller: FeaturesNebur MtzaNo ratings yet

- FD113 Oil Pressure Safety ControlDocument4 pagesFD113 Oil Pressure Safety ControlOnofreNo ratings yet

- Konka Kp2107astn SMDocument14 pagesKonka Kp2107astn SMrhozel2010No ratings yet

- STM ObjectDetection Catalog PDFDocument164 pagesSTM ObjectDetection Catalog PDFDavid SalazarNo ratings yet

- Sony Sawm500Document2 pagesSony Sawm500Dave BellNo ratings yet

- Digital Signal Processing - 13EC302Document3 pagesDigital Signal Processing - 13EC302DrVaibhav MeshramNo ratings yet

- Configuring Layer 3 SwitchingDocument18 pagesConfiguring Layer 3 SwitchingShili WalaNo ratings yet

- CCNA Router Lab TopologyDocument126 pagesCCNA Router Lab TopologynellaNo ratings yet

- Datos Tecnicos Acelerometro AC102-1ADocument1 pageDatos Tecnicos Acelerometro AC102-1AIvan DuranNo ratings yet

- EST Sample Problems 09Document4 pagesEST Sample Problems 09Genesis PinedaNo ratings yet

- Half Power Bandwidth PDFDocument10 pagesHalf Power Bandwidth PDFnemaderakeshNo ratings yet

- GenesysAerosystems - System 60-2Document2 pagesGenesysAerosystems - System 60-2Alex ProkonovNo ratings yet

- Digital Filters For Coherent Optical ReceiversDocument14 pagesDigital Filters For Coherent Optical ReceiversZainab FaydhNo ratings yet

- Expansor EP-06Document5 pagesExpansor EP-06cronica.motaNo ratings yet

- Kelompok 10 (Hasil Cek Plagiasi)Document15 pagesKelompok 10 (Hasil Cek Plagiasi)Diah Restu AnariNo ratings yet

- Wecon Vd3e B Type Servo FlyerDocument7 pagesWecon Vd3e B Type Servo FlyeroscarNo ratings yet

- Control de Nivel ParkerDocument2 pagesControl de Nivel ParkerJorge Barrón OlveraNo ratings yet

- 694853397a773d3d PDFDocument1 page694853397a773d3d PDFAlooomNo ratings yet

- Digital Measurement Techniques-EIC703Document3 pagesDigital Measurement Techniques-EIC703sitaram_1No ratings yet

- Samsung Gt-m8910 Pixon12 Service Manual (Nizam)Document32 pagesSamsung Gt-m8910 Pixon12 Service Manual (Nizam)kamil_yilmaz_6No ratings yet

- PAW3805EK-CJV2 Brief-V1.3 27062017Document1 pagePAW3805EK-CJV2 Brief-V1.3 27062017rreglosNo ratings yet

- CAN Bus Reverse Engineering Using Vehicle Spy 3Document27 pagesCAN Bus Reverse Engineering Using Vehicle Spy 3RonalD gamarraNo ratings yet

- DATASHEET Gocator 2600 US HDR WEB-2Document2 pagesDATASHEET Gocator 2600 US HDR WEB-2tvngzrcxtrNo ratings yet

- LOWW Arrival RNAV Transition 16 26052016Document5 pagesLOWW Arrival RNAV Transition 16 26052016Дима ГирманNo ratings yet

- IOT Light Control SystemDocument7 pagesIOT Light Control SystemJanakiramanNo ratings yet

- U952p PRDocument3 pagesU952p PRszlaciba2_326117182No ratings yet

- Multeq-X User Guide V1.0 © 2021 Audyssey Laboratories, Inc. All Rights ReservedDocument35 pagesMulteq-X User Guide V1.0 © 2021 Audyssey Laboratories, Inc. All Rights ReservedSarvesh KumarNo ratings yet

- International StandardDocument32 pagesInternational StandardHOSSEINNo ratings yet

- CCf825 - INST - OPS R1 (1) .2 PDFDocument386 pagesCCf825 - INST - OPS R1 (1) .2 PDFRoman U100% (1)

- McIntosh MC2105 Solid State Stereo Power Amplifier Manual HiFi EngineDocument1 pageMcIntosh MC2105 Solid State Stereo Power Amplifier Manual HiFi EngineRudy RolonNo ratings yet