0 ratings0% found this document useful (0 votes)

18 viewsK-2801B November 08 2023

K-2801B November 08 2023

Uploaded by

rizfian1927The document provides a predictive maintenance report for refrigerant compressor B (K-2801B) at the DPCU area of MOPU Prameswari 8. Vibration measurements and thermal images were taken. The highest vibration was found at the motor's horizontal NDE point, but was stable and within acceptable limits. Spectrum data showed peaks indicating potential misalignment between the motor and compressor. Thermal images showed the motor and compressor were in normal condition. The report recommends continuing monitoring and checking alignment opportunities, but finds the current condition of the equipment is acceptable.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

K-2801B November 08 2023

K-2801B November 08 2023

Uploaded by

rizfian19270 ratings0% found this document useful (0 votes)

18 views11 pagesThe document provides a predictive maintenance report for refrigerant compressor B (K-2801B) at the DPCU area of MOPU Prameswari 8. Vibration measurements and thermal images were taken. The highest vibration was found at the motor's horizontal NDE point, but was stable and within acceptable limits. Spectrum data showed peaks indicating potential misalignment between the motor and compressor. Thermal images showed the motor and compressor were in normal condition. The report recommends continuing monitoring and checking alignment opportunities, but finds the current condition of the equipment is acceptable.

Original Description:

Vibration report

Original Title

K-2801B_November_08_2023

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The document provides a predictive maintenance report for refrigerant compressor B (K-2801B) at the DPCU area of MOPU Prameswari 8. Vibration measurements and thermal images were taken. The highest vibration was found at the motor's horizontal NDE point, but was stable and within acceptable limits. Spectrum data showed peaks indicating potential misalignment between the motor and compressor. Thermal images showed the motor and compressor were in normal condition. The report recommends continuing monitoring and checking alignment opportunities, but finds the current condition of the equipment is acceptable.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

18 views11 pagesK-2801B November 08 2023

K-2801B November 08 2023

Uploaded by

rizfian1927The document provides a predictive maintenance report for refrigerant compressor B (K-2801B) at the DPCU area of MOPU Prameswari 8. Vibration measurements and thermal images were taken. The highest vibration was found at the motor's horizontal NDE point, but was stable and within acceptable limits. Spectrum data showed peaks indicating potential misalignment between the motor and compressor. Thermal images showed the motor and compressor were in normal condition. The report recommends continuing monitoring and checking alignment opportunities, but finds the current condition of the equipment is acceptable.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 11

MOPU PRAMESWARI 8

Predictive Maintenance Report

Date : November 08th , 2023

Area : DPCU

Equip. Name : Refrigerant Compressor B

Tag No. : K-2801B

Wo No. :-

Prepared By : Rizfian

Table Of Content

1. Introduction .................................................................................................................... 2

2. Resume of Finding and Recommendation ..................................................................... 2

2.1 Finding .......................................................................................................................... 2

2.2 Recommendation ......................................................................................................... 2

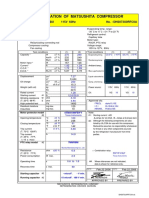

3. Unit Spesification ............................................................................................................ 3

3.1 Equipment Identity ....................................................................................................... 3

3.2 Measurement Point Scheme ........................................................................................ 3

3.3 Analysis Parameter Setting ........................................................................................... 3

4. Measurement Data ......................................................................................................... 4

4.1 Operation Parameter.................................................................................................... 4

4.2 Overall Vibration and Trends (IPS RMS) ....................................................................... 4

4.3 Vibration Spectrum Data .............................................................................................. 6

5. Thermography .............................................................................................................. 10

K-2801B PDM-Prameswari 8 Page 1 of 11

1. Introduction

Predictive Maintenance is a part of maintenance program at MOPU Prameswari 8. The

Purpose of this program is to gain control of plant machinery, significantly reducing

maintenance cost, increasing productivity, improving product quality, achieve plant reliability

and profitability.

2. Resume of Finding and Recommendation

2.1 Finding and Analysis

▪ The highest vibration is 0.148 IPS (RMS) at NDE motor horizontal (M1H) and stable from

previous measurement.

▪ Spetrum data shows dominant peaks at 1X, 2X & 5X TS, Indicates misalignment problem

between motor & compressor.

▪ Blade pass frequency (5xTS) at compressor has appear with acceptable limit.

▪ Thermal image pattern at motor and compressor shows normal condition.

2.2 Recommendation

▪ Equipment (motor and compressor) are acceptable to operated.

▪ Please check alignment if any opportunity.

▪ Continue monitoring to see the vibration trending and thermal image pattern.

K-2801B PDM-Prameswari 8 Page 2 of 11

3. Unit Spesification

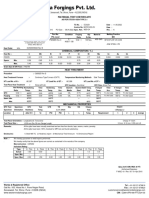

3.1 Equipment Identity

Equipment : Refrigerant Compressor B

Area : DPCU

Tag Number : K-2801B

Driver : Motor

Connection : Coupling (Disc)

Driven : Screw Compressor

Power Rate : 280 kW

Driver RPM : 3582

Driven RPM : 3582

Support : Rigid

Driver Standard : ISO 10816-3

Driven Standard : ISO 10816-3

Bearing Driver DE : 6319/C3

Baring Driver NDE : 6319/C3

Bearing Driven DE : Journal Bearing

Bearing Driven NDE : Journal Bearing

3.2 Measurement Point Scheme

3.3 Analysis Parameter Setting

Analyzer VibXpert II Single channel

AP Set Standard Measurment Vel. /2-1600 Hz/ 2 lin. / Δf 1 Hz

AP Set Bearing Measurement Roll.bear.enve. 800Hz 0.5Hz

Sensor VIB 6.142

Measurement Mode Continous Measurement

K-2801B PDM-Prameswari 8 Page 3 of 11

4. Measurement Data

4.1 Operation Parameter

2023

No Description th th

Limit Unit

Sept 20 Nov 08

1 Fro P Suc 1.62 1.88 Bar

2 P_Exh 13.67 15.47 Bar

3 P_Oil 11.98 13.78 Bar

4 Suction Filter -0.94 -0.88 Bar

5 Location 100 100 %

6 Current 35.6 35.6 A

7 T_Oil 50.3 52.7 °C

8 T_Oil Sep 59.7 61.6 °C

9 T Suc -14.9 -10.2 °C

10 T_A Winding 105.4 105.8 °C

11 T_B Winding 98.8 99.3 °C

12 T_C Winding 110.9 111.5 °C

13 T_Bearing 65.4 66.3 °C

14 T-Un_Bearing 52.8 53.7 °C

15 Oil Sep. Level 553.8 555.1 mm

16 DP_Oil Filter 0.95 0.95 Bar

17 T_Exh 67.5 67.9 °C

4.2 Overall Vibration and Trends (IPS RMS)

Standard ISO 10816-3

Alarm(C) 0.18 Danger (D) 0.28

Description Point Unit 20-Sep-23 9-Oct-23 08-Nov-23

NDE M1H IPS RMS 0.185 0.142 0.148

NDE M1V IPS RMS 0.1 0.122 0.087

NDE M1A IPS RMS 0.047 0.057 0.046

Motor

DE M2H IPS RMS 0.065 0.121 0.044

DE M2V IPS RMS 0.063 0.079 0.047

DE M2A IPS RMS 0.032 0.041 0.023

DE C1H IPS RMS 0.065 0.076 0.072

DE C1V IPS RMS 0.041 0.053 0.056

DE C1A IPS RMS 0.092 0.083 0.094

Compressor

NDE C2H IPS RMS 0.06 0.051 0.054

NDE C2V IPS RMS 0.045 0.046 0.062

NDE C2A IPS RMS 0.103 0.082 0.1

K-2801B PDM-Prameswari 8 Page 4 of 11

The trends show that the motor vibrations were stable within the acceptable level.

The trends show that the compressor vibrations were stable within the acceptable level.

K-2801B PDM-Prameswari 8 Page 5 of 11

4.3 Vibration Spectrum Data

▪ M1H-Motor NDE Horizontal

▪ M1V-Motor NDE Vertical

▪ M1A-Motor NDE Axial

K-2801B PDM-Prameswari 8 Page 6 of 11

▪ M2H-Motor DE Horizontal

▪ M2V-Motor DE Vertical

▪ M2A-Motor DE Axial

K-2801B PDM-Prameswari 8 Page 7 of 11

▪ C1H-Compressor DE Horizontal

▪ C1V-Compressor DE Vertical

▪ C1A-Compressor DE Axial

K-2801B PDM-Prameswari 8 Page 8 of 11

▪ C2H-Compressor NDE Horizontal

▪ C2V-Compressor NDE Vertical

▪ C2A-Compressor NDE Axial

K-2801B PDM-Prameswari 8 Page 9 of 11

5. Thermography

Description Thermal Image (0C)

Motor

Compressor

K-2801B PDM-Prameswari 8 Page 10 of 11

Based on Thermal Pattern (qualitative method), the equipment is good condition.

K-2801B PDM-Prameswari 8 Page 11 of 11

You might also like

- FichaTecnica LX95LAQHDocument8 pagesFichaTecnica LX95LAQHaugusto izquiel50% (4)

- P-2801B-1 November 08 2023Document9 pagesP-2801B-1 November 08 2023rizfian1927No ratings yet

- NT2212GKV2 925CD02Document2 pagesNT2212GKV2 925CD02Rajeesh P RaviNo ratings yet

- Gas Line Size ResultDocument3 pagesGas Line Size Resultjenish parekhNo ratings yet

- G-7501A November 12 2023Document9 pagesG-7501A November 12 2023rizfian1927No ratings yet

- 362Document2 pages362Ajay AsodariyaNo ratings yet

- Test SheetDocument3 pagesTest SheetNemo NeoNo ratings yet

- 2 Phase VerticalDocument4 pages2 Phase VerticalJAZEEL ALAVINo ratings yet

- Ntu6238gkv2 925ed60Document2 pagesNtu6238gkv2 925ed60Manuel MolinaNo ratings yet

- Report Vibrasi Plant CP-2Document13 pagesReport Vibrasi Plant CP-2hafiz_hayat_44190215No ratings yet

- A11627SE-04 - CVDS Rev C Technical Specification 840GDocument2 pagesA11627SE-04 - CVDS Rev C Technical Specification 840GMichael Adu-boahenNo ratings yet

- A11627SE-08 - CVDS Rev B Technical Specification 840GDocument2 pagesA11627SE-08 - CVDS Rev B Technical Specification 840GMichael Adu-boahenNo ratings yet

- Baru - Aux Engine Performance Reports March 2022Document12 pagesBaru - Aux Engine Performance Reports March 2022Dragoș GreceanuNo ratings yet

- NT2180GKV2 923MD04Document2 pagesNT2180GKV2 923MD04Christian DelgadoNo ratings yet

- E-1801A-02 November 7 2023Document8 pagesE-1801A-02 November 7 2023rizfian1927No ratings yet

- PCH Series: Btu/h Kcal/h Watt TR Btu/h Kcal/h Watt TR % Btu/h.WattDocument1 pagePCH Series: Btu/h Kcal/h Watt TR Btu/h Kcal/h Watt TR % Btu/h.WattrianartoNo ratings yet

- Data Motor & Pump-1Document29 pagesData Motor & Pump-1naspauzanNo ratings yet

- C56 FDDocument198 pagesC56 FDneomar BaptistaNo ratings yet

- Lionn Auto SoftwaresDocument2 pagesLionn Auto SoftwaresLIONN ONESOLUTIONNo ratings yet

- Water Cooled Centrifugal Chiller: Technical Data SheetDocument2 pagesWater Cooled Centrifugal Chiller: Technical Data SheetNguyễn Hồng TháiNo ratings yet

- Jadestone Re-Cylinder Project On MH64 10H1324-96 Higher Flow Option (6.75 ND)Document5 pagesJadestone Re-Cylinder Project On MH64 10H1324-96 Higher Flow Option (6.75 ND)basvkaranNo ratings yet

- FichaTecnica LA95LAQHDocument8 pagesFichaTecnica LA95LAQHkelvis castroNo ratings yet

- 3233 FileversionDocument44 pages3233 FileversionJulioNo ratings yet

- Man 372 Diesel Fuel Pump Test SheetDocument3 pagesMan 372 Diesel Fuel Pump Test SheetTamer Moustafa100% (1)

- Pre Oh Survey U2 NSPCL RourkelaDocument8 pagesPre Oh Survey U2 NSPCL RourkelaSameer KulkarniNo ratings yet

- Air Cooled Screw Chiller Performance DatasheetDocument2 pagesAir Cooled Screw Chiller Performance DatasheetJuan Carlos Soto OrihuelaNo ratings yet

- Compression SelectionDocument2 pagesCompression SelectionIrfan HilmanNo ratings yet

- 1900 - EC2157-signedDocument4 pages1900 - EC2157-signedDeepak HoleNo ratings yet

- 1485 - Ec0251Document6 pages1485 - Ec0251Deepak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 108622-2371 TDDocument4 pages108622-2371 TDririnmars22No ratings yet

- Ffi12bx1 513200085Document2 pagesFfi12bx1 513200085Leonardo FernandesNo ratings yet

- NE6188CZDocument9 pagesNE6188CZhobolghaniNo ratings yet

- 100 615 - DE - Booster - 1pump - Standby - SubmittalDocument10 pages100 615 - DE - Booster - 1pump - Standby - SubmittalEfrain CorroNo ratings yet

- ISCH RotaryAC-Comp 2P20S3R126B1A SpecSheetDocument2 pagesISCH RotaryAC-Comp 2P20S3R126B1A SpecSheetoscar emilio SalasNo ratings yet

- Cat2p14s126b 1hDocument2 pagesCat2p14s126b 1hsara carneiroNo ratings yet

- nle80cn_105h6074_r290_115v_60hz_07-2024_dsDocument8 pagesnle80cn_105h6074_r290_115v_60hz_07-2024_dsdejesus.alonso.cetis105No ratings yet

- Chiller InductorDocument2 pagesChiller InductorAlberto Steven Ospino GómezNo ratings yet

- V-Cone® Preliminary Sizing: by CPI Ingenieria y Admon. de Proyectos S.A. de C.VDocument1 pageV-Cone® Preliminary Sizing: by CPI Ingenieria y Admon. de Proyectos S.A. de C.VManuel Carvajal GrajalesNo ratings yet

- Consolidate dataDocument6 pagesConsolidate dataManishNo ratings yet

- Aeef 60HP 4PDocument2 pagesAeef 60HP 4PBlessy GollenaNo ratings yet

- Matsushita DHS73C12RBU Compressor Spec SheetDocument1 pageMatsushita DHS73C12RBU Compressor Spec SheetBenjamin DoverNo ratings yet

- 2P18S236A-1A: Panasonic Industrial CompanyDocument2 pages2P18S236A-1A: Panasonic Industrial CompanyPablo Burgos100% (1)

- Aesv1s-N 4P 55KW 380KW 50HZ SpecDocument1 pageAesv1s-N 4P 55KW 380KW 50HZ SpecAchmad KNo ratings yet

- 0P16-I-IN-DTS-01-007 Datasheet For Temperature Gauge - Rev2Document6 pages0P16-I-IN-DTS-01-007 Datasheet For Temperature Gauge - Rev2fathan fathullahNo ratings yet

- ME Performance Test 25.11.2022Document3 pagesME Performance Test 25.11.2022Taha FaNo ratings yet

- TEK20141027023SPECDocument1 pageTEK20141027023SPECHary FadlyNo ratings yet

- Datasheet H2930uabc MetricoDocument1 pageDatasheet H2930uabc MetricoRodrigo J. MarqueziniNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- Compressor Specifications H2DA124DBELDocument1 pageCompressor Specifications H2DA124DBELCarlos José CastorinaNo ratings yet

- MPBA1con 40 Psi en SucciónDocument1 pageMPBA1con 40 Psi en SucciónleonnelNo ratings yet

- 2K20S3R236A-6B: Panasonic Industrial CompanyDocument22 pages2K20S3R236A-6B: Panasonic Industrial CompanyGeiler Benitez PiñaNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)lionnautosoftwares2No ratings yet

- Consolidate Data R2Document11 pagesConsolidate Data R2ManishNo ratings yet

- v4555 PipDocument7 pagesv4555 Pipbdrepublicadominicana2020No ratings yet

- Compressor Specifications - © Bristol Compressors International, IncDocument1 pageCompressor Specifications - © Bristol Compressors International, IncWall Art VenezuelaNo ratings yet

- Selection Sheet PFS1101DBRYV CEWT Final RevisedDocument1 pageSelection Sheet PFS1101DBRYV CEWT Final Reviseder_bhavinNo ratings yet

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Hydraulic Trip Interface Failure Probabilities and Spurious Trip RatesDocument17 pagesHydraulic Trip Interface Failure Probabilities and Spurious Trip RatesEliyanto E BudiartoNo ratings yet

- Airport DrainageDocument4 pagesAirport DrainageSaddaqat100% (1)

- Usfull Solar Pump Inverter Catalog 2021Document12 pagesUsfull Solar Pump Inverter Catalog 2021علاء البناء100% (1)

- AASTU Engineering Geology Chapter 4FCEDocument65 pagesAASTU Engineering Geology Chapter 4FCEnaod nasirNo ratings yet

- 4as TemplateDocument3 pages4as TemplateJaranilla VianingNo ratings yet

- Analiza Material Rai Henek Mota Ratau (Quarry) Ba Sub Base Course IntroduzaunDocument3 pagesAnaliza Material Rai Henek Mota Ratau (Quarry) Ba Sub Base Course IntroduzaunJerogas Kadeli100% (1)

- AP Physics 1 - Motion QuestionsDocument14 pagesAP Physics 1 - Motion QuestionsAnonymous RzU94z100% (1)

- Session 9 Ch7Document3 pagesSession 9 Ch7Trung Kiên NguyễnNo ratings yet

- SBM-1st-Quarter-week-2-scientific-method EditedDocument14 pagesSBM-1st-Quarter-week-2-scientific-method Editedmonica saturninoNo ratings yet

- Concept and Theory of AgeingDocument26 pagesConcept and Theory of Ageinghoneyy825No ratings yet

- Literature Review Shams Ul Mulk IFE-18833Document13 pagesLiterature Review Shams Ul Mulk IFE-18833safder aliNo ratings yet

- Chapter Statics, Lecture Notes, Chapter 5Document74 pagesChapter Statics, Lecture Notes, Chapter 5RayanNo ratings yet

- Indian Community School KuwaitDocument4 pagesIndian Community School KuwaitAadhiseshan ManojNo ratings yet

- ASERD - GHANA Call For FacilitatorsDocument3 pagesASERD - GHANA Call For FacilitatorsSule SeiduNo ratings yet

- 1967 Cape Gelidonya A Bronze Age ShipwreDocument137 pages1967 Cape Gelidonya A Bronze Age ShipwreMarco FreitasNo ratings yet

- S0600 Aa Pro 130Document23 pagesS0600 Aa Pro 130opruzhak-boxNo ratings yet

- Animal ModelsDocument21 pagesAnimal ModelsSudarshan UpadhyayNo ratings yet

- Psychology and Consumer Behavior: Annals of The University of Petroşani, Economics, 18 (2), 2018, 119-126 119Document9 pagesPsychology and Consumer Behavior: Annals of The University of Petroşani, Economics, 18 (2), 2018, 119-126 119Nourhane CHEBABNo ratings yet

- CFA ScholarshipDocument2 pagesCFA ScholarshipiamdarshandNo ratings yet

- midterm-in-FINANCIAL ANANLYSISDocument6 pagesmidterm-in-FINANCIAL ANANLYSISHazel VelosoNo ratings yet

- Chapter 14 - The Russian CoreDocument4 pagesChapter 14 - The Russian CoreCaitlinKyawNo ratings yet

- Technical ReportDocument40 pagesTechnical ReportmelskureNo ratings yet

- 2024 ESW Book Draft FINAL20240228 SMDocument226 pages2024 ESW Book Draft FINAL20240228 SMcookiesNo ratings yet

- Li Et Al - SHRINK-SWELL INDEX DATABASE FOR MELBOURNEDocument16 pagesLi Et Al - SHRINK-SWELL INDEX DATABASE FOR MELBOURNETharun DelpachitraNo ratings yet

- Clinical Study ProtocalDocument13 pagesClinical Study ProtocalSparsh SharmaNo ratings yet

- Wilson2017 Article LeonhardEulerDocument1 pageWilson2017 Article LeonhardEulerHao-Nhien Q. VuNo ratings yet

- Organizational Commitment and Expertise in Determining Community Satisfaction Through Good Governance Quality of Community Services and Community EmpowermentJournal of The Knowledge EconomyDocument16 pagesOrganizational Commitment and Expertise in Determining Community Satisfaction Through Good Governance Quality of Community Services and Community EmpowermentJournal of The Knowledge Economybungalily102No ratings yet

- Indigenous and Modern Environmental EthicsDocument358 pagesIndigenous and Modern Environmental EthicsAbiyot NegeraNo ratings yet

- Mini ProjectDocument11 pagesMini Project20WH1A04A6 YALAGAM SUPRIYANo ratings yet

- Earth Hour Is A Worldwide Movement Organized by The: (Hide)Document4 pagesEarth Hour Is A Worldwide Movement Organized by The: (Hide)Andreea IacobNo ratings yet