20 VL

20 VL

Uploaded by

Umair RaisCopyright:

Available Formats

20 VL

20 VL

Uploaded by

Umair RaisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

20 VL

20 VL

Uploaded by

Umair RaisCopyright:

Available Formats

20VL Series

www.vishay.com

Vishay Cera-Mite

EMI Suppression Capacitor, Ceramic Disc,

Class X2, 400 VAC

FEATURES

• Complying with IEC 60384-14

• High reliability

• Radial leads

• Singlelayer AC disc safety capacitors

• Material categorization: for definitions of

compliance please see www.vishay.com/doc?99912

APPLICATIONS

• X2 according to IEC 60384-14

• Line-to-line filtering (Class X)

• EMI / RFI suppression and filtering

QUICK REFERENCE DATA

DESCRIPTION VALUE DESIGN

Ceramic Class 2 The capacitors consist of a ceramic disc of which both sides

Ceramic Dielectric Y5V Z5U are silver-plated. Connection leads are made of tinned

copper having a diameter of 0.025" (0.64 mm). The

Voltage (VAC) 400 400

capacitors may be supplied with radial kinked or straight

Min. Capacitance (pF) 9000 10 000 leads having a lead spacing of 0.375" (9.5 mm) or 0.250"

Max. Capacitance (pF) 100 000 10 000 (6.4 mm). The standard tolerance is ± 20 %. Coating is

made of flame retardant epoxy resin in accordance

Mounting Radial

with “UL 94 V-0.”

INSULATION RESISTANCE

CAPACITANCE RANGE

Min. 1000 F

9 nF to 0.1 μF

TOLERANCE ON CAPACITANCE

RATED VOLTAGE

± 20 %

IEC 60384-14:

DISSIPATION FACTOR X2: 400 VAC, 50 Hz

2.0 % max. at 1 kHz; 1 V

DIELECTRIC STRENGTH BETWEEN LEADS

CERAMIC DIELECTRIC Component test, 100 % test at production line:

Y5V, Z5U 1250 VAC, 50 Hz, 2 s

As repeated test at customer side admissible only once with:

CATEGORY TEMPERATURE RANGE 1080 VAC, 50 Hz, 2 s

-25 °C to +125 °C Random sampling test (destructive test):

CLIMATIC CATEGORY ACC. TO EN 60068-1 1250 VAC, 50 Hz, 60 s

25 / 125 / 21 DIELECTRIC STRENGTH OF BODY INSULATION

OPERATING TEMPERATURE RANGE 2300 VAC, 50 Hz, 60 s (destructive test)

-30 °C to +125 °C (1)

Note

(1) For explanation about the difference of operating temperature

range and temperature characteristic of capacitance, please see

www.vishay.com/doc?48299

Revision: 23-Jul-2021 1 Document Number: 23107

For technical questions, contact: ceramitesupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

20VL Series

www.vishay.com

Vishay Cera-Mite

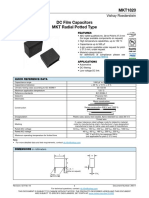

DIMENSIONS in inches (millimeters)

20VLP10-R

1.250" min. T

LO 0.187" max. max.

(32 mm)

(4.75 mm)

D

Dmax. Tinned Copper Leads LS

max. LS

Ø

1.25" min.

Tmax. (32 mm)

0.125"

max. (3.2 mm)

LO

ORDERING INFORMATION, CERAMIC X2 CAPACITORS 20VL

WIRE SIZE LS LO

Dmax. Tmax.

C TOL. LEAD SPACE LEAD OFFSET ORDERING

DIAMETER THICKNESS

(μF) (%) AWG INCH (mm) INCH (mm) INCH (mm) CODE

INCH (mm) INCH (mm)

± 1 mm ± 0.5 mm

Y5V

0.009 ± 20 0.530 (13.5) 0.150 (3.8) 0.055 (1.4) 20VLD90-R

0.010 ± 20 0.620 (15.7) 0.150 (3.8) 0.063 (1.6) 20VLS10-R

22 0.025 (0.64) 0.375 (9.5)

0.020 ± 20 0.720 (18.3) 0.150 (3.8) 0.055 (1.4) 20VLS20-R

0.100 ± 20 0.950 (24.1) 0.230 (5.8) 0.067 (1.7) 20VLP10-R

Z5U

0.010 ± 20 0.530 (13.5) 0.160 (4.1) 22 0.025 (0.64) 0.250 (6.4) 0.067 (1.7) 20VLSS10-R

Notes

• Alternate lead spacings of 7.5 mm and 10 mm are available bulk or tape and reel on request

• Minimum lead clearance according to IEC 60384-14: 0.118" (3 mm)

TAPE AND REEL OPTIONS

Part number codes and specifications for tape and reel packaging are found in the general information document

www.vishay.com/doc?23140.

APPROVALS

IEC 60384-14 - Safety tests

This approval together with CB test certificate substitutes all national approvals.

CB Certificate (www.vishay.com/doc?22247)

X2-capacitor: CB test certificate: DE1-63496 9 nF to 0.1 μF 400 VAC

VDE (www.vishay.com/doc?22246)

X2-capacitor: VDE marks approval: 40003982 9 nF to 0.1 μF 400 VAC

DIN EN 60384-14 VDE 0565-1-1 - Safety tests

Underwriters Laboratories Inc. (www.vishay.com/doc?22245)

X2-capacitor: UL test certificate: E99264 9 nF to 0.1 μF 400 VAC

UL 60384-14, CSA E60384-1, CSA E60384-14

Revision: 23-Jul-2021 2 Document Number: 23107

For technical questions, contact: ceramitesupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

20VL Series

www.vishay.com

Vishay Cera-Mite

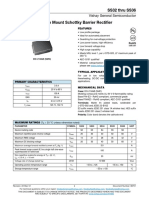

MARKING

Sample

CM

20VL 203M

IEC 60384-14

X2 400V~

XX - XXX

Notes

• Marking IEC 60384-14 does not apply for Ø 9 mm

• “XX - XXX” is a placeholder for date code and lot number:

“XX -” is the year and month according to IEC 60062

“- XXX” is the last 3 digits of the lot number

CAPACITANCE CHANGE VS. TEMPERATURE (Typical)

Axis Title

60 10000

Temperature dependence of the capacitance

40

Capacitance Change ΔC/C (%)

20

1000

0

2nd line

1st line

2nd line

-20

-40

100

-60 Z5U

-80 Y5V

-100 10

-55 -35 -15 5 25 45 65 85 105 125

Temperature (°C)

STORAGE

The capacitors must not be stored in a corrosive atmosphere, where sulphide or chloride gas, acid, alkali or salt are present.

Exposure of the components to moisture, should be avoided. The solderability of the leads is not affected by storage of up to

24 months (temperature +10 °C to +40 °C, relative humidity up to 60 % RH). Class 2 ceramic dielectric capacitors are also

subject to aging see general information (www.vishay.com/doc?23140).

SOLDERING

SOLDERING SPECIFICATIONS

Soldering test for capacitors with wire leads: (according to IEC 60068-2-20, solder bath method)

SOLDERABILITY RESISTANCE TO SOLDERING HEAT

Soldering temperature (235 ± 5) °C (260 ± 5) °C

Soldering duration (2 ± 0.5) s (10 ± 1) s

Distance from component body 2 mm 5 mm

SOLDERING RECOMMENDATIONS

Ceramic capacitors are very sensitive to rapid changes in temperature (thermal shock) therefore the solder heat resistance

specification (see table above) should not be exceeded. Exposing the capacitor to excessive heating may result in thermal

shocks that can crack the ceramic body. Similarly, excessive heating can cause the internal solder junction to melt.

Revision: 23-Jul-2021 3 Document Number: 23107

For technical questions, contact: ceramitesupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

20VL Series

www.vishay.com

Vishay Cera-Mite

When soldering radial leaded ceramic capacitors with a soldering iron, it should be performed under the following conditions

and should not exceed:

• Maximum temperature of iron-tip: 400 °C

• Maximum soldering iron wattage: 50 W

• Maximum soldering time: 3.5 s

Failure to follow the above cautions may result, in worst case, in short circuit or cause fuming or thermo-mechanical damage

when the product is used.

Leaded ceramic capacitors are not designed for reflow process or dipping the body into a solder melt.

CLEANING

The components should be cleaned immediately following the soldering operation with vapor degreasers.

CLEANING (ULTRASONIC CLEANING)

To perform ultrasonic cleaning, observe the following conditions:

• Maximum rinse bath capacity output: 20 W/liter

• Maximum rinsing time: 300 s

• Do not vibrate the PCB/PWB directly

• Excessive ultrasonic cleaning may lead to mechanical damage

SOLVENT RESISTANCE

The coating and marking of the capacitors are resistant to the following test method:

IEC 60068-2-45 (method XA)

MOUNTING

We do not recommend modifying the lead terminals, e.g. bending or cropping. This action could break the coating or crack the

ceramic insert. In order to avoid such failures we are offering different lead wire designs (e.g. straight, inline, inside crimp,

outside crimp etc.) If however, the lead must be modified in any way, we recommend support of the lead with a clamping fixture

next to the coating. If a defined product stop is required for mounting on a PCB, a mechanically formed product stop or a

mounting tool should be used.

OPERATING VOLTAGE

In case the voltage is applied to the circuit, starting as well as stopping, may generate irregular voltage for a transit period

because of resonance or switching. Be sure to use a capacitor with a rated voltage range that includes these irregular voltages.

OPERATING TEMPERATURE AND SELF-GENERATED HEAT

Keep the surface temperature of a capacitor below the upper limit of its rated operating temperature range. Be sure to take into

account the heat generated by the capacitor itself. When the capacitor is used in a high frequency, pulse, or similar application,

it may have self-generated heat due to dielectric dissipation.

Temperature increase due to self-generated heating should not exceed 20 °C while operating at an atmosphere temperature of

25 °C.

When measuring, the surface temperature, make sure that the capacitor is not affected by radiant, conductive and convective

heat by its surroundings. Excessive heat may lead to thermo-mechanical deterioration of the capacitor's characteristics and

reliability.

RELATED DOCUMENTS

General Information www.vishay.com/doc?23140

CB Test Certificate www.vishay.com/doc?22247

VDE Marks Approval www.vishay.com/doc?22246

UL Test Certificate www.vishay.com/doc?22245

Revision: 23-Jul-2021 4 Document Number: 23107

For technical questions, contact: ceramitesupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay's knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customer's responsibility to validate that a particular product

with the properties described in the product specification is suitable for use in a particular application. Parameters provided in

datasheets and / or specifications may vary in different applications and performance may vary over time. All operating

parameters, including typical parameters, must be validated for each customer application by the customer's technical experts.

Product specifications do not expand or otherwise modify Vishay's terms and conditions of purchase, including but not limited

to the warranty expressed therein.

Hyperlinks included in this datasheet may direct users to third-party websites. These links are provided as a convenience and

for informational purposes only. Inclusion of these hyperlinks does not constitute an endorsement or an approval by Vishay of

any of the products, services or opinions of the corporation, organization or individual associated with the third-party website.

Vishay disclaims any and all liability and bears no responsibility for the accuracy, legality or content of the third-party website

or for that of subsequent links.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please

contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

© 2023 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED

Revision: 01-Jan-2023 1 Document Number: 91000

You might also like

- Capacitor Proteccion Igbt Gen Del Medical 440lseriesDocument5 pagesCapacitor Proteccion Igbt Gen Del Medical 440lseriesRoman LopezNo ratings yet

- WKO Series EMI Suppression Capacitor, Ceramic Disc, Class X1, 440 V, Class Y2, 300 VDocument5 pagesWKO Series EMI Suppression Capacitor, Ceramic Disc, Class X1, 440 V, Class Y2, 300 VYoseph TsegayeNo ratings yet

- vkpDocument5 pagesvkpdmitrijrybin751No ratings yet

- WKP Series EMI Suppression Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 VDocument5 pagesWKP Series EMI Suppression Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 Vakeem alturkiNo ratings yet

- 440L Series: AC ACDocument1 page440L Series: AC ACAutor AutorNo ratings yet

- 615 RseriesDocument7 pages615 Rseriesmohamed saadaNo ratings yet

- VY1 Series EMI Suppression Safety Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 VDocument8 pagesVY1 Series EMI Suppression Safety Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 VheribertosfaNo ratings yet

- 440L Series: Vishay Cera-MiteDocument6 pages440L Series: Vishay Cera-MiteBashir MtwaklNo ratings yet

- WYO Series: AC ACDocument4 pagesWYO Series: AC ACtaha aliNo ratings yet

- WKO Series: AC ACDocument4 pagesWKO Series: AC ACGeorge GryphoneNo ratings yet

- DC DC AC AC: Vishay Cera-MiteDocument4 pagesDC DC AC AC: Vishay Cera-MiteAnonymous oyUAtpKNo ratings yet

- SMDY1 Series AC Line Rated Ceramic Disc Capacitors Class X1, 760 V, Class Y1, 500 VDocument7 pagesSMDY1 Series AC Line Rated Ceramic Disc Capacitors Class X1, 760 V, Class Y1, 500 Vumut bayNo ratings yet

- Vishay 715c-ktDocument7 pagesVishay 715c-ktrogerNo ratings yet

- S SeriesDocument11 pagesS Series380665791408maksNo ratings yet

- Ceramic CapacitorDocument8 pagesCeramic CapacitorparapNo ratings yet

- MKP 3366 y 2Document12 pagesMKP 3366 y 2Vincent Don KasambalaNo ratings yet

- CapacitorDocument17 pagesCapacitorjuliolocNo ratings yet

- Vishay Roederstein: FeaturesDocument17 pagesVishay Roederstein: FeaturesAdiyatma DjatnikaNo ratings yet

- Vishay f1772x2Document13 pagesVishay f1772x2rogerNo ratings yet

- SMD CAPDocument15 pagesSMD CAPRajeshreddyBaireddyNo ratings yet

- AC03 Safety (AC03..CS) : Vishay DraloricDocument3 pagesAC03 Safety (AC03..CS) : Vishay Draloricyenassiri278No ratings yet

- Vishay: FeaturesDocument7 pagesVishay: FeaturesnoorupillaNo ratings yet

- Dseries 1762011Document10 pagesDseries 1762011fatahillah ataNo ratings yet

- EMI Suppression KEMETDocument2 pagesEMI Suppression KEMETavo638No ratings yet

- Pha Surge Suppressor Capacitors: Vishay ESTADocument7 pagesPha Surge Suppressor Capacitors: Vishay ESTAAndes PutraNo ratings yet

- WIMA Snubber MKPDocument5 pagesWIMA Snubber MKPmaurotapiagk1No ratings yet

- Limit Switches: General CharacteristicsDocument17 pagesLimit Switches: General CharacteristicsIonica VladNo ratings yet

- Série Condensateurs 136 VishayDocument11 pagesSérie Condensateurs 136 VishayALAIN GOUDEAUNo ratings yet

- Ceramic Capacitors: Vy1, Vy1 Compact, and Vy2Document4 pagesCeramic Capacitors: Vy1, Vy1 Compact, and Vy2Faraz ElectronicNo ratings yet

- Quadhifreq 1391243 PDFDocument17 pagesQuadhifreq 1391243 PDFDinu Racautanu MironNo ratings yet

- WEG DWB 50070240 en PDFDocument56 pagesWEG DWB 50070240 en PDFwil alfNo ratings yet

- DIODES Vs 36mtseriesDocument7 pagesDIODES Vs 36mtserieshocine gherbiNo ratings yet

- SS32 Thru SS36: Vishay General SemiconductorDocument4 pagesSS32 Thru SS36: Vishay General SemiconductorMantenimiento AsistelNo ratings yet

- SC - Low Voltage Catalogue - Aluminium - 2020Document18 pagesSC - Low Voltage Catalogue - Aluminium - 2020ooi.impacNo ratings yet

- S202M-K16UC: Miniature Circuit Breaker - S200MUC - 2P - K - 16 AmpereDocument5 pagesS202M-K16UC: Miniature Circuit Breaker - S200MUC - 2P - K - 16 AmpereMary RoshmaNo ratings yet

- S202M-K6UC: Miniature Circuit Breaker - S200MUC - 2P - K - 6 AmpereDocument5 pagesS202M-K6UC: Miniature Circuit Breaker - S200MUC - 2P - K - 6 AmpereLucas CruzNo ratings yet

- SafetydnDocument5 pagesSafetydnDigital ModelsNo ratings yet

- DWB - Molded Case Circuit BreakersDocument68 pagesDWB - Molded Case Circuit BreakersHélio SousaNo ratings yet

- MKP1848 DC-Link: Vishay RoedersteinDocument21 pagesMKP1848 DC-Link: Vishay RoedersteinRiad RiadNo ratings yet

- Miniature Circuit Breaker - S200 - 4P - C - 10 Ampere: Product-DetailsDocument6 pagesMiniature Circuit Breaker - S200 - 4P - C - 10 Ampere: Product-DetailsbilalNo ratings yet

- Miniature Circuit Breaker - S200 - 1P - C - 16 Ampere: Product-DetailsDocument5 pagesMiniature Circuit Breaker - S200 - 1P - C - 16 Ampere: Product-DetailsHector SuarezNo ratings yet

- BZX 85Document6 pagesBZX 85sone13No ratings yet

- Eng GeneralCable CatalogueDocument32 pagesEng GeneralCable CatalogueEvgeniy ShinkarenkoNo ratings yet

- VS-MB Series: Vishay SemiconductorsDocument7 pagesVS-MB Series: Vishay SemiconductorsMohammed Mosaad LyricsNo ratings yet

- ZOV Series - High Energy Varistors: DescriptionDocument4 pagesZOV Series - High Energy Varistors: DescriptionIgor PNo ratings yet

- Miniature Circuit Breaker - S200 - 1P - C - 10 Ampere: Product-DetailsDocument6 pagesMiniature Circuit Breaker - S200 - 1P - C - 10 Ampere: Product-DetailsYurivilca Yurivilca GianmarcoNo ratings yet

- VFD 1.8-3kVDocument2 pagesVFD 1.8-3kVpejmanpNo ratings yet

- 800v Ac MccbDocument21 pages800v Ac MccbRahul PatelNo ratings yet

- Vishay Roederstein: FeaturesDocument15 pagesVishay Roederstein: Featuresiman wahyudinNo ratings yet

- Sbyv26C: Vishay General SemiconductorDocument5 pagesSbyv26C: Vishay General SemiconductorSalomon ChoqueNo ratings yet

- CP CB4010-ENG-400AR-3Document2 pagesCP CB4010-ENG-400AR-3mehdi HKNo ratings yet

- Vishay Semiconductors: FeaturesDocument4 pagesVishay Semiconductors: FeaturesAhmed Sherif CupoNo ratings yet

- VS 36mb100aDocument7 pagesVS 36mb100aatu wentNo ratings yet

- MKP1848S DC-Link: Vishay RoedersteinDocument15 pagesMKP1848S DC-Link: Vishay RoedersteinRaphael Santos do NascimentoNo ratings yet

- Miniature Circuit Breaker - S200 - 2P - C - 20 Ampere: Product-DetailsDocument5 pagesMiniature Circuit Breaker - S200 - 2P - C - 20 Ampere: Product-DetailsAbdullrahim AlastalNo ratings yet

- CP Ac3050-Eng-200srDocument2 pagesCP Ac3050-Eng-200srAduldech SrasamranNo ratings yet

- BZX85-Series Zener Diodes: Vishay SemiconductorsDocument6 pagesBZX85-Series Zener Diodes: Vishay SemiconductorsDodi ArvaniNo ratings yet

- Ceramic Disc Capacitors Class 1 and 2, 1 KV To 50 KV, General PurposeDocument3 pagesCeramic Disc Capacitors Class 1 and 2, 1 KV To 50 KV, General PurposeIman AkbariNo ratings yet

- Schneider Electric - ComPact-NSXm - LV426209Document4 pagesSchneider Electric - ComPact-NSXm - LV426209Djeddou RabieNo ratings yet

- Hype Cycle: For Emerging Technologies, 2010Document11 pagesHype Cycle: For Emerging Technologies, 2010mrgirishNo ratings yet

- Debangshu Ari CVDocument1 pageDebangshu Ari CVDebangshu AriNo ratings yet

- Introduction To Networks: KVS Regional Office Jaipur - Session 2020-21 Page 14 of 19Document3 pagesIntroduction To Networks: KVS Regional Office Jaipur - Session 2020-21 Page 14 of 19adamNo ratings yet

- Introducing The New International Standard For BIM, ISO 19650Document4 pagesIntroducing The New International Standard For BIM, ISO 19650AntoineNo ratings yet

- Lec 8Document20 pagesLec 8Aaistora ZedanNo ratings yet

- OPMA 5364 Part 5Document33 pagesOPMA 5364 Part 5Tran Tuan AnhNo ratings yet

- GadDocument1 pageGadFakhruddin DhilawalaNo ratings yet

- DS-2CD2T26G2-2I 4I-D Datasheet V5.7.0 20220609Document6 pagesDS-2CD2T26G2-2I 4I-D Datasheet V5.7.0 20220609indrayadi2009No ratings yet

- IT File Tarandeep Singh Copy 2Document60 pagesIT File Tarandeep Singh Copy 2user-509376No ratings yet

- Digital Marketing (Jerath) SU2019Document5 pagesDigital Marketing (Jerath) SU2019Antara BannerjeeNo ratings yet

- KFS - Kyocera Fleet ServicesDocument31 pagesKFS - Kyocera Fleet ServicesGlaydson Alves de MoraesNo ratings yet

- Catalog Thang May Gia Dinh SuntecDocument23 pagesCatalog Thang May Gia Dinh SuntecthanhnamdktdNo ratings yet

- Job Vacancy Survey in Quarter 2018 Classification of Occupations in Romania (COR) 1Document2 pagesJob Vacancy Survey in Quarter 2018 Classification of Occupations in Romania (COR) 1Bradut SuciuNo ratings yet

- Network Update Ron Line HelpDocument118 pagesNetwork Update Ron Line HelppalosotNo ratings yet

- All Pricelist March 2016Document8 pagesAll Pricelist March 2016Abhimanyu KumarNo ratings yet

- pts830 DatasheetDocument4 pagespts830 DatasheetteehoweNo ratings yet

- B35 HBM PDFDocument2 pagesB35 HBM PDFCristhian TaipeNo ratings yet

- Unit Test 1. Label The Parts of The ComputerDocument5 pagesUnit Test 1. Label The Parts of The Computerapi-467900306No ratings yet

- OZ9939GNDocument12 pagesOZ9939GNEduardo SierraNo ratings yet

- Access All Areas With The: Premium DR Room To GoDocument8 pagesAccess All Areas With The: Premium DR Room To GoNguyen AnhNo ratings yet

- ZYXEL Users-Guide NSG100 Version 1.33 Edition 2Document58 pagesZYXEL Users-Guide NSG100 Version 1.33 Edition 2Jeremie RosetteNo ratings yet

- DNSDocument10 pagesDNSAbhilash GhadaiNo ratings yet

- PHLAudio - Bass 20cm-8inchDocument1 pagePHLAudio - Bass 20cm-8inchRoberto richardsenNo ratings yet

- 21.2.10 Optional Lab - Configure ASA Basic Settings Using The CLIDocument14 pages21.2.10 Optional Lab - Configure ASA Basic Settings Using The CLIEvaristo PalacínNo ratings yet

- SY3200 EmanualDocument102 pagesSY3200 Emanualapi-375021143% (7)

- ABB - Smart Sensor Installation - 8.5x11 - 9.17 - LR PDFDocument4 pagesABB - Smart Sensor Installation - 8.5x11 - 9.17 - LR PDFFerozMujawarNo ratings yet

- Iso Astm 52901 2017Document9 pagesIso Astm 52901 2017FantasticNo ratings yet

- F. FeasibilityDocument2 pagesF. Feasibilitypatricia gunioNo ratings yet

- Autolab SDK manualDocument34 pagesAutolab SDK manualtecushNo ratings yet

- V.S.B. Engineering College, Karur Department of MechanicalDocument2 pagesV.S.B. Engineering College, Karur Department of MechanicalsakthisparcoNo ratings yet