LG Flatron E700SH

LG Flatron E700SH

Uploaded by

jayakarwCopyright:

Available Formats

LG Flatron E700SH

LG Flatron E700SH

Uploaded by

jayakarwCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

LG Flatron E700SH

LG Flatron E700SH

Uploaded by

jayakarwCopyright:

Available Formats

LG Flatron E700SH

Reference Schematic: T530B/S, CHASSIS CA-138

SMPS Voltages: (Standby) +54V (+50.5V PWR ON) +85V (+81.1V PWR ON) +6.1V +7.6V +15.6V B+ Voltage during PWR ON- 87.1V EHT output voltages: +403V -158V +40.9V PROBLEM: when I switch ON the monitor, a thin blue arc jumps from the LOTs body to the ferrite core followed by one big spark and loud sound like busting of a cracker. There is another spark at the same time jumping from ferrite core steel clamp tip to PCB ground. This cycle keeps on repeating. A very fine horizontal crack (half the size of hair) visible on the LOTs body. The spark is jumping from that crack to the ferrite core and from the core to the ground.

Steps taken to solve the problem:

1. I covered the crack with little hot melt glue, the arcing and sparing completely stopped. 2. In order to make a strong and reliable seal, I removed the glue and used M-SEAL to close the crack. I spread M-SEAL all around the crack touching the ferrite core. After switching ON, frying and hissing noise could be heard coming from around the seal. When I bought a screw driver near the ferrite core, tiny spark is jumping from core to screw driver. The noise also stopped when I bought a screw driver over the seal. 3. I fixed a small aluminum piece close to the seal and ground the aluminum to ground using a 10meg resistor. The frying noise completely disappeared. The set continuously worked only for 3 to 4 hours. After a power cut when I switched ON the set the screen violently shook and the set was dead. The horizontal output transistor, HOT was blown1. 4. I removed the M-SEAL and used a lot of hot melt glue over the crack, replaced the HOT. Now the situation became worse, the sparking moved to another place near the crack and close to the core. The sparking was

heavy and continuous. 1. I think there was a lot of stress on the HOT from the leaking corona* the HOT could have been running hot as i did not test it. The HOT also could have become weak due to arcing and sparking during pre-repair.

*If there is no sufficient strength to form an arc or spark there will leaking of high voltage through the air called the corona discharge. The frying or hissing sound are the sound of corona. Points to remember: 1. Never run the set when there is arcing, sparking or corona discharge. The HOT would blow any time. 2. Never use M-SEAL, in very high voltage area, as it is a chalk putty. Use only 100% silicon sealant for sealing high voltage cracks. (100% silicon sealant are used for making fish tank, Dr.Fix silicon sealant, RTV Anabond silicon sealant are the products that can be used) 3. If there is external arcing, sparking or corona discharge from flyback transformer, try silicon sealant to cover the crack, if spark moves to some other place the only option is to replace the flyback transformer.

Horizontal flyback working:

When the PWR button is pressed the microprocessor switches ON the horizontal drive signal to HOT. The horizontal output stage receives power from SMPS +50V rail for a brief period. The microprocessor senses the horizontal flyback plus from the LOT and switches ON the B+ drive. If the flyback plus is low or not present there will be no B+ drive, but the horizontal drive signal to HOT is present indefinitely. The B+ voltage changes according to the resolution selected from computer. 100 Watts bulb test: (100W bulb has 40 ohms cold resistance) I put a 100 Watts bulb in series with B+ voltage (between the 1 ohms 2 watt resistor and LOT pin2). There was no B+ drive as thee was 25 volt drop across the bulb. Next I put an 80 ohms resistor in place of the bulb. Now there was 10 volt across the resistor, still no B+ drive. Putting a 60 ohms resistor started the B+ drive.

You might also like

- 03 - HUAWEI - Training SmartLogger, SmartACU and SmartPIDDocument22 pages03 - HUAWEI - Training SmartLogger, SmartACU and SmartPIDSav Sasha100% (1)

- HHO Pulse Charger 2.0 InfoDocument4 pagesHHO Pulse Charger 2.0 InfoAleksa Nataša Rančić100% (1)

- Water Fuel Cell - Build Manual - Tap Water (Daves Stanley Meyer Xogen Free Energy)Document10 pagesWater Fuel Cell - Build Manual - Tap Water (Daves Stanley Meyer Xogen Free Energy)andr3y775% (4)

- Induction Cooker TeardownDocument14 pagesInduction Cooker TeardownNguyễn Hồng DươngNo ratings yet

- High Voltage Plasma Generator KitDocument6 pagesHigh Voltage Plasma Generator KitJayam SonaniNo ratings yet

- Panasonic SB Wa930eeDocument35 pagesPanasonic SB Wa930eeJose Domingo Maltez Vallecillo0% (1)

- Conventional Ignition SystemrevDocument20 pagesConventional Ignition SystemrevSuparman St0% (2)

- Thane Heins CoilsDocument7 pagesThane Heins Coilsadrian_pt4795100% (3)

- 220-12 Volt DC Power SupplyDocument16 pages220-12 Volt DC Power Supplychachunasayan89% (18)

- Wrong Answer SummaryDocument3 pagesWrong Answer Summaryavishek mishra100% (2)

- Fuji Starting Guide G11S-LE2 - Lift - 7Document54 pagesFuji Starting Guide G11S-LE2 - Lift - 7Nguyen Anh Tu100% (3)

- Tesla Coil High Voltage GeneratorDocument3 pagesTesla Coil High Voltage GeneratorSergio Dell'amico100% (1)

- Flyback Transformer DriverDocument3 pagesFlyback Transformer DriverArnab AcharyaNo ratings yet

- Circuitos Electronicos para ChisperoDocument13 pagesCircuitos Electronicos para ChisperoEfra SosaNo ratings yet

- K 57Document3 pagesK 57pamuncakNo ratings yet

- Tesla Coil DriverDocument9 pagesTesla Coil DrivercatalinbrvNo ratings yet

- Voltage Drops - OD and Other Circuits: How An Ohmmeter WorksDocument9 pagesVoltage Drops - OD and Other Circuits: How An Ohmmeter Workshanif274No ratings yet

- Tram 2 PreampDocument30 pagesTram 2 Preampdecky999100% (1)

- Circuits Hight VoltajeDocument45 pagesCircuits Hight VoltajeRICHIHOTS2No ratings yet

- Ts900notes ValuableDocument2 pagesTs900notes Valuabledijagnostika111No ratings yet

- PDF Troubleshooting CRT TV Power Problem DLDocument16 pagesPDF Troubleshooting CRT TV Power Problem DLmehrab babaeiNo ratings yet

- Fisher 500-T Service ManualDocument12 pagesFisher 500-T Service ManualMrWasabihead50% (2)

- BTC50 60 InstructionsDocument4 pagesBTC50 60 InstructionsHasheem AliNo ratings yet

- E-Choke Design UKDocument13 pagesE-Choke Design UKtehnotonNo ratings yet

- Troubleshooting CRT TV Power ProblemDocument16 pagesTroubleshooting CRT TV Power ProblemJoy Chowdhury50% (2)

- FRB 15 Watt Instruction PacketDocument8 pagesFRB 15 Watt Instruction PacketStephen Dunifer100% (1)

- PowerLabs Flyback DriverDocument8 pagesPowerLabs Flyback DriverJayam SonaniNo ratings yet

- Little Dot I+ Reference GuideDocument10 pagesLittle Dot I+ Reference GuidenotandreiNo ratings yet

- Twin Loop Treasure Seeker: Robert and David CroneDocument5 pagesTwin Loop Treasure Seeker: Robert and David CronesafdsfdNo ratings yet

- 15 Watt FET FM Amp Rev 2 Assembly InstructionsDocument7 pages15 Watt FET FM Amp Rev 2 Assembly InstructionsStephen Dunifer100% (4)

- Guidelines To Bucking Coils PDFDocument19 pagesGuidelines To Bucking Coils PDFpic2007100% (1)

- 100 IC CircuitsDocument60 pages100 IC CircuitssabNo ratings yet

- CRT TV Power ProblemDocument15 pagesCRT TV Power ProblemJoy Chowdhury50% (2)

- Preamplificador HI-FI Con LME49720 y Tonos PDFDocument6 pagesPreamplificador HI-FI Con LME49720 y Tonos PDFJoanna NunezNo ratings yet

- Advanced Tips and Tricks Power Supply STR 6701Document2 pagesAdvanced Tips and Tricks Power Supply STR 6701Kiray VillanuevaNo ratings yet

- Summary Ac Contactor Failure Cause and EffectDocument9 pagesSummary Ac Contactor Failure Cause and EffectVinci Valcu ParneNo ratings yet

- Motor Failure Report PDFDocument13 pagesMotor Failure Report PDFpranav0567% (3)

- Twin LoopDocument5 pagesTwin LoopBalbalaManiuk100% (1)

- Radon IonChamberElectronics ENGDocument26 pagesRadon IonChamberElectronics ENGperezNo ratings yet

- Our Solid-State Tesla Coil Can Produce Sparks As Long As 8 Inches With A Peak Output of About 100,000 Volts.Document8 pagesOur Solid-State Tesla Coil Can Produce Sparks As Long As 8 Inches With A Peak Output of About 100,000 Volts.Carlos Guzman100% (2)

- Strobe Troubleshooting GuideDocument5 pagesStrobe Troubleshooting Guide1dsmark27088No ratings yet

- BTC30 40insDocument4 pagesBTC30 40inspatgarettNo ratings yet

- Sylvania LD320SS8 LCD TV RepairDocument7 pagesSylvania LD320SS8 LCD TV RepairалександрNo ratings yet

- Diy Minipro DC/DC ConverterDocument14 pagesDiy Minipro DC/DC Convertermrcinek01No ratings yet

- Transistorized Amplifier RepairDocument11 pagesTransistorized Amplifier RepairAC5CHNo ratings yet

- Thrust Block Fault Finding (DS01042/D)Document9 pagesThrust Block Fault Finding (DS01042/D)egemen7404612No ratings yet

- DIY Spot Welder PDFDocument4 pagesDIY Spot Welder PDFwienslaw5804100% (2)

- ADA MP-1 Noise-ModDocument19 pagesADA MP-1 Noise-ModAndrei Popa100% (1)

- A Powerful Stun GunDocument13 pagesA Powerful Stun GunLê Thiên ThanhNo ratings yet

- TH 32 C 400 DDocument58 pagesTH 32 C 400 DAnonymous nIcSGEwNo ratings yet

- AirCraft Band Receiver 2012Document4 pagesAirCraft Band Receiver 2012Smail HondoNo ratings yet

- Matchett 140801073955 Phpapp01Document8 pagesMatchett 140801073955 Phpapp01MamachelloNo ratings yet

- Testing Lucas Voltage Regulators (Triumph)Document4 pagesTesting Lucas Voltage Regulators (Triumph)caldasferreirasoutoNo ratings yet

- InstallingHot StartrelayDocument5 pagesInstallingHot StartrelayjuanNo ratings yet

- Epas Common CoreDocument11 pagesEpas Common Corerey brionesNo ratings yet

- Kit Manual IN14Document19 pagesKit Manual IN14Caio VilarNo ratings yet

- POWERLABS' High Voltage Solid State Flyback DriverDocument11 pagesPOWERLABS' High Voltage Solid State Flyback DriverArnab Acharya50% (2)

- IC7000 All ModsDocument24 pagesIC7000 All ModsJuan Carlos CancioNo ratings yet

- AX84 Hi-Octane Mods 101004Document4 pagesAX84 Hi-Octane Mods 101004Leandro BarbosaNo ratings yet

- Transformer TestingDocument20 pagesTransformer TestingcaesparzaNo ratings yet

- How To Recap The Royal 500Document4 pagesHow To Recap The Royal 500El Tio la VaraNo ratings yet

- Motion Picture Operation, Stage Electrics and Illusions: A Practical Hand-book and Guide for Theater Electricians, Motion Picture Operators and Managers of Theaters and ProductionsFrom EverandMotion Picture Operation, Stage Electrics and Illusions: A Practical Hand-book and Guide for Theater Electricians, Motion Picture Operators and Managers of Theaters and ProductionsNo ratings yet

- 4 Study of Characteristics of SCR, MOSFET & IGBTDocument12 pages4 Study of Characteristics of SCR, MOSFET & IGBTSeminars BRECWNo ratings yet

- Hyundai N500 ManualDocument76 pagesHyundai N500 ManualPac CoolNo ratings yet

- Fermi FET Technology Seminar ReportDocument21 pagesFermi FET Technology Seminar Reportimcoolsha999No ratings yet

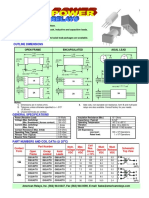

- High Power Reed RelaysDocument1 pageHigh Power Reed RelaysNestor Dino DominiciNo ratings yet

- Lab 8fsdDocument4 pagesLab 8fsdAnonymous ycaTC6ENo ratings yet

- Lab Manual Part 2Document9 pagesLab Manual Part 2Mm M100% (1)

- Automatic Side Stand For Two WheelerDocument51 pagesAutomatic Side Stand For Two WheelerGopuNo ratings yet

- Power Circuit 32 InchDocument48 pagesPower Circuit 32 InchSaidfa FaNo ratings yet

- Vlsi DesignDocument67 pagesVlsi DesignramakrishnaNo ratings yet

- WTW Ol 06 MonitorsDocument4 pagesWTW Ol 06 MonitorswilfredoNo ratings yet

- Metaphysics and CosmologyDocument36 pagesMetaphysics and CosmologysensorseekerNo ratings yet

- China NEMA23 2phase Hybrid Stepper Motor With Advanced Technology - China NEMA 23 Stepper Motor, Step MotorDocument6 pagesChina NEMA23 2phase Hybrid Stepper Motor With Advanced Technology - China NEMA 23 Stepper Motor, Step MotororegondaveNo ratings yet

- Saep 333Document39 pagesSaep 333brecht1980100% (1)

- A Ring Oscillator-Based Temperature Sensor For U-Healthcare Gin 0.13m CMOSDocument4 pagesA Ring Oscillator-Based Temperature Sensor For U-Healthcare Gin 0.13m CMOSnidhalNo ratings yet

- PCR Ev20mdtDocument27 pagesPCR Ev20mdtiozsa cristianNo ratings yet

- Merlin Gerin Technical Guide Medium VoltageDocument80 pagesMerlin Gerin Technical Guide Medium Voltagepavlovicg100% (1)

- Chapter 4.0 Sensor and Signal CondDocument49 pagesChapter 4.0 Sensor and Signal CondmathewosNo ratings yet

- WSG-MF: Gearless Synchronous Lift MachineDocument2 pagesWSG-MF: Gearless Synchronous Lift MachineCristianNo ratings yet

- PSV3St - Phase-Sequence Voltage Protection Stage1 (PSV3St1) Stage2 (PSV3St2)Document29 pagesPSV3St - Phase-Sequence Voltage Protection Stage1 (PSV3St1) Stage2 (PSV3St2)rajeshNo ratings yet

- Syc KK MF enDocument13 pagesSyc KK MF encipyyyy100% (1)

- MCQ CH 2 ElectrochemistryDocument2 pagesMCQ CH 2 ElectrochemistryGaurav SonarNo ratings yet

- Ds Thomas Picolino Vte-Dte Rotary VaneDocument12 pagesDs Thomas Picolino Vte-Dte Rotary Vanesemih KokNo ratings yet

- Alpha: SemiconductorDocument11 pagesAlpha: SemiconductorJuan Carlos VillegasNo ratings yet

- Designing A 4-20ma Current LoopDocument5 pagesDesigning A 4-20ma Current LoopAhmad HuseinNo ratings yet

- PH307 EndsemDocument2 pagesPH307 EndsemHarshita TripathiNo ratings yet

- Electrical Measurements and Instrumentation (Introduction To Instrumentation Engineering) October 2019Document25 pagesElectrical Measurements and Instrumentation (Introduction To Instrumentation Engineering) October 2019tesfaye meberateNo ratings yet