Professional Documents

Culture Documents

Tornos

Tornos

Uploaded by

farid said errahmani0 ratings0% found this document useful (0 votes)

241 views150 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

241 views150 pagesTornos

Tornos

Uploaded by

farid said errahmaniCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 150

TORNOS WORKS LTD. - MOUTIER (SWITZERLAND)

Established in 1899 ~ Telephone 6 4928 and 64924 ~ Cable address: Tornos Moulier

Ori

ators of the Sliding Head the ToRNOS factory wes established in Moutler, Switzerlond, in 1880 for the monutc-

Automatic ture of precision machinery uted In the woteh industry. The success ofthe Origine

TORNOS Sliding Heod Automatic was such thatthe faclory soon went over ellogsther

{othe bulldng of his type of machine, This policy hos been fllowed for mare than

75 years

“The mokers of TORNOS are the wor's largest producers of the “Swits type” of

sutomatic they hove #0 perecd it thet In performance, predsion and workmanship

Nis ordoy ina clos by ist

“The TORNOS is othe fore wherever extreme accuracy ix required nell branches of

Industry where high ouput o be combined with high-class fish, thus avoiing in

‘many cases subsequent machining operations. TORNOSAutometics wil lithe xtreme

‘ccuracy requirements of manufacturers of fine watches, clocks, meer instrument

Sauer, telephone, telegraphs, radios, cameras, ypewrles, adding machines, cit

plone parts ond mony other produ

THE TORNOS AUTOMATICS / Working Principles

“The TORNOS difersfundementlly from the traditional design of automatic screw machines, which generally employ indexing turrets

box fel for turing. form fools ee The special feature ofthe TORNOS is he axilly sliding headstock. The headstock, while holding

the rotting bor, cso moves longitudinally on the Bed This mathod hat the greet advantage thatthe bar can be guided in o bushing

Fightin front of the tools. This means tha he stock sot all imes rigidly supported clot f the turning tools Its thus mage posible

to urn very long pers and short parts with high fh, extreme accuracy and uavarying concentiiy. However. short pars ean alto be

machines without guide bushing, ie of he collet, Bar-eed is very simple and occurate: After the etingol operation. when the part

Ir fnihed an! seperated from the stock the headstock cll opens ond th bois held agains the cating eo by the action of o counter=

weigh. The cutingo fools thus used os a stop for Ba feed The Readstock which a his moment isn is most advanced postin, wll

row recede (calle being epen) fora length corresponding to thal ef he component (pus thickness of cutting-of tal). The cll is closed

tnd the cutting off too hich was used axa bar slop recedes, andthe cyte forthe fllowing pert can Begin

Five simple and inexpensive tool bil, mounted on slides in front ofthe guide bushing, wil rn the mast complicated component by ©

combined redielin-ecd ofthe fools ond an aval fad af the rolling bor as! the tol. The possiblities ofthis method ore such tat the

the of form lols is usualy evoided. The quality of surface finish achieved through the sliding heod method, specially when rather long

tnd slender pars are concerned is incomparably better than what is oblaned by any olher system. Production of TORNOS Automatics

invery high, even for hard see! pars, dve to their effin! speed ranges and eecelerating device,

TORNOS Avtomotis can take alarge numberof euxiley ataehment and devices, which ore mounted in fronton horizontal surface,

con tho side of the machine bed, or an the vertical tool bracket. Single and multspndleériling and threading otachmens ttechmens

for centering, reaming, slting, back drilling, eras ring, undercuting, copying tc. are availabe

‘Working with guide bushing Working wthou! guide bushing, right of the calle!

Technical Features of TORNOS Automatics

Cabinet Base

‘contin electra contol and driving mechanism of headspinle,cemshall and front attachments, change gears snd pulley. ol pump,

selety devices topping camshaft in case of hecdspinde bell brecking and other accidents, Special care hat been fen fo prevideeony

eects to he driving mecheniem,

Headstock

The headstock is sliding longtudinelly onthe bed (s08 explanation on Sheet T. 311). Thi longitudinal led ofthe headstock is governed

by one or several et coms (Fig. 579) or bye bel-cam (Fig. 679 if very long petls have tobe made, The very long bed ofthe machine

provides afl-lagth bearing forthe headstock in any working positon, even for very long par.

‘When uting Hat cams, the radial stroke fhe cam i tansformed int the longitudinal motion af the hesdstock by eur well-known, RADIAX

‘mechanism (ig 579 ond S80. The remarkcbly high capacity ofthe Radiax makes I possible to turn all work of average length witht

ams, thus eliminating expensive bellcams. Provision is alzo made fr varying the raho between headstock and cam When uted with

wo cons, the Rasiox device enables similar components of diferent ies to Be machined without changing the cms. The thru ofthe

‘chucking mechanism is obsorbed by the machine bed and not by the headstock, thus avelding any undue wecr ofthe headstock side,

‘Chucking con be operated in any poiion ofthe heedstock wihou! new adjustment. For chucking, simple calles are used, and in specil

‘ates double cone collet. No displacing of eas necesrary when changing fom ating wilh guide bushing fo work without guide buahing

(G28 explancton on shee. 911). The spindle inthe heodsock, made of special sel, satisfies the highet requirements In fromthe spine

‘uns in a special high precision bron or adjustable needle becring. A!the rear end the spindles equipped according tothe kind fone

wale posts or usual repeliion work) wit selflignng ball and thrust besrnge wth automatic compensation for anil wesr. Looding of ¢

ew bor is very easy. The machine Is cutomaialy Hopped es 2000 os tne end ofthe Baris reached

Camshaft

‘TORNOS Automatics have one single comsha! made in one piece, enauring perfect caordintion ofall operations. Mis mourned in four

bearings onthe back ofthe machine and driven bya worm gearing. Speciel means are provided for easy adjustment ofthe normal Wear.

Came are ehanged without removing camshaft

‘Accelerator

“The accelerator i used for increasing the speed of he camshaft during idle movements of he machine e0Fig. SO sheet 7. 313). The

eves i pecialy interesting when working sel parts, Production canbe Increased considerably In meny ease.

Radial Tools

Five tol holders are mounted on long sides radially otached to a rigid bracket fixed tthe bed (Fg. $7). The Ww horizontal oo are

Placed on a rocker. A special machine with 6 redial tools is supplied for some highly compliested part ofthe watch industry. Each foo)

's provided wih independent micrometer odjsiment (Fig. 578). The verte tools are clamped with single screw and racking lamp

(Fig. 57) enabling 10 set the fools vary clote tothe work, thus avoiding vibrations, which are specially hermful fo corbide tipped tools,

(On especial machine wed for certain parts of he watch industry, the hwo horizontal tools (rocker loos) can be placed atom angle end

1 to 8 cams con be used for headstock feed and 1 Yo 6 came for the rocker tole,

Guide Bushings

‘The guide bushing holder i mounted inthe tool holder bracket can easly be removed when working without guide bushing eee above

under headstock" ond sheet T. 311). The use ofthe gulde bushing is recommended for places whore length exceeds three times te

mer of he stock material, or for pars requiring very high dlareer precision. The guide bush holder may be of stationary or revolving

lype, The revolving guide bush holder (Fg. 65, shat T. 313) i supplied on request nly. The buthing Healt whih s mounted in he holder

‘may be solid or edjstable (split) In clameter. The asjustable guide bushing i specially uted Yor small diameters, Bushings are offen

carbide lined =

Auxiliary Attachments

TORNOS Automatics con recive «large numberof auxiliary etachmants ensuring maximum versatiiy ofthe machine single ond mle

‘spindle dling and threading ertochmen's.ctachments for centring, reaming, slong, undercling, back driling row driling, copying.

fe Some ofthese alechments are shown herein. Many other atachments and those made for special purposes ere dealt with In

separaeliteroture. Base for fron atachmenis is horizontal (Fg. 583 — highly apprcited feature of TORNOS Astomati) Wt ensures

stobiliy and perfect alignment of ttachmens wth headstock spindle, feclitats canting and allows axil displacement incase of need

All ttachments are interchongectle. Attachments which are mounted onthe sde af he machine bed (otachments fr centring, sling,

copying, at) can be used joy withthe eon! atacnmants

Safety Stopping Devices

Safty devices ore provided fo stp the camshalt insantancouty whenever headepndle bet Breaks. Safety topping devices are also vale

able te guard ogcins foul slong or threcding (Fig. 602, sheet T- 313), hus avoiding damage to tools end atachments ond eliminating

wasted parts

Auxiliary Attachments

Single Spindle Threading Attachment

The atchment provided with «threading spindle operating ot

speed. Its used for RH and LH threading by the

rthod, The attachment is contalled by the sfety

+ stopping the camshett in cae of fauly threading (shown

‘Three-Spindle Drilling and Threading Attachment

Is normaly supplied with wo soiling spindles and ane threading

nal buton special request one driling spindle and two thread

pullays onthe main shaft of he machine, The ache can oe

De held in deiling or treating postion.

(Owing toe great versity he etachment i he mest popular

fone. Its ao controled bythe saley device stoping the cams!

i ease of faut threading (69 602).

\We oo supply Spindle Dring and Threading Atachment,and

1, 2and Spindle Driling Atachmets,Driling ond Theeoding

‘Aochmonts con be used withthe Lateral Centring Attachment

(ig. S63 sheet T. 312.

Slotting Attachment

When fined and eat, the screw ie tken by @ swing arm and

carried in front of a saw. It works also a separator and can be

sad as such in some cates where no tating ie required. The

“techment is controlled by the sley device stopping he camshaft

In cose of faulty sloting (Fg 602)

Sofety Stopping Device in cave of foully Threading and

Slotting

le used with single of muitapindle Threading Attaenments end

Soming Atachment, Istantaneousl top the camshaft in case of

faulty threading or slotting Wis controled by 2 ne tripping mes

chonlam and avoids damage fo fole and atichments, ot wll at

‘waited pars The device i enlrly mechanics, guaranteed foc.

brook and has proved is necessity.

Back Drilling Attachment

Copying Attachment

“The tachment will be used fo

vary exact profiles, seh of top

rocker ne longer controlled by #

Revolving Guide Bush Holder

‘The device i inlended for square or hexogon stock, or for me:

able type

Cam Shaping Machine Type CR2

The machine is used for hand finishing of Pat coms wsed

con automatic screw machines. The com which have fst

been reughed on a miling machin or with 2 dtk fil, cre

shaped on this cam-fnishing machine, end thus given the

Fish indispensable a preeson screw machine work, The

‘mochine may receive either a simple cam holding arbor

{or bobbing conceneie cam rections (fg. 682) or arbor

with eccentric slide for machining operative curves

(fs. 618.

The side-ret, which is placed perpendicularly to the

spindle and oulomatically compenstes wear,emures ecu

‘ate adjustment. The planing Yoo carried bythe long

tudinal op sid. Large-szed, mat ehromed seals realy

facia adjustment.

In edaion, he machine is equipped with o swiveling

Imerometer (met chromed) wih which the planed sections

con be checked without removal of he cam,

‘Shopng Rises and Falls of Com

‘Shaping Concentric Cam Sections

For this primery operation, the cam i affixed fo the simple comholing

arbor (ig, 82). Forward and backward mation ofthe hand lever with he

tefthond cautes the fool fo shape a cam section running coneeniealy 0

the bore ofthe com. Length of et Is set ax required by two adjustable

stops. Forwerd and latarel advanes of he foo s operated wih he righ

hhond. The external concentric cam sections machined by means of the

crank mounted on the rear spindle end, afer releasing he hand lever

and removing the sop pin. The motion Is no longer alernte but can

Shaping Operative Curves (Rize and Falls)

For this second operation, the cam-holding arbor with eccentric side i

sd (ig 618). Ecentie postion of he slide i adjusted by raeans of i

Kourled serew. The cutter must be Brought into contact withthe outer

point a the Beginning af the curve andthe inner point al the end of the

‘aurve. The curve is then shaped in tha same way 0 he concentric cam,

sections the result wil be an ere ane not an Archimedes spiral. The

rroris negligible except in the ase of long cam sections, ond these con

be subdiviged if necessary

The simple, sturdy and accurate consruction ofthis machine ensures the

production of high-precision, heovyservice came

Shaping Concanvie Cam Sections

Specifications

Diameter af cam-holding arbor 20. mmo (%/")

Maximum cam-dlameter machineble 260 mm (10'")

Maximum gauge of micrometer... SOmm (2")

Net weight with standard acessories 155 Ibs

Floor space. 39 20"

Drawing of Ring-Cem or Seam

Cam Drewing Divider Type CC

Cam Micrometer Type CM2

Is used for quick and precise measuring of flat cams, bell

‘cams and ring-eams, For messuringbell-cams and ring-

‘cams, micrometer can be mounted on a vertical support

(6,

This cam measuring machine con be vied for measuring

fat cams upto 300 mm ai. (11 "> and bellcoms up

Yo 240 mm dia. (97!) ond 200 mm (77) height. The

machine is supplied with tt of chucking rings for cam

bores. On reguest supporting dic for ring and bell-cars

and special chucking rings, secording fo buyer's specie

cation ean be supplied

Max. gauge of micrometer: 50 mm 2")

Net weight 29 Ibs,

Drawing of « Flot Cam

‘Cam Drawing Machine Type CT-2

Used for drawing fla cams, ballecms and ring-coms. Machine is very

strong an sturdy. Precise and eat 19 read owing fo lerge viding plote

‘mounted inside the Body and thus well protected

‘The Cam Drawing Machin i supplied with « Cam Drawing Divider

Type EC whichis used for deawing concentric arcs on flat coms.

The movable point is placed Inthe main eenter hole ofthe hexagonal

socket mounted on vies and holding the cam, while the fixed pelnt

traces he aes on the cam. The sackets provided with cer eles, from

‘which it is posible te connect with an are any ether poins en the cam,

Floor space ofthe Machine CT:-2. rts

[Net weight incl. Cam Drawing Divider Type CC 90 ibe

Maximum range fr fot cams! up to 11a

brelkeome: up to 10%" da

Graduation of dividing pate: 360° 1 graducton

TORNOS SA - MOUTIER (SUISSE)

Percour lateral simple

Permet execution de percage et fraisage lateraux par trant-

onde la piece

hrverlchtung mit einer Spindel

et fur die Austuhrung von itichen Bohr- und Frés:

Single Cross Driling Attachment

Picks-up the piace for cross ailing oF milling operations

Perceur Intra! double

Est uillse pour des porgages latéraux doubles avec anglages de

Ghague cole ou trou isisral, pour des Maisages lateraus ou en

Bout ge pidee, par transport de a pistes

ueroohrvorrchtung mit zwel Spindetn

Dieser Apparat ist geeignet um Werksticke von Belden Seiten

her au banven oder au trisen, und dae Guerioch au beige,

Selten anausenken,

Duplex Cross Driling Attachment

Picks-up the piece for cross ering or miling operations trom

Both sides, and countersinking of the cross hole at both sides,

Percour lateral

En plus des pu

percea ot angige pat Faria,

2s latéraux, la pldco pout otro

‘verbohrvorrichung und Gegenbohrverichtung,

Mit Hite dieser Apparatekombination warden dle Tele nicht nur

Suilicn gobonrt oder golrast. sondern auch von inten” gebohrt

tind angesenkt.

Single Cross Dring and Back Dring At

In acaition to cross driling or miling. the

Back dries with the hale countersunk W requ

eux apparels pour des pidces présen-

age et on percage

bohrvoriehtung

Jerwendung dieser Apparaie ist geeignet um

Aut der Abstochseile sine Barung und eine Frasung aussulunren

Sloting and Back Dring Attachment

This is used for the simultaneous operations of back sloting and

ack dling,

T DE ie Sine

TURNOS SA - MOUTIER (SUISSE)

our exteuter des taraudages et tetages du cow

posterieur de ta piece. Pew sre combine dans catains cot Seek

fe Sercour lateral

Gegengewindeschneidepparat

Die Teile xonnen inten mit einem inners oder Aussengewinge

versenen werden Cer Gegengewnceschneddapparst kane noch

Gleicheenig mit singe Querbohwarnentung in gemissen’ Favey

Back Threading Attachment

Is used for rear treading or tappin

Sand in ome enaoe car” Ge Uta” sh

Eenuncton wih the cross “aeing

Fendeur en rox

Permet detlectuer Ia partie postériaure de a pidce desirasages

Simples ou #n eros

Schitzapparat 2um kreuzweisen Schlitzen

Einfache oder kreuzweise Schitze werden aut der Abstechseite

Gelrast Ber Verwendung von 2 Frasemn kann auch om Vienant

Js used for simple back sitting, oF for miling a square oF

‘tossed slots at the rear.

(205) 246-9511

CContre-poupée sur combiné 9 broches

eo disposi est utllsé pour saicr et entsiner Ia place pendant

ertaines opérations are telles que: suppression cl teton do

coupe, contecentrage, tc

Gegenspindeisiock aut komb. 2-spindl, Apparat

Das Werkstick wird wahtend des Avstechens in der Gegen:

spincel gespannt, die mit dor Mauptepindelsynctron (auf Ble

Vorrichtung cient 28. tur Vermerdung des Abstocnbutzons, Tr

‘ina hintere Zentiorung,

.dslock on 2-Spinale

‘Atachment

This device is used to grip the piece

atthe front end and revolve simultane:

‘ously with the. headsioe. spindle it

Bermits the sliminstion of cut off ips

and" can also be used for back canta

Appareil tetera burin

Permot de realise des fietages qui ne pourralent pas étre tats

par ilere ou roulage (par exemple devrare une porte), des f=

{ages do-grance precision ns! que des Nisieges Ge ve-sane-in

ane ou plustours entibes,

Gowindestehiapparat

kénnen (25. hiner einem Ansa). Femer wird der Apparat ur

sehr genaue Gewinde, uné eins und mehrgangige Schnecken:

ewinge gebraucht.

‘Thread Chasing Attachment

Permits threading to be. performed

Which cannot by carried out by using

‘ie or by. ali

TORNOS

SLIDING HEAD WiGH.SPEED PRECISION

AUTOMATICS

a

Lani

R-16, RR-20

Machine with combined 3-apinate contin,

Grling and threading stiachment

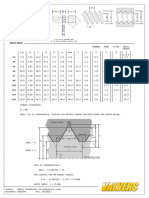

SPECIFICATION ma mr Rao Re RRZO

Normal stock capacity Yat f the one

Spindle ‘bore 7 vee em ‘ie

‘Turning length in one chucking tie ate i

‘uring length King . z s ne

ee vin ve ya

Maximum threading diameter ae eat 2

Number of spincle speed changes 20 A 238 =

\ so-so 050d

Range of speeds } s'000 900000 sito RPM

Numer of camshaft speed changes for each spindle speed “a8 3 ae 3

Motor ‘spovd ee

HP required 18 2 23 asHe

Floor space: engin i * sr 5

‘wk Es fa wa i

Weight het 8 = 11801660 zrad be

Grose (craiiary"packing) 1100, 45026510 Ibs

Packing for fength : Fs er a

fea shipments wd PS oe St

feign er er me

volume 60 ES yas 205

[1985 weight (packing for Sea‘shipmenty | 1280 1600200780 Ibe |

Changes of ata contained inthis prospectus are reserved

Auxiliary Attachments: *

TORNOS WORKS LTD. 2740 MOUTIER (SWITZERLAND)

TORNOS WORKS LTD. - MOUTIER (SWITZERLAND)

AUTOMATIC SCREW MACHINES

conrents

‘The Operating Principle of TORNOS Automatics .

Résumé of Important Points

a 0

Specifications a

PanteList seseeee re w

Unpacking ~ Cleaning - Installation ..... v

Lubrication ut

lectical Eaulpment vo

Seming-Up fostruetions vu

Tool-Head - Cotter and Bushes ......, *

Headstock x

x

Camshaft - Cams ~ Accelerator xt

Stock Feed Mechanism £42 xi

Ausiary Attachments, Special Devices. seen OV

Bapmpee Dancing EMEA DINE ATE Hee

Pica ath KSACUDRiL/IG AIF (/2- TA, IQ nted, 12-8, 2B

Prex-ue k storia AT Cniu-r. e-éay

‘AIL rights strictly reserved on the drawings and texts, which must not

be reproduced, copied or communicated to third persons without our

written consent,

Operating Instructions

R-128/200

usines ToRNOS SA (TORNOS) souriea suisse)

L_THE OPERATING PRINCIPLE OF TORNOS AUTOMATICS

L_THE OPERATING PRINCIPLE OF TORNOS AUTOMATICS

‘The headstock moves anially on a slide and carsies the stock (mall its movements, This means

1, That the bar can be guided in a bush very near tothe cools, the work being fed through the guide bushing to the

tools bythe siding headstock. Thus the bar {s machined without overhanging and a high accuracy ean be obtained

on the DIAMETER of the parts, whether Long or shor.

2. That the longitudinal turing operations are executed through the axial siding movements of the headstock, All

radial tools can be used for these operations without giving any axia feed tothe tals: the cesult again fe great

accuracy In the LENGTHS of the pars

3. Thar through combination of axial movement of sliding headstock and radial infeed of the tools any tape can be

produced with simple and inexpensive too! hits and without using form tools,

Short pars can be produced without guide bushing. tn tls case the bush-holder is removed and the headstock brought

"ight up to the tools. The work is thus done in ftont ofthe collet

‘Settingup for another job is very easy. All the Lengths are given by the headstock cams and the diameters can be ad=

usted on the tools through micrometer screws,

OPERATING CYCLE : The zero mark of the cams corresponds to the beginning of collet opening. When the collet Is

open, the stock Is held against the cutting-off tool by means of a counterweight. The headstock recedes by a length

‘corresponding to the length of the component plus width of paring-off tol. The collet is closed and the cutting-off

tool withdrawn, Now follow the various machining operations until the camshaft as made one revolution and reaches

the point where the cycle for the following part begins (provided that only one partis made per camshaft revolution,

6 Is usually the ease)

LL, IMPORTANT POINTS

1. Before running the machine by power, make suze thatthe motor revolves in the right direction (to avold damage to

the belts),

2. Lubrification of the headstock should be watched carefully. If unde overheating of front beating is noticed, check

quality of of.

3. The machine should be frequently cleaned, spectally spindte nose, collet and chucking sleeve.

44. Before running the camshaft by power, make one complece revolution by moving handcrank by hand (in aiticlock «

Wize direction) to make sure that all moving pans of the machine work correctly.

55. Do not move the headstock without putting the spindle in motion (to avold damage to the belts.)

8. Make sure that the current is cuteoff on all phases before touching the electsteal ewuipment,

7. The back end of the bar should be ground to a point before inserting it into the feed tube.

8 Ie i recommended that the bar diameter be checked to make sure that i¢ will go through the bush without setzing,

Inspect collet operation after Insertion of each new bar.

9. To maintain good quality work the tools should be ground at regular intervals.

10, When spindle Is running, do not stop camshaft when the collet ts

i the position closed (to avold undue pressure)

11. felt tension should not be too tigi.

12, Spindle and camshaft speeds to be adapted to quality of material

T. 140

USINES ToRNOS Sa WOUTIER (suisse)

Y¥. Front and Stde Elevation of R-10 Automatic (fig. RA-£.23/24)

Front and Side Elevation of Re10 Automatic (fg. RA-£.23/24)

A360 Motor Betts

A-361 Headstock Belt

A862 Threading off Beir

A383 Threading el

4-364 Gear Box to Accelerator Belt

4-865 Main Shaft to Geat Box Belt

A-268 Motor to Pump Drive Belt

Pump Delve to Accelerator Belt

Pump Drive to Back Drilling Amtachment Bett

1X. Radial Tools (fig. 9/2 and 9/28)

As 1 Tool Bracket

As 2 Rocker Atm

Az 3 No.1 Tool Stide

As 4 No.1 Tool Holder

As 5 No.2 Tool slide

As 6 No.2 Tool Holder

As 7 Lower Lever of Tool No.9

8

Connecting Rod of Toal No. 8

‘As 9 Fixing Bolt of Connecting Rod

Az10 Upper Lever of Too! No.3

AsI1 Micrometer Screw

‘AsI2 Tool Slide Plate

Acl® Vertieal Tool Slides

Asl Sole Plate for Vertical Toot Siides

AcI5. Vertical Tool Holder

As18 Tool Clamp

AsIT Lower Lever of Tost No.

‘A-IB Connecting Rod of Tool No.4

A-19) Upper Lever of Tool No.4

+20 Lower Lever of Tool No.8

3h

A~46 Radtax plat

AxéT Pusher late

AsGB Upper Radian Lever

A-4@ Radlax Bole

‘A=50 Siding Block of Upper Radtax Lever

A-SI Roller of Lower Radiax Lever

A-52_ Lower Radiax Lever

‘AWS Radiax Beaks

A-54. Roller Holders of Lower Radlax Lever

+55 Adjusting Serew

IMPORTANT

R10

‘A969 Rear OIt Splash Guard, Attachment side

A-9T0. ‘Transparent OM Splash Guard

A-OT1 Rear OMI Splash Guard, Headstock side

A-O72 Attachment Belts Guard

+373 Cabinet Doot

A-O™4 Motor Guard Door

A075. ‘Transparent Oll Splash Guard

A-8T6. Motor Guard

‘+37 Front OM Splash Guard, attachment side

As 21 Connecting fod of Tool No.

As 22 Upper Lever of Toot No.5

As 29 Lower Lever Besks

A+ 24 Stop Pin of Lower Levers

‘Az 25 Beak Holder

As 26 Rocker Arm Cam Beak

As 27 Micrometer Serew

‘As 28 Micrometer Serew

Az 29 Tool Fastening Screws

‘As 30 Cemtring Screw of Toot No.1

As 31 Centzing Screw of Toot No.2

As 82 Cenming Screws of Tools Nos.9, 4, 5

‘Az 88 Lock Screw

‘As 84 Axdal Setting Mfcsometer Screws of

Toole Not.3, 4, 5

‘As 89 Rocker Arm Stop Screw

As 6 Rocker Atm Stop Bott

‘As 87 Rocker Arm Fulerum Pin

‘As 88 Rocker Arm Fulerum Nut

‘Ax 89 Rocker Arm Fulcrum Pin Lock Nat

Sell Cam Device (Hig. 3/13)

Ax840 Adjusing Screws

|A-341 Supporeing Pin

A-242 Beak Support

A-343 Gulde late

A844 Lock Screws

‘A345 Reat Support

A-346 Ball Beating

A-847 Roller

A848 Poller Support

‘A-840 Beak

Toast

When ordering Spare Parts, please sate :

= Name and ttem Number

= Namber of

Number of Machine

Example : Spindle Nose Cap Aa8l, drawing 9/14,

for RelO Machine Serial No. 15022

USINES TORNOS SA

TORNOS)

MOUTIER (SuIsse}

X, Headstock (fig. 3/ld = 9/1f - 3/23)

‘As 61 Spindle Nose Cap As 10 Colter Adjusting Nut ‘As 80 Sliding Stock

Az 82 Collet Sleeve As TL Adjusting Nut ‘Az BI Lower Chucking Lever

[Ax 68 Collet Sleeve Operating Bush As 12 Rear Ball Bearings ‘Az 82 Lower Chucking Lever desk

As &4 Toggle A+ 73 Pulley Supporting Sleeve ‘Az 88 Lower Chucking Lever Roller

Az 85. Goller Spring A> 14 Reat Spindle Nut Az 84 Headstock Cover

Ax 66 Collet Ax 75 Pulley ‘As 85 Spindle Note Guard

Aq 67 Main Spindle As 76 Rear Headstock Guant As 88 Stop Pin

Ax 68 Toggle Sleeve As 78 Upper Chucking Lever As 81 Gulde Roller

Az 89. Gripping Bobbin As 79 Eccentric Trunmlon Ax 88 Bele

‘As 89 Headstock Body

XL Cabiner (ig. 3/98 - 3/1 = 3/8 = 9/10

AA251. Fastening Screw 4-286. Chip Tray As281 Pulley

A252. Removable Bearing A267 Threading off Pulley A-282 Motot Sleeve Pulley

‘+259 Bearing Removing Screw A268 Threading Puiey A283. Motor

‘A-254 Disengaging Lever A269 Left-Hand Flange A-284 Gear Box flody

A-255 Disengaging Rod A-270. Bearing Flange ‘A285. Driving Pulley

A258 Nut of Disengaging Rod A-271 Ott Drain cep Au288 Worm Wheet

A-257 Lock Nut of Disengaging Rod A212 Stepped Speed-Palley ‘A287 Worm

A-258 Malashaft Headstock Pulley A-273. Main Shaft ‘A-288 Lubrifieation Gear

+259 Headstock Jockey Pulley A214 Gear. 4-289 Helleal Geats

A-260 Flange of Headstock Jockey Pulley A275 Stepped Speed-Pulley ‘A290 Lubrification Gear

A-281 Flange Stop of Headstock Jockey A276. Pulley of Back Drilling Attachment Aq291 Driving Pulley

Pulley A217 Cabinet ‘4-292 Pump Drive Body

‘A-262 Supponing fod of Attachment JockeyA-278 Support of Headstock ‘8-298 Suction Veins

Pulley Jockey Pulley A294 Clomting Plate

A-268 Lever of Attachment Jockey Pulley 4-279 Lever of Headstock ‘4-298 Pulley

A-264 Roller of Attachment Jockey Pulley Jockey Pulley A298 Suction Vein Holder

‘A-285 Filtration Pot A-280 Pulley A-395 Oil Level Sight

xu Shaft with and without Accelerator (fig. 3/4 = 8/6 = 3/64)

‘As 91 Headstock Plate Cams AsI12 Indexing Cam of Stoeting ‘As128 Worm

As 92 Play Adjusting Ring. Atcachment ‘A=129 Pinion

‘A= 88 Collet Closing Beak As113. Cam Helder of Sloting ‘Ael80_ Driving Pulley

‘A= 94 Beak Holding Drum ‘Attachment AsISI Worm Whee! Cover

‘Aw 95 Collet Opening Beak AsIL4 Cam Holder of Drilling Avl32 Adjusting Screw

As 96 Cam Shaft 4 Threading Attachment ‘AuI93 Fastening Screws

Az 7 Bell Cam AsLIS. Cam Sector of Drilling

‘As 98 Bell Cam Adaptor & Threading Attachment ‘Ax195 Closing Block

Az 89 Accelerator Disengaging Tilp —A-I16- Indexing Cam of Drilling ‘As136.Cluteh inion

‘Aq100 Accelerator Trip Holding Drum & Threading Attachment AsI37 Pin

A-1OL Ring Cam of Back Drilling AsII Indexing Cam Holdet of ‘Acl45: Pulley

‘Avcachment Drilling & Threading Attachment A148 Accelerator Pulley.

As102 Accelerator Engaging Trp Acl1B Engaging Beak of Drilling AsIST Accelerator Engaging Lever

A-108 Worm Wheel & Threading Attachment ‘Aq148 Friction Lever Connection

A-104 Vertical Too! Cams AsI19. Beak Holding Drum of Drilling A=148 Nat

‘A-105. Rng Cam of Slotting Attachment & Threading Attachment ‘Aq150 Nur

A-106- Indexing Cam of Drilling Ax120. Safety Beak of Drilling Acl6L Nut

‘& Threading Attachment & Threading Attachment ‘Ax152 Lock Nut

AsLOT Engaging Beak of Drilling AsI21 land Winding Lever ‘A153. Feletion Driver

& Threading Attachment Az122_ Delving Shaft Sleeve An154 Rings

‘A108. Safety Beak of Drilling ‘+129. Spring Fin A-I85. Accelerator Disengeging Lever

& Threading Auachment Aq12s. Delving Shaft ‘Aq188 Feletion Lever

A109 Cam Sleeve of Vertical Tool Cams A=125 Adjusting Nut A+I8T Connecting Rod

A-L10. Rocker Arm Cam A128 Clute AsI6B Accelerator Bracket

ASUIL Mask Cam AsI27 Thrust Ball Bearing ‘4189. Ball Bearing Sleeve

7 asta

USINES TORNOS SA

A- 176 Disengaging Device racket

A+ 177 Pivoting Support

A+ 178 Hand Lever

‘Aj 179 Spring Tension Adjusting Screw

‘A+ 180 Spring Tension Adjusting Nut

‘4-181 Spring Retaining Hooke

4+ 182 Headstock Rens Speing

A+ 183 Adjusting Screw

A+ 184 Pivot racket

A~ 185 Tube Bracket

A+ 186 Lamp aracker

‘Aj 187 Signal Lamp Guard

A- 190 But Feed Tube

‘A+ 11 Push Roa

A 192 Disengaging Trip

A- 188 Disengaging Rod

A+ 194 Feed Cord

A+ 195 Switch

[A> 196 Disengaging Trip

|A- 201 Tube Bracke

[A~ 202 Feed Cord Pulley Support

|A~ 203 Feed Gord Pulley

‘A~ 204 Lamp Bracket

|A~ 205 Disengaging Trip

‘A. 208 Ditengaging Rod

A= 207 Ditengaging Rod racket

A~ 208 Silent 88 Feed Tube

‘A- 209 Pivot Bracket

A= 210 Cord Collet

‘A-211 Gord Collet Nut

‘A= 212 Push Rod

A+ 221 Tube Holger stand

A222 Tube Holder Stand Rod

A= 228 Stop Ring of Pivoting Support

A= 224 Pivoting Support

A- 225 Tube dracket

= 226 Feed Coed Pulley

A+ 227 Feed Coed Pulley Support

‘+ 228 Large Feed Cord Pulley

‘A= 225 Feed Cord Pulley Support

4+ 290 Small Feed Cord Pulley

‘Ay 231 Bar Feed Counce

A= 241 Tube Bracket

A= 244 Feed Card Pulley Support

Az 245 Feed Cord Pulley Support

‘As 402 Connecting Rod for the Levers

‘A+ 403 Upper disengaging Lever

‘As 408 Beak of Lever 403

‘A= 405 Beak of Lever 406

A+ 408 Lower disengaging Lever

A+ 407 Receeding spring

A+ 408 Adjustable stopping screw

‘A= 409 Beak holding Drum

A+ 410 Beak for the Drumm

AZ 411 Beak of the handle support

A= 412 Handte support

A= 413 Contactor Lever

[A= 414 Piston

[A~ 415 Disengaging Rod

A~ 416 Serew of the fixing bolt

= 417 Axle of the fixing bolt

XIV. SAFETY OF THE DRIVE (fig. 3/5i)

A= 765 Clamp for the disengaging tod

‘Ax 106 Safety Lever

A= 767 Lever Support

|A~ 168 Clutch Lever

A~ 769 Roller

MICRONIC NEEDLE BEARING

Leaflet No, T, 243/14)

A= 89 Headstock Body Opening

A= 1001 Nut

A 1002 Clamp

A= 1003 Clamp

‘A~ 1008 Nut

A= 710 Safety Beale

As 771 Beak of the disengaging Lever

‘Az 772 Support of the Safety Lever

A+ 713 Disengaging Lever

‘As 14 Roller of the disengaging Lever

PLAIN GUIDE BUSH HOLDER

ee

161 Plain ath

162 fuk Chuck

19 ah Nut

164 uh Holder Sleeve

105 Steve Nut

REVOLVING STEADY BUSH HOLDER (fig. 1/12)

47 Bearing Special Nut

49 Headstock Nove Normal Cap

165 Sleeve Nut

166 Adjustable Steady Bush

169 Lock Nut

1. 357/

TTL Headstock Nose Special Cap

172. riving Reds

173. Driving Ring

173a Special Delving Ring

174 Steve

MOUTIER

(suisse)

Aj 418 Adjusting serew for the

beak engaging

As A419 Adjusting serew

A+ 420 Fixing bole of the disengaging rod

A=421 Extension

‘A= 422 Pin forthe upper disengaging Leve

A423 Reat Lever

‘A=4%4 Pin for the ear Lever

A+425 Lamp beacker

[A+ 426 Protection Sheath

4-427 Flexible Guard

A= 428 spring ur

A= 429 Signal Lamp

‘A= 430 Lamp Sleeve

A= 431 Lamp Socket

‘Az 432 Pin for the Handle Support

‘Ax 483 Contactor

A= 434 Receeding spring of Lever A= 409

‘Ay 485 Adjusting Screw of the Sleeve

‘A+ 438 Spring for the Handle Support

A+ 497 Spindle of the contactor Lever

Az 498 Spindle of the lower disengaging 1

‘Az 498 Spring for the sliding tod

Aj 440 Bush

Az 44 Adjusting ting

Aj 442 Leaning Pin

‘Ax 443 Thrust race of the push rod

A+ 444 Handle for tightening

A+ 445 Spindle forthe roller

‘A= 448 Fastening Screw

‘As 447 Pin for che Thrust Race

A- 175 Ditengaging Rod

A- 127 Support for the Levers

‘A. 128 Safety Lever

A- 781 Disengaging Rod Flange

‘A- 133 Disengaging Trip of the Lever

Ax 194 Safety Beak of the Sleeve

ADJUSTABLE GUIDE BUSH HOLDER

Figs V7

186 Adjusrable Bush

181 Intermediate sieeve

168 Incermediate Sleeve Nut

169 Lock Nut

170 Steeve Chuck

178 Adjusting Nut

176 Bronze Bearing

177 Beating Adjusting Nut

178 Thrust Race

H+ warasse = verschiag - Crate

C+ caisse - kiste - case

USINES TORNOS S.A. MOUTIER (SUISSE)

USINES TORNOS SA TORNOS MOUTIER (Suisse)

P,100 Came plate poupée 360° / Spindelsock-Flachiaave 260° / Headstock plate cam 960°

Pr LOL Came outils vericaux 3802, 1809,120° g90/ Kurve senlzechte Werkzeuge 960,180, 120°, 60°/ vertcal

tool eam 360°, 1809, 120°, 60°

102 Came bascule 3602 / Wippenkurve 260° / Racket arm cam 360°

108 Came nombradu perc, -caraudeur / Schaltkuve komb,Sspindl. Apps / Indexing cam of 9-ip.comb, attachment

104 Came de nombrage du fendeur / Schathurve Schlitzapparat / Indexing cam of slotting atachment

105 Came de fermenue bascule / Wippeascliesurve / Mask cam of rocker am

106 Came de pergage du pete, taraudeur / Sohrhurve komb.d-ipindl. Apps / Feed cam of 3-ip,combsattachment

P-10T Aanesu (ebauché, complet) du pete, taraudeur / Ringkitve (Komplett)komb,Jeipindl, App, / Ring cam blank

of S1pscomb,azachment

P.108 anneau d'avance du fendeut / Vorhesrbeitere Ringhurve Schiteapparat / Ring cam of slong attachment

PsL09 Came e’amorsage pour fide ouvrante / Einrdckhurve selbwatfnender Gewindeschneidhopt / Die-engaging cam

for solf-opening diehead

110 Anneau de pereage du contre-perceur / Ringhurve Gegenbobrvorrichtung / Feed cam of back-driling attachment

111 Came de fermerite de 1a fibre ouvrante/ Sehllesiurve sltitatinender Gewindeschneickopt / Mask cam of

self-opening diehead

Pal12 Came de débourage du pesceur-taraudeur / Kurve fur Spsneentieerung komb,S-spindl, App, / Chip clearing cam

of 3-sp,comb,anachment

Pell Bec 2 2 wous de débeayage d'accélération avec taquet et éctou / Grower Accelerator-Austchaltnocken / Lage

aceelerater disengaging trip

P.114 Dito = 21 wou / Dito - Klein / Dino - Small

PLLIS Bec 3 2 tous d'embrayage d'accélération avec taquet ex Gerou / Grower Accelesttor-Einschalmnocken / Large

acoelerator engaging trp

P.116 Dito = 21 wou / Dito - Klein / Dito - Small

P1117 Menchn porte-carme & breguets du fendeur / Kurventzommel mit Kupplung far Schlitzapparst / Cam holder with

clutch, sloting attachment

P.118 Becs de bascule / Wippenkurvennocken / Rocker arm cam beaks

P2119 Parte-beos de bascule / Nockeahalter der Wippe / Rocker arm beak holder

7.120 Bec de serrge de 12 pince de poupée avec taquet et rou / Spannocken der Spaanzange fur Spindeltock, mit

Sehtaube und Murter / Collet closing beak

P.121 Dito = de dessezrage / Dito - Entspannocken / Ditto - Opening

P1122 Bec d'amorcage de la troche de taraudage du perceur-taraudeur / Einrdcknocen fir Gevindespindel kom.9-ping

“Apparat / Die-eagaging beak for threading spindle of 9 sp.comb. attachment

7.123 Bee 2 1 wou d'embrayage du perceur-taraudeur / Kleiner Einschaltnocken kom. 3~ipindl, App. / Small fection

exgaging beak of 3~sp.combsatachment

P6124 Dito = 22 tous / Dito = Gros / Dito - Large

P1125 Bague pour remplacer une came poupée / Ring enstelle der Spindelstocliurve / Rng to replace headstock cam

7,126 Bee 42 uous de streté du perceur-traudeut 9 toches / GroserSichesbeltmocken komb.3~pindl. App. / Large

safety beak for Sspacomb,atachment

P4127 Dito = 21 tou / Dito = Klein / Ditto ~ Small

7,128 Bague cuverte pour emplacer une came des outs verticaux / Grower offenet Ring anstlle einer Kurve dr snk

rechten Werkzeuge / Large open ting to replace vertical tool cams

P4129 Dito = prcame fermerare bascule / Dito ~ anstelle der Wippenschlisskurve / Ditto - to replace matk cam f.rocke

130 Bague de 1a came-cloche / Ring Glockenkurve / Ring of bell-cam

PLLSI Porte-gale prelevier inf 2vance-poupée / Rollenhaiter untererRadiaxhebel / Roller holder of lower Radiax lever

1192 Bee pour dite / Spindetstocknocken / Radiax beak

139 Taquet et rou latéraux pour mauchons porte~ Schaeideieen J 165 3h om at. 6b

be Se 2yischonring 60

be Ge Schneideisen-talter mit stite 60

‘ mate

Filtre J 20 4p, Sa7 am 6g SchnoSdeizen #20, Sa7 om st. bg

& hile 422 EES | ieuettiee foe py ng

7) Portontaraua & pins 7. Gowindebohrer-ialter a/2enge, 7

Je Pince de pertectaraud 7a Gewindebohrer-Zange Te

Te Porta-taraud ad tige P fevindahonrer-initor Scie 7

8 Chien do sorrage 8 Spannimagcen

9 Praise au Pendeur 9 Sonlitesriser 5

20° Burial 210 rohstant 20

Pince de poupée pour R- 125 ( corps 26 mm )

Headstock Collet for 8-225 ( shaft 16 mm

lstook Collet

Drill & Tap Collet,

Adjustable Bush

Plain Aueh

Bush of Slotting Attachment

Bush of Slotting Attachnent

Die Holger with txt

Dte 20 mm dig.li-5 =m thick

Die 16 m dias) m thick

Intornediate Aine

Die Holder with Rod and

FT = tates

sm thisk

ieiser nite Saliet

Tep Holder Collet

Tap Holder with Red

Torele

Siotting Saw

cutter

: 1 2

{— rr

xe el

228 1g.

Pour XIV-T.

Fur XIV-T

For XIV-T

22

USINES TORNOS SA MOUTIE

R (SUISSE)

EXECUTION

AUSFUHRUNG |

EXECUTION

AUSFUHRUNG II

USINES TORNOS SA MOUTIER (SUISSE)

USINES TORNOS SA TORNOS) sourier wsuissey

PINGES BICONIQUES POUR TOURS “TORKO:

Lorsque la pitce 2 décolleter exige, du fait de sa forme ou de la qualité de I'acter, des efforts de persage ou

de tournage considérables, il peut atriver que le serrage ordinaize ne suffice pas,

1 existe pout nos tours de capacité 10 mm et ausdessus, un dispostif die : SERRAGE BICONIQUE, La pince ext

teprésentée par 1a fig. 1. Elle nécessite une douille de serrage, un écrou du nea et un resort speciaux (fig. 2

3.et 4), Les deux cOnes de serage ont, évidemment, une action plus énergique qu'un cOne unique,

Ce dispositif facilite aussi le serrage des barres dont le diaméure n'est pas tds réguliers Il présente, cependant,

3 cOLE de ses avantages, quelques inconvenient :

= 1a capacité en longueur de 1a machine est légdtement réduite,

= au moment du serrage, comme 1 pince n'a pas d'arée de longueur, 18 barre est appuyée tr2sfortement con-

tre le burin de coupe : il convient, pour ne pas détériorer ce demiet, de peévoir, en général, un léger recut

1a came poupée, Si 'on veut donc une longueur particulidxement réguliére des pices, il faut, apr2s woreie

de ce burin de coupe, franchir } nouveau avec Tui le bout de 1a barre,

Le dtposiif de serrage biconique n'est livté que sur demande, Il s'adapte sans difficuté aucune & 1a place du

serrage stantard de nos machines,

Fig. 1

pee

P|

Fig. 4

Deuscher Text auf der Ruckseite

English cext on back page

T. 255A,

USINES TORNOS SA MOUTIER (Suisse)

DOPPELKONISCHE SPANNZANGEN FUER TORNOS -AUTOMATEN

Bei Sohr~ oder Dreharbeiten, die wegen der Form des Werkstickes oder Qualittt des Stahles, einen betoaders

grosien Achslaldruck auf die Werkstange erfordesn, kann es vorkommen, dass dle normale Spannzange nicht

Bengt

Fur Automaten ab 10 mm Durchlass (st eine Zusarzausrustung fur die Verwendung von doppelkonischen Spann

‘angen erhaltich, Diese Ausristung besteht aus einer Zange Figs 1, einer Spannhilse Fig. 2, einer Spindelkopl=

mutter Fig. $ und einer Spezialfeder Fig. 4. Die Spannwitkung dieser Zange ist bedeutend grésser als diejenige

der einfachen Zange, Sie ist auch nutzlich wenn die Werkstangen im Durchmesser nicht besonders egelmassig

sind,

Neben diesen Voreeilen hat die Verwendung von doppetontschen Zangen auch kleinere Nachtetl

= dle Dreblange des Automaten wird leicht reduziert,

~ belm Spannen wird die Stange sehr stark gegen den Abstechstahl gedruckt, weil die doppelkonische Zange

keine Schuleer besltzt um ein Vorschieben 2u vethinder, wie es bel der normalen Zange dex Fall it, Um

‘eine Beschidigung des Absteckstahles zu verhuten, empfiehlt es sich dahet {m allgemeinen auf der Spindel

stocklurve eine leichte Riickwarsbewegung einzuschalten, Wenn die Lange des Drebteiles sehr regelmassig

sein sol, ist es natig, mit dem Abstechstahl nach desten Rlcklauf, das Ende det Werkstange noch einmal

leicht abzudrehen,

Die Vorrichtung fr doppelkonische Zangen wird nur auf spezielien Wunsch geliefert, Sie kann ohne weiteres

anstelle der normalen Ausristung verwendet werden,

DOUBLE CONE COLLETS FOR "TORNOS" AUTOMATICS

(Owing to the shape of the par or machining resistence of the material during some drilling ot turning opera.

tons a considerable axial pressure is exerted, In such cases the standard collet may not grip firmly and in con=

sequence, the bar is pushed back during the machiaing operation.

‘Automatics from 10 mm stock capacity and upwards, can be supplied with a special equipment, to that Double

Cone Collets can be used, This equipment includes a collet Fig 1, a collet sleeve Fig. 2, 2 spindle note cap

Fig. 3 and a special spring Figs 4, Naturally, the Double Cone Collet has a greater chucking power than the

standard collet.

‘The Double Cone Collet is alo weful when the bar stock varies in diamete

Ic should, however, be noved that the we of the Double Cone collet has some disadvantages #

= Firstly, because of the Longer spindle nose, the Length capacity of the Automatic Is slightly reduced,

= Secondly, during the chucking operation the bar is pushed strongly against the cutting-off rool, due to the

fact that the Double Cone Collet has no shoulder to stop advancing, To avoid damaging the cutting-off mol,

it is recommended to provide for a slight drop back of the headstock during the closing of the collet, If the

length dimensions of the part have to be kept to close limits, itis necessary to face the end of the bar. This

can most conventently be done by entering the cutting off tool again after the exit.

‘The equipment forthe use of the Double Cove Colle is only supplied on special request, It can be ured without

any difficulty in place of the standard equipment,

1, 255A

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5837)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (862)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (591)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (351)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (268)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Kempsmith Universal Dividing HeadDocument4 pagesKempsmith Universal Dividing Headfarid said errahmaniNo ratings yet

- LandisDocument23 pagesLandisfarid said errahmaniNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Dro SNS 2V-3V (English Manual)Document59 pagesDro SNS 2V-3V (English Manual)farid said errahmani50% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BRT BarnesCatalogDocument49 pagesBRT BarnesCatalogfarid said errahmaniNo ratings yet

- Cincinnati MI ML Service and Parts 1957 v4Document157 pagesCincinnati MI ML Service and Parts 1957 v4farid said errahmaniNo ratings yet

- 105450Document193 pages105450farid said errahmaniNo ratings yet

- dwg1045 20130217 Metric Bolt DimensionsDocument1 pagedwg1045 20130217 Metric Bolt Dimensionsfarid said errahmaniNo ratings yet

- Monarch Lathes 60 Series Op and Parts Manual20140206Document106 pagesMonarch Lathes 60 Series Op and Parts Manual20140206farid said errahmaniNo ratings yet

- Catalogue: Products For Oil&gas IndustryDocument39 pagesCatalogue: Products For Oil&gas Industryfarid said errahmaniNo ratings yet

- 02 Dividing Head 1Document22 pages02 Dividing Head 1farid said errahmaniNo ratings yet

- Manual Lathes: The World Turns On Colchester LathesDocument8 pagesManual Lathes: The World Turns On Colchester Lathesfarid said errahmaniNo ratings yet

- Canons: Canons Par Types Canons Par Types de Machines Canons À Galets HabeggerDocument26 pagesCanons: Canons Par Types Canons Par Types de Machines Canons À Galets Habeggerfarid said errahmaniNo ratings yet

- Schaublin102 ChariotDocument6 pagesSchaublin102 Chariotfarid said errahmaniNo ratings yet

- TT4100 Ops Manual 990039Document23 pagesTT4100 Ops Manual 990039farid said errahmaniNo ratings yet

- Forkardt Mandrins Type F Instruction de ServiceDocument11 pagesForkardt Mandrins Type F Instruction de Servicefarid said errahmaniNo ratings yet

- Workshop Practice Series 05 - Milling Operations in The Lathe - 3Document64 pagesWorkshop Practice Series 05 - Milling Operations in The Lathe - 3farid said errahmani100% (2)

- Buyers Guide: Gear SkivingDocument92 pagesBuyers Guide: Gear Skivingfarid said errahmaniNo ratings yet